Section 111 - HAZMAT Fundamentals

advertisement

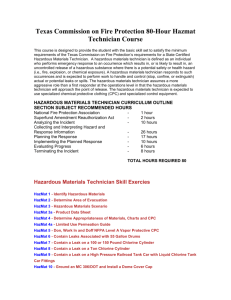

111. HAZMAT Page 1 of 9 111. HAZMAT FUNDAMENTALS References: [a] OPNAVINST 5100.19D, Navy Occupational Safety and Health (NAVOSH) Program Manual for Forces Afloat [b] OPNAVINST 4790.2H, Naval Aviation Maintenance Program (NAMP), Vol. V [c] OPNAVINST 5100.23F, Navy Occupational Safety and Health (NAVOSH) Program Manual [d] OPNAVINST 5090.1B, Environmental and Natural Resources Program Manual .1 Define the following terms: [ref. a, app. B] a. HM : Any material that, because of its quantity, concentration, or physical or chemical characteristics, may pose a substantial hazard to human health or the environment when purposefully released or accidentally spilled. b. HW : Any discarded material (liquid, solid, or gas) which meets the definition of HM and/or is designated as a hazardous waste by the environmental protection Agency or a State authority. Define the term HM .2 Discuss the six categories of hazardous material and the personal protective equipment required for handling each. [ref. a, app. G] 1) FLAMMABLE AND COMBUSTIBLE MATERIAL A flammable material is any solid, liquid, vapor, or gas that will ignite easily and burn rapidly with a flash point less than 1500F. Handling and Usage Requirements ensure that adequate supply and exhaust ventilation is maintained in all spaces where HM is used, Ensure PPE (eye protection, respirators, gloves appropriate to the HM in use, etc.) is in good operating condition and is readily available to all personnel working with HM. 2) TOXIC MATERIAL A toxic material has the inherent capacity to produce personal injury or death through ingestion, inhalation, or absorption through any body surface. Toxic materials are considered, and often marked by the manufacturer as being, poisonous. Handling and Usage Requirements Avoid contact with toxic materials by the proper use of suitable impermeable protective clothing, respiratory protection, and by strictly following all prescribed safehandling procedures. 3) CORROSIVE MATERIALS Corrosive materials are chemicals such as acids, alkalis, or other liquids or solids which, when in contact with living tissue, will cause severe damage to such tissue and/or metals by chemical action. Handling and Usage Requirements As a minimum, wear chemical goggles, full-face shields, and rubber gloves when handling acids or other corrosive materials. Greater protection may be required as specified by Maintenance Requirement Card, NSTM, industrial hygiene survey, or manufacturer's instructions. 4) OXIDIZERS An oxidizer is any material, such as chlorate, perchlorate, permanganate, peroxide, nitrate or nitrite which yields oxygen readily to support the combustion of organic matter, or which may produce heat, or react explosively when it comes in contact with many other materials. Created by LTJG KyungNho "TACO" Kim Reviewed by CWO3 Dale Lansdown 111. HAZMAT Page 2 of 9 Handling and Usage Requirements ensure that adequate supply and exhaust ventilation is maintained in all spaces where HM is used, Ensure PPE (eye protection, respirators, gloves appropriate to the HM in use, etc.) is in good operating condition and is readily available to all personnel working with HM. 5) AEROSOLS Materials in aerosol containers: An ever-increasing demand exists for pressurized (aerosol) dispensers for the application of paints, enamels, lacquers, insecticides, inspection penetrant kits, lubricating oils, silicones, and rust preventatives. Handling and Usage Requirements ensure that adequate supply and exhaust ventilation is maintained in all spaces where HM is used, Ensure PPE (eye protection, respirators, gloves appropriate to the HM in use, etc.) is in good operating condition and is readily available to all personnel working with HM. 6) COMPRESSED GASES Aboard Navy ships, numerous cylinders of compressed gases will be found. Compressed gases are used for welding operations (oxygen and acetylene), in refrigeration and air conditioning systems, and for purging various systems (nitrogen). Handling and Usage Requirements Avoid contact with toxic materials by the proper use of suitable impermeable protective clothing, respiratory protection, and by strictly following all prescribed safehandling procedures. .3 Explain incompatible material and give an example used in naval aviation. [ref. a, app. G] Incompatible HM/HW - Materials that react with each other to produce undesirable products. Mixing Incompatible hazardous material can6 produce heat, pressure, fire, explosion, toxic or irritating effects, or flammable dusts, mists, fumes, or gases. NOTE: See the chart below for incompatible material. .4 State the responsibilities of the following personnel in the HM/HW Program: [ref. b, ch. 20] a. Commanding Officer (1) Designate, in writing, an officer as the Maintenance Department HMC&M Program Manager. (2) Maintain close liaison with the host station environmental office or ship HAZMAT and HAZWASTE Coordinator on all environmental issues. (3) Ensure command adheres to CHRIMP requirements and acquires all HAZMAT through the installation's HAZMINCEN b. Maintenance Officer (1) Nominate, to the CO, an officer as the Maintenance Department HMC&M Program Manager. (2) Develop local command procedures (as required) per Appendix E. Include written emergency procedures to contain, control, and resolve HAZMAT spills. (3) Designate, in writing via the MMP, a department HMC&M Supervisor. (4) Gain adequate familiarity, through local ship/station environmental office, with applicable DOD and local environmental, HAZMAT and HAZWASTE laws, rules, regulations, and procedures pertaining to the Maintenance Department Created by LTJG KyungNho "TACO" Kim Reviewed by CWO3 Dale Lansdown 111. HAZMAT Page 3 of 9 c. Program manager (1) Ensure an aggressive program of environmental awareness and compliance within the Maintenance Department. Recognize a CO’s potential personal liability for infractions and bring to the CO's immediate attention any potential violations or concerns that may impact achieving 100 percent compliance. (2) Assist the Maintenance Department in identifying and resolving any potential or actual environmental compliance, HAZMAT, or HAZWASTE related problems. Keep the chain of command informed of any violations or noncompliance issues. (3) Supervise and coordinate the HMC&M Program to ensure compliance with OPNAVINST 5090.1, OPNAVINST 5100.19 and OPNAVINST 5100.23, NAVSUP Publication 722, all applicable federal, state, and local regulations, and this instruction. (4) Develop Maintenance Department emergency spill procedures, per Appendix E, to contain, control, and resolve HAZMAT spills, and submit to the host station environmental office or ship HAZMAT and HAZWASTE Coordinator for incorporation into the Pollution Prevention Plan. The station and ship Pollution Prevention Plan shall be reviewed and updated annually. (5) Maintain close liaison with the ship or station Environmental Office and Legal Department in all environmental issues. (6) Screen all required environmental reports and records. (7) Review CSEC audits and reports to aid in the assessment of the HMC&M Program. (8) Nominate, to the MO, an E-5 (or above) as HMC&M Supervisor. (9) When ashore, ensure all materials used are listed in AUL, and are properly handled. Submit recommended AUL changes, via the ACC/TYCOM, to COMNAVAIRSYSCOM (AIR-3.1.4). When afloat, ensure all materials used are listed in the SHML and are properly handled. Submit recommended SHML changes, via the ship HAZMAT and HAZWASTE Coordinator and the ACC/TYCOM, to NAVICP. (10) Coordinate with ship and station HAZMINCEN to establish HAZMAT requirements and assure product availability during all shifts. (11) Establish a departmental HAZMAT Control Committee. Select members and assign responsibilities per OPNAVINST 5100.23. (12) Fully use the CHRIMP facility once established by the host ship or station. d. HMC&M Supervisor (1) Attend the HMC&M Technician course (Course A-322-2600) or equivalent, within 120 days of assignment and hold this position a minimum of 2 years. (2) Maintain a program file to include: (a) Applicable POCs, for example, HAZMINCEN Supervisor, Industrial Hygienist, Safety Officer, and Environmental Officer (b) Active list of AUL and SHML used by each work center within the Maintenance Department. (c) Program related correspondence and message traffic. (d) Applicable references or cross reference locator sheets. (3) Maintain an up-to-date library of MSDS, either through HMIS or the HAZMINCEN, of all HAZMAT used by each work center in the Maintenance Department. Obtain and keep on file MSDS not included in the HMIS. (4) Ensure only materials listed in the AUL are available and properly labeled, handled, and used. Forward AUL change recommendations Created by LTJG KyungNho "TACO" Kim Reviewed by CWO3 Dale Lansdown 111. HAZMAT Page 4 of 9 via the appropriate ACC/TYCOM to COMNAVAIRSYSCOM (AIR-3.1.4) when ashore. When afloat, materials listed in the AUL must also be listed in the SHML, and will be available in the HAZMINCEN. Forward SHML change recommendations to NAVICP via the ship HAZMAT and HAZWASTE Coordinator and appropriate ACC/TYCOM. (5) Assist in maintaining an aggressive program of environmental awareness and compliance throughout the Maintenance Department. Recognize the CO’s potential personal liability for infractions. Keep the chain of command informed of any concerns or possible violations and assist in correcting any occurrences. (6) Conduct meetings with all work center supervisors or their designated HMC&M Petty Officers at least monthly (more often if required) to discuss HMC&M implementation, review procedures, and disseminate new regulations and requirements. (7) Ensure all work center supervisors and their designated HMC&M Petty Officers have completed formal or local HAZMAT storage and handling training within 30 days of assignment. (8) Provide liaison between the Supply and Maintenance Departments for monitoring HAZMAT procurement. NOTE: Stockpiling of HAZMAT is not consistent with the goals of the HMC&M Program and shall be avoided. (9) Control Maintenance Department storage facilities and HAZWASTE collection points and ensure compliance with OPNAVINST 5090.1 and established ship or shore requirements. Ensure all flammables are stored in an approved flammable storage locker. (10) Ensure work center supervisors maintain Uniform HAZWASTE Manifests and other required documents per OPNAVINST 5090.1. (11) Screen all required environmental reports and records. (12) Assist QA in screening all NAMDRP reports dealing with environmental issues to ensure they are accurate, clear, concise, and comprehensive. NOTE: Conflicts may arise with existing technical publications, TDs, and procedures caused by rapidly changing HAZMAT and HAZWASTE environmental compliance regulations. Conflicts should be reported to the FST/LMTC on an environmental report, HMR, EI, or TPDR, with NAVAIRDEPOT Jacksonville (Code 4.3.4P) and ACC/TYCOM as information addressees. (13) Review recommended changes to the AUL and SHML or procedural changes that effect the HMC&M Program. (14) Fully use the CHRIMP facility once established by the host ship or station (15) Review and recommend, via QA, any material or process changes that may need FST/LMTC or ACC/TYCOM attention for approval. (16) Ensure effective shelf life processes are in effect for work center HAZMAT. (17) Maintain a HAZMAT log to identify material issued, used, retained for reuse, and disposed of as HAZWASTE. d. Division Officer (1) Ensure all HAZMAT from aircraft, SE, and related maintenance actions is properly handled, collected, and disposed of per all applicable federal, state, and local regulations, and this instruction. (2) Designate, in writing, work center HMC&M Petty Officers. Created by LTJG KyungNho "TACO" Kim Reviewed by CWO3 Dale Lansdown 111. HAZMAT Page 5 of 9 (3) Gain adequate familiarity, through local ship/station environmental office, with applicable DOD and local environmental, HAZMAT, and HAZWASTE laws, rules, regulations, and procedures pertaining to the division. (4) Ensure an aggressive program of environmental awareness and compliance is maintained within the Maintenance Department. Recognize the CO’s potential personal liability for infractions and bring to the CO’s immediate attention any potential violations or concerns that may impact the command’s ability to achieve 100 percent compliance. e. Work center supervisor (1) Ensure Hazardous Material Control and Management Program and follow-on training is provided to personnel. Training shall include personnel responsibilities and shall be documented on the NAMP Indoctrination Training sheet (Appendix E) in the individual's qualification/certification record. (2) Ensure all personnel receive command HMC&M and hazardous communications training per OPNAVINST 5100.19 and OPNAVINST 5100.23 within 30 days of assignment (3) Review work center AUL and SHML annually and route change recommendations through the HMC&M Supervisor per OPNAVINST 5090.1. (4) Ensure an MSDS for each HAZMAT used is available at a centralized location within the activity, and personnel directly involved in the handling and use of the material have received job specific training per OPNAVINST 5100.19 and OPNAVINST 5100.23. (5) Use an effective shelf life process for all work center HAZMAT. (6) Maintain complete and accurately prepared HAZMAT logs to identify material issued, used, retained for reuse, and disposed of as HAZWASTE (I-level only). NOTE: In sites where a CHRIMP has been established by the host ship or station, work center supervisors should use the CHRIMP computergenerated reports to satisfy the requirements of paragraphs 20.3h(5) and 20.3h(6) above. (7) Provide the HMC&M Supervisor with updated lists of HAZMAT in the work center. Forward all material substitutions and process changes (8) Allow workers to only use HAZMAT acquired from the HAZMINCEN (nothing borrowed from another source). (9) Recommend qualified personnel for designation as HMC&M Petty Officers. f. HMC&M Petty officer (1) Assist the Work Center Supervisor in all matters related to HMC&M in the work center. (2) Attend all Maintenance Department/Division HMC&M meetings (3) Maintain an inventory of all HAZMAT present in the work center and ensure current shelf life has not expired. (4) Maintain an accurate AUL for the work center. (5) Maintain an adequate supply of containers, labels, spill response material, and related items in the work center. (6) Ensure a weekly inspection of work center HAZMAT and HAZWASTE sites is accomplished and maintain a record of all inspections. NOTE: In sites where a CHRIMP has been established by the host ship or station, work center supervisors should use the CHRIMP computergenerated reports to satisfy the requirements. Created by LTJG KyungNho "TACO" Kim Reviewed by CWO3 Dale Lansdown 111. HAZMAT Page 6 of 9 (7) Provide the HMC&M Supervisor with updated lists of HAZMAT in the work center. Forward all material substitutions and process changes. (8) Contact the Maintenance Department HMC&M Supervisor when collection drums are full. (9) Maintain a profile log for each container of HAZWASTE. (10) Prepare necessary documentation for each container of HAZWASTE (11) Notify the Maintenance Department HMC&M Supervisor prior to establishing new HAZWASTE streams or HAZWASTE collection points. .5 Describe the label marking requirements of HM/HW. [ref. c, ch. 7] A label developed by the facility that contains the following information from the MSDS: the manufacturer’s name, product identity, and hazard warnings. HAZMAT removed from the original container poses the same risk to the user and the environment as it does in the original container. Without marking the secondary container, the possibility arises where persons nay use the contents of the secondary container incorrectly. An example of this would be to put paint stripper in a spray detergent bottle. Unmarked, another person my use what he/she thinks is GP, when in reality, it is paint stripper. .6 Discuss requisitioning/return of HM and the purpose of the AUL. [ref. a, app. C; ref. c, ch. 7] 1. HM Requisitioning (1) Before ordering any HM, ships shall determine that a valid requirement exists. The Ships Hazardous Material List (SHML) provides the requirements for shipboard HM. Ships shall order only material allowed by this document, unless otherwise specifically authorized by the commanding officer (or other designated officer O-5 and above). (2) If a HM minimization center (HAZMINCEN) is in operation, this center shall requisition all HM (SHML is a record of the HM authorized aboard U.S. Navy surface ships) 2. HM return. At the completion of a maintenance action, the end of the workday, or the end of a 7-day use period, work centers shall return unused HM that was issued from the HAZMINCEN and its container as well as any residue from the maintenance action to the HAZMINCEN. The AUL shall identify the process(es) for each HM it lists. The activity shall maintain this AUL for all HM it allows for use. .7 State the purpose of, information contained on, and required location of the MSDS. [ref. a, app. B] Material Safety Data Sheets (MSDS’s)are technical bulletins containing information about materials, such as composition, chemical, and physical characteristics, health and safety hazards, and precautions for safe handling, use, and disposal. MSDSs shall be maintained for every item of HM aboard either through the HMIS or by hard copy for open purchased items. They shall be readily accessible to supervisors and personnel who actually use or handle HM. .8 Describe required training for all hands with respect to the HM/HW Program Hazardous Material Control and Management Program and follow-on training is provided to personnel. Training shall include personnel responsibilities and shall be documented on the NAMP Indoctrination Created by LTJG KyungNho "TACO" Kim Reviewed by CWO3 Dale Lansdown 111. HAZMAT Page 7 of 9 Training sheet Ensure all personnel receive command HMC&M and hazardous communications training per OPNAVINST 5100.19 and OPNAVINST 5100.23 within 30 days of assignment. a. Types of HM in their work area and aboard ship. b. What HW is and how it is disposed of. c. How to read and interpret hazard warning labels. d. What an MSDS is, how to read it, and where a copy is available for review. General information on HM handing, stowage, use and disposal. e. Protective measures when handling HM. f. Emergency procedures. .9 Explain the information and procedures to be followed when a HM/HW spill is discovered. [ref. a, app. B] All discoveries of spills or situations that may lead to a spill must be verbally reported immediately to supervisory personnel and the officer of the deck (OOD)/command duty officer (CDO). Crewmembers are not to remain in the area to investigate the spill. Whenever possible, however, the discoverer /initial response team shall report the following information: a. Time of spill discovery. b. Location of spill. c. Identification of spilled material. d. Behavior of material (reactions observed). e. Source of spill (e.g., tank, container). f. Personnel in vicinity of spill (list by name and department). g. Volume of spill. h. Anticipated movement of spill (e.g., leakage to lower deck passage from amidships toward galley). i. Labeling or placarding information (copy data from spilled container only after exposure to spill is eliminated). j. The CO shall report all overboard spills of hazardous substances as required. NAVOSH : 1. Discovery & notification 2. Initiation of action 3. Evaluation 4. Containment & D.C 5. Dispersion of Gas 6. Clean up / decontamination 7. Disposal of HW 8. Certification 9. Follow Up / report .10 State the storage requirements for on-site HM/HW. [ref. b, ch. 20] Aircraft maintenance departments must place special emphasis on the HMC&M Program and fully support all federal, state, and local environmental laws and regulations concerning HAZMAT handling, storage, use, reuse, minimization, and disposal. (1) Maintain an inventory of all HAZMAT present in the work center and ensure current shelf life has not expired. (2) Maintain an accurate AUL for the work center. (3) Maintain an adequate supply of containers, labels, spill response material, and related items in the work center. (4) Ensure a weekly inspection of work center HAZMAT and HAZWASTE sites is accomplished and maintain a record of all inspections. Created by LTJG KyungNho "TACO" Kim Reviewed by CWO3 Dale Lansdown 111. HAZMAT Page 8 of 9 (5) Ensure all HAZMAT and HAZWASTE containers are properly labeled, segregated, and free of corrosion and leakage. (6) Maintain a profile log for each container of HAZWASTE. .11 Discuss the requirements for HM inventories. [ref. a, app. C] 1. Inventories. HAZMINCEN shall establish high and low (reorder point) stock levels for each HM it manages and shall strive to maintain levels above the low-level point. When the stock level of a HM reaches a reorder point, HAZMINCEN shall obtain resupply from the supply department bulk stowage and repackaged as necessary into units of issue work centers normally require. HAZMAT items must be stored in properly marked containers, suitable to the contents of that container. Incompatible items shall not be stored together. HAZMAT storage areas shall be inspected daily to insure that these requirements are met. Bar-code control, list master inventory by type and location, and Track it. .12 Discuss the requirements for proper disposal of HW. [ref. d, ch. 12] The 1992 FFCA provides that any HW generated on public vessels (which includes Navy vessels) shall not be subject to the storage, manifest, inspection, or record keeping requirements until such waste is transferred to a shore facility: Ships’ forces are required to follow the requirements of reference with respect to the segregation, packaging, handling, safety, and labeling of HM. In addition ships shall segregate solid wasted in compliance with regulations of the State in which the waste is to be off loaded; the receiving shore facility shall provide information regarding waste segregation requirements. The “Used Hazardous Material” label required for every container of used HM transferred horn the ship contains a process description of how the HM was used. If identification and labeling are not provided by the ship, the receiving shore activity may designate ship’s used HM and solid waste based on laboratory analysis, and charge the ship or fleet accounts, for lab testing, and any additional handling, documentation, administrative and overhead costs. a. Adhesives - Store used or excess adhesives as you would flammable materials (in approved, labeled containers) pending shore disposal. b. Grease - Store spent or spilled greases in approved containers, original can, or double plastic bags. Seal and label container or bag with contents and store as used hazardous flammable material pending shore disposal. c. Hydraulic fluid - Store spent or excess fluid in approved containers for proper shore disposal. d. Fuels - Store all excess fuels in fire safe drums for proper shore disposal. e. Waste oils - Store spent or excess oil and lubricants in approved containers for proper shore disposal. f.Paint/paint thinners - Store all used and excess paint and thinners in approved containers for proper shore disposal. * Common idea: follow the detailed Regulation. Most commonly, double bag and label. Created by LTJG KyungNho "TACO" Kim Reviewed by CWO3 Dale Lansdown 111. HAZMAT Created by LTJG KyungNho "TACO" Kim Page 9 of 9 Reviewed by CWO3 Dale Lansdown