TEXAS COMMISSION ON FIRE PROTECTION CERTIFICATION

advertisement

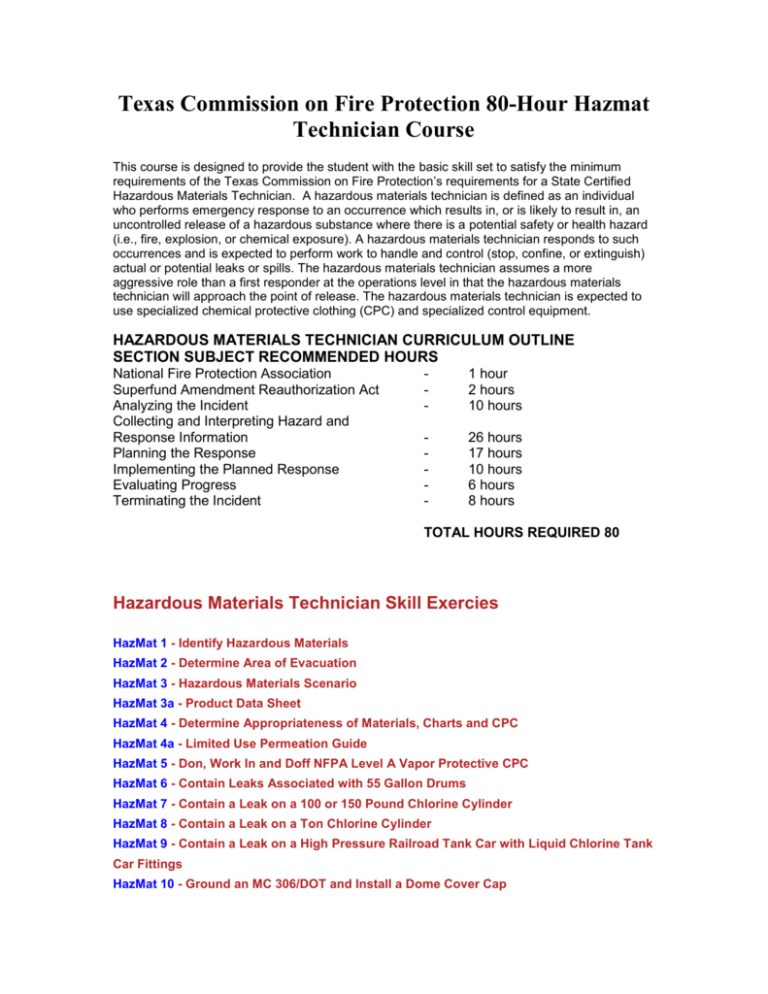

Texas Commission on Fire Protection 80-Hour Hazmat Technician Course This course is designed to provide the student with the basic skill set to satisfy the minimum requirements of the Texas Commission on Fire Protection’s requirements for a State Certified Hazardous Materials Technician. A hazardous materials technician is defined as an individual who performs emergency response to an occurrence which results in, or is likely to result in, an uncontrolled release of a hazardous substance where there is a potential safety or health hazard (i.e., fire, explosion, or chemical exposure). A hazardous materials technician responds to such occurrences and is expected to perform work to handle and control (stop, confine, or extinguish) actual or potential leaks or spills. The hazardous materials technician assumes a more aggressive role than a first responder at the operations level in that the hazardous materials technician will approach the point of release. The hazardous materials technician is expected to use specialized chemical protective clothing (CPC) and specialized control equipment. HAZARDOUS MATERIALS TECHNICIAN CURRICULUM OUTLINE SECTION SUBJECT RECOMMENDED HOURS National Fire Protection Association Superfund Amendment Reauthorization Act Analyzing the Incident Collecting and Interpreting Hazard and Response Information Planning the Response Implementing the Planned Response Evaluating Progress Terminating the Incident - 1 hour 2 hours 10 hours - 26 hours 17 hours 10 hours 6 hours 8 hours TOTAL HOURS REQUIRED 80 Hazardous Materials Technician Skill Exercies HazMat 1 - Identify Hazardous Materials HazMat 2 - Determine Area of Evacuation HazMat 3 - Hazardous Materials Scenario HazMat 3a - Product Data Sheet HazMat 4 - Determine Appropriateness of Materials, Charts and CPC HazMat 4a - Limited Use Permeation Guide HazMat 5 - Don, Work In and Doff NFPA Level A Vapor Protective CPC HazMat 6 - Contain Leaks Associated with 55 Gallon Drums HazMat 7 - Contain a Leak on a 100 or 150 Pound Chlorine Cylinder HazMat 8 - Contain a Leak on a Ton Chlorine Cylinder HazMat 9 - Contain a Leak on a High Pressure Railroad Tank Car with Liquid Chlorine Tank Car Fittings HazMat 10 - Ground an MC 306/DOT and Install a Dome Cover Cap HazMat 11 - Establish a Two-Step Decontamination Reduction Corridor (CRC) HazMat 12 - Perform a Two-Step Decontaminationt HazMat 13 - Select Appropriate Monitoring Equipment HazMat 14 - Demonstrate Field Maintenance of Monitoring Equipment HazMat 15 - Operate CDV 700S Radiological Monitoring Equipment HazMat 16 - Operate Gas monitoring Equipment HazMat 17 - Operate Colorimetric Monitoring Equipment HazMat 18 - Demonstrate Test Strip Operation and Limitations HazMat 19 - Demonstrate Test Strip Operation and Limitations HazMat 20 - Develop a Plan of Action HazMat 21 - Describe Product Removal and Transfer Considerations for Overturned Cargo Tanks HazMat 22 - Describe Response Objectives and Identify Action Options