CE527 - Lect5

advertisement

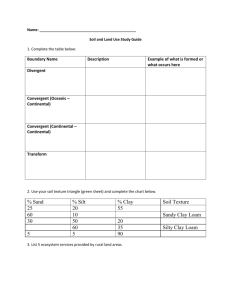

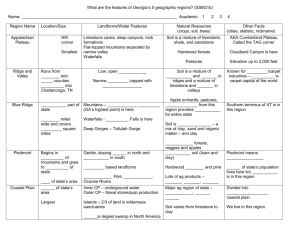

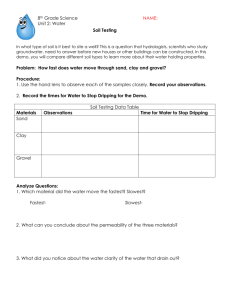

CE 527 Solid Waste Management Clay Liners and Membrane Liners Dr. S. K. Ong Clay Liners To achieve a hydraulic conductivity of 1 x 10-7 cm/s Rule of Thumb - at least _____ fines (silt and clay, < 0.002 mm), but > _____ would be more appropriate - % gravel should be less than ____, although some studies have shown that up to 50% have not significant impact on the hydraulic conductivity (very much dependent on the composition of the remaining fraction) - Plasticity index (PI) should be greater than 10, ideal PI between ______, between 30 to 40 – soil will be sticky and difficult to work [The definition of clay varies depending on the standard used, see Figure 15 – 1]. ASTM - sand sized particles passing through No. 4 sieve but not able to pass a No. 200 sieve (0.075 mm to 4.74 mm) - particles passing through a No. 200 sieve are treated as fines (silt and clay) - clay is distinguished from silt entirely based on the plasticity criteria - plasticity of a soil refers to the capability of a material to behave as a plastic, moldable material - four states: liquid, plastic, semisolid and solid - plasticity characteristics of a soil are quantified by three parameters LL – Liquid limit PL – Plastic limit PI – Plastic index LL – the water content corresponding to the arbitrary limit between the liquid and plastic states of consistency of a soil PL – water content corresponding to the arbitrary limit between the plastic and semisolid states of consistency of a soil - dividing line between liquid and plastic is the LL and plastic and semisolid is PL LL of a soil – water content at which the groove is closed ½ in. when the soil sample is jarred in the standard manner by exactly 25 drops (or blows) from a height of 1 cm in a standardized liquid limit device PL of a soil - water content at which the soil begins to crumble when rolled into small threads (1/8 in. in diameter without the threads breaking into pieces). Materials used in Natural Soil Liners - many different types of clay exist - generally three main groups are used for clay liners nonswelling clay such as kaolinite, illite (see Table) - generally good for compacted clay liners of depth of 0.5 m or greater swelling clays such as montmorillonite (smectite clay), bentonite, a naturally occurring material with montmorillonite as a common mineral present (note the expansion index of sodium montmorillonite about 2.5 as compared to that of calcium montmorillonite) preferably use calcium rather than sodium smectite group (minerals is made of: __________________________________________________ _________________________________________________ kaolinite – octahedral and tetrahedral layer smectite – tetra – octa – tetra – Exchange cation – tetra – octa – tetra ) Table Clay Group Cation Exchange Capacity (meq/100 g) Spec. Surface Area (m2/g) Expansion Index Kaolinite Sodium Calcium Illite Sodium Calcium Montmorillonite (smectite) Sodium Calcium Other factors Molding Water Content The degree of saturation of soil liner material at the time of compaction is perhaps the single most important variable that controls the engineering properties of the compacted material. The change in hydraulic conductivity with molding content is shown below: Where d is the dry unit weight = /(1+ ) = total unit weight or wet density = water content of each compacted specimen Soil with less than the optimum water content has high hydraulic conductivity and soils with greater than optimum water content tend to have low hydraulic conductivity and low strength. Compaction Energy increase compaction energy, hydraulic conductivity compaction is dependent on the weight of the roller, number of passes, thickness of the soil lift to be compacted Desiccation desiccation of soil liners occurs whenever the soil liner dries during or after construction cause shrinkage and cracking , resulting in preferential pathways overburden stress on liner components may assist in preventing a change in the hydraulic conductivity (for bottom liners and not true for final cover). Waste- Soil Liner Interactions Effects of Inorganic Compounds such as Cations Leachate has a variety of high valency cations present that can be exchanged with the cations present in the clay Clay are collodial particles with a negative surface charge. Positively charged cations and water are attracted to the surface of the clay forming a zone of water and ions surrounding the clay particles Due to the strong electrostatic forces, a layer of cations and water will be immobile relative to the clay particle. This layer of immobile water and cations is referred to as the diffuse double layer (DDL). Fluid flowing through the clay layer will be affected by the immobile layer. On a microscale level, the hydraulic conductivity of the soil will be controlled by the thickness of the DDL. When the DDL shrinks. More area will be opened for flow - resulting in higher hydraulic conductivity. The reverse is true. The thickness of the DDl can be estimated using the Gouy-Chapman equation where where - dielectric constant (dimensionless) n - electrolyte concentration (mol/cm3) z - cation valence Assume a compacted soil liner of sodium bentonite is used. Polyvalent cations, e.g., Ca 2+, Fe2+, Fe3+ in the leachate if there is a leak will displace the sodium, resulting in a decrease in the thickness of the DDL and there fore increasing the hydraulic conductivity. Note that the presence of the polyvalent cations will also cause flocculation and aggregation of the clay. Note that we do not have long-term data on the effects of leachate on the clay liners. The limited evidence available shows that the long-term effect of exposure to leachate may not be as severe as originally thought. One reason is that the clay liner is under several thousand tons of waste and any change will be corrected for by the weight of the trash. Precipitation and the development of active biomass near the upper surface of the soil liner produce a clogging action that reduces the effective hydraulic conductivity of the barrier. A study on a clay liner that was exposed to leachate for 15 years showed that the upper 15 cm contained high Fe, Zn, Cu and Pb. In addition, the first 20 cm was black and oily, suggesting microbial activity. Beyond 15 cm, the concentrations of polyvalent cations were at background levels. Diffusion transport of Cl and Na reached 1.5 m into the clay in the 15 years. Please note that if you have cracks in the soil liner, the leachate will move very rapidly out of the clay liner system. Neutral Organic Compounds The hydraulic conductivity of clay can change in the presence of organic compounds Water has a dielectric constant, , of approximately 80. Based on the Guoy-Chapman equation, the DDL will shrink in the presence of organic solvents, effectively opening up flow paths (see Figure 2-26). Pure organic liquids of several types can substantially increase the permeability. Note that dilute aqueous solutions of organic liquids do not appear to affect the permeability of clay liners. A rule of thumb is that concentrations up to 0.1% by weight can be tolerated. Flexible Membrane Liners (FML) or Geosynthetics synthetic materials, mostly plastics, used in place of or to enhance the function of natural soil materials. Function of geomembranes are generally used for isolation of liquids or as a vapor barrier. EPA's de minimis leakage requirement is 1 gallon/acre/day for geomembranes. Other types of similar materials include geotextile - for reinforcement. Separation, filtration and drainage geonets - for drainage geogrids - for slope stability geomats - for prevention of erosion of exposed slopes such as landfill caps Major types of polymers, two major classes thermoplastic - can be repeatedly reworked to the desired shape by heating and cooling thermoset. - can be processed once only Two most commonly used polymers - polyvinyl chloride and polyethylene Major types of Geomembranes in Current Use Thermoplastic Polymers Thermoset Polymers Combinations Polyvinyl chloride (PVC) Butyl or isopreneIsobutylene (IIR) Epichlorohydin rubber PVC - nitrile rubber Ethylene propylene Diene monomer (EPDM) Polychloroprene (neoprene) PVC-ethyl vinyl acetate Polyethylene (VLDPE, LLDPE, MDPE, HDPE) Chlorinated polyethylene PE-EPDM chlorosulfonated Polyethylene (CSPE or hypalon) Composition of geomembranes consists of four major components ________ - the polymer __________ - e.g., epoxides, phosphates, polyesters -Impact flexibility to the compound, although some plasticizers are subjected to microbial attack - improve handling by modifying physical and mechanical properties _________ - e.g., mineral particles, metallic oxides, fibers and reclaimed polymers - increase the stiffness of the geomembrane without altering the permeability _________ - general stabilization purpose, prevent ultraviolet light degradation _________ - e.g., antioxidant - to reduce aging from ozone Typical Formulation of Geomembranes Type Resin Plasticizer Carbon Black and/or Filler Additives PVC CSPE EIA VLDPE HDPE Leakage Rates There is no such thing as an impermeable geomembrane They have very low permeability but still allow some leakage Moisture moves through by diffusion. Vapor transmission test conducted using ASTM E96. Sample is placed on top of a small aluminum cup containing a small amount of water. Cup placed in a controlled humidity and temperature chamber of 20% RH. Humidity in cup is 100%. Moisture diffuses through the membrane and rate of diffusion estimated based on weight loss. Vapor Transmission Material Thickness (mil) PVC 30 Water Vapor Transmission (g/m2day)* 1.9 Thickness (mil) 10 20 Methane Transmission (mL/m2/day.atm) 4.4 3.3 CPE CSPE HDPE 40 0.4 40 0.4 34 1.6 30 0.02 98 0.06 34 1.4 LLDPE 18 2.3 _____________________________________________________________________________ * in terms of gal/acre day multiply by 1.07 Pinholes Leakage through geomembrane can also occur due to pinholes and large holes leakage through geomembrane is drastically reduced when placed on a low permeability soil such as clay such composite liner is only effective if the geomembrane and clay are in close contact over the entire surface Typical Rates of Leakage through Primary Liner - (liters/heactare/day) Hydraulic Head - 3 cm Hydraulic Head - 30 cm Geomembrane/clay Geomembrane/silt Geomembrane/sand Geomembrane/gravel Note - 5 holes/ha, each hole 2 mm diameter Attachment of Geomembranes Geomembranes are seamed using Thermal seaming - heat only at > 260o C, - include hot air bonding or hot wedge or knife bonding - good for thermoplastics Chemical seaming - use solvents to dissolve the FML or by vulcanizing the surface - long term integrity suspect when it comes into contact with the leachate Degradation Concerns Ultraviolet Degradation - short wavelengths of sunlight (315 to 380 nm) enter into the polymer system and cause chain scission and bond breaking - carbon black is used as a blocking agent to retard UV degradation - manufactured with 2 - 3 % carbon - FML should be buried within 6 to 8 weeks of laying out Chemical Degradation - various chemicals can be attack the membrane - to evaluate capability use EPA 9090 method to assess chemical resistance (immerse FML in leachate for at least 120 days at 23 and 55o C. Perform physical and analytical tests on unexposed and exposed FML to establish baseline data on changes on samples exposed to the leachate. Tests include puncture, tensile strength, etc.) See attached compatibility chart. Swelling Degradation - all polymers swell when exposed to liquid including water - in general HDPE swells the least, PVC the most - secondary effects that cause degradation Extraction Degradation - components of geomembrane formulation are extracted causing the properties of the remaining materials to be compromised, e.g., breaking the bond of plasticizers, resulting in the extraction of the plasticiizer with time. Delamination Degradation - if the geomembrane is fabricated in layers, there is a possibility that the liquid entering between layers may cause delamination and failure Thermal Expansion and Contraction - FML may be stretched tight in locations which may lead to failure of seams. Oxidation Degradation - oxidation of polymers caused by gases or liquids interfacing with the geomembranes, e.g., free radicals such as oxygen atom may diffuse and react with polymers - antioxidant added to scavenge oxygen and free radicals Biological Degradation - unlikely for resin portion to degrade - microorganisms can interact with plasticizers or fillers Comparison of 3 FML for Landfill Applications Property CSPE Heat Resistance Excellent Microbial resistance Good Chemical resistance Very good (poor to aromatic hydrocarbons) Ultraviolet Resistance Excellent Puncture Resistance Fair to good Field seams Best made on Warm day Ease of placement Good PVC Poor above 140o C -very good HDPE Excellent Good excellent Poor Good Excellent If thick, good If thin, fair Fusion or extrusion welding used in field, no glues needed Fair Good, but tendency To lose plasticizer and Shrink - must be Installed loosely Cost High Low Moderate Tensile Strength No information High Excellent Ozone resistance good Poor No information Cold Weather Difficulties Good resistance to Stiff and brittle -Cracking in cold weather _________________________________________________________________________________ Cost (1994 prices) 20 mil PVC = $_____/m2 100 mil HDPE = $_____/m2 or ______ cent per mil per square foot.