The Solution to the Detection of Food Safety Problems

advertisement

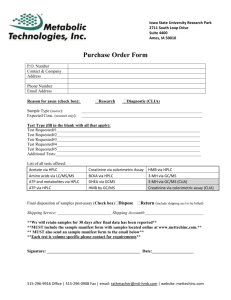

Name: Suen Yung Lee (Lily) University no.: 2005247081 Group: ECEN2802O Name of the Journal: Science in Hong Kong. Name of the article: High Performance Liquid Chromatography: The Solution to the Detection of Food Safety Problems In recent years, the problem of food safety has been getting more serious in Hong Kong. From the overuse of preservatives in processed food a few years ago to the use of non-permitted colourings in Chinese New Year foods recently, many similar cases have increased public concern over food safety. Fortunately, in Hong Kong, the Government Laboratory is responsible for the analysis of the food composition, food additives, contaminants and other harmful substances in food (GL 2007a), so that harmful substances in food can be discovered and suitable actions can be taken to protect public health. One of the most common techniques used for food analysis is the high performance liquid chromatography (HPLC). The purpose of this article is to discuss how HPLC contributes to solving food safety problems in Hong Kong. The article begins by explaining the principles of HPLC. It goes on to give examples of the application of HPLC on the detection of harmful substances in food. Finally, it discusses how HPLC helps the government protect public health. HPLC aims at the separation of every component in a given food sample (Heftmann 2004), based on the size of the particles of each component (OSUEMSI 2004). It involves the use of two phases: the stationary phase which is immobile, and the mobile phase which can travel freely (Nielsen 1998). Nowadays, HPLC is carried out automatically using a machine called “high performance liquid chromatograph” in the Government Laboratory (GL 2007b) (Figure 1). A liquid which acts as the mobile phase is pumped from the solvent reservoir through an injector, where the sample is loaded into the machine by injection in liquid form (OSUEMSI 2004) (Figure 2). The 1 mobile phase liquid assists the propagation of the liquid sample (OSUEMSI 2004) to a long, open column packed with a special porous material which serves as the stationary phase (Nielsen 1998). The separation of components in the sample is based on the size of the particles of each component. Particles with sizes smaller than the pore of the packing material can pass through the column rapidly, while those which are larger than the pore are retained in the column and flow out less quickly (OSUEMSI 2004). As a result, components of different particle sizes flow out of the column at different times and are separated. Eventually, each component passes through a detector which records the amount of the component (OSUEMSI 2004). In this way, the quantity of food components of different particle sizes can be measured with HPLC. Figure 1: A high performance liquid chromatograph (Source: http://www.labomatic.ch/pdf/unit_hplc2_e.pdf) 2 Figure 2: The components of a high performance liquid chromatograph (Rounds and Gregory, III, 1998) HPLC has been effective in the analysis of harmful substances present in food products in Hong Kong. For example, with the help of HPLC, the Government Laboratory successfully discovered the use of nitrate and/or nitrite, which are preservatives for meat products, above the permitted level in a few traditional Chinese preserved sausage samples in Hong Kong (CFS 2004) (Figure 3). As nitrites may react with other components in meat to form a cancer-causing substance called nitrosamine (CFS 2004), a level of nitrites above the permitted one must not be allowed. In addition, HPLC helped the Government Laboratory monitor the use of preservatives and colourings in Chinese New Year foods, for example, steamed puddings, fried dumplings, seeds and glutinous rice balls (CFS 2000). An analysis showed that a few steamed puddings contained benzoic acid, a non-permitted preservative (CFS 2000) (Figure 4). Several samples of steamed puddings and fried dumplings were also found to contain non-permitted colourings (CFS 2000). The consumption of these foods may cause adverse health effects. With HPLC, the Government Laboratory also discovered the types of foods which may pose risks to the public health, so that suitable actions could be taken to protect the health of Hong Kong people. 3 Figure 3: Traditional Chinese preserved sausages found in Hong Kong. Some of the sausage samples were found to contain amounts of nitrate and/or nitrite above the permitted level (Source: original). Figure 4: Steamed puddings, an example of Chinese New Year foods. Some of the samples collected in Hong Kong contained non-permitted preservatives and colourings (Source: original). The data obtained from HPLC is sent to various government departments in Hong Kong, for example, the Centre for Food Safety, so that these departments can give advice to customers and set up guidelines for food manufacturers to ensure public health. For example, the customers are advised to avoid buying colourful food 4 products which may contain non-permitted colourings or excess permitted colourings (CFS 2000). The food manufacturers are educated to add appropriate amounts of preservatives to food products (CFS 2004). After suitable actions are taken to protect public health, the data from HPLC is still useful. For example, recently, the government has used the data on the Chinese New Year foods to give advice to the public on how to select Chinese New Year foods which are safe to consume (CFS 2007). Not only does HPLC help the Hong Kong government discover problematic food products, it also allows the government to make plans to minimize the harmful effects of these food products on public health. In conclusion, HPLC has been effective in monitoring the safety of food products in Hong Kong. It is useful in the separation of different components in food so that those which are under concern can be analyzed. Based on the results obtained from HPLC, the government can take action to protect the health of Hong Kong people. It is expected that the technology of chromatography will continue to improve, so that it will enhance the efficiency of food analysis by the Government Laboratory. References: [CFS] Centre for Food Safety. 2000. Chemical Hazard Evaluation: Use of Preservatives and Colouring Matter in Chinese New Year Foods [online]. Available: http://www.cfs.gov.hk/english/programme/programme_rafs/programme_rafs_fa _01_04_cny.html Accessed: 2007 Mar 20. [CFS] Centre for Food Safety. 2004. Chemical Hazard Evaluation: meat curing in Chinese cuisine: a risk assessment on Lap-mei [online]. Available: http://www.cfs.gov.hk/english/programme/programme_rafs/programme_rafs_fa _01_03_report.html Accessed: 2007 Mar 19. [CFS] Centre for Food Safety. 2007. Food Safety Focus [online]. Available: http://www.cfs.gov.hk/tc_chi/whatsnew/whatsnew_fstr/files/FSF7%202007-0221.pdf Accessed: 2007 Mar 20. [GL] Government Laboratory. 2007a. Government Laboratory home [online]. Available: http://www.govtlab.gov.hk/english/home.htm Accessed: 2007 Mar 18. 5 [GL] Government Laboratory. 2007b. Food and Environmental Hygiene B Section [online]. Available: http://www.govtlab.gov.hk/english/abt_aasd_fehb.htm Accessed: 2007 Mar 18. Heftmann E, editor. 2004. Chromatography: fundamentals and applications of chromatography and related differential migration methods. Amsterdam: Elsevier. 518p. Nielsen SS, editor. 1998. Food analysis. Gaithersburg, MD: Aspen Publishers. 630p. [OSUEMSI] The Ohio State University Environmental Molecular Science Institute. 2004. HPLC [online]. Available: http://www.chemistry.ohio-state.edu/~pmazzer/HPLC.htm#_top Accessed: 2007 Mar 19. References for figures: (Figure 1) Labomatic. Undated. LABOPREP HPLC workstations [online]. Available: http://www.labomatic.ch/pdf/unit_hplc2_e.pdf Accessed: 2007 Apr 14. (Figure 2) Rounds MA, Gregory, III JF. 1998. High Performance Liquid Chromatography. In: Nielsen SS, editor. Food analysis. Gaithersburg, MD: Aspen Publishers. 630p. Number of words: 820 6