To :

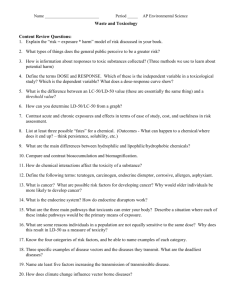

advertisement

General Technical Guideline for Environmentally Sound Management of Wastes Consisting of, Containing or Contaminated with Polychlorinated Dibenzo-p-dioxins (PCDDs) and Polychlorinated Dibenzofurans (PCDFs) Response to the March 2004 Draft Comments on the Comments of the World Chlorine Council (WCC) and Canada On behalf of CEWEP, the European representation of 200 incineration plants from 13 countries, treating annually around 30 million tons of municipal solid waste in an environmentally sound way, we would like respond to some of the comments made on the above mentioned guidelines. 1. Incineration temperature (paragraph 90) We do not agree with the proposals from Canada and the WCC to rise the low incineration temperature to 950 or 1 000 °C. These figures seem to be quite arbitrary. Incineration is the most widely used method for the destruction of POPs. It is highly regulated demanding very low levels of emissions, e.g. in the European Waste Incineration Directive (WID) 2000/76/EC, which prescribes emission < 0.1 ng/Nm3 for dioxins/furans. According to this directive incineration plants shall operate with a temperature of 850 °C for two seconds. Only if hazardous wastes with a content of more than 1 % of halogenated organic substances, expressed as chlorine, are incinerated, the temperature has to be raised to 1 100 °C for at least two seconds. These figures are coherent with the Best Available Technique for Waste Incineration, the BREF WI, and they are based on long experience with destruction of PCDD/F by incineration. The requirement of 2 seconds guarantees a long (and sufficient) burn out. A higher temperature does not automatically mean lower PCDD/F emissions. The dioxins/furans emission limits of 0.1 ng/Nm3 requirement by the WID is achieved by incineration plants operating according to the WID, i.e. 850 °C for 2 seconds. In practice, the incineration plants represented by CEWEP achieve much lower dioxin emissions with 850 °C for 2 seconds. However, if hazardous wastes with a content of more than 1 % chlorine are incinerated, the temperature has to be raised to at least 1 100 °C for at least two seconds, according to the WID. The technical guidelines should be consistent with the WID, the BREF WI and practical experience. Not at least due to the climate protection (Kyoto protocol), the energy efficiency and the sustainable use of resources (energy), it is not advisable to operate with higher temperatures than necessary as this always consumes additional energy. 2. Further comments: Paragraph 123 Incinerators destroy waste containing POPs on the one hand and have to treat their residues (bottom ash, boiler ash and fly ash) in an environmentally sound way on the other hand. Paragraph 123 says: The following PCDDs and PCDFs wastes are suitable for hazardous waste landfills: solid matrices with a bulk concentration and leachate concentration below regulatory limits; semi-solid form that are suitable for and have undergone immobilisation prior to landfilling; solid residues (fly ash, bottom ash, slag, scrubber sludge, treated soil, treated metals, etc.); The third bullet mentions bottom ash and slag. These residues are considered non hazardous and they are often used in road construction. Therefore, they are not suitable for hazardous waste landfills. Paragraph 41: First bullet, the term ‘auto-shredder fluff’ should either be excluded or it should be defined clearly what is to be understood under this term. As to our understanding, auto-shredder fluff can be destroyed through waste incineration. Paragraph 95: The term ‘proper treatment of by-products’ needs definition. It should be ensured that byproducts of mobile incinerators, such as fly ash, have to be treated in the same way as those of fixed incinerators. Suggestion: Include a sentence: “The by-products of a mobile incinerator must be treated in the same manner as the by-products of a fixed incinerator”. If you have any queries please do not hesitate to contact us. CEWEP will try to provide you with any information available. With kind regards, Dr. Ella Stengler Managing Director CEWEP Confederation of European Waste-to-Energy Plants 12A, Boulevard Clovis B-1000 Brussels Tel. : +32.2.770 63 11 mailto : ella.stengler@cewep.com http://www.cewep.com