Onur Erkal

advertisement

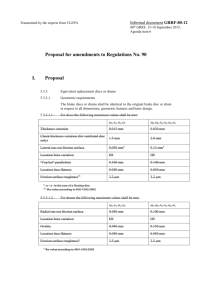

CERAMIC BRAKE DISCS INDEX 1.1. Abstract (p.2) 2.1. Introduction (p.2-3) 3.1. Importance of brake systems (p.3-4) 3.2. Facts about braking (p.4-5) 3.3. Brake systems, drum vs. disc brakes (p.5-6) 3.4. How disc brake systems work (p.6-7) 4.1. Properties of ceramics (p.8) 4.2. Materials used in the ceramic composite brakes (p.8-9) 4.3. Advantages of ceramic composite brake discs (p.9) 4.3.1. Ceramic composite brakes can hold extreme temperatures (p.9-12) 4.3.2. Ceramic composite brakes are very hard and resistant to wear (p.12-14) 4.3.3. Ceramic composite brakes have low density, they are light (p.14-15) 4.4. Disadvantages of ceramic composite disc brakes (p.15-16) 4.5. Using areas and Future of ceramic composite disc brakes (p.16) 5.1. Conclusion (p.17-18) 6.1. Patents (p.18) 7.1. References (p.19) 1.1. Abstract In our daily life the most common way of transportation is automobiles. Everyday car manufacturers spend huge amounts of money to find a way to improve their products about performance, safety and comfort. Because of that they invent new things or improve the parts that already exist to make their cars better. But one of the vital themes about the car manufacturing is safety. When we talk about a car’s safety, the first thing comes in our mind is braking systems. Nowadays we see in almost all high-performance sport cars a new type of braking system, which includes ceramic brake discs. In even luxury cars these systems are available as an optional item. Actually this kind of braking system is being used in Formula 1 since some years, which is the highest point of automotive industry. These types of brakes have got many advantages according to the material specifications of ceramic about safety as well as about comfort and performance. As a mechanical engineer and a person who is interested in cars, I have chosen to investigate ceramic brake discs in my project. I think these types of brakes will be commonly used in upcoming years and it is important to learn and investigate about mechanical developments that will simplify our life, which is also one of the leading goals of an engineer. 2.1. Introduction For understanding of the concept of ceramic disc brakes and their advantages, we should follow a path, which helps us. That path should cover first the importance of the braking systems in our daily life. Then we should analyze the brake systems used in automobiles and differences between them. Without analyzing these concepts, we will not be able to see how a braking system works, and which differences the ceramic brakes bring and we will not be able to see the advantages of it. 2 Then we should analyze the properties of ceramics to understand their differences from other materials used in brake technology. That will also help us to see the reasons of using ceramics and ceramic composite materials. After that we should go deeper for understanding the positive sides of ceramic composite materials, which we can sum them under 3 titles, which are resistant to heat greater than conventional materials, high hardness resulting low wear and low density resulting low weight. These positive sides of the ceramics have got many influences on the brake technology which lead us to the advantages of ceramic composite brake discs like; better performance, better road-holding under braking, acceleration and cornering, greater comfort on poor road surfaces, improvement in agility and handling, exceptional fade resistance thanks to consistently high friction values, more immediate and precise response, generous safety reserves, even in competition use, resistance to expansion or warping, virtually no susceptibility to corrosion, low service and maintenance costs, excellent sound-damping properties and lower fuel consumption and lower CO2 emissions due to lower weight. As a result of these great positive sides of ceramic composite brakes discs, there is only one negative side, which is important; the price. That’s why engineers are trying hard to reduce the costs of ceramic discs and we see the examples of these in high performance sports cars and some luxury cars, where their costs are insignificant when comparing with their specifications. 3.1. Importance of Braking Systems In the recent years automotive industry has developed very quickly. With the improvements in the engine technology, car makers produce more powerful and efficient engines. With the new developments in aerodynamics technology everyday new cars with less drag coefficients (Cd) are produced. And by using of lighter materials than steel or iron in producing the chassis of the cars, the weight of the cars are reduced. As a result of all these developments new cars with higher top speeds, with quicker acceleration facts and with better handling values are produced. 3 But to balance this increased performance of the current cars, the braking technology should be developed as well, because for a car stopping is more important than accelerating or top speeding. Safety of the cars has the leading role in automotive industry than the performance of the cars. Otherwise fatal accidents in the traffic will increase and more people will die in these accidents. That’s why engineers are interested very much with the development of the car brake systems. A moving car has a certain amount of kinetic energy, and the brakes have to remove this energy from the car in order to stop it. The kinetic energy lost by the moving part is usually translated to heat by friction. But we know from the kinetic energy formula (E = ½m·v2) that kinetic energy increases with the square of the velocity. That means, if the speed of a vehicle doubles, the energy of it becomes four times greater. So; the brakes must dissipate four times greater energy to stop it and consequently the braking distance is four times as long. That fact also explains us the importance of the braking and the importance of the improvement of braking systems, because it should be developed more progressive to balance the improved performance of the cars. Otherwise it can not satisfy the requirements that the new cars with high performances bring. 3.2. Facts about braking The common principles that braking systems use when stopping a car: friction and heat. By applying resistance, or friction, to a turning wheel, a vehicle's brakes cause the wheel to slow down and eventually stop, creating heat as a product. The rate at which a wheel can be slowed depends on several factors including vehicle weight, braking force and total braking surface area. It also depends heavily on how well a brake system converts wheel movement into heat and, subsequently, how quickly this heat is removed from the brake components. Because of that cooling of the discs is very important by disc brake systems. And this is the reason that the disc brake systems are being used in cars rather than the drum brake systems in the last years. 4 After heat and friction, another term is important for the braking systems. The coefficient of friction is a dimensionless scalar value which describes the ratio of the force of friction between two bodies and the force pressing them together. The coefficient of friction depends on the materials used. For example, ice on steel has a low coefficient of friction, because the two materials slide past each other easily, where rubber on wood board has a high coefficient of friction, because the materials do not slide past each other easily. Coefficients of friction range from near zero to greater than one. 3.3. Brake Systems, drum vs. disc brake systems There are two types of braking systems used in vehicles especially in cars; which are (a) drum brake system and (b) disc brake system. A drum brake is a brake in which the friction is caused by a set of shoes or pads that press against the inner surface of a rotating drum. The drum is connected to a rotating wheel. However in the disc brake system a brake disc is connected to the wheel or the axle. To stop the wheel, friction material in the form of brake pads mounted in brake caliper is forced mechanically, hydraulically, pneumatically or electromagnetically against both sides of the disc. Friction causes the disc and attached wheel to slow or stop. 5 Although both systems look very similar, disc braking system is much effective than the drum brake system. Drum brakes would often fade and lose their effectiveness under high braking conditions, like descending a hill with a heavy load or repeated highspeed slow downs. Usually this fading was the result of too much heat created within the drum. Because the principle of braking involves turning kinetic energy into heat, drum brakes can only operate as long as they can absorb the heat generated by slowing a vehicle's wheels. Once the brake components themselves become saturated with heat, they lose the ability to stop the vehicle. One of the first improvements about the braking technology is that the manufacturers, on a widespread scale, switched from drum to disc brakes in the early '70s. Since the majority of a vehicle's stopping power (between 60 and 90 percent) is contained in the front wheels, only the front brakes were upgraded to disc during much of this period. Since then, many manufacturers have included their new models with fourwheel disc brakes. (3) 3.4. How disc brake system works Disc brakes work with the same principle that the drum brakes work. But instead of including the major components within a metal drum, disc brakes use a slim rotor/disc and small caliper to halt wheel movement. Within the caliper are two brake pads, one on each side of the rotor, that clamp together when the brake pedal is pressed. The major difference about the disc brakes is that the rotor also the disc is fully exposed to outside air. This allows cooling the rotor constantly, which is overheated during braking and causes fading. That difference is the biggest reason that in current cars the drum brake system is no longer used and replaced with the disc brake system. 6 This cooling of the disc lets the heat of the disc decline and that helps to the improvement of the brake performance. A driver with disc brake system could carry his speed deeper into a corner and apply greater braking force at the last possible second without overheating the components. It also allows not diminishing the braking performance even after repeated braking, when driving down a mountain for example. Most car disc brakes are vented, which means they have vents on in that pumps air through the disc to provide cooling. At high speeds the wind that the car receives is a great potential to cool the discs, which are overheated. 7 4.1. Properties of Ceramics Ceramics are compounds between metallic and nonmetallic elements; they are most frequently oxides, nitrides and carbides. Some of the common ceramic materials include aluminum oxide (Al2O3), silicon dioxide (or silica, SiO2), silicon carbide (SiC) and silicon nitride (Si3N4). With regard to mechanical behavior, ceramic materials are relatively stiff and strong comparable to metals. In addition, ceramics are typically very hard. On the other hand they are extremely brittle. Ceramics are very good insulators of heat and electricity and are more resistant to high temperatures and harsh environments than metals and polymers. 4.2. Which materials used in ceramic brake discs Automotive braking systems normally employ conventional or ventilated brake discs and pads. In these systems, the brake discs are made of steel or grey cast iron, which are then paired with organic-composite brake pads. These types of friction materials are suitable for use in braking systems with moderate loads, where they exhibit a relatively high and stable friction coefficient, a low-wear rate and are quiet during operation. However, car manufacturers are trying to design more luxury and sports-class vehicles which require braking systems that provide more braking power than 8 conventional braking systems. Accordingly, new materials are introduced into braking systems in the case of disc materials, for example, carbon–ceramic C-C/SiC composites, which can provide more friction and operate at higher temperatures. Carbon-ceramic is a ceramic composite material, composed of carbon fiber within a silicon carbide matrix, socalled carbon fiber reinforced silicon carbide (C/SiC). It is clear that new pad materials can resist higher temperatures compared to conventional organic-based materials need to be used with these ceramic-based materials, like metal–matrix composites (MMC). 4.3. Advantages of ceramic composite brake discs 4.3.1. Ceramic composite brakes can hold extreme temperatures One of the most important properties of ceramics is that they are very good insulators of heat, which means they can hold very high temperatures without any failure. This fact is one of leading advantages of ceramic composite brake discs compared to the conventional brake discs made of grey cast iron. In the comparison experiment two test specimens, one made of grey cast iron and another made of ceramic–carbon composite 9 are used. The test specimens used in the test device were discs with an outer diameter of 60 mm and a width of 8 mm. The discs were rotated at various speeds. The stationary testing-pad flats had dimensions of 8mm×16mm×7 mm. Three different relative velocities between the discs and the pads were used, i.e., 5.95, 10.96 and 14.81 m/s, which correspond to car speeds of 40, 80 and 120 km/h. Three different loads were applied through the loading cell, i.e., 100, 200 and 300 N, which resulted in nominal contact pressures of 0.42, 0.84and 1.16MPa, typical of the whole range of pressures found in real braking systems. (1) (a) Temperature of pads and coefficient of friction in grey cast iron against metal–matrix composite contacts as a function of the testing time during shown. (b) Average coefficient of friction after 50 s of testing as a function of pressure and relative velocity 10 (a) Temperature of pads and coefficient of friction in C/C SiC composites against metal– matrix composite contacts as a function of testing time during loading cycles at pressure of 0.84MPa and at 10.96 m/s. Insertion is a detail from (a). (b) Average coefficient of friction after 50 s of testing as a function of pressure and relative velocity. The first result shows us that the temperatures generated at the contacts of ceramic–carbon composite C/C SiC and the metal–matrix composite(MMC) are very high; under the testing conditions they reached more than 800◦C, which is more than two times higher than conventional contacts with grey cast iron. The other results shows us that the coefficient of friction in the contacts with the ceramic–carbon composite C-C/SiC was, in comparison to grey cast iron: (a) two times higher, i.e., above 0.5 and (b), much more uniform in the range of conditions used, with typically only a 10–30% variation. (1) 11 If we want to make a simple conclusion from these results, ceramic composite brakes can work properly at very high temperatures and they provide a great braking capacity. They provide even better results with higher pressures also with higher loads compared with the conventional brake discs. In addition to that their performance does not decrease after repeated braking. All of these results show that ceramic composite brakes provide better performance, better road-holding under braking, acceleration and cornering, improvement in agility and handling, more immediate and precise response and generous safety reserves even in use at the limits. 4.3.2. Ceramic composite brakes are very hard and resistant to wear Another important property of the ceramics is the hardness of the material. When compared with the classical brake discs based on gray cast-iron, the structure of the ceramic composite brake discs is more solid. That fact prevents the discs from wear and waste and provides a longer life time. Compared with an identical brake disc made of steel, this material lasts four times longer: the high abrasion resistance of ceramic discs means that they will last for up to 300,000 kilometres. (4) In addition to that, the extreme surface hardness of the material is also a sign for holding to higher friction values, which means a higher brake capacity is provided, so with same size of disc larger loads can be carried. Another advantage of the structure of the ceramic composite brake discs is that they are non-metallic, which means that the discs are unsusceptible to solid and liquid road salts as well as to corrosion and rust. These facts decrease the costs of the service and increase the safety of the brakes in a long time period. In the hardness and wear comparison experiment, three test samples used in the test device. The brake system consisted of a redesigned commercial rear caliper and a ceramic composite disc of 196mm×6mm with an effective radius of 84.5mm. The specific pressure was 1.14MPa, whereas the hydraulic pressure was 1.48MPa. The speed was held constant at 660 min−1. (8) 12 Structure of the composite brake disc: (a) SEM micrograph of the SiC layer on the C/C composite base and (b) schematic representation of the composite disc. The 3 different samples used in the experiment are; the conventional brake disc consisting only metal constituents named as M35; another disc having a formulation with the addition of graphite named as G15; and the disc that includes the addition of the SiC abrasive to the base metallic matrix named K5. The difference between the microstructures of two samples; (a) with the addition of graphite G15 and (b) with the addition of SiC K5. 13 As the first result the deformation of the base metallic matrix is more clearly visible in the G15 sample than in the K5 sample, where the abrasive particles suppress the moving of the metallic phases. Another result of this experiment is that ceramic composite disc has got a much more hardness than the other samples. (5) If we want to make a simple conclusion from these results, because of the high hardness of the ceramic composite discs, they do not wear easily, they last longer and they provide greater brake capacity than the conventional brake discs. In addition to the hardness, their non-metallic surface prevents corrosion and rust, and these provide a longer lifetime. Moreover because of the structural type of ceramics, the noise created at the wheels is less than the conventional brakes and that increases the comfort. 4.3.3. Ceramic composite brakes have low density, they are light Carbon-Ceramic brake discs offer a tremendous weight advantage (about 50% 65%) over traditional grey-cast iron components, because of their low densities. This reduces the weight unsprung masses (the mass that includes the weights of the suspension, wheels, wheel spindles, wheel bearings, tires, and a portion of the weight of driveshaft, springs, shock absorbers, and suspension links). In general, the speed and agility of a car will increase as its weight is reduced. The influence of weight is multiplied if a component is rotating. That means the weight save in unsprung mass is very crucial for a high-performance car. If weight can be saved in these areas, the benefits in terms of handling are immense; resulting in noticeably improved handling and agility and of course performance. (2) 14 If we want to give an example about the weight comparison between two systems, we can show the Porsche 911 GT2 (front brakes only) with disc dimensions 350 mm x 34 mm. The weight of the brakes made of grey iron is 23.2 kg where the weight of the brakes made of ceramic composite materials is 11.5 kg. That means there is 11.7 kg difference between two systems. And if we include the rear brakes we should multiply this difference with two, which ends up over 20 kg weight difference. 4.4. Disadvantages of ceramic disc brakes The only disadvantage of ceramic disc brakes is their cost. When compared with the conventional brake disc made of grey iron they are very expensive, almost 5 to 10 times. For example by the famous sports car manufacturer Porsche, the cost of the optional ceramic composite brakes is nearly 8000€, which of course does not reflect the real net cost of it. However, it is obvious that they are very expensive than the normal 15 brake discs. That’s why ceramic composite brake discs are only available in high performance cars or very luxury costs, where such a cost is negligible when compared with the price of the car itself. But there a lot of researches to decrease the cost of the ceramic composite brake discs and in 10 to 15 year time period the cost difference between two systems will be as small as negligible. (6) 4.5. Using areas and Future of ceramic composite disc brakes The ceramic composite brake discs were first used in fast train applications late ‘80s. Then it was used in some aircraft brake applications. In the late ‘90s thanks to the development in technology and decrease in the costs of high tech equipments it has began to be used in automotive industry. These ceramic composite brakes have been used in Formula 1 since some years, which is the highest point of automotive industry. Because these cars should operate at extreme performance conditions, this kind of brakes were very suitable for them. Nowadays best sports car manufacturers such as Porsche, Ferrari, Lamborghini, Mercedes and Audi are using ceramic composite brake discs in their top models. However the costs of this kind of brakes are still too expensive to be used in regular cheap cars. But there are a lot of researches, which try to decrease the costs of this kind of brake discs. With the changes in the formulations of the composites, it is possible to find combinations with cheaper materials and with the same properties. After seeing the development in this area in the last 10 years, it is obvious that ceramic composite brake discs will be used more commonly in the future. 16 5.1. Conclusion In this project, we have interested with a new technology in the automotive industry, which is a new brake disc system; ceramic composite disc brakes. There are a lot of advantages of using ceramic composite materials in the brake discs thanks to the positive properties of the material ceramic. If we summarize these properties; great heat resistance, very high hardness and low weight due to the low density. These positive properties of the ceramic composite brakes cause to a lot of advantages about the cars safety, performance and comfort. First of all because ceramic brake discs can hold extreme temperatures, they do not get overheated like the conventional brake discs. That provides a lot of benefits about the safety and the performance of the cars such as great brake capacity under frequently repeated use like driving down a mountain or driving at high speeds in a track, generous safety reserves even under high loads and better road-holding under braking. Another important feature of the ceramic composite brake discs is their very high hardness compared with the conventional brake discs. This property brings a lot of advantages about the performance and the safety of the cars, too like; they do not wear easily, they last longer and they provide greater brake capacity. Because of the extreme surface hardness a ceramic composite brake disc lasts almost as long as the lifetime of a car and they dampen the noise created at the wheels, which increases comfort. The third positive side of the ceramic composite brake discs is that they have a low weight due to the low density of the material. Because weight is very important for the performance, agility and handling of the cars, that property provides a lot of advantages. Especially the influence of weight is multiplied if a component is rotating. That means the weight save in unsprung mass (which includes all the rotating parts at the wheels) is very crucial for high performance. If weight can be saved in these areas, the benefits in terms of handling are immense; resulting in noticeably improved handling and agility, more immediate and precise response and better acceleration results. Besides these many advantages, there is one important disadvantage of the ceramic composite brakes, which is the price. When compared with the conventional brake discs they are very expensive, but there are a lot researches to decrease the price of 17 them by new formulations of composites. And if we take care about the development of this kind of brake discs in the last few years, it is likely that they will be commonly used in the future. 6.1. Patents US 7,175,796 B2 METHOD FOR PRODUCING CERAMIC BRAKE DISKS FROM BMC Gerd Ehnert, Vic Fezensac (France) Assigned to Menzolit-Fibron GmbH, Bretten (Germany) Appl. No. 10/381,518 PCT Filed Sep. 19, 2001, PCT No. PCT/EP01/10800 § 371(c)(1), (2), (4) Date Aug. 13, 2003, PCT Pub. No. WO02/27208, PCT Pub. Date Apr. 04, 2002. Claims priority of application No. 100 49 748 (DE), filed on Sep. 29, 2000; and application No. 101 39 288 (DE), filed on Aug. 09, 2001. Prior Publication US 2004/0035657 A1, Feb. 26, 2004 Int. Cl. B29C 45/14 (2006.01); F16D 69/00 (2006.01) U.S. Cl. 264—257 [264/325] 10 Claims 1. A process for producing ceramic brake disks from BMC, comprising the following process steps: a) producing a BMC compound with a matrix comprising phenolic resin and carbon reinforcing fibres the carbon reinforcing fibres having a length between 6 mm and 50 mm, b) producing a green compact of the ceramic brake disks from the BMC compound using a transfer-moulding process or an injection/compression process, c) pyrolysing the green compact for the purpose of producing a porous moulded article and d) melt infiltrating the porous moulded article with a melt for the purpose of producing a moulded article with reaction-bonded fibres. 18 7.1. References 1) Development and use of an apparatus for tribological evaluation of ceramic-based brake materials Wear, Volume 259, Issues 7-12, July-August 2005, Pages 1079-1087 M. Kermc, M. Kalin and J. Vižintin 2) Performance of ceramic enhanced phenolic matrix brake lining materials for automotive brake linings Wear, Volume 259, Issues 7-12, July-August 2005, Pages 1088-1096 K.W. Hee and P. Filip 3) Ceramic brake discs for high performance vehicles Metal Powder Report, Volume 56, Issues 7-8, July-August 2001, Page 24 4) Performance of ceramic enhanced phenolic matrix brake lining materials for automotive brake linings Wear, Volume 259, Issues 7-12, July-August 2005, Pages 1088-1096 K.W. Hee and P. Filip 5) Characteristics of wear particles produced during friction tests of conventional and unconventional disc brake materials Wear, Volume 255, Issues 7-12, August-September 2003, Pages 1261-1269 Peter J. Blau and Harry M. Meyer 6) Optimization of ceramic friction materials Composites Science and Technology, Volume 66, Issue 15, 1 December 2006, Pages 2895-2906 Ling Han, Li Huang, Jinsheng Zhang and Yafei Lu 7) Performance of ceramic enhanced phenolic matrix brake lining materials for automotive brake linings Wear, Volume 259, Issues 7-12, July-August 2005, Pages 1088-1096 K.W. Hee and P. Filip 8) Friction behavior of sintered metallic brake pads on a C/C–SiC composite brake disc Journal of the European Ceramic Society, Volume 27, Issues 2-3, 2007, Pages 1411-1417 Zmago Stadler, Kristoffer Krnel and Tomaz Kosmac 19