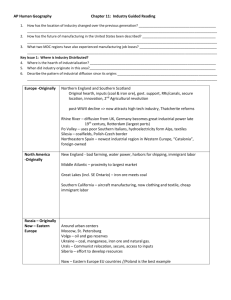

Export-infrastructure-report - Department of Industry, Innovation

advertisement