UBAVKA CECEZ - Sherwood Electromotion Inc.

advertisement

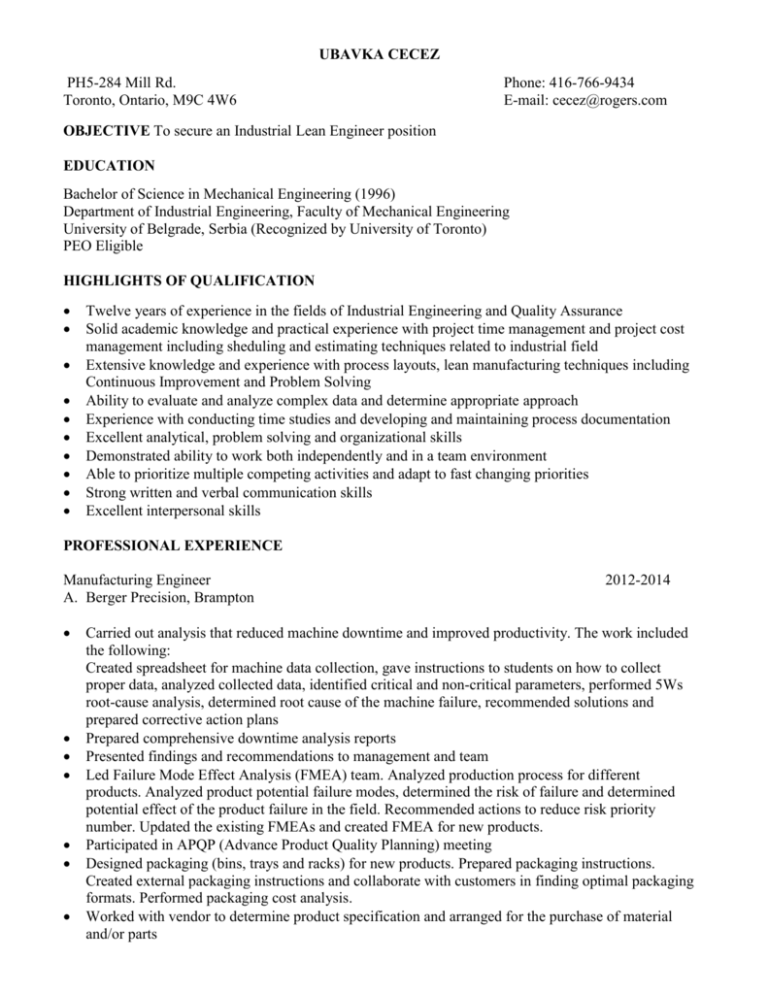

UBAVKA CECEZ PH5-284 Mill Rd. Toronto, Ontario, M9C 4W6 Phone: 416-766-9434 E-mail: cecez@rogers.com OBJECTIVE To secure an Industrial Lean Engineer position EDUCATION Bachelor of Science in Mechanical Engineering (1996) Department of Industrial Engineering, Faculty of Mechanical Engineering University of Belgrade, Serbia (Recognized by University of Toronto) PEO Eligible HIGHLIGHTS OF QUALIFICATION Twelve years of experience in the fields of Industrial Engineering and Quality Assurance Solid academic knowledge and practical experience with project time management and project cost management including sheduling and estimating techniques related to industrial field Extensive knowledge and experience with process layouts, lean manufacturing techniques including Continuous Improvement and Problem Solving Ability to evaluate and analyze complex data and determine appropriate approach Experience with conducting time studies and developing and maintaining process documentation Excellent analytical, problem solving and organizational skills Demonstrated ability to work both independently and in a team environment Able to prioritize multiple competing activities and adapt to fast changing priorities Strong written and verbal communication skills Excellent interpersonal skills PROFESSIONAL EXPERIENCE Manufacturing Engineer A. Berger Precision, Brampton 2012-2014 Carried out analysis that reduced machine downtime and improved productivity. The work included the following: Created spreadsheet for machine data collection, gave instructions to students on how to collect proper data, analyzed collected data, identified critical and non-critical parameters, performed 5Ws root-cause analysis, determined root cause of the machine failure, recommended solutions and prepared corrective action plans Prepared comprehensive downtime analysis reports Presented findings and recommendations to management and team Led Failure Mode Effect Analysis (FMEA) team. Analyzed production process for different products. Analyzed product potential failure modes, determined the risk of failure and determined potential effect of the product failure in the field. Recommended actions to reduce risk priority number. Updated the existing FMEAs and created FMEA for new products. Participated in APQP (Advance Product Quality Planning) meeting Designed packaging (bins, trays and racks) for new products. Prepared packaging instructions. Created external packaging instructions and collaborate with customers in finding optimal packaging formats. Performed packaging cost analysis. Worked with vendor to determine product specification and arranged for the purchase of material and/or parts UBAVKA CECEZ Created work instructions and process flow charts Facilitated and applied 5S (Sort, Set in Order, Shine, Standardize, Sustain) method to improve efficiency and operation Quality Auditor Johnson Control Inc., Whitby 2004 –2009 Performed inspection of materials to authorized part number specifications Initiated non-conforming material reports and followed procedural requirements for proper disposition Interacted with manufacturing team members to determine root cause of quality issues and ensured that corrective and preventive actions are implemented Involved in ongoing activities to maintain QS 9000/TS 16949 standards that included assisting with surveillance and re-certification audits Analyzed SPC data and assisted in improving manufacturing process capability Performed first offs, in process and final inspections Prepared reports and correspondence on completed inspections Prepared Control Plan as required Performed dimensional checks, capability study, Gauge R&R and PPAP Maintained and calibrated precision measuring instruments Quality Engineer eCMM Solution Canada Inc., Toronto (computer maker) 2011- 2011 Performed first offs, in process and final inspections Identified problems found in extrusion/expansion processes of heat shrinkable tubes and recorded them in QA database Collected non-conformance data and maintained and updated quality system documents, indexes and databases Quality Engineer GBM Rivet & Fasteners Inc., Toronto 2011-2012 Conducted internal quality auditing to ensure that processes and operating procedures are followed Carried out inspection on suspected, unapproved parts to determine a level of deviation from the specification Coordinated repair, rework and containment activities for indentified spills Performed first off color inspection on door panel and floor console using eye color gauge Reviewed daily production sheet to report supplier scrap Followed up with supplier to resolve issues As a member of the Production Improvement time, applied Kaizen method to improve production processes and reduced waste Quality Control Inspector DSG-CANUSA, Division of SHAWCOR, Toronto PAGE 2/4 2003 - 2004 Inspected product at different stage of production for visual defect, faulty electrical and mechanical connection Identified and mark acceptable and defective assemblies and returned faulty assemblies to production for repair UBAVKA CECEZ Provided corrective action report for all non-conforming products Inspected and tested the performance of computer systems components using SLAM software program Quality Assurance Engineer DSG-CANUSA, Division of SHAWCOR, Toronto 1999- 2000 Received tenders for automotive parts, wrote Request for Proposal, and evaluated supplier bids Prepared Purchase Orders Reviewed procurement documents to ensure compliance with applicable codes, standards and engineering requirements Provided a summary description and detailed evaluation of each vendor Interacted with government agencies to ensure compliance with commercial laws Industrial Engineer DMB, Belgrade, Yugoslavia (TIER 1 Supplier- Zastava, Fiat) 2002- 2003 Applied DSG-CANUSA policies, instructions and procedures regarding gage capability studies, material inspection, product testing and inspection and statistical process control (SPC) Performed capability study by applying statistical methods in order to obtain gage R&R results Participated in testing and evaluation of existing products and new developments Collected non-conformance data and maintained and updated quality system documents, indexes and databases Analyzed SPC data and assisted in improving manufacturing process capability Identified problems found in extrusion/expansion processes of heat shrinkable tubes and recorded them in QA database Procurement Officer DMB, Belgrade, Yugoslavia (TIER 1 Supplier- Zastava, Fiat) PAGE 3/4 1997- 1999 Successfully created procedures for obtaining ISO 9001 and ISO 9002 quality control certificate Developed and implemented appropriate documentation for inspection points in accordance with ISO quality standards Conducted internal quality audits to ensure that processes and operating procedures are followed Coordinated with other manufacturing engineering personnel in the development and implementation of new processes and technology in support of product innovations Analyzed manufacturing variances and made recommendations on improvements to plant process efficiencies Conducted plant surveys to analyzed production flow Improved production capacity by identifying production bottle necks and performing optimization analysis UBAVKA CECEZ PAGE 4/4 PROFESSIONAL DEVELOPMENT SEMINARS Introduction to Ontario’s Physical Markets (IESO Training) – Toronto, 2014 FMEA-Failure Mode Effect Analysis e-Learning (Web-Based Training), 2012 Interconnected Power Systems Operation – Toronto, 2011 Introduction to NERC Reliability Standards – Toronto, 2011 Introduction to Ontario Electricity Market Operation – Toronto, 2011 Introduction to Electricity – Toronto, 2010 Power System Components – Toronto, 2010 Process Improvement Using Six Sigma (ASQ Webinar) - Toronto, 2010 AutoCAD 2010, Humber College - Toronto, 2010 ASQ Certified Quality Engineer e-Learning (Web-Based Training), 2009 Introduction to Corrective / Preventative Action (ASQ Webinar) - Toronto, 2007 Measurement System Analysis – Toronto, 2005 Root Cause Problem Solving 8D - Toronto, 2003 AutoCAD 2000, ALC, Training & Development – Toronto, 2001 Internal Quality Audit Process - Belgrade, Serbia, 1998 Fundamentals of Quality Assurance - Belgrade, Serbia, 1997 ISO and International Standards - Belgrade, Serbia, 1997 REFERENCES Available upon request