CM Jeffery_Routine production of Cu

advertisement

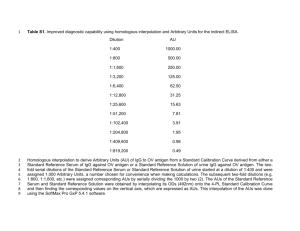

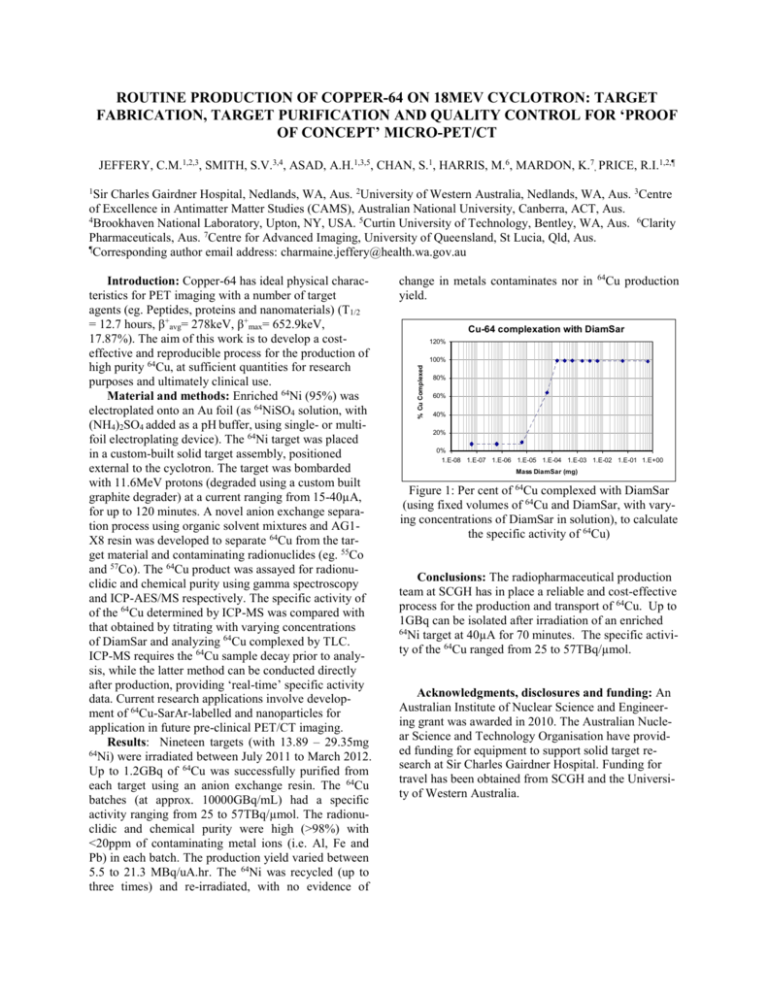

ROUTINE PRODUCTION OF COPPER-64 ON 18MEV CYCLOTRON: TARGET FABRICATION, TARGET PURIFICATION AND QUALITY CONTROL FOR ‘PROOF OF CONCEPT’ MICRO-PET/CT JEFFERY, C.M.1,2,3, SMITH, S.V.3,4, ASAD, A.H.1,3,5, CHAN, S.1, HARRIS, M.6, MARDON, K.7, PRICE, R.I.1,2,¶ 1 Sir Charles Gairdner Hospital, Nedlands, WA, Aus. 2University of Western Australia, Nedlands, WA, Aus. 3Centre of Excellence in Antimatter Matter Studies (CAMS), Australian National University, Canberra, ACT, Aus. 4 Brookhaven National Laboratory, Upton, NY, USA. 5Curtin University of Technology, Bentley, WA, Aus. 6Clarity Pharmaceuticals, Aus. 7Centre for Advanced Imaging, University of Queensland, St Lucia, Qld, Aus. ¶ Corresponding author email address: charmaine.jeffery@health.wa.gov.au change in metals contaminates nor in yield. 64 Cu production Cu-64 complexation with DiamSar 120% 100% % Cu Complexed Introduction: Copper-64 has ideal physical characteristics for PET imaging with a number of target agents (eg. Peptides, proteins and nanomaterials) (T1/2 = 12.7 hours, β+avg= 278keV, β+max= 652.9keV, 17.87%). The aim of this work is to develop a costeffective and reproducible process for the production of high purity 64Cu, at sufficient quantities for research purposes and ultimately clinical use. Material and methods: Enriched 64Ni (95%) was electroplated onto an Au foil (as 64NiSO4 solution, with (NH4)2SO4 added as a pH buffer, using single- or multifoil electroplating device). The 64Ni target was placed in a custom-built solid target assembly, positioned external to the cyclotron. The target was bombarded with 11.6MeV protons (degraded using a custom built graphite degrader) at a current ranging from 15-40µA, for up to 120 minutes. A novel anion exchange separation process using organic solvent mixtures and AG1X8 resin was developed to separate 64Cu from the target material and contaminating radionuclides (eg. 55Co and 57Co). The 64Cu product was assayed for radionuclidic and chemical purity using gamma spectroscopy and ICP-AES/MS respectively. The specific activity of of the 64Cu determined by ICP-MS was compared with that obtained by titrating with varying concentrations of DiamSar and analyzing 64Cu complexed by TLC. ICP-MS requires the 64Cu sample decay prior to analysis, while the latter method can be conducted directly after production, providing ‘real-time’ specific activity data. Current research applications involve development of 64Cu-SarAr-labelled and nanoparticles for application in future pre-clinical PET/CT imaging. Results: Nineteen targets (with 13.89 – 29.35mg 64 Ni) were irradiated between July 2011 to March 2012. Up to 1.2GBq of 64Cu was successfully purified from each target using an anion exchange resin. The 64Cu batches (at approx. 10000GBq/mL) had a specific activity ranging from 25 to 57TBq/µmol. The radionuclidic and chemical purity were high (>98%) with <20ppm of contaminating metal ions (i.e. Al, Fe and Pb) in each batch. The production yield varied between 5.5 to 21.3 MBq/uA.hr. The 64Ni was recycled (up to three times) and re-irradiated, with no evidence of 80% 60% 40% 20% 0% 1.E-08 1.E-07 1.E-06 1.E-05 1.E-04 1.E-03 1.E-02 1.E-01 1.E+00 Mass DiamSar (mg) 64 Figure 1: Per cent of Cu complexed with DiamSar (using fixed volumes of 64Cu and DiamSar, with varying concentrations of DiamSar in solution), to calculate the specific activity of 64Cu) Conclusions: The radiopharmaceutical production team at SCGH has in place a reliable and cost-effective process for the production and transport of 64Cu. Up to 1GBq can be isolated after irradiation of an enriched 64 Ni target at 40µA for 70 minutes. The specific activity of the 64Cu ranged from 25 to 57TBq/µmol. Acknowledgments, disclosures and funding: An Australian Institute of Nuclear Science and Engineering grant was awarded in 2010. The Australian Nuclear Science and Technology Organisation have provided funding for equipment to support solid target research at Sir Charles Gairdner Hospital. Funding for travel has been obtained from SCGH and the University of Western Australia.