SAMPLE Confined Space Entry Program

advertisement

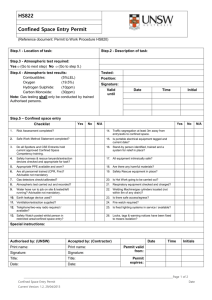

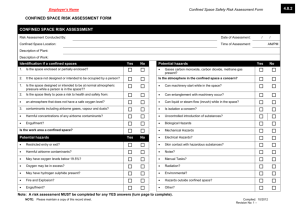

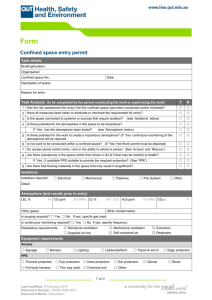

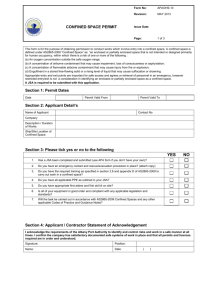

SAMPLE Winery Confined Space Entry Program TABLE OF CONTENTS Page No. 1.0 PURPOSE ...................................................................................................................... 1 2.0 SCOPE ........................................................................................................................... 1 3.0 DEFINITIONS ................................................................................................................. 1 4.0 GENERAL REQUIREMENTS ........................................................................................ 3 5.0 RESPONSIBILITIES ...................................................................................................... 4 6.0 TRAINING REQUIREMENTS......................................................................................... 7 7.0 ENTRY PERMITS .......................................................................................................... 8 8.0 ALTERNATE ENTRY PROCEDURES ........................................................................... 9 9.0 NON-PERMIT SPACES ............................................................................................... 10 10.0 CONFINED SPACE PERSONNEL ........................................................................... 10 11.0 AIR TESTING REQUIREMENTS .............................................................................. 11 12.0 EMERGENCY RESPONSE ....................................................................................... 12 13.0 CONTRACTORS PERFORMING CONFINED SPACE ENTRY ................................ 12 14.0 PROCEDURE REVIEW............................................................................................. 13 15.0 RECORDKEEPING ................................................................................................... 13 16.0 REFERENCES .......................................................................................................... 13 1.0 PURPOSE The purpose of this procedure is to outline the controls and responsibilities for entering, working in, and exiting a confined space to provide for the protection of winery personnel, Contractors and equipment. 2.0 SCOPE This procedure contains the minimum accepted practices for working inside of a confined space at any winery facility. All personnel involved in confined space entry activities will adhere to the requirements and procedures contained in this document. Confined space entry will only be performed when there is no other alternative less hazardous way to carry out the task. As wineries evaluate their confined spaces and procedures, measures should be put into place to reduce the likelihood of personnel being required to enter confined spaces to perform work. 3.0 DEFINITIONS Attendant - An individual who is stationed outside one or more permit spaces who monitors the authorized entrants and who performs all attendants’ duties assigned in this program. Authorized Entrant - An individual who is authorized by an employer to enter a permit space. Confined Space - An area that meets all of the following criteria: A. Is large enough and so configured that an individual can bodily enter and perform assigned work. B. Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, vaults, pits). C. Is not designed for continuous personnel occupancy. Emergency - Any occurrence (including any failure of hazard control or monitoring equipment) or event, internal or external to the permit space that could endanger entrants. Enclosed Space - A working space such as an open vault, building crawl space, or tunnel that: A. Has a limited means of egress or entry. B. Is designed for periodic employee entry under normal operating conditions. C. Under normal conditions does not contain a hazardous atmosphere, but that may contain a hazardous atmosphere under abnormal conditions. Engulfment - The surrounding and effective capture of a person by a liquid or a finely divided (flowable) solid substance that can be aspirated to cause death by filling or plugging the respiratory system or that can exert enough force on the body to cause death by strangulation, constriction, or crushing. Entry - The action by which a person passes through an opening into a permitrequired confined space. Entry includes ensuing work activities in that space and is considered to have occurred as soon as any part of the entrant's body breaks the vertical or horizontal plane of an opening into the space. Entry Permit - A written or printed document that is provided by the employer to allow and control entry into a permit space. Entry Supervisor - A person responsible for determining if acceptable entry conditions are present in a permit space where entry is planned, and creating and signing the entry permit. Authorizing entry and overseeing entry operations, and for terminating entry as required. Entry team – Refers to the entire team assigned to a confined space, (entry supervisor, attendant, entrants, and the monitor.) Hazardous Atmosphere - An atmosphere that may expose individuals to the risk of death, incapacitation, impairment of ability to self-rescue from a permit space, injury or acute illness as the result of oxygen deficiency, toxic and/or flammable gases and vapors or any other atmospheric condition that is immediately dangerous to life or health. Hot Work Permit - A written authorization to perform hot work, received from an authorized supervisor or other site personnel authorized to write and issue hot work permits. Isolation - The process of blanking or blinding, removing a section of line, duct or pipe, a double block and bleed, lock-out / tag-out of all sources of energy as may be required to protect a permit space against the release of energy and material into the space. Lockout / Tagout - An established procedure for the placement of locking and tagging devices on energy isolating devices, ensuring that the energy isolating device and the equipment being controlled cannot be operated or started while work is being conducted. Non-Permit Confined Space - A confined space that does not contain, or with respect to atmospheric hazards, does not have the potential to contain any hazard(s) capable of causing death or physical harm. Oxygen Deficient Atmosphere - An atmosphere containing less than 19.5 percent or lower oxygen content by volume. Oxygen Enriched Atmosphere - An atmosphere that contains 23.5 percent or higher oxygen by volume. Permit - Required Confined Space - An area that meets the definition of a confined space and has one or more of the following characteristics: A. Contains or has a potential to contain a hazardous atmosphere. B. Contains a material that has a potential of engulfing an entrant (i.e. water or sand). C. Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor that slopes downward and tapers to a smaller cross-section. D. Contains any other recognized serious safety or health hazards (i.e. wind, insecure footing, electrical). Retrieval System – the equipment (including a retrieval line, chest or full-body harness, rescue hook, wristlets, if appropriate, and a lifting device or anchor) used for non-entry rescue of persons from permit spaces. Testing/Monitoring - The process of identifying and evaluating the hazards that may be present inside of a confined space. When testing for atmospheric hazards, first test for oxygen, then for combustible gasses and vapors, and then for toxic gasses or vapors. Tester/Monitor - The person assigned the task and specifically trained on how to perform specific testing in and around the permit spaces. 4.0 GENERAL REQUIREMENTS Confined spaces at wineries typically include the following: tanks/fermenters, rotary fermenters, bladder presses, and other enclosed spaces such as process water vaults, utility vaults, crush pits, sanitary sewer vaults, and other areas that are enclosed and were not designed for occupancy. The following general requirements are required to be implemented when working in or around confined spaces: When practical, all confined spaces shall be permanently marked. A sign shall be installed at each opening of the Confined Space. Signs should contain the following text or similar language: DANGER – PERMIT REQUIRED CONFINED SPACE DO NOT ENTER Spaces not permanently marked (ex. Manholes) shall be posted with a portable sign when access to the space is required. All confined spaces where there is an opening that can easily be walked into (floor openings, manhole openings, etc.) shall have a physical barrier (guardrail, cover, gate, etc.) When required, isolating energy sources to the confined space shall be performed in accordance with the winery Lock-out/Tag-out Program. If “hot work” conditions exist, precautions shall be taken in accordance with the winery Hot Work Program. Cylinders of compressed gases are never permitted in a confined space. No smoking is permitted in a Confined Space or near the entrance/exit area. Air monitoring is required before and during entry into any confined space. Portable electrical equipment used in Confined Spaces shall be supplied power through a ground fault interrupter or be battery powered. Under the OSHA regulations, each site is also required to implement the following: 1. Make a list of all confined spaces at the site. 2. Determine if each space is a permit-required space and document this on an inventory form. 3. Complete the appropriate Required Confined Space Permit or Certificate to document the space hazards and control measures. For Non-Permit spaces, which have historically shown that no atmospheric hazards are present (through historically documented air monitoring readings), do not have to complete a NonPermit Entry Certificate if documentation is in place that shows that there has never been a problem inside of the space (i.e., crush pits equipped with stairs). 4. Have a written rescue plan. 5. Keep an up to date list of all trained CSE Supervisors, Entrants and Attendants. 5.0 RESPONSIBILITIES Risk Manager Facilitate the implementation of the Confined Space Entry Program at all winery locations Approve the Confined Space Entry Program and all revisions General Manager/ Department Manager Ensure that a list of confined spaces at the site is maintained. Coordinate with outside responders as part of pre-emergency planning. Ensure site personnel are trained on the requirements of this procedure, the hazards associated with confined space entry, and the safety requirements to be implemented whenever working in or around confined spaces. Act as the Confined Space Program Administrator for their department or site and designate authorized confined space entry supervisors who will manage dayto-day confined space operations and complete confined space entry permits. Ensure all confined space entry equipment is maintained and inspected according to the manufactures recommendations. Ensure that the provisions of this procedure are implemented during all confined space operations and activities involving confined spaces Consult employees to assess their views the procedure effectiveness and to identify any problems with the procedure. Keep copies of completed confined space permits for at least 2 years Work with the winery Risk Manager to modify this procedure, as needed Confined Space Entry Supervisor Ensure requirements for entry have been completed before entry is authorized. Ensure confined space monitoring is performed and logged every 15 minutes by personnel qualified and trained in confined space entry procedures and air monitoring procedures. Ensure a list of monitoring equipment and personnel qualified to operate the equipment is maintained. Ensure that the rescue team has simulated a rescue in a confined space within the past twelve (12) months. Know the hazards that may be faced during entry, including the mode (how the contaminant gets into the body), signs or symptoms, and consequences of exposure. Fill out the appropriate permit/certificate and sign the permit when all acceptable conditions have been met. Determine the entry requirements. Notify all involved employees of the permit requirements. Post the permit in a conspicuous location near the job. Renew the permit or have it reissued as needed (a new permit is required every shift). Post any required barriers and signs. Remain alert to changing conditions that might affect the conditions of the permits (i.e., require additional atmospheric monitoring or changes in personal protective equipment). Ensure periodic atmospheric monitoring is done according to permit requirements. Ensure that personnel doing the work and all support personnel adhere to permit requirements. Ensure the permit is canceled when the work is done. Ensure the confined space is safely closed and all workers are cleared from the area. Confined Space Attendant Maintain effective and continuous communication with personnel during confined space entry, work, and exit. Order personnel to evacuate the confined space if he/she: o o o o o o observes a condition which is not allowed on the entry permit; notices the entrants acting strangely, possibly as a result of exposure to hazardous substances; notices a situation outside the confined space which could endanger personnel; notices a hazard within the confined space that has not been previously recognized or taken into consideration; must leave his/her work station; or must focus attention on the rescue of personnel in some other confined space that he/she is monitoring. Immediately summon the Rescue Team if crew rescue becomes necessary. Keep unauthorized persons out of the confined space, order them out, or notify authorized personnel of an unauthorized entry. Employee Attending confined space refresher training at least annually. Taking care of their PPE Reporting unusual conditions associated with confined space equipment or confined space operations to their supervisor or confined space entry supervisor immediately (i.e., before entering a confined space). Following instructions from the Confined Space Entry Supervisor and the Confined Space Attendant Following all health and safety measures developed by the winery around confined spaces and other safety hazards. Read and observe the entry permit requirements. Remain alert to the hazards that could be encountered while in the confined space. Properly use the personal protective equipment that is required by the permit. Immediately exit the confined space when: o o o o they are ordered to do so by an authorized person; they notice or recognize signs or symptoms of exposure; a prohibited condition exists; or the automatic alarm system sounds. Alert Attendant(s) when a prohibited condition exists and/or when warning signs or symptoms of exposure exist. Rescue Team The Rescue Team members shall: 6.0 Complete a training drill and simulate a rescue least annually. Respond immediately to rescue calls from the Attendant or any other person recognizing a need for rescue from the confined space. In addition to emergency response training, receive the same training as that required of the authorized entrants. Have current certification in first aid and CPR. TRAINING REQUIREMENTS All personnel working in and around confined spaces must receive training. Training will consist of the following: Training Frequency – training shall be conducted before the employee is first assigned duties within a confined space; before there is a change in assigned duties; when there is a change in permit space operations that presents a hazard for which an employee has not been trained; and when the winery has reason to believe that there are deviations from the confined space entry procedures required in this program, or that there are inadequacies in the employee’s knowledge or use of these procedures. General Training - All employees who will enter confined spaces shall be trained in entry procedures. Personnel responsible for supervising, planning, entering, or participating in confined space entry and rescue shall be adequately trained in their functional duties prior to any confined space entry. Training shall include: 1. Explanation of the general hazards associated with confined spaces. 2. Discussion of specific confined space hazards associated with the facility, location, or operation. 3. Reason for, proper use, and limitations of personal protective equipment and other safety equipment required for entry into confined spaces. 4. Explanation of permits and other procedural requirements for conducting a confined space entry. 5. A clear understanding of what conditions would prohibit entry. 6. Procedures for responding to emergencies. 7. Duties and responsibilities of the confined space entry team. 8. Description of how to recognize symptoms of overexposure to probable air contaminants in themselves and co-workers, and method(s) for alerting the Attendant(s). Refresher training shall be conducted as needed to maintain employee competence in entry procedures and precautions. Specific Training - Training for atmospheric monitoring personnel shall include proper use of monitoring instruments, including instruction on the following: Training for Attendants shall include the following: procedures for summoning rescue or other emergency services; and proper utilization of equipment used for communicating with entry and emergency/rescue personnel. Training for Emergency Response Personnel shall include: 7.0 proper use of the equipment; calibration of equipment; sampling strategies and techniques; and OSHA exposure limits for anticipated contaminants (i.e., CO2, CO, O2, H2S, SO2, flammable atmospheres) rescue plan and procedures developed for each type of confined space that is anticipated to be encountered; use of emergency rescue equipment; first aid and CPR techniques; and work location and confined space configuration to minimize response time. ENTRY PERMITS A confined space permit or certificate will be completed for each confined space entered at any of the winery facilities following the requirements of this procedure. Permit-Required Confined Space Entry Requirements The following procedures must be implemented for all permit-required confined spaces: Identify and evaluate the hazards of permit spaces before employees enter them; Specify acceptable entry conditions (use the Confined Space Entry Permit located in “FORMS”); Perform air monitoring of the space prior to entry and continuously during entry; Isolate the permit space using lock-out/tag-out methods (i.e., lock and tag out compressed gas system on presses, lock out pumps and electrical connections in sumps, etc.); Purge, inert, flush, or ventilate the permit space as necessary to eliminate or control atmospheric hazards; 8.0 Provide barriers as necessary to protect entrants from external hazards; Verify that conditions in the permit space are acceptable for entry throughout the duration of an authorized entry; Designate the communication methods that will be used between the entrant and the attendant; Designate rescue requirements and place equipment needed next to the permit-required confined space in the event that an emergency rescue is needed; Provide at least one attendant outside the permit space for the duration of entry operations; Designate employees who have active roles in the entry process – Entry Supervisor, Entrant, Attendant, Rescue, etc.; The winery Confined Space Entry Permit shall be completed and signed by the Entry Supervisor; and Permits shall be cancelled at the end of each shift, or when new hazards arise. A CSE Permit is only valid for one work shift (i.e., 8 hours). ALTERNATE ENTRY PROCEDURES Alternate entry procedures may be used if the only hazard present in the confined space (as determined by the Entry Supervisor) is: 1) atmospheric in nature, and 2) the atmospheric hazard can be controlled by mechanical ventilation alone, and if 3) the Permit Space atmosphere will not become immediately dangerous to life and health (IDLH) if the mechanical ventilation fails. After evaluating the “Permit Required Confined Space” and establishing appropriate atmospheric controls, the Entry Supervisor may reclassify the Permit Space as an Alternate Entry Space by completing the Confined Space Alternate Procedure Certificate located in “FORMS”. Under Alternate Procedures, the Entrant may enter the confined space without the assistance or use of an attendant, following the procedure below. Establish and ensure that the mechanical ventilation system is operations and providing clean, fresh air to the entrants work location within the space during the entire entry; Test the atmosphere of the space prior to entry into the space Use and continually operate a personal gas detector during the entire confined space operation Immediately evacuate the space if ventilation fails, or if the portable air sampling equipment fails to enters alarm mode, and Immediately evacuate the space if you discover, or become aware of a previously unrecognized hazard. If this occurs, immediately notify the Entry Supervisor. The Entry Supervisor will re-evaluate the space and implement appropriate safety precautions prior to resuming the confined space operation. Note: Entry supervisor may act as Entrant during Alternate Entry Confined Space operations. No Attendant is necessary for Alternate Procedure entries, unless assistance is needed to accomplish safe entry and exit by the Entrants (i.e., tripod to enter a tank, etc.) All steps taken to reclassify the Permit Space to an Alternate Entry Space must be written on the entry permit. All confined spaces shall be considered Permit-Required until the pre-entry procedures demonstrate otherwise. 9.0 NON-PERMIT SPACES If the confined space poses no actual or potential atmospheric hazards and if all hazards within the space are eliminated without entry into the space, the permit space may be reclassified as a non-permit confined space for as long as the nonatmospheric hazards remain eliminated. Examples of this type of space would be a crush pit or other open top sump that does not contain hazardous atmospheres and does not have the potential to contain hazardous atmospheres or other safety hazards. A crush pit would not meet the definition of a non-permit space if SO2, fermenting grapes, carbon monoxide from operating vehicles (grape trucks, vehicles, etc.), or other materials that could cause a hazardous atmosphere, even in small quantities, were present. If it is necessary to enter the permit space to eliminate hazards, such entry will be performed as a permit-required confined space entry. If hazards arise while employees are working in a non-permit space, each employee shall exit the space immediately. The site shall then reevaluate the space and determine whether it must be reclassified as a permit space. A Non-Permit Certificate, located in “FORMS”, must be completed for all non-permit spaces prior to entry. 10.0 CONFINED SPACE PERSONNEL The following individuals are required when entry into a Permit Required Confined Space is necessary. Employees shall receive the appropriate level of training before entry into the Confined Space is permitted. Note: An attendant can also act as an entry supervisor if properly trained. Entry Supervisor Attendant Entrant The following individuals are required when entering an Alternate Procedure Confined Space, but only after an Alternate Procedure Confined Space Certificate has been completed to document that the space is safe to reclassify: Entry Supervisor (to complete Alternative Procedure Certificate) Attendant (only needed if access to space requires the use of a tripod and/or hoist) Entrant The following individuals are required when entering a Non-Permit Confined Space. 11.0 Entry Supervisor (to complete Non-Permit Certificate) Entrant AIR TESTING REQUIREMENTS The atmosphere within the space will be tested prior to entry to determine whether dangerous air contamination and/or oxygen deficient atmospheres exist inside of the space. Continuous air monitoring shall also be conducted while personnel are working inside of a confined space, and readings documented every 15 minutes. The following is the minimum level of air testing that will be required inside of common confined spaces: Tanks and fermenters – during and after fermentation (i.e., during pumice shoveling) Carbon Dioxide (CO2) Alcohol (flammability/LEL) Oxygen (O2) Sulfur Dioxide (SO2) Carbon Monoxide (CO) – if space could accumulate engine exhaust Tanks, fermenters and crush pits – when clean and empty of grapes Oxygen (O2) Other contaminants that may have been or may be introduced into the space due to entry or adjacent activities such as Flammable materials (LEL), Carbon Monoxide from engines (CO), or other potential contaminants. Manholes, vaults, etc. associated with waste or sanitary sewers Flammability/LEL Oxygen (O2) Hydrogen Sulfide (H2S) Carbon Monoxide (CO) – from nearby engines and equipment Other contaminants that might be present Equipment Vaults (non-processing) Flammability/LEL Oxygen (O2) Hydrogen Sulfide (H2S) Carbon Monoxide (CO) – from nearby engines and equipment Other contaminants that might be present 12.0 EMERGENCY RESPONSE Emergency Response Plan The Department Manager/Entry Supervisor shall maintain a written plan of action that has provisions for conducting a timely rescue of individuals within a confined space, should an emergency arise. The written plan shall be kept onsite where the confined space work is being conducted. All affected personnel shall be trained on the Emergency Response Plan. Retrieval Systems and Methods of Non-Entry Rescue Retrieval systems shall be available and ready when an authorized person enters a permit space, unless such equipment increases the overall risk of entry, or the equipment would not contribute to the rescue of the entrant. Retrieval systems shall have a chest or full-body harness and a retrieval hook that allows the rescue team to remotely grab the harness and pull the entrant to the tank opening for removal. A mechanical device shall be available to retrieve personnel from vertical confined spaces more than five (5) feet deep. For wine tanks and fermenters with side access doors, a full body harness is required to be worn at all times while inside of tanks. A retrieval system shall either include the use of a lifeline, a rescue hook, or a paddle – whichever equipment makes the most sense for rescuing employees from these locations. 13.0 CONTRACTORS PERFORMING CONFINED SPACE ENTRY When the winery arranges to have employees of another employer (i.e., contractor) perform work that involves confined space entry, the winery will: Inform the contractor that the workplace contains permit spaces and that the permit space entry is allowed only through compliance with this program or the OSHA regulations; Apprise the contractor of the elements, including the hazards identified and the winery’s experience with the space that make the space in question a permit space; 14.0 Apprise the contractor of any precautions or procedures that the winery has implemented for the protection of employees in or near permit spaces where contractor personnel will be working; Coordinate entry operations with the contractor, when both the winery and contractor personnel will be working in or near permit spaces; Verify that the appropriate air monitoring and air monitoring equipment is being used and performed by the contractor. Verify that the appropriate rescue procedures are in place; and Debrief the contractor at the conclusion of the entry operations regarding the permit space program followed and regarding any hazards confronted or created in the permit spaces during entry operations. PROCEDURE REVIEW This procedure will be reviewed annually by the Risk Manager and Department Managers and revised as necessary. 15.0 RECORDKEEPING Copies of all Confined Space Entry Permits shall be maintained for at least 2 years. Training documentation shall be maintained for at least 5 years after the employees last training date. 16.0 REFERENCES Federal OSHA Regulations.