Supplementary Materials-10

advertisement

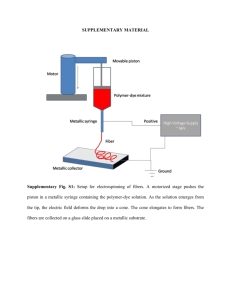

SUPPLEMENTARY MATERIALS Shear Avalanches in Metallic Glasses under Nanoindentation: Deformation Units and Rate Dependent Strain Burst Cut-off X.L. Bian1, G. Wang1,*, K.C. Chan2, J.L. Ren3, Y.L. Gao1, Q.J. Zhai1 1 Laboratory for Microstructures, Shanghai University, Shanghai 200444, China 2 Department of Industrial and System Engineering, the Hongkong Polytechnic University, Kowloon, Hongkong 3 School of Mathematics and Statistics, Zhengzhou University, Zhengzhou 450001, China *Corresponding author: g.wang@shu.edu.cn Contents I. Experimental procedures………………………………………………………….2 II. Fig. S1 Load-displacement (P-h) of three metallic glasses………..……………3 III. Fig. S2 Determination of the instrument noise……………………...………....4 IV. Fig. S3 Strain burst size distributions as a function of indentation depth at four loading rates…………………………………………………………………….5 1 I. Experimental procedures Ingots of the Co-based, Fe-based, Zr-based and Ce-based metallic glasses were prepared by arc melting a mixture of pure metal elements, followed by suction casting in a Cu-mould to form rod-like metallic glasses. For the Mg65Cu25Gd10 metallic glass, a Cu-Gd mixture was firstly pre-alloyed by arc melting the mixture of pure metal elements in an argon atmosphere, and then the mixture of pure Mg element and Cu-Gd pre-alloy was induction melted, and injected into the copper mould to form the rod-like samples. Structural analyses were ascertained using X-ray diffraction (XRD). Prior to indentation experiments, each metallic glass sample was mechanically polished to a mirror finish. Instrumented nanoindentation experiments were performed using a MTS Nano Indenter XP (Oak Ridge, TN) with a Berkovich diamond tip. Fused silica was used as a standard sample for the initial calibration. Before indentation, the tip was brought into contact with the specimens’ surface at a depth of 2 µm to obtain the maximum loads, and then indentations were conducted under a load-control mode to the maximum loads at different loading rates of 0.2, 0.6, 1, 2 to 3 mN/s. The peak load was held constant for 5 s to eliminate instrument noise. Before fully unloading, a load holding segment was undertaken at about 10% of the peak load for 77 s (as indicated by the red arrows in Fig. 1 and Fig. S1), serving as a thermal drift calibration. Testing at each loading rate was repeated 10 times to generate enough statistical information, and at the same time to exclude the occasional case. 2 0.2 mN/s 2 mN/s (a) 1 mN/s (b) 360 350 340 330 320 310 300 1100 1150 1200 1250 1300 400 300 200 400 Load (mN) 500 Load (mN) 0.6 mN/s 3 mN/s 300 200 100 100 0 (c) 0.2 mN/s 0.6 mN/s 1 mN/s 2 mN/s 3 mN/s 300 600 900 1200 Displacement (nm) 0 1500 500 1000 1500 2000 Displacement (nm) 250 Load (mN) 200 0.2 mN/s 0.6 mN/s 1 mN/s 2 mN/s 3 mN/s 150 100 50 0 500 1000 1500 2000 Displacement (nm) 2500 Fig. S1 Load-displacement (P-h) curves during nanoindentation at various loading rates for three metallic glasses. The start points of the curves are offset for clearly viewing. (a) Fe41Co7Cr15Mo14C15B6Y2, (c) Zr41.25Ti13.75Ni10Cu12.5Be22.5, and (c) Ce68Al10Cu20Co2. 3 2500 (a) Displacement (nm) 1997.1 1996.4 1995.7 1995.0 1994.3 Experimental data Fitting line 1993.6 (b) 231 232 233 234 235 236 237 238 239 T (s) hraw-hfit (nm) 1.0 0.5 0.0 -0.5 h = 2 nm -1.0 231 232 233 234 235 236 237 238 239 T (s) Fig. S2 Determination of instrument noise. (a) Fitting curve of displacement plotted against time for the holding segment on Mg65Cu25Gd10 at a loading rate of 1 mN/s. The scattered points are experimentally measured from the holding segment. The red solid line is fitted by a linear function. (b) The difference between the raw displacement data and the fitted curve versus time. The maximum h value (marked by the red arrows) is equal to 2 nm, indicative of the background noise is 2 nm. 4 (b) 0.10 (a) 0.24 h/h 0.16 0.2 mN/s 0.12 0.08 Co-based Fe-based Zr-based Mg-based Ce-based h/h 0.20 0.06 1 mN/s 0.04 0.08 0.04 0.02 0.00 0.00 0 800 1200 1600 2000 h (nm) 0.08 400 800 1200 1600 2000 h (nm) (d) 0.06 2 mN/s h/h 0 0.04 0.08 Co-based Fe-based Zr-based Mg-based Ce-based 0.06 h/h (c) 400 Co-based Fe-based Zr-based Mg-based Ce-based 0.04 0.02 0.02 0.00 0.00 0 400 800 1200 h (nm) 1600 2000 3 mN/s 0 400 800 1200 h (nm) Co-based Fe-based Zr-based Mg-based Ce-based 1600 2000 Fig. S3 Strain burst size distributions as a function of indentation depth for the five metallic glasses at different loading rates. One can see that the strain burst sizes at all loading rates exhibit random fluctuations, although the size distributions of the five metallic glasses seem to have a declining trend as the indentation depth increases. Additionally, the maximum strain burst size increases with loading rate decrease. 5