Jerry R. Boyle[1] - Clarkson University

advertisement

![Jerry R. Boyle[1] - Clarkson University](http://s3.studylib.net/store/data/007321419_1-b664abce006eeced0a7fba0a52eaf95e-768x994.png)

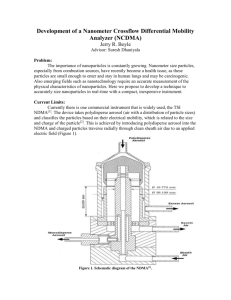

Development of a Nanometer Crossflow Differential Mobility Analyzer (NCDMA) Jerry R. Boyle1 and Suresh Dhaniyala2 Mechanical Engineering The importance of nanoparticles is constantly growing. Nanometer size particles, especially from combustion sources, have recently become a health issue, as these particles are small enough to enter and stay in human lungs and may be carcinogenic. Also emerging fields such as nanotechnology require an accurate measurement of the physical characteristics of nanoparticles. Here we propose to develop a technique to accurately size nanoparticles in real-time with a compact, inexpensive instrument. Currently there is one commercial instrument that is widely used, the TSI NDMA[1]. The device takes polydisperse aerosol (air with a distribution of particle sizes) and classifies the particles based on their electrical mobility, which is related to the size and charge of the particle[2]. This is achieved by introducing polydisperse aerosol into the NDMA and charged particles traverse radially through clean sheath air due to an applied electric field. The electric field strength can then be varied to change the size of monodisperse aerosol (air with particles of one size) exiting the NDMA. The NDMA is accurate but also expensive and the technique used results in a low concentration of particles in the monodisperse aerosol due to a large sheath air to aerosol flow ratio and the difficulty of charging nanometer particles (only a small fraction of the particles are able to be charged). The effects of this low concentration can be seen in experiments which involve conditioning the particles and analyzing its effects, such as in the case of thermodesorption[3]. Particles of a known size are heated to expel the outer volatile surface then passed through a cooled tube to deposit the volatile material. However, as the particle size decreases, more particles are lost due to increased thermophoretic deposition thus complicating any analysis of these particles. Therefore, there is a need for a new technique that can output a high concentration of monodisperse aerosol and at high size resolution. One option to improve performance is to increase the aerosol flow rate, however, this will often lower the sizing resolution[4]. This project employs a modified electrical classification technique to generate monodisperse aerosol at high concentrations. 1 2 Class of 2005, Mechanical Engineering, Clarkson University, Honors Program Mentor, Assistant Professor, Clarkson University 73 The schematic diagram of the proposed NCDMA is shown in Figure 1. Rather than a coaxial aerosol-sheath flow system, a new flow system is proposed. This new technique will introduce sheath air into the aerosol flow through the inner porous tube as the flow passes through an electric field. This results in a radial drag force that opposes the electrical force. The balance of forces results in the focusing of particles of one size. With this technique, a higher aerosol to sheath air flow ratio can be used, thus a higher concentration of monodisperse particles can be obtained. Figure 1. Basic Schematic of new proposed flow system. The instrument designed has required flow and particle trajectory modeling. A 2-D model was constructed where the flow field is calculated using potential flow theory and particle trajectories are calculated assuming stokes drag and electric force. A MatLAB script was written to calculate particle trajectories and range of focused particles. Having produced desirable results (good particle separation at low sheath to aerosol flow ratios) CFD modeling using the software FLUENT was used to verify the validity of potential flow modeling. The results from CFD simulations are in agreement with the results of MatLAB as shown in Figure 2. A more accurate axi-symmetric model has been constructed in Fluent and the results show desirable particle separation. A prototype has been designed and will be built for testing and comparison with other particle sizing instrumentation. 74 Figure2. Comparison of MatLAB and FLUENT results. Results show similar trends and focusing ranges. References: 1. D. -R. Chen, D. Y. H. Pui, D. Hummes, H. Fissan, F. R. Quant and G. J. Sem. “Design and evaluation of a nanometer aerosol differential mobility analyzer (Nano-DMA).” J. Aerosol Sci. Vol. 29 (1998): 497-509. 2. Hinds W. C., Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles., Wiley, New York, 1999. 3. S. Philippin, A. Wiedensohler and F. Stratmann. “Measurements of non-volatile fractions of pollution aerosols with an eight-tube volatility tandem differential mobility analyzer (VTDMA8).” J. Aerosol Sci. Vol. 35 (2004): 185-203. 4. D. R. Collins, A. Nenes, R. C. Flagan and J. H. Seinfeld. “The Scanning Flow DMA.” J. Aerosol Sci. Vol. 31 (2000): 1129-1144. 75