THERMODYNAMICS LAB 4 – Thermal Conductivity

advertisement

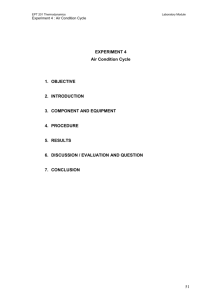

LAB 5 Refrigeration Cycle 1.0 OBJECTIVE 1. To study the cycle of refrigeration system. 2. To measure related temperatures and pressure of refrigeration system. 3. To plot P-H diagram for the refrigeration system and to determine coefficient of performance (COP) of refrigeration system. 2.0 INTRODUCTION AND THEORY 2.1 GENERAL Heat energy always flows naturally from a higher to a lower temperature level. That is, hot areas naturally cool off and cold areas naturally warm up. Therefore, moving heat from a lower to a higher temperature requires the input of work (or heat), usually to create a pressure differential in the cycle refrigerant. The refrigerant (acting as a heat transfer fluid) is used to transfer heat energy from a lower temperature to a higher temperature. The refrigerant is evaporated at a temperature lower than the desired temperature in the freezer or cooler. The condensing temperature of the refrigerant is increased by compression so that it can either be rejected to the environment or recovered as useful heat. The basic refrigeration cycle, with all steps combined, is shown in figure 1. The main components of refrigeration are: i. ii. iii. iv. v. Compressor Condenser Filter and Dryer Expansion valve or capillary tube Evaporator 2.2 Refrigeration cycle A standard refrigeration cycle works as follows: 1 - 2 adiabatic compression of gaseous (i.e. saturated or superheated vapor) refrigerant fluid from p1, T1 to p2, T2. 2 – 3 isobaric cooling and condensation of the refrigerant fluid. State 3 is saturated liquid or compressed liquid at p3 = p2. The heat is rejected to the environment. Page 1 of 14 3 – 4 adiabatic throttling to p4 = p1. The throttling process is isenthalpic, h3 = h4. 4 – 1 isobaric evaporation (and possibly superheating) of the refrigerant fluid, back to state 1. The refrigeration cycle can be divided into four phases with all phases is combined in closes system. These four steps are: Step 1, Evaporation: Liquid refrigerant at a sufficiently low pressure is brought into contact with the heat source (the medium to be cooled). The refrigerant absorbs heat and boils, producing a low-pressure vapor. The heat exchanger used for this process is called the evaporator. Step 2, Compression: The compressor raises the pressure of the refrigerant vapor, normally using an electric motor drive. This increases the temperature at which the vapors will condense to a temperature above the temperature of the heat sink. Most common compressors are reciprocating (piston and cylinder) or screw (looking much like an old meat grinder) compressor designs. Step 3, Condensing: The high-pressure refrigerant gas now carrying the heat energy absorbed at the evaporator plus the work energy from the compressor enters the condenser. Since the refrigerant's condensing temperature is higher than that of the heat sink, heat transfer will take place, condensing the refrigerant from a high-pressure vapor to a high-pressure liquid. Step 4, Expansion: The condensed liquid's pressure is reduced (called "throttled") to the lower pressure evaporator using a valve, orifice plate or capillary tube device. In actual practice, the condenser cools the refrigerant a bit more, sub cooling it below the condensing temperature. This is an important efficiency improving attribute to the cycle, since it reduces the amount of refrigerant liquid that has to evaporate (it is called flashing at this stage in the cycle) to a gas in the expansion valve to reduce the pressure and temperature of the liquid entering the evaporator. This reduction in flash gas is important to improve system performance. The refrigeration process flow are describe below : a) Compressor starts. b) Low pressure vapour refrigerant is compressed and discharged out of the Compressor. c) The refrigerant, at this time is at High Pressure. d) The refrigerant flows through the discharge line to the condenser. e) The condenser gives up heat absorbed and changes from vapour to liquid f) The high pressure liquid then flows through the Filter Drier to the Thermal Expansion Valve(TXV) or Capillary tube. g) The Thermal Expansion Valve (TXV) control the liquid refrigerant into the Evaporator. h) As the refrigerant flows through the expansion device, changes to Low Pressure liquid. i) In the Evaporator, heat is absorbed and the refrigerant begin to change in state from liquid to vapour. j) The low pressure vapour refrigerant moves back to the compressor. k) The cycle start over again Page 2 of 14 Page 3 of 14 2.2 Pressure-Enthalpy Diagram The Pressure-Enthalpy (P-H) diagram is another way of looking at the refrigeration cycle. It has the advantage of graphically showing the process, the cooling effect and the work required to make it happen. Figure 2 : P-H Chart Figure 2 shows the Pressure-Enthalpy (PH) diagram for the refrigeration. The process for each of the components is indicated. Point 1 to 2 - Compression process. The work is the change in enthalpy from point 1 to point 2. Simply, Btu/lb. times the lb./min equals compressor power. Compressors end up with the work of compression as heat in the refrigerant. The vertical aspect of the curve shows the rise in refrigerant pressure (and temperature) from 1 to 2. Point 2 to 3 - Condensation process. The process takes place in the condenser. Once the refrigerant is saturated, condensation occurs and the refrigerant changes from a gas to a liquid. Like the evaporator, the line is horizontal indicating constant pressure. Point 3 to 4 - Expansion process. The process is happen in expansion device such expansion valve or capillary tube. This appears as a vertical line from point 3 to point 4, indicating the pressure (and temperature) drop that occurs as the refrigerant passes through the capillary tube. Point 4 to 1 - Evaporation process. The evaporator process is from point 4 to point 1. As the refrigerant changes from a liquid to gas, the pressure (and temperature) stays constant. The heat is being absorbed as a phase change (latent energy). The refrigeration effect is the change in enthalpy from 4 to 5, simply expressed as Btu/lb.. Page 4 of 14 The efficiency of the refrigeration (COP) cycle can be found through the ratio between the segment 4 -5 and 1-2 : COP = h5 - h4 h2 - h1 http://laurens.apogee.net/ces/library/crbcc.asp http://www.kfupm.edu.sa/me/ 431 refrigeration www.freeze-co.com/Documents/RefrigerationCycle.pdf Application Guide AG 31-007, Mc Quay Airconditioning Page 5 of 14 3.0 EQUIPMENT / APPARATUS Figure 3: Refrigeration Unit 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Schematic diagram High and low pressure gauges Flow meter Digital Thermometer Sight Glass Drier Evaporator Cabinet Condenser Compressor Control Board. Page 6 of 12 4.0 Experiment Procedure No. 1. 2. 3. 4. 5. 6. 7. 8. Procedure Fully open valve V1 , V3, V 4 , V6, V7 and V8 Fully Close valve V2 and V5 Switch ‘ON’ Power supply. Wait about 5 minutes until the system is stabile. Record the power of the compressor. Record the pressure: i. High pressure (HP) - Red gauge ii. Low pressure (LP) - Blue gauge The pressure need to add 1 bar for atm pressure consideration. Take the temperature probe. At Compressor : i. Measure temperature at compressor inlet ( T1) ii. Measure temperature at compressor outlet ( T2) 9. At Evaporator i. Measure temperature at before entering capillary tube ( T3) ii. Measure temperature at Evaporator outlet ( T evaporator ) 10. 11. 12. 13. 14. Record the Refrigerant flow rate at flow meter. Fill at the data in Table 1. Using P-H diagram, Plot your data referring to figure 2. From the P-H diagram, determine the enthalpy (h) at the all points measured. End of Experiment Page 7 of 12 LAB 5 REFRIGERATION CYCLE Lab Result GROUP NUMBER :___________________________ DATE OF EXPERIMENT :___________________________ GROUP MEMBERS NAME : (Reminder: Do not accept your group member to sign if his/her contribution is not satisfy) 1)_______________________________signature:__________ 2)_______________________________signature:___________ 3)_______________________________signature:__________ 4)_______________________________signature:___________ 5)_______________________________signature:___________ 6)_______________________________signature:___________ Mark : Page 8 of 12 5.0 Data & Result No. 1. 2. No. 3. 4. 7. 8. Description Pressure (bar) High Pressure ( HP) + 1 bar (atm) Low Pressure (LP) + 1 bar (atm) Description Temp. (ºC) Temperature at compressor inlet ( T1) Temperature at compressor outlet ( T2) Temperature at before capillary tube ( T3) Temperature at Evaporator ( Tevaporator) Table 1 Note : 1. 2. 3. 4. 5. 6. Using given P-H diagram, Plot your data referring to figure 2. Step 1 : Draw the horizontal line of High pressure (HP) Step 2 : Draw the horizontal line of Low pressure (LP) Step 3 : At Low Pressure (LP) line plot T1. Step 4 : At High pressure (HP) line plot T2 and T3 Step 5 : t point T3 draw vertical line that will cut to LP line. This intersection is point T4. 7. Step 6 : Draw a line that will connecting T1, T2, T3 , T4 and T5 . 8. Step 7 : To find the enthalpy ( x-axis), draw the vertical line to the x- axis. The intersection is the enthalpy for that point. 9. Record the enthalpy in table 2 : Point 1 2 3 4 5 Temperature , ºC Enthalpy (h) , kJ/kg Page 9 of 12 6.0 QUESTIONS Page 10 of 12 Answer all questions below: 6.1 Calculated the efficiency of the refrigeration (COP) . 6.2 Using your own word, explain the function of Compressor in refrigeration system?. 6.3 Using your own word, explain the function of Condenser in refrigeration system?. 6.4 Using your own word, explain the function of evaporator in refrigeration system?. 6.5 Using your own word, describe the whole refrigeration process Page 11 of 12 7.0 DISCUSSION Include a discussion on the result noting trends in measured data, and comparing measurements with theoretical predictions when possible. Include the physical interpretation of the results and graphs, the reasons on deviations of your findings from expected results, your recommendations on further experimentation for verifying your results, and your findings. 8.0 CONCLUSION Based on data and discussion, make your overall conclusion by refer Page 12 of 12