Analytical representation of the liquidus surface in ternary systems

advertisement

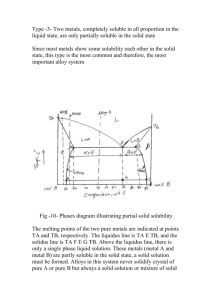

ANALYTICAL REPRESENTATION OF THE LIQUIDUS SURFACE IN TERNARY SYSTEMS V. Filippov1, V. Il’ves2, K. Shunyaev1 1 Institute of Metallurgy, Ural Branch of Russian Academy of Sciences, Amundsen str., 101, 620016, Ekaterinburg, Russia 2 Institute of Electrophysics, Ural Branch of Russian Academy of Sciences, 106 Amundsen str. 620216 Ekaterinburg, Russia Abstract A new method for describing the phase equilibria of a multicomponent system in the matrix form is proposed. A system of equations which describes a higher order phase diagram consists of: polynomial expressions correspond to the hypersurfaces representing the phase boundaries of one-phase regions and the relationships expressing the phase equilibria between phases. As an example, the results of liquidus surface estimation of quasi-ternary InBi-Sn-Pb alloys are presented. For liquidus surface representation in this system three binary subsystems and only few experimental data on ternary alloys are used. The method can be applied to the phase diagrams as a whole or its parts. Introduction Surface mount assembly processes for products that does not experience harsh temperature environments, as well as production of electronic devices whose operation is based on their temperature response, such as thermal cutoff fuses, often use low-temperature solders as substantial materials. For that purpose, various low-melting alloys are used, since one single alloy may not be appropriate as a universal solution. These alloys generally melt below 250 °C and are multicomponent, usually composed of tin, lead, silver and one of low melting element such as bismuth, indium, cadmium or gallium. In the design, development, processing and understanding of multicomponent alloys, their phase diagrams play an important role. Since experimental determination of multicomponent phase diagrams can be time-consuming, expensive and difficult, theoretical evaluation based on a far less number of experimental data is substantial. Despite the well knowledge of binary phase diagrams at a constant pressure, phase equilibia for higher order systems are less studied. The phase diagram can be calculated and investigated using both thermodynamic 89 methods and mathematic ones. The elaboration of the algorithms and attendant software, based on a mathematical description of phase diagrams surfaces. In this paper a new approach in estimation of liquidus surface in ternary phase diagrams on the basis of three binary subsystems and few experimental data is presented. The new method is used for determination of liquidus surfaces of low-melting InBi-Sn-Pb alloys and results are compared with those available in the literature. Calculation procedure The liquidus or solidus temperature T in m-component systems may be represented by the n-th order Scheffe polynomial expansion [1] using atomic fractions xi: T n x 1 i m i i k 2 1 i j m n x x j ( xi x j ) k 2 s x1s1 x2s 2 ...xms k , k 3 1 i1 i2 ... ik m ij i (1) where s1 s2 ...sk n ; β are constant coefficients. Any number of coefficients β necessary to adequately represent the temperature in a system may be included. The liquidus or solidus surface resulted from N measurements can be represented in matrix form: T(1, N ) B(1, M ) X( N , M ) , (2) where M is the number of coefficients β to be determined; T is column vector of the measured values of temperature; X is concentration matrix; B is column vector of coefficients β. The first and second arguments in parentheses indicate the number of rows and columns, respectively. The values of β are determined by the method of Gauss. The phase equilibrium can be expressed in matrix form by the relation: T ( x1 , x2 ,..., xm ) T ( x1 , x2 ,..., xm ) ... Tq ( x1q , x2q ,..., xmq ) Tf , (3) 90 where q is maximum number of phases in the phase equilibrium; Tf is the phase equilibrium temperature. For any phase diagram, matrices Xi and relations (3) are parts of a large a matrix X. Number of sub-matrix Xi in X depends on the number of phases in the system multiplied by the number of surfaces bounding phase. Number of relations (3) in X is determined by the reaction scheme. Let's consider for example the matrix X for the liquidus surface in the ternary system with one of the invariant point: 0( N 3 , M 3 ) X1 ( N1 , M 1 ) 0( N 2 , M 2 ) 0( N , M ) X ( N , M ) 0( N , M ) 1 1 2 2 2 3 3 , 0( N1 , M 1 ) 0( N 2 , M 2 ) X3 ( N 3 , M 3 ) X 2 (1, M 2 ) X3 (1, M 3 ) X1 (1, M 1 ) (4) where 0 is zero sub-matrix; Ni and Mi are number of experimental points and coefficients β in i-th sub-matrix, respectively. In the liquidus surface calculation of ternary systems usually the coefficients of the binary systems can be treated as known, only the coefficients of the ternary polynomial are unknown. In general, the composition of the ternary eutectic point ( x1e , x2e , x3e ) is not known and may be found from the condition: T1 ( x1e , x2e ) Te 0 , e e T2 ( x1 , x2 ) Te 0 (5) where Ti ( x1e , x2e ) is the temperature at the eutectic point for i-th liquidus surface equation (1). The system of equations (5) can be solved by any minimization method (e.g., Newton-Raphson or simplex). Results and discussion Experimental data for analytical representation of the liquidus surface of binary sub-systems (Sn-Pb, InBi-Sn, InBi-Pb) are obtained from the literature [2-4]. Measured liquidus temperatures of 9 ternary InBi-Sn-Pb alloys are taken from ref. [5]. Results of the liquidus surface 91 calculation the quasi-ternary InBi-Sn-Pb system are presented in Fig.1. Deviations of the experimental points from the calculated liquidus surface not exceed 1.5 oC. The calculated and experimental [6] values of composition and temperature of the InBi-Sn-Pb eutectic point are given in the Table. The results of the calculation of eutectic point coordinates obtained in [5] without the use of condition (3) (i.e., by extrapolation of these surfaces to the point of intersection) are shown also in the Table 1 for comparison purposes. Pb 0.00 1.00 300 0.25 0.75 x Sn 250 0.50 200 x Pb 0.50 150 0.75 100 0.25 E 0 10 0 15 Sn 0.00 0 20 1.00 0.25 0.50 0 10 0.75 0.00 1.00 InBi xInBi Fig.1. Calculated projection of liquidus surface of the InBi-Sn-Pb system Thus, the use of relation (3) in calculation makes it easier to describe the liquidus surface in the concentration range where no experimental points (i.e., near the eutectic point). 92 Table 1. Composition and temperature of the InBi-Sn-Pb eutectic point. InBi 69.71 69.58 70.80 Composition, at. % Sn 16.3 12.64 14.58 Pb 14.0 17.78 14.62 Temperature, oC Ref. 58.0 45.2 57.9 [6] [5] our data Conclusion A new method for describing the phase equilibria of a multicomponent system in the matrix form is proposed. Method is applicable for any ternary system whose phase diagrams of binary subsystems and a few appropriate experimental points are known. Liquidus surfaces of the low-melting quasi-ternary InBi-Sn-Pb system is constructed as illustration of the proposed method. Liquidus surfaces of the low-melting quasi-ternary alloys are constructed as illustration of the proposed method. Advantage of presented method is the possibility of analytical representation and determination of liquidus temperature of arbitrary composition of considered ternary alloy. Acknowledgement This work was supported by the Russian Foundation, project no. 14-03-01126-a. 1. 2. 3. 4. 5. 6. References Sheffe H: 'Experiments with mixtures'. J. Roy. Statist. Soc. 1958 20B (2) 344. Karakaya I, Thompson W T: 'The Pb−Sn (Lead-Tin) system'. J. Phase Equilibria 1988 9 (2) 144-52. Dooley G J, Peretti E A: Phase Diagram of the System InBi-Sn. J. Chem. Eng. Data 1964 9 (1) 90-91. Boa D, Ansara I: 'Thermodynamic assessment of the ternary system Bi-In-Pb'. Thermochimica Acta 1998 314 (1) 79-86 Il'ves, V G, Filippov V V, Yatsenko S P: 'Liquidus and enthalpy of mixing of liquid alloys in quasi-ternary InBi-Cd-Pb and InBiPb-Sn systems'. Rasplavy 1994 (1) 15-22 (in Russian). Mei Z, Holder H, Vander Plas H: 'Low-Temperature Solders'. Hewlett-Packard Journal 1996 (8) Article 10. 93