Forecasting the Benefits of Performance Based Standards

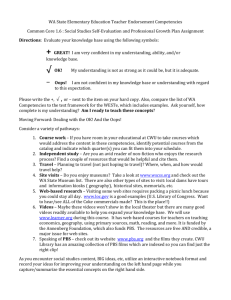

advertisement