Synthetic procedures - Royal Society of Chemistry

advertisement

Supplementary Material for Faraday Discussions

This journal is © The Royal Society of Chemistry 2004

Organisation in two series of low-dimensional polymer electrolytes with high ambient

lithium salt conductivity.

Jianguo Liu, Yungui Zheng, Yen-Po Liao, Xiangbing Zeng, Goran Ungar and

Peter V. Wright

Dept. of Engineering Materials, University of Sheffield, Mappin St.,Sheffield, UK S1 3JD

Electronic supplementary information.

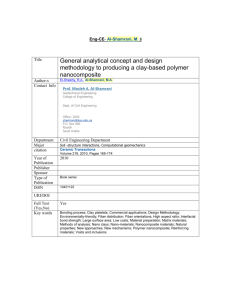

Table S!. X-ray data for C16On polymers and complexes with LiBF4 and LiClO4

Polymer or complex

d- spacing (/ Å, 26oC)

d- spacing (/ Å, 50oC)

C16O1

4.16, 15.91, 32.00

4.51, 33.88 (amorphous)

C16O1:LiBF4 (1:1)

3.87, 4.17, 6.09, 16.18, 32.54

3.88, 4.16, 6.07, 33.29

C16O2(100%)

4.16,8.25, 16.59, 33.68

4.60, 33.10 (amorphous)

C16O2(100%):LiBF4 (1:1)

3.87, 4.17, 4.84, 6.12, 8.39, 16.88, 34.28

3.87, 4.16, 4.83, 6.12, 33.88

C16O3(100%)

4.19,9.20, 12.14, 18.49, 37.64

4.45, 32.73

C16O3(100%):LiBF4 (1:1)

4.19, 4.83, 12.86, 19.49, 39.44

4.84, 41.13

C16O4(100%)

3.97, 4.19, 4.47, 9.33, 12.72, 18.73, 38.39

4.41, 32.18 (amorphous)

C16O4(100%):LiBF4 (1:1)

4.22, 14.31, 43.62

4.46, 43.62

C16O5(40%):LiBF4 (1:1)

3.89, 4.16, 19.69, 39.44

3.87, 4.14, 44.63

C16O5(100%)

4.17, 37.64

4.44, 33.29 (amorphous)

C16O5(100%):LiBF4 (1:1)

4.22, 14.93, 46.06

4.39, 42.97

LiBF4

4.06, 4.35

C16O1:LiClO4 (2:1)

3.90, 4.20, 6.76, 16.73, 33.88

3.89, 4.27, 35.55

C16O1:LiBF4 (2:1)

4.18, 16.36, 32.73

4.41, 33.29

C16O1X

4.23, 36.92

4.62, 35.12

C16O1X:LiClO4 (2:1)

4.25, 37.15

3.96, 4.33, 38.40

C16O1X:LiBF4 (2:1)

4.22, 36.45

4.24, 36.92

Numbers in bold indicate sharp reflections.

Table S2. X-ray data for C16O5-C16O1 copolymers and complexes

Polymer or complex

d- spacing (/ Å, 26oC)

d- spacing (/ Å, 50oC)

C16O5(100%)

4.17, 37.64

4.44, 33.29

C16O5(100%):LiBF4 (1:1)

4.22, 14.93, 46.06

4.39, 42.97

C16O5(75%)

4.18, 12.80, 18.73, 38.65

4.47, 33.68

C16O5(75%):LiBF4 (1:1)

4.18, 13.80, 21.20, 41.72

4.40,44.63

C16O5(40%)

4.18, 17.98, 36.92

4.47, 32.54

C16O5(40%):LiBF4 (1:1)

3.89, 4.16, 19.69, 39.44

3.87, 4.14, 44.63

LiBF4

4.06, 4.35

Numbers in bold indicate sharp reflections.

Supplementary Material for Faraday Discussions

This journal is © The Royal Society of Chemistry 2004

Synthetic Procedures

Dimethyl sulphoxide (DMSO) was dried and distilled before use. Other reagents were

used without further purification.

Synthesis of poly[2,5,8,11,14-pentaoxapentadecamethylene(5-hexadecyloxy-1,3phenylene)] (C16O5 copolymer (method X)

5-hexadecyloxy benzene-1,3-dimethanol (i) and 1,11-dichloro-3,6,9-trioxaundecane

(tetraethyleneglycol dichloride) were prepared as described previously12. The polymer

C16O5X(50%) was prepared by heating 1.89g (0.005mol) 5-hexadecyloxy benzene1,3-dimethanol (i), 1.16g (0.005mol) tetraethylene glycol dichloride and 2.24g

(0.04mol) potassium hydroxide in 5ml dimethyl sulphoxide for 7 days with gentle

stirring at 90C under a nitrogen atmosphere. The polymer was precipitated in water

and the mixture was neutralized by addition of concentrated acetic acid. The polymer

was separated and washed with hot water several times to remove inorganic salts and

finally with hot methanol several times to remove monomer. The product is yellow.

1

H NMR: H(400MHz; solvent CDCl3; standard SiMe4) 0.86 (3H, t, CH3), 1.25 (25H,

s, 12CH2), 1.45 (2H, m, -CH2), 1.75 (2H, m, -CH2), 3.65 (7.5H, t (broad), 4CH2

ethoxy), 3.92 (2H, t, -CH2), 4.45 (2H, s, -CH2, benzyl), 6.85 (2.5H, m,

C6H3aromatic). 1H NMR results show that the molar proportion of the tetraethoxy

segments (= 3.65ppm) is ca. 50% of the side chain groups. The 2 benzylic

hydrogens are only half of the 4 expected and the FTIR spectrum shows medium ester

C=O at 1720 cm-1 suggesting that the polymer is an ether-ester. GPC gave molar mass

averages <Mn> = 29,224, <Mw> = 257,711, <Mz> = 677, 074. DSC of C16O5

indicates that the polymer melts at 33C.

Synthesis of C12C18O5X (method X)

The copolymer, abbreviated as C12C18O5X(18%), was prepared by heating 0.81g

(0.0025mol) 5- dodecyloxybenzene -1, 3-dimethanol, 1.02g (0.0025mol) 5octadecyloxybenzene -1, 3-dimethanol, 1.16g (0.005mol) tetraethylene glycol

dichloride, 2.24g (0.04mol) potassium hydroxide and 2.24g potassium carbonate in

30ml dimethyl sulphoxide for 7 days with gentle stirring at 90C under nitrogen

atmosphere. The polymer was precipitated in water and the mixture was neutralized

by addition of concentrated acetic acid and extracted into chloroform. After

evaporation of the chloroform, the residue was washed with hot water several times to

remove inorganic salt and finally with hot methanol several times to remove the

monomer. The product is pale brown. 1H NMR H(400MHz; solvent CDCl3; standard

SiMe4) 0.86 (3H, t, CH3), 1.25 (23H, s, 11.5CH2), 1.45 (2H, m, -CH2), 1.75 (2H, m,

-CH2), 3.65 (3H, t (broad), CH2 ethoxy), 3.92 (2H, t, -CH2), 4.45 (2H, s, CH2

benzyl), 6.85 (3H, m, C6H3 aromatic). 1H NMR results suggest 15.5 side chain -CH2which is consistent with an equimolar mixture of -C12H25 and -C18H37 side chains. The

results also show that the molar proportion of the tetraethoxy segments (= 3.65ppm)

is only ca. 18% of the side chain groups and the 2 main chain benzylic -hydrogens

are only 50% of the expected 4 hydrogens. The FTIR spectrum shows a medium ester

C=O band at 1720 cm-1 indicating that the polymer C12C18O5X(18%) is an etherester. GPC gave molar mass averages <Mn> = 2,614, <Mw> = 52,541 and <Mz> =

1,069,798.

Synthesis of 1,3-bis (bromomethyl) -5- hexadecyl -oxybenzene (ii)

Supplementary Material for Faraday Discussions

This journal is © The Royal Society of Chemistry 2004

Under a dry atmosphere, 5 g(13.2mmol) of 5- hexadecyloxybenzene -1, 3dimethanol (i) was suspended in 20 ml dry diethyl ether and cooled to 0°C with

stirring. Into the suspension, 3.18g(11.7mmol) of phosphorous tribromide was added

dropwise whilst keeping the temperature of the mixture below 5°C. After completion

of the addition, the solution was stirred for 10 hours at room temperature, and then

refluxed for 12 hours. The reaction mixture was then poured into a crushed ice bath.

The organic solid was washed with a 10% aqueous sodium carbonate and then with

water. The product was extracted into diethyl ether and the solution was dried over

MgSO4. The solvent was evaporated to yield 6.3g white crystals, m.p. 68C. 1H NMR

H(400MHz; solvent CDCl3; standard SiMe4) 0.86 (3H, t, CH3), 1.25 (24H, s, 12

CH2), 1.43 (2H, m, -CH2), 1.76 (2H, m, -CH2), 3.98 (2H, t, -CH2), 4.70 (4H, d, 2

-CH2 benzyl ), 6.87 (2H, s, 2H aromatic). 6.96 (1H, s, H aromatic). Elemental

analysis: Br, required 31.68%, found 31.49%. IR: 3050cm-1, 2849cm-1, 1600cm-1,

1590cm-1, 1500cm-1, 680cm-1.

Synthesis of poly{[2,5,8,11,14-pentaoxapentadecamethylene(5-hexadecyloxy-1,3phenylene)]0.75 - co- [ 2-oxatrimethylene(5-hexadecyloxy-1,3-phenylene)]0.25,

}C16O5 (75%) ( method Y)

The polymer C16O5(75%) was prepared by heating 1g (0.002mol) of bis-1,3(bromomethyl) -5- hexadecyloxybenzene (ii), 0.385g (0.002mol) tetraethylene glycol,

and 0.89g (0.016 mol) potassium hydroxide in 2ml dimethyl sulphoxide for 5 hours

with gentle stirring at 30 ~ 60C. The polymer was precipitated in water and the

mixture was neutralized by addition of concentrated acetic acid. The polymer was

separated and washed with hot water several times to remove inorganic salt and

finally with hot methanol several times to remove monomer. The product was pale

yellow. The yield was 0.45g (42%). 1H NMR H(400MHz; solvent CDCl3; standard

SiMe4) 0.86 (3H, t, CH3), 1.25 (24H, s, 12CH2), 1.45 (2H, m, -CH2), 1.75 (2H, m, CH2), 3.65 (12H, m, 6CH2 ethoxy), 3.92 (2H, t, -CH2), 4.45 (4H, s, -CH2 benzyl),

6.85 (3H, m, C6H3 aromatic). The 1H NMR shows that molar proportion of

tetraethoxy segments (= 3.65ppm) is 75% of the molar equivalent of side chain

groups. However, the full compliment of 4 benzyl hydrogens suggests that the main

chain structure is entirely polyether. GPC molar mass averages Mn = 9,335, Mw =

61,305, Mz = 260,113. The DSC of C16O5(75%) indicates that the polymer melts at

28.30C.

Synthesis of poly{[2,5,8,11,14-pentaoxapentadecamethylene(5-hexadecyloxy-1,3phenylene)]0.40

co[

2-oxatrimethylene(5-hexadecyloxy-1,3phenylene)]0.60}C16O5 (40%) (method Y)

The polymer C16O5(40%) was prepared by heating with gentle stirring at 50 ~ 60C

of 1g (0.002mol) 1, 3-bis (dibromomethyl) -5- hexadecyloxybenzene, 0.2888g

(0.0015mol) tetraethylene glycol, 0.1876g (0.0005 mol) 5-hexadecyloxy benzene-1,3dimethanol and 0.44g (0.008mol) potassium hydroxide in 1ml dimethyl sulphoxide

and 1 ml tetrahydrofuran (THF) for 3days. The polymer was precipitated in water and

the product isolated using the same procedure as above. The product is white. 1H

NMR spectrum was identical to that above with the exception of the peak at 3.63

ppm (6.5H, m, 3.3 CH2 ethoxy), corresponding to 40% tetraethoxy segments in the

Supplementary Material for Faraday Discussions

This journal is © The Royal Society of Chemistry 2004

polymer backbone. GPC gave molar mass averages Mn = 7,176, Mw = 14,194, Mz =

24,089. DSC indicates that the polymer melts at 35.76C.

Synthesis of poly[2,5,8,11,14-pentaoxapentadecamethylene(5-hexadecyloxy-1,3phenylene)] C16O5(100%) (method Y)

The polymer C16O5(100%) was prepared by heating with gentle stirring at 50

~ 60C 1g (0.002mol) 1, 3-bis (dibromomethyl) -5- hexadecyloxybenzene, (ii) 0.385g

(0.002mol) tetraethylene glycol, and 0.44g (0.008mol) potassium hydroxide in 1ml

dimethyl sulphoxide and 1 ml tetrahydrofuran (THF) for 3 hrs. The polymer was

precipitated in water. The mixture was neutralized by addition of concentrated acetic

acid. The polymer was separated and washed with hot water (T >50C) several times

to remove inorganic salt and finally with hot methanol several times to remove

monomer. The product is white. 1H NMR: H(400MHz; solvent CDCl3; standard

SiMe4) 0.86 (3H, t, CH3), 1.25 (25H, s, 12CH2), 1.45 (2H, m, -CH2), 1.75 (2H, m,

-CH2), 3.65 (16H, m, 8CH2 ethoxy), 3.92 (2H, t, -CH2), 4.45 (4H, s, -CH2,

benzyl), 6.85 (3H, m, C6H3aromatic). GPC gave molar mass averages Mn = 15,753,

Mw = 37,992, Mz = 77,258. DSC of C16O5 indicates that the polymer melts at

22.89C.

Synthesis

of

poly[2,5,8,11-tetraoxadodecamethylene(5-hexadecyloxy-1,3phenylene] (C16O4(100%) (method Y)

The polymer C16O4(100%) was prepared as above but the molar equivalent

of triethylene glycol was used. The yield is (75%). 1H NMR: H(400MHz; solvent

CDCl3; standard SiMe4) 0.86 (3H, t, CH3), 1.25 (24H, s, 12CH2), 1.45 (2H, m, CH2), 1.75 (2H, m, -CH2), 3.65 (12H, m, 6CH2 ethoxy), 3.92 (2H, t, -CH2), 4.45

(4H, s, -CH2, benzyl), 6.85 (3H, m, C6H3aromatic). GPC: molar mass averages Mn =

8,369, Mw = 21,555, Mz = 39,720. DSC of C16O4 indicates that the polymer melts at

28.07C.

Synthesis of poly[2,5,8,-trioxanonamethylene(5-hexadecyloxy-1,3-phenylene,

C16O3(100%) (method Y)

The polymer C16O3(100%) was prepared as above but the molar equivalent

of diethylene glycol, was used. The yield was 79%. 1H NMR: H(400MHz; solvent

CDCl3; standard SiMe4) 0.86 (3H, t, CH3), 1.25 (25H, s, 12CH2), 1.45 (2H, m, CH2), 1.75 (2H, m, -CH2), 3.65 (8H, m, 4 CH2 ethoxy), 3.92 (2H, t, -CH2), 4.45

(4H, s, -CH2, benzyl), 6.85 (3H, m, C6H3aromatic). GPC molar mass averages Mn =

8,174, Mw = 17,409, Mz = 29,000. DSC of C16O3 indicates that the polymer melts at

32.53C.

Synthesis

of

poly[2,5-dioxahexamethylene(5-hexadecyloxy-1,3-phenylene,

C16O2(100%) (method Y)

The polymer C16O2(100%) was prepared as above but the molar equivalent of

ethylene glycol was used. The yield was 64%. 1H NMR: H(400MHz; solvent CDCl3;

standard SiMe4) 0.86 (3H, t, CH3), 1.25 (25H, s, 12CH2), 1.45 (2H, m, -CH2), 1.75

(2H, m, -CH2), 3.65 (4H, m, 2 CH2 ethoxy), 3.92 (2H, t, -CH2), 4.45 (4H, s, -

Supplementary Material for Faraday Discussions

This journal is © The Royal Society of Chemistry 2004

CH2, benzyl), 6.85 (3H, m, C6H3aromatic). GPC molar mass averages Mn = 9,110, Mw

= 74,063, Mz = 284,061. DSC of C16O2 indicates that the polymer melts at 37.76C.

Synthesis of poly[ 2-oxatrimethylene(5-hexadecyloxy-1,3-phenylene)] (C16O1)

(method Y)

The polymer C16O1 was prepared as above but the glycol was replaced by the

molar equivalent of 5- hexadecyloxybenzene -1, 3-dimethanol (i). The product is

white and the yield was 63%. 1H NMR: H(400MHz; solvent CDCl3; standard SiMe4)

0.86 (3H, t, CH3), 1.25 (25H, s, 12CH2), 1.45 (2H, m, -CH2), 1.75 (2H, m, -CH2),

3.92 (2H, t, -CH2), 4.45 (4H, s, -CH2, benzyl), 6.85 (3H, m, C6H3aromatic). GPC

molar mass averages Mn = 4,272, Mw = 10,594, Mz = 17,510. DSC of C16O1

indicates that the polymer melts at 40.92C.

Synthesis of C16O1X (method X)

The polymer C16O1X was prepared by heating with gentle stirring at 60C of

1.00g (0.00264mol) 5- hexadecyloxybenzene -1, 3-dimethanol, and 3g (0.04mol)

potassium hydroxide in 5ml dimethyl sulphoxide for 7 days. The polymer was

precipitated in water; the mixture was neutralized by addition of concentrated acetic

acid and extracted into chloroform. After evaporation of the chloroform, the residue

was washed with hot water several times to remove inorganic salt and finally with hot

methanol several times to remove the monomer. 1H NMR: H(400MHz; solvent

CDCl3; standard SiMe4) 0.86 (3H, t, CH3), 1.25 (25H, s, 12CH2), 1.45 (2H, m, CH2), 1.75 (2H, m, -CH2), 3.92 (2H, t, -CH2), 4.45 – 4.9 (2H, s, -CH2, benzyl),

6.85 – 7.8 (3H, m, C6H3aromatic). FTIR showed a strong band at 1720 cm-1. GPC

molar mass average Mw =10,000. DSC of C16O1X indicates that the polymer melts at

42C.

Synthesis of polymer II (PTHFC12)

Polymer II (PTHFC12) was prepared by standard Williamson condensation of

hydroxy-terminated polytetrahydrofuran (Mn = 1688 g mol-1) with 1,12dibromododecane and excess powdered KOH (8 molar ratio) at 90oC. Polymer II

(PTHFC12) was purified by washing with dilute aqueous acetic acid followed by

water and dried under vacuum. The GPC result gave molar mass averages M w =

39,000. DSC of PTHFC12 indicates that the solution deposited polymer melts at 30C

whereas melt-recrystallised polymer melts at 24C.

Synthesis of ‘polymer’ III (DC18PTHF)

Polymer III (DC18PTHF) was prepared by standard Williamson condensation of

8.44g (0.005mol) hydroxy-terminated polytetrahydrofuran (Mn = 1688 g mol-1 ) with

3.33g (0.005mol) 1-bromododecane and excess powdered (8 molar ratio) 2.24g KOH

in 40ml dimethyl sulphoxide for 7 days at 90oC. Polymer III (DC18PTHF) was

purified by washing with dilute aqueous acetic acid followed by water and dried

under vacuum. 1H NMR: H(400MHz; solvent CDCl3; standard SiMe4) 0.86 (13H, t,

CH3), 1.25 (127H, s, 32 CH2), 1.6 (140H, m, 68 -CH2 butoxy, 2-CH2 ), 1.75 (2H,

m, -CH2), 3.4 (137H, t, 68 -CH2 butoxy), 3.6 (5H, s, 2 CH2). GPC molar mass

averages Mn = 3,250, Mw = 4724, Mz = 6,599. Polydispersity is 1.45. DSC of

DC18PTHF indicates that the polymer melts over the range 10 - 35C.

Supplementary Material for Faraday Discussions

This journal is © The Royal Society of Chemistry 2004

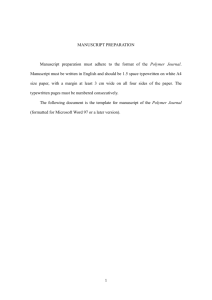

Molecular Dynamics modelling using Cerius2 software

C16O5 (Polymer I) – Li salt complexes

anions

Lithium ions

End view

-

40 - 45Å

Side view

Modelling by G. Ungar

C16O1 :Li salt complex

33Å

C16O1 : LiBF4 (2 :1) dark grey spheres, carbon; light grey spheres, hydrogen; red,

oxygen; pink, lithium; purple, boron; green, fluorine. (atomic radii are not to scale)