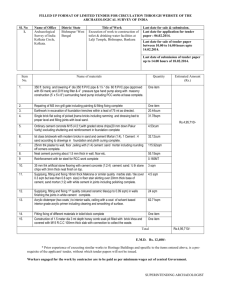

ANNEXURE – III - Engineering Projects India Ltd.

advertisement

ANNEXURE – III DETAILED TECHNICAL SPECIFICATION FOR CIVIL WORK. Work shall be carried out by the party as per the detail working drawings to be issued to them by EPI in phases. They may visit the site and see layout of the buildings and ascertain themselves with the approach to the work site etc. Party shall carry out the works as per Indian safety regulation. The board specification of the civil work is given below:1.0 Earth Work : Excavation shall be carried out in all kinds of soil, (soft and hard), boulder studded seal etc. Excavated pit shall be always kept dry by pumping out of sub-soil / rain water during construction. In case of acidic soil, acid pumps shall be used otherwise normal dewatering pump shall be used. During excavation all underground / over ground facilities like bables, pipes etc. to be protected with due care. Nearby existing facilities, foundation must be retained, in case of damage the same shall be rectified by the Party. 1.1.. During excavation shoring work shall be provided and proper slope to be kept during cutting. Necessary site plan shall be provided by EPI. If good soil at designed depth is not found then further excavation shall be done to reach at strong foundation level. 1.2 After completion of foundation, back filling shall be done with good excavation earth in layer of 150 mm and well-compacted remmed, watered before next layer is laid. 1.3 Surplus excavation earth shall be dumped at allotted place within a lead of 1 KM inside plant. 2 Concrete : 2.1 Plain cement concrete (PCC) grade as per BOQ shall be used at base of foundation for column, tie beam at ground level, Equipment foundation, base of trench, brick foundation, underground pipe. 2.2 PCC of required thickness as per drawing and grade/proportion as per BOQ shall be laid below floor with 40 mm/ 20 mm downgraded aggregate with black trap stone and coarse sand. D:\116100797.doc 2.3 Reinforced cement concrete of grade (M20/M25) with 20 mm and down graded aggregate shall be used for all other places like all foundation, column, beam, slab and any other RCC work as per drawing. 2.4 Cement shall be either ordinary Portland cement 43 grade or Portland blast furnace slag cement comprising to IS:269-1989. Cement shall be kept dry and will not contain lump. 2.5 All coarse & fine aggregate shall conform to IS:383-1970. Fine aggregate shall be of approved river bed and coarse aggregate shall be of approved black trap-stone. 3 D. P. C : 3.1 It shall be 40 mm thick with cement concrete(1:1:5:3) with 10 mm & down graded stone coarse aggregate with approved water proofing compound mixed in appropriate proportion on all external walls. 4 Reinforcement : 4.1 Reinforcing (R/F) bars shall be either cold twisted deformed (CTD) or thermo mechanically treated (TMT) as per IS:1786-1985. The same will be supplied by EPI 4.2 R/F shall be made concreting. 4.3 Cover to R/F shall be provided by use of cement sand mortar block (1:4). 4.4 Binding wire shall be gauge 16 SWG approved annealed wire. 4.5 Dowels shall be of 12 mm dia 75 mm long @ 750 mm c/c. free from mill scales, rust grease or oil before 5 Shuttering : 5.1 Shuttering work shall conform to IS:456-2000. This shall preferably be made of steel/Wooden Batton/Plyboard. Maximum use of ply/wooden shuttering shall be 3(Three) times. 6 Bitumen Painting : All underground Structure like column foundation, equipment foundation etc. in contact with earth shall be treated with 2 coats of bitumen painting(Salimer or equivalent) of grade 20 / 30 as per standard over concrete surface. 7 Brickwork : 7.1 The brickwork shall be mostly 250 mm thick conforming to IS:22121991. The brick shall be of class 5013 conforming to IS:1077-1992. Bricks shall be whole, sound, well burnt, free from cracks, well shaped, D:\116100797.doc uniform in size. The compressive strength shall be 5 N/sq.m (Min). The cement sand mortar for brick work shall be 1:6. 8 Plastering : 8.1 All plastering work shall be carried out as per IS:1961-1972. Walls (Outside) : 15 mm thick in cement sand mortar 1:6. 1st operation and 5 mm thick with water proofing compound varying from 3 to 5% as per manufacturers specification. Walls (Inside) : 15 mm thick in mortar 1:6. Ceiling : 10 mm thick in mortar 1:4. 8.2 After plastering wall, it shall be covered by watering for 7 days (minimum). 9 Flooring : 9.1 For building top of floor will be IPSS with 40 mm thick M-15 concrete cast in panels(1M/1M) having 2 mm thick alluminium metal strip, divider. Floor should be free from cracks & crevices. 9.2 Acid proof tiling work : Acid resistant non-slippery flooring for all areas handling with acid shall be provided. 9.3.1 Bitumen Primer : The bitumen primer coat to be applied on throughout cleaned and dry concrete and / or masonary surface in the exposed tanks. Pump foundation etc. shall be heavy grade bitumastic corrosion resistant primer conforming to IS:158 type II and laying process as per IS:9510 (latest). Primer shall be applied in two layers. 9.3.2 Bitumastic impervious liner : On the above primer, mastic compound shall be laid as per IS:9510. The specific gravity of mastic shall be 2 and penetration at 25 deg.C (100gm/5mm) shall be 1. the liner thickness shall be 15 mm. Test certificate for the above work shall be submitted to EPI’s Client 9.3.3Tiles : Sulphuric acid resistant tiles of size 230mm x 114mm x 40mm thick shall be used in the acid prone area and as per specification in IS:4860 class II. D:\116100797.doc 9.3.4 Bedding & Jointing : For bedding & jointing of tiles (6 mm thick) as per IS:4832 Part – II consisting of cement and resin in proportion by approved manufacturers shall be laid. 10 Door & Windows : 10.1 Process building shall have adequate nos of wooden doors. The doors shall be wooden single or double leaf. Door frame shall be of teak wood and shutters shall be of teak wood. All wood shall be well seasoned by a suitable process and suitable preservative treatment shall be given on it panel shall be 40 mm thick and frame 125 mm x 75 mm, shutter shall be 20 mm thick. Paints will be supplied by EPI. 10.2 All windows shall be of wooden frame with glazing as per IS standard. All glazing shall be made of 6 mm thick wired glass panes. Paints will be supplied by EPI. 10.3 Wherever utility / non-explosive buildings require steel doors this shall be made of MS steels fixed on angle frames and bracings. Airtight steel doors in motor / control room shall be provided. 11 Roof, chajjas and their water proofing and ventilation : (i). 10 years guarantee shall be given by the party on completion of the work. (ii). The temperature of 32 degree centigrade during summer has been recorded at the project site. Suitable and adequate ventilation arrangements shall be provided in all buildings. (iii). Chajjas of adequate size with side drops and front drops shall be provided to the windows and front door opening to stop rain beat hitting the fittings. (iv). Cast Iron/PVC rain water pipes shall be provided for all buildings, wherever required. The rain water pipes shall have grating at top and shoe at the bottom. The joints shall be jointed with clamp and cement or mortar. The arrangement should be such that there should be free of rain water through pipes. D:\116100797.doc 12 Paintings (i..) Steel Structures, after erection shall be clear off rust and scale and given 2 coats of red oxide zinc chromate primer finished by 2 coats of Synthetic enamel. Equipments shall be given red oxide primer finished by Synthetic enamel. (ii).. All walls of buildings shall be given two coats of colour washes on the external surface and two coats of lead free paint on internal surface and ceiling. (iii.) Red oxide zinc chromate primer will be in the scope of the Party. EPI will supply the Paint. 13 Foundation bolts & inserts : All the materials for foundation bolts, nuts insert shall conform to IS:1363 (Latest) 14 Drains : (i). (ii). (iii). (iv). (v). Storm water drainage will be through traperzoidal / Rectangular section of drain. Min depth will be 200 mm walls to be plastered with using extra cement 15 mm thick (1:6) wall / base will be made of concrete. Drain will be in a slope and this will be kept in screeding (M-5) concrete. Each building drains will be connected to main drain along the road as per drawing. In road crossing necessary hume pipe / box dram shall have to be provided. Main drain will be connected to a existing pit / main drain nearby. 15 Pathway / Gantry : Pathway / Gantry should having following specification. (i). From the main roads all the buildings will be connected by pathway / gantry 3.0 M (minimum) width. However, the width will be fixed as per layout and width will be maximum of 4.5 M. (ii). Over the compacted earth there will be 150 mm hardcore of broken stone. There will 100 mm thick RCC laid over stone. Also 80 mm thick stone kerbs, RCC kerbs either side of the pathway / gantry shall be laid with suitable gap for draining of rain water. (iii). All pathway / gantry near the buildings shall be leveled. All pathways shall be constructed first up to WBM level and RCC at the top shall be D:\116100797.doc laid after erection / movement of heavy machineries for entry in to the building is over. (iv). Necessary RCC / Hume pipe shall be constructed wherever there is a crossing of pipes, cables, dram with the pathway road within the plant. 16 Water Supply : (i). Water supply lines within the battery limit up to the individual building and inside the building as per requirement shall be planned. The water mains shall however be designed keeping in view the ultimate requirements of the plant. The supply system shall be designed by laying suitable pipe lines considering the present requirement and supply shall be taken from a point one meter outside the battery limit. Supply line for drinking water requirements for employees shall also be considered. The pipe connections for the water supply for process water, fire fighting and drinking water will be available at one metre outside the battery limit for connection by the Party. 17 Other Technical requirements : Site clearance, leveling and area drainage. Site clearance, leveling grading of the area for construction of the buildings as and where required, should be done. Depending on the site condition, areas where these buildings shall be locate, suitable concrete drains of adequate size for quick and efficient discharge of storm / surface water is recommended. All buildings shall be provided with drains and catch pits which shall be suitably connected to effluent treatment plant. 18 Anti-Termite Treatment : Provisions for Anti-termite treatment (ATT) for buildings need special attention. ATT given to the buildings will be as per specification laid down in the latest version of IS:6313 (Part-II). Ten years guarantee shall be obtained from the party entrusted with the job of ATT and submitted to the Purchaser. 19 Levels of buildings and plinth protection : The general plinth level should be minimum 300 mm above average ground level. In case of low lying areas / buildings located in depressions, the plinth level should be suitably raised. In no case the plinth level of the building shall be below the level of the concrete road inside the fenced area of the unit. The plinth protection of minimum 750 mm all around the building shall be provided. All process and storage D:\116100797.doc buildings will be provided with suitable ramp as per building specification. The slope of ramp will be 1:5. 20 Finishes in Technology / Production Building : The interior surface of walls and columns shall be perfectly vertical and even. The interior surface of walls and columns and ceilings and the flooring shall be finished smooth and shall be free from cracks and crevices so that no dust settles on it. Internal corners of walls shall be rounded of to prevent dust accumulation. All internal areas of buildings shall have minimum 150 mm high skirting of corresponding floor finishes. 21 Consumption of water & power : The water and electricity will be supplied by project authority, from a suitable taping point against payment. 22 General condition of the contract : (i). Party’s representative (representative of Indian origin only shall be permitted to visit the site before placement of order) are advised to visit the site by making prior appointments with the Sr. Manager giving suitable time. Party shall be deemed to have full knowledge of all relevant documents, samples, site conditions etc. before submission of his tender. Party shall be deemed to have inspected and examined the site and its surroundings and to have satisfied them selves before submission their tenders as to eliminate conditions. The firm contour and nature of site, nature of work and materials necessary for completion of works the means of across to the site, the accommodation they may require and in general shall be deemed to have themselves obtained all necessary information on inspection of site as to risks, contingencies and offer circumstances which may influence or affect their rates. Party shall satisfy himself after visiting this site as to the nature of the subsoil to be encountered and the bearing pressure as we well as depth at which the original soil will be encountered for the purpose of foundations. (ii). The materials of construction should be suitably selected by the Party but should confirm to relevant IS specification. Party shall submit samples / drawings / test reports of the materials to be used to the project authorities for their approval. The responsibility of quality work will however be the responsibility of the Party. (iii). All construction materials including cement & steel have to be arranged by the Party themselves. D:\116100797.doc (iv). Contract labour (Regulation and Abolition Act 1970) The executing agency who required to employ more than twenty workmen on the work under this Contract, shall be bound by the contract labour (Regulation and Abolition) Act 1970 and Rules framed there under. No tenderer or executing agency can undertake or execute his work without a License issued by Licensing Officer. (v). Minimum wages payable to Labour. Schedule of minimum wages is not enclosed along with the tender but the executing agency is deemed to have full knowledge regarding the minimum wages payable to labourers as legally effective. Irrespective of the fact that Gazette Notification may not have been published or that he was unaware of the increase in minimum wages. The minimum wages legally effective referred to above are the minimum wages notified in Gazette or governed by any local regulations whichever is higher. (vi.) Notwithstanding anything mentioned as above and in Annexure, the executing agency has to abide by statutory rules of the Govt. of India and Govt. (including Workman’s compensation Act. 1923, Factory Act. 1948, Payment of wages Act. 1936, Apprentices Act. 1961 and rules framed thereon). D:\116100797.doc