HSE Specification - Public Health

Petroleum Development Oman L.L.C.

PUBLIC HEALTH

Document ID SP-1232

Document Type Specification

Security Not Restricted

Discipline Full name of the discipline

Document Owner Corporate Functional Discipline Head-Health

Month and Year of Issue March 2013

Version 6.0

Keywords

Copyright: This document is the property of Petroleum Development Oman, LLC. Neither the whole nor any part of this document may be disclosed to others or reproduced, stored in a retrieval system, or transmitted in any form by any means (electronic, mechanical, reprographic recording or otherwise) without prior written consent of the owner.

Petroleum Development Oman LLC

Document Authorisation

Document Owner Document Custodian

Revision: 5.0

Effective: June-12

Document Author

Dr Sulaiman Al Rawahi

MCC - CFDH

Date: 01/03/2013

Dr Suad Al-Lamki

Cooperate Public

Health Advisor

Date: 01/03/2013

Dr Suad Al-Lamki

Cooperate Public

Health Advisor

Date: 01/03/2013

Revision History

The following is a brief summary of the four most recent revisions to this document.

Details of all revisions prior to these are held on file by the Document Custodian.

Version No. Month & Year Author’s Name and Title Scope / Remarks

Version 6.0 March 2013

Version 5.0

June 2012

Version 4.0

March 2007

Version 3.0

June 2003

Dr Suad Al-Lamki

Cooperate

Public Health Advisor

Dr Suad Al-Lamki

Cooperate

Public Health Advisor

Khalifa Al-Maskery Industrial

Hygiene Advisor

Said Gheithy

CSM/34

Changes made on food handlers fitness to work

Addition of 2 Appendix

Appendix I, J & CHANGE OF

Appendix I to K

Changes to the checklist to two parts; Public Health & Welfare

Appendix H

Changes to the following sections;

2.3.1, 2.3.3, 2.3.4, 2.3.5, 2.3.6,

2.3.7, 2.4, 2.5, 2.7,

ppendix C Water standards,

Appendix G camp Inspection checklist

Changes to the following sections;

2.1, 2.2, 2.3.1, 2.3.3, 2.3.5,

2.3.6, 2.3.7, 2.4, 2.6, 2.7.

Appendix D and G

Section changed

2.3.2 from Pantry to

Thawing.

New section

Appendix E; kitchen design, F;

Cutting boards colour code

Changes to the following sections:

1.5, 2.3.7, 2.4

Appendix F

2.11 Private Properties

Section removed

Page 2 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

A

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Version 2.0

June 2003 Said Gheithy

CSM/34

1.8 Reporting Format

New Section added

2.3.6 HACCP Quality

System

Appendix F: Section I – 8

Electrical

Changes to the following sections:

2.3.1, 2.3.2, 2.3.5, 2.3.6,

2.4

Appendix D

New Section added

2.11 Private Business Facilities

User Notes:

1. The requirements of this document are mandatory. Non-compliance shall only be authorised by a designated authority through STEP-OUT approval as described in this document.

2. A controlled copy of the current version of this document is on PDO's live link. Before making reference to this document, it is the user's responsibility to ensure that any hard copy, or electronic copy, is current. For assistance, contact the Document Custodian .

3. Users are encouraged to participate in the ongoing improvement of this document by providing constructive feedback

Page 3 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Page 4 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Related Business Processes & CMF Documents

Related Business Processes

Revision: 5.0

Effective: June-12

Code

CP-122

Business Process (EPBM 4.0)

HSE Management System Code of Practice

Parent Document(s)

Doc. No.

21/90

8/2006

Document Title

Muscat Municipality Local Order "Colours of Tankers”

Chemical and bacteriological limits specified in Omani Standard

Other Related CMF Document(s)

Doc. No.

SP-1279

SP-1285

SP-1275

SP-1277

SP-1231

SP-1194

SP-1009

Document Title

Specification for Civil & Building Construction

Specification for Construction and Building Services

Specification and Criteria for Design of Civil Building Works Update

Spesification for Transportable Accommodation Units

Spesification for Occupational Health

Specification for Chemicals Management

Specification for Waste Management

SP-1006 Specification for Aqueous Effluents

The related CMF Documents can be retrieved from the Corporate Business Control

Documentation Register CMF .

Page 5 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

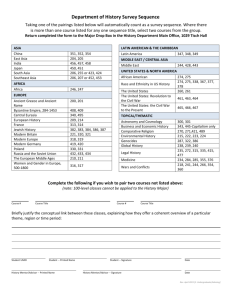

TABLE OF CONTENTS

Food Handlers and Personal Hygiene .......................................................... 13

Procurement and Goods Receiving

.............................................................. 14

.............................................................................. 14

................................................................................................ 15

Cold Stores - Refrigerators and Freezers

Preventing Cross Contamination

..................................................... 16

.................................................................................... 17

.................................................................. 17

................................................................................................. 18

......................................................................... 18

Codex HACCP Food Safety Management System ....................................... 20

Clean and Sanitise Thermometer ................................................................. 20

Food Transportation and Food Service ........................................................ 21

Page 6 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Safety Precautions and First Aid Requirements ........................................... 26

APPENDIX A - Thawing and Cooking Times of Frozen Meat and Poultry ..................... 27

APPENDIX C – Correct Sampling of Drinking Water for Bacteria .................................. 29

APPENDIX D - Drinking Water Standards (Oman STDS 08/2006) ............................... 30

APPENDIX E - Public Health Standards for Swimming Pools ....................................... 32

APPENDIX J – Management of suspected food borne illness ..................... 54

Page 7 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

1 Introduction

1.1 Purpose and Objectives

This Specification describes PDO's requirements for managing public health risks associated with the activities of PDO and its Contractors and addresses the health hazards associated with accommodation camps and workplace amenities.

1.2 Scope and Applicability

This Specification applies to all camps, offices, buildings and other premises belonging to or occupied by PDO, Contractors or Sub-Contractors authorised to work on behalf of PDO.

This Specification addresses:

Sleeping accommodation.

Food hygiene (including kitchens, pantries, dining halls, dry food stores, cold stores, and food handlers).

Pest control.

Toilets and washing facilities.

Waste management.

Water management.

Barber shops.

Laundries.

Recreational facilities.

This Specification does not address health hazards associated with job tasks in the workplace (refer to SP1231 “Occupational Health”).

1.3 Review and Improvement

Any user of this document who encounters a mistake or confusing entry is requested to immediately notify the Document Custodian using the form provided in CP122 “HSE

Management System document”, Part 2 Chapter 3.

This document shall be reviewed as necessary by the Document Custodian, but no less frequently than every four years. Triggers for full or partial review of this Specification are listed in CP122 “HSE Management System document”, Part 2 Chapter 8.

1.4 Distribution

Team Leaders/Area Co-ordinators are responsible for ensuring that all PDO and Contractors facilities under their control are managed according to the requirements of this Specification.

Corporate Functional Discipline Heads are responsible for ensuring that the requirements of this

Specification are reflected in the documents for which they are responsible.

Contract Holders are responsible for communicating this Specification to Contractors, and for ensuring that the requirements of this Specification are adhered to within the scope of their contracts.

Contractors are responsible for ensuring that activities undertaken within the scope of their contracts are managed in accordance with the requirements of this Specification.

Page 8 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

2 Performance Requirements

2.1 Pre-Occupancy Inspection

No camp, office, building or other premises shall be occupied as fit for occupancy until approved by PDO. This requirement shall also apply to an existing camp, office, building or premises at the start of a new contract.

Accomodation and Food Premises shall be inspected and approved by the Occupational and

Public Health Teams from the planning, commissioning to final operational & implementation stage to ensure the accommodation units and food premises meet the required living conditions specification and food safety standards.

2.2 Camp Facilities

All camp facilities shall be constructed to provide protection against pests and adverse weather conditions and shall comply with:

PDO-SP-1279:

PDO-SP-1285:

PDO-SP-1275:

Specification for Civil & Building Construction.

Specification for Construction and Building Services.

Specification and Criteria for Design of Civil Building Works Update.

Temporary transportable units such as porta-cabins shall meet the requirements of:

PDO-SP-1277: Transportable Accommodation Units.

In permanent camps, a minimum total area of 4 square metres (m 2 ) per person shall be provided, and a minimum separation distance of 2 metres between beds. A maximum of 4 persons shall occupy a room or cubicle at any one time.

In mobile camps a minimum total area of 3m 2 per person shall be provided and a minimum separation distance of 1 metre between beds.

A full length cupboard (locker) shall be provided for each occupant.

Beds with firm springs, or suitable hard-board (without curvature), shall be provided and fitted with a suitable mattress of at least 6cm thickness, a blanket, two sheets, two pillows and two pillow cases.

Bed linen shall be washed at least once a week. Any evidence of bed bugs shall be reported immediately to the camp supervisor.

Air conditioning should be by means of windows or split units and should include cooling and heating system.

All sleeping accommodation shall be air-conditioned. Where sleeping accommodation is provided in temporary transportable units such as porta-cabins, heating shall be provided in accordance with PDO-SP-1277 and PDO-SP-1285(B). Porta-cabins shall also be installed/ secured in accordance with PDO-SP-1277 and PDO-SP-1285(B)

Sufficient natural and artificial light (minimum 150 Lux intensity) shall be provided in all rooms.

2.3 Kitchen

Kitchens should be designed and constructed to ensure a linear flow of activities from goods delivery to serving of meals.

1. The floor area of a kitchen shall be at least 1m 2 per person served (e.g. the kitchen area for a mess seating 100 persons shall be at least 100m 2 )

Page 9 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

2. The floor shall be durable, non-absorbent, non-slip and without crevices in which dirt, bacteria and insects can lodge. Angles and junctions between floor and wall shall be covered.

3. Adequate drainage shall be provided. Shallow, glazed half-round floor channels with removable gratings shall be installed. All sinks, wash hand basins and potato peelers shall have water seal traps to prevent drain odour. For camps equipped with manholes and grease traps, these shall be situated outside the building.

4. Walls shall be smooth, impervious, light in colour and durable from floor to ceiling.

5. The ceiling shall be smooth, fire-resistant, light coloured, covered at wall joints and easy to clean.

6. Adequate lighting shall be provided (minimum of 500 Lux intensity in general working areas).

7. No items shall be kept on window ledges. Fly screens shall be fitted on all kitchen windows that can be opened.

8. Doors shall be tight-fitting and self-closing. Self-closing doors shall not be wedged open. Fly screens shall be fitted on all kitchen doors which open to the outside. Swing doors shall have sight panels. Doors shall be made of fire proof materials other than wood

9. The kitchen shall be air-conditioned and vented in accordance with PDO-SP-1285(B)

“Air Conditioning Installation". A hood, including a primary grease filter, shall be fixed over cooking stove or cookers and an extractor fan of a suitable size shall be installed.

10. Aluminium/stainless steel sheets shall be fitted at cooking stove or cookers areas if porta-cabins are used as kitchens.

11. For washing hands, separate, hands free taps with long handles (surgical) shall be provided in kitchens, together with a liquid soap dispenser, liquid soap and disposable paper towels. Hands shall be washed after every stage of food preparation.

12. Sufficient number of double-unit stainless steel sinks shall be provided with a supply of running hot and cold water, detergents and sanitising solutions. Cloths shall not be used to wipe and dry dishes, crockery and cutlery - air drying or disposable paper towels shall be used.

13. Where large pots are used, a seperate pot washing room shall be provided with AC unit, ventilation, lights and aluminium shelves. Further the platform shall be raised to the working height and the surface shall be tiled for easy cleaning.

14. A separate cleaning equipment storage area is required either at the entrance to the kitchen or inside kitchen to store all the cleaning equipments / PPE in use away from the processing area to avoid contamination. The area shall be appropriate enough and equipped with hooks / SS shelves /SS stands to leave the equipment / PPE to be stored and air dry when not in use.

15. Where a kitchen is located in a permanent building including camps for projects, an

Automatic Dishwashing Machine (ADM) shall be provided. All crockery and cutlery shall be washed by the caterer only

16. At least two electronic fly-killers shall be installed, but advice on numbers & positioning shall be per manufacturer’s specifications. Insect killers which have removable trays are preferred for easy disposal and cleaning

2.4 Dining Hall (Mess)

1. The mess shall be large enough to seat 50% of the camp population. A minimum of 1.5 x 1.4M

2 shall be provided for each employee

Page 10 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

2. Tables and chairs, or reasonably comfortable benches as an alternative, shall be provided and maintained in a clean condition.

3. The mess shall be air conditioned and well lit (minimum light intensity of 300 Lux).

4. At least two electronic fly-killers shall be installed, but advice on numbers & positioning shall be per manufacturer’s specifications. Electronic fly killers shall not be fixed directly near or above tables where food is served or consumed.

5. All doors to the outside shall be self-closing and shall not be wedged open.

6. Wash hand basins shall be provided with a liquid soap dispenser, liquid soap and disposable paper towels. The area shall be well shaded enclosed and protected from dust or sand.

7. Cold drinking water in clean, glass water jugs with lids shall be provided on each table.

2.5 Food Hygiene

2.5.1 Food Handler Fitness

All food handlers must possess a current Medical Fitness Certificate issued by a recognised medical facility. All medical Fi tness for food handlers’ certificates shall contain results of stool microscopy and culture results.

The camp supervisor shall keep copies of all certificates readily available on site. The PDO

Cooperate Public Health Adviser shall have the right to review Medical Fitness Certificates and to stop the work of any employee who fails to produce their Certificate.

All records of medical evaluations that must be carried out annually or periodically as per the recommendation on stool analysis on all food workers should be kept and followed up if necessary.

No personnel to work in a food environment if suffering from skin inflammation, vomiting, diarrhoea, a fever or a sore throat, eye, nasal or ear discharge, illnesses that can be passed on through food such as Salmonella and those caused by other transmitted food handling diseases such as giardia.

Any food handler suffering from any of the above health conditions or cuts in his hands or body shall immediately report to his supervisor and shall be kept away from food handling work until he gets clearance from an approved Medical Practitioner.

Minor abrasions, cuts and burns must be covered with an approved and easily visible waterproof dressing.

Food handlers should be vaccinated against Tetanus, Hepatitis A and Hepatitis B and records of these kept on medical file.

2.5.2 Training Requirements

All Food handlers must receive a Basic Induction within the contractor organisation to Level 1

Food Hygiene before commencing any food preparation activities

All food handlers shall be trained in Level 2 Food Hygiene within the contractor organisation (refmandatory training matrix) the first 3 months of employment.

The training shall include elements of:

• Hazard Analysis and Critical Control Points System (HACCP).

Page 11 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

• Causes of food poisoning.

• Basic bacteriology.

• Personal hygiene.

• Prevention of food contamination.

• Pest control.

• Cleaning.

• Food Hygiene and Food Safety.

Refresher training for all food handlers on Level 2 Food Hygiene shall be conducted every 2 years.

Food handlers shall include store keeper, catering supervisor, rig boy, camp boss chefs, cooks, waiters and kitchen boys (helpers

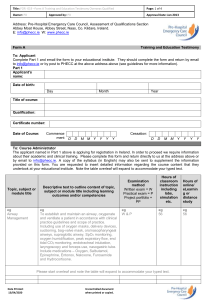

Mandatory Training Requirements

Page 12 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Food Safety Food Safety Mgt (HACCP)

Job Title

Operations/Area

Manager

Induction Level 2 Level 3

Before commencing on-site

Internal before commencing on-site

Level 4 Level 3

Internal

Level 4

Food Hygienist

Camp

Supervisor or

Camp Boss

Before commencing on-site

Before commencing on

- site

Internal before commencing on-site

Internal before commencing on-site

External Within

6 months of employment

Internal

Internal with External assessment

External

Within 3 months employment of

External within

3 months of employment

Head Chef Before commencing on- site

Internal before commencing on-site

Internal with External assessment

Internal

Food Safety

Mgt Auditing

External within

3 months of employment

Assistant Cooks e.g. Butcher,

Baker,

Prep,

Salad

Before on- site commencing

Waiters

Other and

Food

Handlers e.g. store keepers, general assistants

Before commencing on-site

Internal before commencing on-site

2.5.3 Food Handlers and Personal Hygiene

Food handlers’ personal hygiene practices and cleanliness must minimise the risk of food contamination.

Page 13 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Food handlers, including waiters and waitresses must not wear any jewelry other than a plain wedding ring and small sleeper earrings in pierced ears which should not contain stones.

Each food handler shall be provided with a minimum of three uniforms, aprons, caps and nonslip footwear. Uniforms must be in good repair and be easy to clean.

Food handlers must have a clean and tidy appearance, clean hands with short fingernails and short hair which should be covered during food preparation.

Food workers shall understand that they must do whatever is reasonable to stop unnecessary contact with ready-to-eat food, not to sneeze, blow or cough over unprotected food or surfaces likely to come into contact with food

Any injured food handler shall make sure that bandages or dressings on any exposed parts of the body are covered with a waterproof covering.

Food handlers must not smoke or use tobacco or similar preparations where food is handled.

Food handlers must wash their hands with antibacterial soap after every activity. Hand washing must be restricted to wash-hand basins and hand drying to paper towels. Sinks for food equipment must not be used for hand washing.

Hands must be washed always:

On entering and re-entering the kitchen or food service area.

Before handling any prepared foods. After handling all raw food.

After handling all food and non-food waste or refuse.

After any cleaning procedure. After touching ears, nose, mouth or hair. After using the

WC.

Food handlers shall wear plastic disposable gloves whilst serving food. Gloves are to be replaced after each use.

2.5.4 Procurement and Goods Receiving

Purchasers of food commodities must satisfy themselves that food suppliers operate clean/hygienic premises and supply foods to the specified standard.

Specified members of staff should be responsible for the receipt of food supplies and must ensure that no food is placed on the floor unless adequately protected from contamination.

Examination of deliveries must include checks against specified standards to ensure that:

Food commodities are clean, where appropriate and free from obvious contamination.

Canned goods are not damaged (e.g. leaking, rusty or blown) and canned foods are checked for refrigeration requirements (e.g. catering size canned, cooked meats).

Date-coded products are received and able to be used within the period specified.

Perishable goods are of a high quality.

Frozen food is supplied at or below –18°C

Foods requiring refrigeration are delivered at 5°c or below, unless advised differently according to manufacturer’s or supplier’s instructions.

Cook chill foods are supplied at between 0°C and 4°C

Weighing scales used for deliveries should not be used for general kitchen use, and should be thoroughly cleaned between the weighing of different food particularly raw meats.

2.5.5 Food Hazard Procedures

Any items found to be sub-standard on delivery and not conforming to specification must be rejected.

Page 14 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Standard Procedures for the disposal of rejected foods and contingency plans for their replacement must be applied.

Local food hazard procedures for the safe withdrawal and disposal of foods must ensure that such foods are adequately labelled, recorded and set aside and do not re-enter the food chain.

Foods identified as being contaminated must be separated and secured for safe off-site (for) disposal.

2.5.6 Food Storage

1. All dry food shall be stored on stainless steel shelves or stainless steel half/low tables.

The area underneath shall be kept clean at all times (for this reason wooden pallets shall not be used to store food products). Metal or plastic bins with tight fitting covers shall be used for loose grains, flour, etc. And shall be kept on plastic pallets or stainless steel half/low tables

2. Food shall be stored such that it is readily accessible and proper shelving shall be provided where appropriate. Nothing shall be stored underneath benches.

3. Shelves, preferable stainless steel, shall have a non-absorbent finish that is easy to clean. Cupboards and wooden shelves shall not be used.

4. All shelves and racks shall have a minimum clearance of 30cms from ground level.

5. Cleaning chemicals, detergents, mops and brushes shall not be kept in food stores and shall be kept in a separate storage room identified with the Material Safety Data Sheet.

6. The store must always be kept in a clean and tidy condition, and be free of any spillages and pests.

7. Ensure there are no gaps below or above the storage doors, preventing insects from entering the storage area

8. Camp boss office shall not be a part of storage area, this needs to be segregated

Storage is another way to protect food from becoming contaminated or spoiled.

The “first in, first out” (FIFO in accounting) rule, meaning that foods should be used in the order they are delivered, must be utilised. Even “first expiry first out” FEFO is recommended, whichever is applicable

Foods must be stored in a safe and hygienic manner and at the referred temperature as per the table below. The following addition guidelines must be applied:

Foods stored separately from non-food items.

Different types of foods stored separately.

Foods are to be kept clean, cool, covered and pest free.

Stock rotated and dates codes monitored (e.g. ‘Best by’ and ‘Use by’ dates)

Cooked and raw foods clearly identified and stored separately.

Milk, cream and fats separated from all raw products and strong smelling products, which could taint them.

All ambient ( room temperature stored ) packed food to be kept off the floor flours/cereals etc. are to be stored in covered mobile containers after opening.

Raw potatoes and vegetables kept on duckboards or low racking.

Perishable food shall be placed in plastic perforated crates/baskets

Bread kept refrigerated, or in a well-ventilated conditions.

Fresh fruit and vegetables kept in a cool (5 o -8 o ) and well-ventilated environment to keep the fruits and vegetables fresh.

Frozen Food Frozen meat products, frozen vegetables

Minus 18 o C

Page 15 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Refrigerated Food Fresh raw meat products, fresh poultry and wet fish

Milk, cream cheeses, eggs, fats and cooked meats

1 o C to 4 o C

All food items shall be stored in a well-lit and air conditioned room large enough to ensure that an adequate supply of food, which includes extra stock for emergencies, is available at all times.

2.5.7 Cold Stores - Refrigerators and Freezers

Refrigeration is a method of storage by which spoilage is delayed but not prevented.

Freezer/refrigeration equipment must be covered by a 24-hour call out contract, with a specified response time and their temperatures monitored at least daily.

All cold storage units shall have thermometers and their temperatures shall be monitored and recorded three times a day and records kept.

Fish and fish products shall be wrapped and stored in a separate freezer. Where this is not practical, fish shall be placed in separate compartments, or shelves and be thoroughly wrapped.

Walk-in freezers / chillers shall have metal shelves and good lighting (150 lux). They shall be equipped with safety devices to prevent accidental lock-in. A thermometer gauge shall be fixed outside the unit to give temperature readings of the equipment. The gauge shall be maintained in good working order and calibrated on a Monthly basis. Records of calibration shall be kept by electrician in camp or the camp manager

Ice-cream and ice shall not be stored in the same freezer as meat, fish or poultry to avoid cross contamination and also for odour control.

Each item in the walk-in refrigerator, freezer and dry storage should be in a sealed labelled container, or package with the contents and date received.

Freezer burn does not make food unsafe, merely dry in spots. It appears as greyish-brown leathery spots and is caused by air coming in contact with the surface of the food. Cut freezerburned portions away before cooking the food. Heavily freezer-burned foods may have to be discarded for quality reasons.

If there is a power outage, the freezer fails, or if the freezer door has been left ajar by mistake, the food may still be safe to use if ice crystals remain. If the freezer has failed and a repairman is on the way, or it appears the power will be on soon, do not open the freezer door. If the freezer door was left ajar and the freezer continued to keep the food cold, the food must stay safe.

Introduce dry ice, block ice, or bags of ice in the freezer until power is restored; use an appliance thermometer to monitor the temperature.

A freezer full of food will usually be preserved and safe for cooking about 2 days if the door is kept shut; a half-full freezer will last about a day. The freezing compartment in a refrigerator may not keep foods frozen as long. If the freezer is not full, quickly group packages together so they will retain the cold more effectively. Separate meat and poultry items from other foods so, if they begin to thaw, their juices won't drip onto other foods.

To determine the safety of foods when the power goes on, check their condition and temperature. If the food is partly frozen, still has ice crystals, or is as cold as if it were in a refrigerator (5°C), it is safe to use. Discard foods that have been warmer than 5°C for more than

2 hours. Discard any foods that have been contaminated by raw meat juices. Dispose of soft or melted ice cream for quality's sake.

Page 16 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

2.5.8 Food Handling Areas

Unauthorised persons shall not be allowed in areas where food is prepared /handled. A notice to this effect shall be placed outside these areas.

Food handling areas shall be designed, or set up to permit food handlers to work hygienically, and keep the areas clean. The preferred design for food handling areas; preparation section does not overlap with the flow of raw, cooked food and wastes.

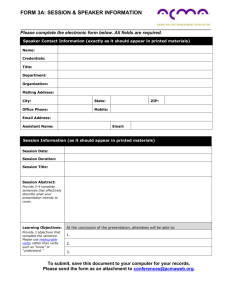

A suggested design for kitchen and handling area in (appendix F).

A specific and measurable cleaning schedule shall be prepared and implemented for each food preparation area and all food preparation equipment:

What is to be cleaned,

frequency of cleaning,

chemicals and process required,

persons responsible,

personal protective equipment used must be documented

PPE signed off by the supervisor.

Waste shall be stored in a clean area/external room and not be permitted to build up in/near food handling areas.

Members of the public who are not food handlers must be restricted from entering food handling areas. Other people, who have legitimate reasons for being in these areas, should be supervised to make sure that they do not handle, sneeze, blow, cough or eat over exposed food or surfaces likely to come into contact with food.

Mobile and temporary premises for storing, preparing and handling food are, as far as is practicable, subject to the same provisions as outlined above.

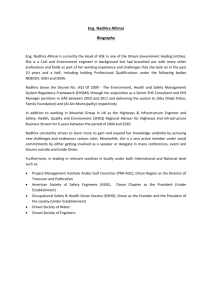

2.5.9 Preventing Cross Contamination

Cross-contamination is the transfer of harmful bacteria to food from other foods, cutting boards, utensils, etc., if they are not handled properly. This is especially true when handling raw meat, poultry, and seafood, so these foods and their juices must be kept away from already cooked or ready-to-eat foods and fresh produce.

To avoid any cross-contamination, cooked and uncooked food shall always be prepared and stored separately.

Pork and pork products shall have separate pots, pans, crockery and cutlery clearly marked and easily identified. Pork shall have separate storage facilities and preparation area.

Separate areas/surfaces shall be provided for preparation of cooked and uncooked foods. All tables must be made of stainless steel and wooden tables are not allowed in kitchens or other food preparation areas. 6 Colour coded cutting boards made of polypropylene or other nonabsorbent synthetic materials shall be provided for meats, chicken, fish vegetables etc. (See

Appendix G- cutting board system). These shall always be kept clean and disinfected after each use. A purpose made polypropylene chopping block shall be provided for cutting large joints of meat. It shall always be kept clean, disinfected, smooth and free of cracks or fissures.

A chain glove shall be provided and used when chopping meat, fish and chicken.

Staff shall adopt a policy of “cleaning as they go” throughout the preparation period.

Page 17 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

All fresh fruits and vegetables consumed without peeling and eaten raw are to be sanitised by immersion in food sanitizer. To follow the label instructions as mentioned in different commercial products. (Immersion in an 80 ppm chlorine solution for 20 minutes; followed by rinsing to remove all traces of chemicals).

2.5.10 Thawing

A facility for defrosting frozen foods shall be provided. This may be either a purpose built "Rapid

Thaw Cabinet", a refrigerator, a chill room with a temperature of 1015°C, or a commercial microwave oven provided with a suitable defrosts programme.

Defrosting times of meat and poultry shall be in accordance with (Appendix B).

Do not assist defrosting by placing the frozen product in water, warm oven, or hot surface. Once food is thawed it shall not be refrozen and must be cooked within 24 hours of thawing.

2.5.11 Cooking

All food should be cooked thoroughly. Food should be cooked as close to the time that it will be served. This reduces the chance of the food becoming contaminated after it has been cooked.

Cooked food shall be stored, either above 63ºC, or below 5ºC to prevent food poisoning pathogens from surviving or multiplying. Cooked food that is to be cooled must not be at ambient temperature for any longer than 90 minutes.

A digital food probe thermometer shall be used to check that the core temperature of all high risk foods has achieved 75ºC.(minimum)

Records of cooking, cold holding and hot holding temperatures should be maintained as part of the food safety management system.

Samples (100g) of all meals served during each meal shall be marked and kept in a freezer for

96 hours before serving. All samples to be labelled and recorded (date and time).

Particular care must be taken when cooking an at risk food such as raw meat, chicken and milk.

These foods must be well cooked, in order to achieve a core temperature of 75°C for 2 minutes and then held at safe temperature, if required for service, at 63°C or above.

2.5.12 Cooling Food

At risk freshly cooked food ( raw meat, chicken and milk) undergoing cooling, either for service cold, or for further processing, must be:

• Kept separate from raw foods.

• Portioned, where appropriate, within 30 minutes of the end of the cooking process.

• Cooled as quickly as possible down to a safe temperature in a controlled environment.

• Cooled without increasing the temperature of the other foods under storage.

Cooked food shall be cooled to 5°C within 6 hours. If a large container of cooked food, for example a beef curry, is placed in a refrigerator for cooling, it can take as long as 24 hours to cool to 5°C. This is very dangerous as the centre of the food will remain warm and allow foodpoisoning bacteria to grow to dangerous levels.

The food must be cooled from 60°C (or higher) to 21°C within 2 hours and from 21°C to 5°C within a further 4 hours.

2.5.13 Reheating of Cooked Foods

Reheating should be limited to recipes which incorporate cooked and chilled ingredients (e.g.

Cauliflower cheese, fish cakes).

Page 18 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Foods to be minced and pureed after cooking should be kept hot during processing to avoid reheating foods.

When reheating foods, a core temperature of 75°C must be achieved for period of 2 minutes.

Where reheating is carried out in comm ercial microwaves oven, the manufacturer’s instructions should be followed.

Reheated foods for hot service, in common with other freshly cooked hot foods, must be kept at a temperature of 63°C or above prior to service.

Once reheated, foods not served must be treated as food waste and disposed of according to locally agreed food hazard procedure. Preheating of all high risk foods should be avoided where possible.

Cold food which is to be served hot will need to be quickly and thoroughly heated at the event until it is steaming hot and then kept hot until it is served. It is best to re-heat the food to a temperature of 70°C to 75° C and hold the food at this temperature for at least two minutes. Use a thermometer to check that all of the food reaches at least this temperature.

Page 19 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

2.5.14 Codex HACCP Food Safety Management System

Catering contractors and sub-contractors put in place shall implement HACCP/Food Safety

Management System in their food handling operations, and maintain permanent procedures based on the Codex Hazard Analysis.

Caterer shall deploy competent food hygiene officer/s with Level 4 Food Hygiene and Level 4

HACCP certificates by an internationally recognised training organisation wherever they are posted as per the requirement of the caterer.

The following principles of HACCP must be applied:

1.

2.

Identify the hazards and potential risks.

Identify the Critical Control Points (CCPs) at the steps at which control is essential to prevent or eliminate a hazard, or reduce it to acceptable levels. Identify critical control points including cross contamination, cooking, cooling, and hygiene.

3.

4.

5.

6.

7.

Establish critical limits at CCPs which separates acceptability from unacceptability. Set up procedures to make sure safety is maintained at all critical control points.

Use the correct signs, tools, and training materials to ensure Implementation of an effective monitoring procedure

Establish corrective actions when a CCP is out of control. Take corrective actions as soon as a CCP is in jeopardy, or when any violations are pointed out by the Health

Department.

Establish verification procedures: Set up a record-keeping system to log all flowcharts, temperature checks the nature and size of the operation

Good hygiene practices and pre-requisite programs should be documented, carried out and monitored.

(Documents must be kept up to date and retained for an appropriate period of 1 years)

.

2.5.15 Clean and Sanitise Thermometer

A stainless steel thermometer with a probe and digital display unit is desired.

As the probe of the thermometer will be inserted into food, the probe must be cleaned and sanitised before it is used to measure the temperature of a different food. If the probe is not cleaned and sanitised, food poisoning bacteria may be transferred from one food to another food. This is especially important when the thermometer will be used to measure the temperature of raw food and then cooked food.

The probe of a thermometer can be cleaned and sanitised by using the following steps:

Washing the probe with warm water and detergent.

Sanitising the probe in an appropriate way (alcoholic swabs are often used).

Rinsing the sanitiser away if necessary (refer to the instructions on the sanitiser).

Allowing the probe to air dry or thoroughly drying it with a disposable towel.

Maintain the thermometer in good working order. Replace batteries if they are empty or drained

(flat) and repair or replace the thermometer if it breaks.

2.5.16 Cleaning and Sanitising Utensils

Clean means ‘clean to the touch’, that is, free from any dirt, dust or food particles that can be seen and does not necessarily smell. Cleaning is the removal of these particles and/or smells.

Page 20 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Sanitise means to apply heat and/or chemicals (or other processes) to a surface so that the number of bacteria on the surface is reduced to a level that is safe for food contact.

Cleaning and sanitising should usually be done as separate processes. A surface needs to be thoroughly cleaned before it is sanitised, as sanitisers are unlikely to be effective in the presence of food residues and detergents.

Food premises must maintain their facilities at a high standard of cleanliness and hygiene. This includes the fixtures, fittings and equipment, as well as those parts of vehicles that are used to transport food.

The standard of cleanliness must ensure that there is no accumulation of garbage, recycled matter, food waste, dirt, grease or other visible matter.

Processing fresh food on or with dirty equipment will transfer bacteria onto the food. Food utensils and equipment must be cleaned and sanitized before each use and between being used for raw food and ready to eat food.

All equipment and work surfaces used in the preparation of a meal must be thoroughly cleaned prior to commencing preparation and cooking of the next meal. Where utensils or equipment have been used continuously over an extensive period to prepare, process or serve the same food, they will also need to be cleaned and sanitized at regular intervals.

Cleaning materials used must stay specific to each area to avoid cross contamination.

Utensils such as cutting boards, bowls and knives need to be thoroughly washed in warm soapy water.

After washing, the utensils should look clean and there should be no food or oily residue.

Ideally an industrial dishwasher with hot wash and drying cycle is desired in large kitchens.

Sinks that are used for washing dishes must be sanitised with a chemical sanitiser or very hot water.

All utensils must then be thoroughly dried before they are re-used. Air-drying is best.

Cleaning personnel should not be involved in the preparation of any foods.

2.5.17 Food Transportation and Food Service

Vehicles used to transport food must be designed and constructed to ensure that food contact surfaces can be cleaned and, if necessary, sanitised to protect the food they are carrying from contamination.

Cooked food shall be transported using food thermal containers. Thermal containers are not to be opened along route. Separate containers for Hot and Cold food.

Hot and cold foods must be delivered promptly to site at safe temperatures and kept covered until served. This is particularly important for “at risk” foods. Delay could lead to bacterial growth, product deterioration and contamination.

Crockery, cutlery and other tableware used in the meal service must be clean and not cracked or chipped and must be transported in closed containers.

Stoves or cookers must be hygienic and service staff must not handle beverage, foods or tableware in a way, which may cause cross contamination.

Page 21 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Hot and cold food should be served at the agreed time of service. Delays could lead to both bacterial growth and product deterioration.

Food temperatures throughout meal delivery must be maintained as follows

Hot foods served at 63°C or above

Cold food to be served at between 1°C and 5°C.

Ice cream to be served frozen at or below –15°C.

2.5.18 Managing Food Allergies

Individual sudden severe allergic reaction to food (Anaphylaxis) is becoming more prevalent in our society. All food handlers should be made aware.

A food allergy is very different to food intolerance. All food allergies must be taken seriously as they can cause life threatening conditions.

Common signs and symptoms of a food allergy include one or more of the following: hives

(raised, red welts on the body), tingling feeling around the mouth, abdominal pain, vomiting and/or diarrhoea, facial swelling, cough or wheeze, difficulty swallowing or breathing, loss of consciousness or collapse (pale or floppy), or cessation of breathing.

The key allergens that trigger these reactions are:

Peanuts, tree nuts (almonds, cashews, Brazil, hazelnut, pistachios, pine nut,) egg, milk, fish, shellfish, sesame, soy and wheat

Where possible such ingredients used in food preparation are to be displayed next to the dish served.

Display a notice: “Please refrain from any food/ or food ingredient previously known to be allergic to you”

2.6 Pest Control

Pest control should be done on a regular, scheduled basis with single point responsibility attached to a particular person responsible for the programme, inclusive of record keeping and management reporting.

General cleanliness and good housekeeping of camps and surroundings shall be maintained as the primary method of pest control. Pests of public health significance include flies, mosquitoes, cockroaches, rats, ants, ferial cats and dogs.

A pest control programme shall be developed and maintained for each camp. Spraying in and around camps shall be carried out periodically once a month minimum. If there is severity of infestation of flies or pests then the frequency of fogging and spraying shall be increased, frequency decided by the prevelant condition.

Food handling area must be regularly inspected for signs of infestation and structural faults which may cause infestation of pests and any sightings (e.g. Cockroaches, ants, insects and mites, rodents, cats and birds) should be reported, recorded and appropriate action taken.

Flash insect killers should be appropriately placed in a suitable site in all food handling area and should be cleaned and maintained on a regular basis.

It is a legal requirement that food premises be kept in such good order, repair and condition as will enable them to be effectively cleaned and kept free from vermin. Regular maintenance is essential in order to comply with the requirement.

Keep areas outside the kitchen free from food waste, other waste materials, weeds and general untidiness.

Page 22 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Keep all waste and unwanted used materials (refuses) storage areas clean. Keep tight-fitting lids on waste bins. Ensure regular collections of waste material (refuse) to prevent accumulation and waste overspill. A separate area for waste food is desirable.

Fly screens attached to doors and window openings are recommended.

Check all incoming materials for infestation.

Keep all food containers off the floor.

Waste disposal is to be cleared regularly to prevent accumulation of food scraps/spillage.

Ensure that grids and filters are kept in place on ventilation openings.

All traces of infestation should be reported immediately to Public Health and maintenance department.

Only the PDO-approved pesticides listed in Table 1 shall be used and to be reviewed yearly

Table 1:

Sr. No

1

Product Name

Dice 2.4 SC

Target Pests

Cockroach & crawling insects

2

3

4

Dice 2.5

Premise SC 200

K-Othrine TF 3.5

Cockroach, ants and crawling insects

Termites

Fogging

5

6

7

8

9

Klerat Pellets

Klerat Wax blocks

Defender Snake Repellent

Epoleon N-200

Epoleon N-70

Rodent

Rodents

Snakes

Deodorizer

Deodorizer

10

11

12

Residex D2.5% EC

Actellic 50EC

Bed-bugs + cockroach

Flies and Ants

Sheltox / Baygon / Actellic aerosols Cockroach, ants and crawling insects

Any other pesticide must be approved by PDO Occupational and Public Health Teams health section prior to use.

All pesticides used must have a SHOC card in accordance with PDO HSE Specification for

Chemicals Management (SP-1194).

Only trained personnel shall be authorised to handle pesticides or to operate pesticide spraying equipment.

Personal protective equipment (PPE) and clothing shall be used in accordance with the relevant

SHOC card and the requirements of PDO PPE Specification (SP-1234).

Keeping of animals shall not be allowed in PDO and contractors camps, e.g. dogs, cats, rabbits etc.

2.7 Sanitary Facilities and Sewage

Toilet and washing facilities shall be provided in, or adjacent to, living quarters, work place and recreation areas. Minimum requirements are specified in (Appendix B).

Page 23 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Toilet and washing facilities shall be kept clean and in good working order at all times.

Toilets and washroom fittings shall be constructed of material which can be easily cleaned. The floors, walls and ceilings shall have a surface finish that can be easily cleaned.

All toilets shall have window openings to the outside air, or be provided with an artificial ventilation system. The proportion of window surface shall be not less than 10% of the floor area.

Lighting of at least 200 Lux shall be provided in all toilets and washing facilities.

A continuous supply of cold and hot water with suitable hand washing soaps shall be provided in, or adjacent to, all toilets and washing facilities.

Floors of showers shall be provided with slip free material.

Shower cubicles shall be provided with doors.

Adequate drainage from all sanitary facilities must be maintained to maintain hygiene standards.

Sewage effluent shall be managed in accordance with PDO Aqueous Effluents Specification

(SP-1006). Sewage sludge shall be disposed of in accordance with PDO Waste Management

Specification (SP-1009).

2.8 Waste Management

Domestic wastes (including kitchen wastes), office wastes and clinical wastes shall be stored, collected and disposed of in accordance with PDO Waste Management Specification (SP-1009).

External waste areas should be kept clean and receptacles covered at all times to prevent pests.

Kitchen waste bins need to have lids thats are foot operated.

Procedures must be in place for the clean and safe internal collection, storage and disposal of food and non-food waste.

Food waste and non-food refuse should be removed regularly from waste collection points and must not be held overnight within the food handling areas.

Internal storage disposal area should be a closed area/ or room with a door to avoid fly infestation of the camp. The floor should be cemented and easily cleanable to maintain the disposal area clean and free of odour. The kitchen waste, storage area should be screened, well ventilated, hygienic, tidy and pest proof.Kitchen waste to be stored in closed skips in case of mobile camps.

2.9 Water Requirements

Water for drinking, cooking, washing and toilets in camps shall be provided from PDO-approved sources.

A minimum water supply of 250 litres per person per day shall be provided.

Water shall be distributed from source by pipes made from UPVC, steel or cast-iron materials approved by the company. No lead pipes shall be used.

Water shall be stored in aboveground tanks made either in stainless steel, galvanised steel or reinforced fibre glass.

Page 24 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Water supplies for domestic and for food handling/drinking shall be separate with separate tanks and pipelines. No criss crossing of pipes to avoid cross contamination to water and pipeline

Water supplies for domestic use shall be disinfected by chlorinating so that a residual free chlorine level of 0.2 mg/l to 0.5mg/l is maintained throughout the distribution system. Check and record the chlorine level daily.

If water is trucked in, the tanker truck shall be licensed in accordance with ROP requirements.

The driver and helper shall have valid Health Certificates issued by the Ministry of Health and registration licence/registration. Copies of each of these certificates shall always be carried in the vehicle, available for inspection at any time.

All water tankers shall be painted blue (ref. Diwan of Royal Court, Muscat Municipality Local

Order No. 21/90 "Colours of Tankers") and shall have the words "POTABLE WATER" written in white on both sides of the tanker in Arabic and in English.

Water tankers shall not be used for any other purpose and shall be kept clean and in good repair. Each water tanker driver and helper shall have a valid health and registration licence/registration.

Water supplied to camps shall comply with the chemical and bacteriological limits specified in

Omani Standard 8/2006 (refer to Appendix D). Bacteriological limits in water storage tanks shall be checked monthly and the tanks shall be cleaned annually. The line or contractor medic shall collect water sample and send it to Ministry of health or reputable Laboratory for bacteriology and chemicals analysis.

Water/ice sampling procedure refers to (Appendix C).

2.10 Laundry

Laundry services shall be provided for all personnel accommodated in camps. The service shall include washing of bed linen, towels, work clothing and personal clothing.

Adequate facilities for washing and drying clothes are provided. Sinks or tubs with hot and cold water, cleaning soap and drying lines to providing washing machines and dryers.

Special laundry facilities (washing machines) should be provided for work clothes that are in contact with oils or chemicals (e.g. grease or pesticides).

Adequate drainage from laundry facilities must be present to ensure stagnant water does not become a potential for disease transmitters such as mosquitoes, flies etc.

Laundry facilities shall be kept clean and maintained in working order.

Individual laundry should be washed and dried separately.

Laundry from any individual that has an infectious disease shall be stored and washed separately from other laundry. A PDO Medical Officer should be consulted to determine any specific washing and handling requirements.

Page 25 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Detergents and other laundry-related chemicals shall be stored in a ventilated room, adjascent to the laundry working area. The chemical storage room shall be well ventilated, have adequate lighting, with air conditioning and exhaust fan

A drying area that is protected against dust and animals shall be provided.

2.11 Recreational Facilities

Recreational facilities shall be provided in all camps. As a minimum, indoor facilities shall include TV, VCR, videos, ‘keep fit’ exercise rooms with appropriate equipment and games.

Outdoor facilities shall be provided where practicable and may include a football/cricket pitch and tennis court.

In camps where swimming pools are provided, these shall be constructed and operated in accordance with PDO-SP-1280 "Guidelines to Swimming Pools". The water quality shall comply with the limits defined in (Appendix E).

2.12 Safety Precautions and First Aid Requirements

The employer must ensure that qualified first-aid can be provided at all times. Appropriately equipped first-aid stations shall be easily accessible throughout the place of work.

Eye-wash stations and/or emergency showers shall be provided close to all workstations where the recommended first-aid response is immediate flushing with water.

Sites shall have in place written emergency procedures for dealing with cases of trauma or serious illness up to the point at which care of the patient can be transferred to an appropriate medical facility.

Stocked first aid boxes must be stored in a cool dry place, but easily accessible to employees.

Installing battery-powered smoke detectors in the facility is advisable.

Fire extinguisher must be installed in the kitchen facility. All kitchen staff must be made aware of the dangers of fires and trained in the use of a fire extinguisher.

Plan two emergency escape routes from each room. Fire drills must be regularly carried out.

Page 26 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

3 Appendices

3.1 APPENDIX A - Thawing and Cooking Times of Frozen Meat and

Poultry

Weight

(kg)

2.25

4.50

6.75

9.00

Approximate thawing time at 10 o C - 15 o C

(Hours)

15

18

24

30

Minimum cooking time in foil at 180 o C

(Hours)

2.50

3.50

4.75

5.75

Page 27 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

3.2 APPENDIX B - Minimum Sanitary Facilities

Type of

Occupancy

Base Camps

Lavatories

1 per persons

Urinals

10 1 per 25

Showers

1 per 10

Revision: 5.0

Effective: June-12

Wash-Hand

Basins

1 per 10

Workshops

Road Camps

Survey parties

Rigs (Site)

1 per 20

1 per 20

1 per 20

1 per 20

-

-

1 per 25

-

1 per 15

1 per 20

1 per 20

1 per 25

1 per 20

1 per 20

1 per 20

1 per 25

Rigs (Camp)

Mobile Camp

1 per 10

1 per 20

1 per 25

-

1 per 10

1 per 25

1 per 10

1 per 25

Construction site

1 per 30 1 per 30 Optional 1 per 30

NOTE: Where any sanitary fittings form an integral part of an individual's living quarters, the number of similar fittings required in communal sanitary facilities in that area may be reduced in agreement with the PDO Occupational and Public Health Teams.

Page 28 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

3.3 APPENDIX C – Correct Sampling of Drinking Water for Bacteria

1. Sample results shall comply with the requirements of SP1232 and shall be collected at least once a month. Representative samples shall be collected from the source, from kitchen(s) and from staff rooms.

2. Sample containers must be sterile and contain reducing agent (sodium thiosulphate). 500 mL sample bottles are available from the MAF Clinic laboratory. Purchase sample bottles from local

CDC laboratory or try ordering from the MAF clinic on x77437. DO NOT use damaged or open containers and never rinse them.

3. Select a tap that is supplying water from a service pipe connected directly to the main. A minimum of 4-9 sampling taps shall be available for populations under 500 and nine sampling points from 501 to 5000 staff. Rotate between taps to obtain representative samples.

4. Select a tap that appears to be clean, and without leaks to the outside of the faucet. Use an alcohol wipe to sterilise the tap if it is specifically required for sampling, or dip a cotton wool swab in 70% ethanol and disinfect the tap by lighting the swab and a holding it under the tap.

5. Use only cold water for sampling. Open the tap fully and let run for 2 to 3 minutes, or a time sufficient to allow clearing of the service line. Reduce the flow to allow filling of the bottle without splashing. It is important that the container be kept closed until immediately before sampling and that the sample is representative of the water system being tested.

6. Fill the container without allowing fingers, tools, or other foreign objects to come in contact with the water. Leave sufficient headspace in container to allow for mixing by shaking before examination.

7. Samples shall be labelled with the location and the time and date of collection.

8. Samples shall arrive at the laboratory within one hour of sampling, or be refrigerated below

10°C in a cool box with ice bricks. SAMPLES must reach the laboratory within 24 hours or they will be refused.

9. Separate samples shall also be collected for chemical analysis including pH, turbidity and

Total Dissolved Solids. The local PDO Production Chemistry laboratory should analyse these.

10. Water sample results shall be made public to all staff monthly.

CDC laboratories (Public Health Labs ) can conduct the water analysis.

CDC Nizwa, Haima, Sohar, Sur, Salalah, Ibra, Ibri, Khasab, Buraimi, Rustaq and CPHL Darsait

Muscat

Page 29 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

3.4 APPENDIX D - Drinking Water Standards (Oman STDS 08/2006)

Physical Properties

Drinking water shall be colourless, tasteless, odourless and free from turbidity.

Chemical Properties a) Toxic chemicals

Substance

Maximum Permissible

Level (mg/l)

Lead

Selenium

Arsenic

Cadmium

0.01

0.01

0.01

0.003

Cyanide

Mercury

Boron

0.07

0.001

0.5 b) Chemicals that have special effects on health

Substance

Maximum Permissible

Level (mg/l)

Fluoride

Nitrate

1.5

50 c) Chemicals that affect the suitability of drinking water

Parameter Maximum Permissible

Level (mg/l)

Total Dissolved Solids

Copper

Iron

Magnesium

Manganese

Zinc

Calcium

Chloride

Sulphate

Phenols

1000

2

1

30

0.4

3

200

600

400

0.002

Total hardness pH range d) Chlorine

500

6.5 – 8

The minimum residual chlorine concentrations required for the effective disinfection of drinking water is 0.2 – 0.5 mg/l.

Page 30 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Bacteriological

Parameter Concentration Limit

Escherichia coli (E/coli)

Coliform organisms nil / 100 ml nil / 100 ml

Notes:

Throughout any year, 95% of samples examined should not contain any coliform organisms.

Samples for both chemical and bacteriological analyses shall be collected from the R.O. plant and kitchen and sent to the Ministry of Health, or reputable laboratories, for analysis by the line? or contractor medic?.

Frequency of sampling:

Check and record chlorine levels daily.

Bacteriological and chemical limits in water storage tanks shall be checked monthly.

Water storage tanks shall be cleaned annually.

Page 31 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

3.5 APPENDIX E - Public Health Standards for Swimming Pools

1. Bacteriological

Parameter Concentration Limit

Total colony (Plate) count

Total coliform not more than 100/ml not more than 10 per 100 ml

Escherichia coli (E. coli) Nil

Compliance with these limits shall be checked weekly.

2. Chemical

Parameter Concentration Limit

Free chlorine

PH

Alkalinity (calcium carbonate)

Total Dissolved Solids (TDS)

1.0 - 3.0 mg/l

7.2 - 7.8

100 - 200 mg/l

1500 mg/l

Compliance with these limits shall be checked twice per day.

3. Physical

Parameter Requirement

Visibility

Sedimentation

Colourless and clear water such that the bottom at the deepest end of the pool is clearly visible at all times.

No algae growth

No sediment or dirt at the pool bottom

Compliance with these limits shall be checked twice per day.

Page 32 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

3.6

Petroleum Development Oman LLC

APPENDIX F - Plan of Well-Designed Kitchen

Revision: 5.0

Effective: June-12

Page 33 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

3.7

Petroleum Development Oman LLC

APPENDIX G – Cutting-board System

RED

BLUE

YELLOW

GREEN

BROWN

WHITE

WHITE H/D BUTCHERY BLOCK

Revision: 5.0

Effective: June-12

CUTTING-BOARD SYSTEM

RAW MEAT

RAW FISH

COOKED MEAT

SALAD/FRUIT PRODUCTS

VEGETABLE PRODUCTS

DAIRY AND BAKERY PRODUCTS

Large joint of meat or fish

Page 34 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

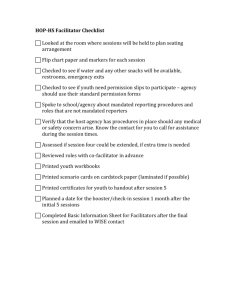

3.8 APPENDIX H – Camp Inspection checklist

Contract No.: Contractor:

Revision: 5.0

Effective: June-12

Site Supervisor: Date :

Location:

Not Applicable = N/A

Inspected by :

General Guidelines

The information in the description section is to assist personnel during the inspection; however, personnel conducting this inspection must be thoroughly familiar with the information relating to camps in the following Company manuals :

PDO HSE SP 1230, 1231, 1232

Public Health inspections are to include all aspects of HSE

Suitable building layout for Receiving, Storage, cooking, dishwashing, food serving and dining areas, accommodation for the staff with sanitary facilities, Laundry, Recreation facilities and medical services.

All the buildings or porta cabins should be compliant with specifications in terms of safe building with no associated known hazards.

Fitted with all emergency escape measures and Exits

Availability of fire extinguishers, fire alarms, escape route signs, escape route maps, emergency telephone numbers, assembly points etc

Electrical: cabling/ earthling/ water resistant plugs etc.

Water supply facilities

Water drainage and sewage disposal

Waste disposal and waste management

Pest control and eradication

Rating System will be used from 1-5

1= Very Poor condition- Totally Unacceptable

2= Poor Condition- Unacceptable

3= Slightly acceptable with great preservations

4= Acceptable with preservations

5= Excellent condition

The Public Health Checklist has been modified to two categories of inspection:

Page 35 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

I. Inspection of food safety

II. Welfare Inspection

Inspection of food safety:

1. Receiving, following FIFO, documenting expiry dates, sorting and storage of food items

2. Cooking, labeling, serving and food sampling

3. Dishwashing, utensils drying and storage

4. Sanitizing the boards, knives, chain glove etc

5. Food handlers hygiene

6. Food handlers fitness to work

7. Food handlers training in food safety

8. Hygienist and camp boss certification on food handling

9. Dining hall, Bain Marie and food serving areas

10. Periodic reviews/inspections or audits per year

11. Water bacteriologic/chemical analysis

Welfare Inspection

1. Accomodation

2. Sanitary facilities

3. Recreation

4. Laundry

5. Medical facilities

Food Safety Inspection Checklist

Page 36 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

S/N DESCRIPTION

Food Receiving & Storage

REMARKS ACTIONS RATING

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Approved vendors

Frequency of supply

Records of suppliers

Method of storage

FIFO Assurance

Expiry dates display

Suitable Storage area space

Separate storage areas for different food items. Frozen, Dry, vegetables & fruits.

Separate storage for chemicals with Shoc

Card display

Secure sound storage area with external doors fitted with brushes or rubber barrier to prevent light / insect entry

Self closing fly screen doors fitted to all external doors in such a way as to provide insect proof ventilation while main door is open.

Electric fly killer installed and operational.

The store is clean and free of any spillage and pests

S torage cleaning’ include light, AC,

Windows, exhaust fans etc.. schedule provided

Frozen food items

15. Suitable and adequate cold storage and refrigerated equipment are available.

16. Requirements:

Frozen food at minus 18

C+ 2

C

Chilled and refrigerated food from 1

C to 4

C.

17. Sufficient number of refrigerators and chest freezers are provided.

18. Temperatures for freezers and chillers are recorded a minimum three times daily

19. Record charts posted on the chillers/freezer unit.

S/N DESCRIPTION

20. Fish and fish products are stored in a

REMARKS ACTIONS RATING

Page 37 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

21.

22.

23.

24. separate freezer. Fish must be firmly wrapped if mixed with chicken/meat

If 'walk-in' freezers are used -

Stainless Steel shelves are available, lighting is adequate (150 Lux), safety devices to prevent accidental lock-in are provided, and a thermometer gauge is fixed outside the unit and portable inside

No external packaging should be present in the freezers.

Clearance provided between freezer/fridges to access the switch at plug socket.

All freezers labelled with their stored contents. (pictures recommended for language barrier)

Dry Food Store is separate from Vegetable & Fruit Store

25. Food items are stored in a well lighted

(150 lux) and air conditioned room large enough with respect to size of the camp to ensure adequate supply of food is available and not

26. congested.

Wall mounted thermometer provided.

(10-16 o C)

27. The storage of food is in such a way that allows the "First-in, First-out" or

FIRST EXPIRY FIRST OUT practice to be observed and expiry date clearly available.

28. Dry food is stored on Stainless Steel shelves which are non-absorbent.

29. The area underneath is kept clean and have a minimum clearance of

30cm from ground level.

30. For loose grains, flour etc., use metal or plastic bins with tight fitting covers on plastic pallets.

31. FIFO tags used on open grain & flour sacks.

32.

33.

Plastic baskets are used to store loose vegetables. Sacks of vegetables to be stored on plastic pallets.

Plastic baskets are used to store loose Fruits. Sacks of Fruits to be stored on plastic pallets.

S/N DESCRIPTION REMARKS ACTIONS RATING

Page 38 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

Kitchen

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

Kitchen is securely anchored against strong winds.

Walkways and stairways to kitchen are free of tripping hazards.

Walkway access to gas cylinder storage area provided.

Gas cylinder emergency shutdown system active. (e.g. free falling weight

& complete shutdown achieved)

On line gas bottles are located outside and chained. A block work separation wall is provided (in cases where the cylinders are closer than 5m from combustible material) and the enclosure is well ventilated.

'No smoking' signs are displayed near the gas cylinders.

Inspection of gas cylinder date is recorded if cylinder is more than

5years since manufactured.

Earthling / grounding for the kitchen is attached.

External caballing is either of an armored / outdoor specification or contained within rigid / flexible conduit.

External wall mounted fire extinguisher provided for kitchen, within affixed inspection date and sun shade provided.

Kitchen is big enough to cater for the number of employees served. (e.g. approx. 1 m 2 per person served).

All doors to kitchen are fitted with self closing mechanisms.

Signage provided for emergency escape route on every door.

Internal doors from canteens to kitchen are fitted with un-authorized access signage.

All doors to kitchen are locked when kitchen not in use.

Page 39 Document Title Printed 15/04/20

The controlled version of this CMF Document resides online in Livelink ®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

Revision: 5.0

Effective: June-12

S/N DESCRIPTION