Table 1 Substrate specificity for purified laccase activity

Supplementary Information

Supplementary Methods

Fungal strain and culture conditions

Stock cultures of Pleurotus sp. (strain ‘MAK-II’) were maintained on the potato dextrose agar

(PDA) slant at 4 °C in the dark. The mycelium from the slant was transferred to PDA plates and incubated at 30 °C for 7 days. Mycelial discs from the peripheral region of actively growing culture were used as inoculum. The production medium contains (g l

-1

): 10.0 mannitol, 2.0 yeast extract, 2.0 L-proline, 0.3 erythromycin, 1.0 KH

2

PO

4

, 0.5 MgSO

4

, 0.01 CaCl

2

, 0.001 FeSO

4

, 0.1

Na

2

HPO

4

, 0.62 CuSO

4

, 0.0275 adenine, and 2.0 biotin in 1 l distilled water (pH 5.0). Laccase production was carried out under submerged fermentation in a laboratory scale bioreactor (5 l working volume capacity). Three liters of the production medium were added to the reactor and sterilized for 20 min at 121 °C at 15 psi. The pre-cultures were prepared in 250-ml Erlenmeyer flasks containing nutrient medium with glucose (20 g l

−1 ) in static conditions at 30 °C. Sevendays-old pre-cultures were homogenized before transferring into the medium in the bioreactor

(20 g l

−1

wet mycelium). The agitator and flow rate of filter-sterilized air were set at 100 rpm and

3 l h

−1

, respectively. The internal temperature of the bioreactor was maintained at 30 °C. After 3 days incubation, vanillic acid (1 mM) was added to the production medium as inducer to enhance laccase production.

Laccase gene amplification using degenerative primers from Pleurotus sp. MAK-II

Laccase gene amplification was performed with primers Cu1F: 5′-CAT(C) TGG CAT(C) GGN

TTT(C)TTT(C) CA-3′ and Cu2R: 5′-G G(A)CT GTG GTA CCAGAA NGT NCC-3′ according

to the method of D'Souza et al. (1996).

1

Effect of metal ions and various reagents on laccase activity

Different metal ions (1 mM) Al 3+ , Ca 2+ , Cd 2+ , Co 2+ , Cr 2+ , Cu 2+ , Fe 2+ , Mg 2+ , Mn 2+ , Na + , Ni 2+ ,

Hg

2+

, and Zn

2+ , or various inhibitors (1 mM; that included cyanide, β-mercaptoethanol, dithiothreitol, ethylenediaminetetraacetic acid, and sodium azide, or various surfactants (1% w/v and v/v; viz.: cetyltrimethylammonium bromide, Sarkosyl, SDS, Tween 20, Tween 80, and

Triton-X 100), or various solvents (5% v/v; that included acetone, acetonitrile, butanol, dimethyl sulfoxide, dimethylformamide, dichloromethane, ethanol, methanol, and isopropanol) were examined on laccase activity by pre-incubating the enzyme in above chemicals (metal ions, inhibitors, surfactants, and solvents ) for 1 h and the remaining enzyme activity was assayed under standard assay condition using 1 mM ABTS as substrate in sodium acetate buffer (100 mM, pH 4.5) at 30 °C. The activity assayed in the absence of any additives (metal ions or inhibitors or surfactants or solvents) was defined as 100%.

2

Supplementary Tables

Supplementary Table 1 Summary of purification steps of extracellular laccase from Pleurotus sp. MAK-II

Yield Purification step Total protein Total activity

(mg)

Culture supernatant 368.4

(Units)

82,000

104 44,800

Specific activity

(Units/mg protein)

222.5

430.7

Purification

(fold)

1

1.93

100

54.6 (NH

4

)

2

SO

4

Fraction

70% (w/v)

Sephadex G-100

DEAE cellulose

36

15

38,000

24,200

1055.5

1613.3

4.7

7.25

46.3

29.5

3

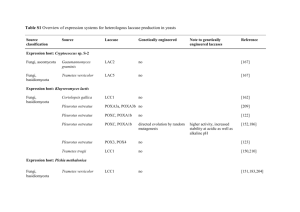

Supplementary Table 2 Comparison of physicochemical properties of laccase from Pleurotus sp. MAK-II and laccases from other white-rot fungi

Name of fungi Molecular mass (kDa)

Cerrena maxima 57.0 pI

3.5

Optimum pH Optimum

4.0-4.2 temperature

(°C)

50

Reference

–

3.0 55

Ganoderma fornicatum

Ganoderma lucidum

Ganoderma lucidum

Ganoderma lucidum

Ganoderma lucidum

Ganoderma lucidum

63.7

38.3

32.18

42.33

43.01

56.04

Ganoderma lucidum

57.17

Lentinula edodes 58.5

Pleurotus eryngii 60.0

Pleurotus eryngii 34.0

4.56

4.79

4.56

4.56

4.71

4.53

–

–

–

5

–

–

–

–

–

3.5

7

3-5

55

–

–

–

–

–

40

50

70

40.0 – 4 50

Pleurotus ostreatus

Pleurotus sajorcaju

Pleurotus sajorcaju

Pleurotus sajorcaju

Pleurotus sajor-

35.0

45.0

70.0

61.0

–

–

–

–

–

–

–

5.0

50

50

50

40

4

caju

Pleurotus sajorcaju

Pleurotus sp.

MAK-II

Pycnoporus sp.

SYBC-L1

Pycnoporus sp.

SYBC-L1

61.0

43.0

55.89

63.07

Trametes pubescens

Trametes pubescens

60.0

120.0

Trametes sp. Ha1 62.0

Trametes sp. Ha1 62.0

–

–

–

–

3.2

–

3.0

5.9

5

6.0

6.0

5.0

5.0

6.0

4.5

3

2.5

70

70

60

60

65

70

25

60

Present study

Supplementary Table 3 Substrate specificity for purified laccase activity

Substrate

ABTS

Guaiacol

Pyrogallol p -Phenylenediamine

Catechol

Absorbance at nm Relative activity (%)

436 100

436 98

450

487

450

82

55

38

Ferulic acid

Tyrosine

Veratryl alcohol

287

280

310

18

0

0

Values represent the mean of three independent experiments, with a maximal mean deviation of ± 5 %. Enzyme activity was measured under standard assay conditions, using ABTS as substrate.

6

Supplementary Table 4 Effect of different metal ions, inhibitors, surfactants, and solvents on purified laccase activity

Chemicals (concentration)

Control (None)

Mg 2+

Mn 2+

Na +

Ni 2+

Hg 2+

Zn 2+

Metal ions (1 mM)

Al 3+

Ca 2+

Cd 2+

Co 2+

Cr 2+

Cu 2+

Fe 2+

Inhibitors (1 mM)

Sodium azide

Cyanide

EDTA

DTT

β-Mercaptoethanol

Surfactants (1%, w/v and v/v)

SDS

Sarkosyl

CTAB

Tween 20

Tween 80

Triton-X 100

Solvents (5%, v/v)

Acetone

Acetonitrile

Butanol

Relative activity (%)

100

96

110

90

79

39

6

47

94

106

75

83

35

125

82

89

96

98

95

90

32

11

54

0

0

100

27

35

7

DMSO

DMF

DCM

Ethanol

92

51

67

98

Methanol

Isopropanol

95

97

Values represent the mean of three independent experiments, with a maximal mean deviation of ± 5 %. Enzyme activity was measured under standard assay conditions, using ABTS as substrate.

8

Supplementary Fig. 1 Chemical structures of the different dyes (a) Congo Red (diazo dye), (b)

Remazol Brilliant Blue R (anthraquinone dye) and redox mediators, (c) 1-hydroxybenzotriazole,

(d) p-coumaric acid, (e) violuric acid, and (f) syringaldehyde used in this study.

9

References

Bettin F, da Rosa LO, Montanari Q, Calloni R, Gaio TA, Malvessi E, da Silveira MM, Dillon

AJP (2011) Growth kinetics, production, and characterization of extracellular laccases from Pleurotus sajor-caju PS-2001. Process Biochem 46:758-764

D'Souza TM, Boominathan K, Reddy CA (1996) Isolation of laccase gene-specific sequences from white rot and brown rot fungi by PCR. Appl Environ Microbiol 62(10):3739-3744

Gaitan IJ, Medina SC, Gonzalez JC, Rodriguez A, Espejo AJ, Osma JF, Sarria V, Almeciga-Diaz

CJ, Sanchez OF (2011) Evaluation of toxicity and degradation of a chlorophenol mixture by the laccase produced by Trametes pubescens . Bioresour Technol 102:3632-3635

Huang WT, Tai R, Hseu RS, Huang CT (2011) Overexpression and characterization of a thermostable, pH-stable and organic solvent-tolerant Ganoderma fornicatum laccase in

Pichia pastoris . Process Biochem 46:1469-1474

Koroleva OV, Gavrilova VP, Stepanova EV, Lebedeva VI, Sverdlova NI, Landesman EO,

Yavmetdinov IS, Yaropolov AI (2002) Production of lignin modifying enzymes by cocultivated White-rot fungi Cerrena maxima and Coriolus hirsutus and characterization of laccase from Cerrena maxima. Enzyme Microb Technol 30:573-580

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680-685

Liu L, Lin Z, Zheng T, Lin L, Zheng C, Lin Z, Wang S, Wang Z (2009) Fermentation optimization and characterization of the laccase from Pleurotus ostreatus strain 10969.

Enzyme Microb Technol 44:426-433

10

Manavalan T, Manavalan A, Thangavelu KP, Heese K (2012) Secretome analysis of

Ganoderma lucidum cultivated in sugarcane bagasse. J Proteomics 77:298-309

Manavalan T, Manavalan A, Thangavelu KP, Heese K (2013) Characterization of optimized production, purification and application of laccase from Ganoderma lucidum . Biochem

Eng J 70:106-114

Murugesan K, Arulmani M, Nam IH, Kim YM, Chang YS, Kalaichelvan PT (2006) Purification and characterization of laccase produced by a white rot fungus Pleurotus sajor-caju under submerged culture condition and its potential in decolorization of azo dyes. Appl

Microbiol Biotechnol 72:939-946

Nagai M, Sakamoto Y, Nakade K, Sato T (2009) Purification of a novel extracellular laccase from solid-state culture of the edible mushroom Lentinula edodes . Mycoscience 50:308-

312 Nakatani M, Hibi M, Minoda M, Ogawa J, Yokozeki K, Shimizu S (2010) Two laccase isoenzymes and a peroxidase of a commercial laccase-producing basidiomycete,

Trametes sp. Ha1. New Biotechnol 27:317-323

Ueda M, Shintani K, Nakanishi-Anjyuin A, Nakazawa M, Kusuda M, Nakatani F, Kawaguchi T,

Tsujiyama S, Kawanishi M, Yagi T, Miyatake K (2012) A protein from Pleurotus eryngii var. tuoliensis C.J. Mou with strong removal activity against the natural steroid hormone, estriol: purification, characterization, and identification as a laccase. Enzyme Microb

Technol 51:402-407

Wang HX, Ng TB (2006) Purification of a laccase from fruiting bodies of the mushroom

Pleurotus eryngii . Appl Microbiol Biotechnol 69:521-525

11

Wang Z-X, Cai Y-J, Liao X-R, Tao G-J, Li Y-Y, Zhang F, Zhang D-B (2010) Purification and characterization of two thermostable laccases with high cold adapted characteristics from

Pycnoporus sp. SYBC-L1. Process Biochem 45:1720-1729

Zucca P, Rescigno A, Olianas A, Maccioni S, Sollai FA, Sanjust E (2011) Induction, purification, and characterization of a laccase isozyme from Pleurotus sajor-caju and the potential in decolorization of textile dyes. J Mol Catal B: Enzym 68:216-

222 http://dx.doi.org/10.1016/j.molcatb.2010.11.008

12