Architechtural Concepts Document

advertisement

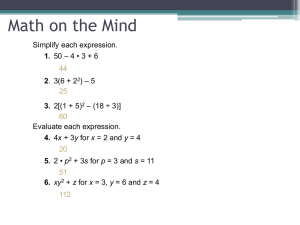

Architectural Concepts Applicable To The Space Island Group Lab-ET Space Station Configuration Prepared For: By: ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION ABSTRACT Space Island Group’s Lab-ET Space Station represents an order of magnitude increase in scale over prior space stations MIR and ISS. SIG’s commercial approach to Lab-ET utilization also represents a significant departure from historically federalized programs. SPACEHAB, Inc. is the preeminent commercial developer/operator of manned space flight infrastructure utilized in the context of these federal programs. SPACEHAB’s Strategic Programs Group has prepared these architectural concepts for commercial applications of the Lab-ET in areas of pharmacological and biological research and on-orbit production, with implications for other commercial applications. INTRODUCTION A variety of architectural and operational concepts are described through text and sketches in the following pages. Many of these concepts are represented, at least in part, in the finished renderings produced by SPACEHAB for SIG and accompanying the delivery of this paper. These concepts seek to optimize the Lab-ET design in areas of technical and operational efficiency, versatility, safety and economy while satisfying the functional requirements of commercial tenants and facility operations. These sketches provided the basis for basic scale models produced using Pro-E CAD. The CAD models were used to validate the scale of the general architectural concepts and were then used to generate perspective views of the architecture suitable for use in generating the artist’s renderings delivered with this paper. The team of artists, CAD operators and designers then cooperatively populated these views with selected outfitting and operations concepts to provide a better vision of how they work together as a system to address the commercial objectives of Space Island Group. SCALE AND MODULARITY As compared to NASA’s ISS, the Lab-ET offers an order of magnitude increase in the scale of the facility. Envisioned commercial applications represent a similar increase in the scale of operations and installations to be hosted by the Lab-ET. SPACEHAB’s outfitting concepts reflect these increases in scale by defining a standard modular outfitting increment offering approximately 1 cubic meter of volume and emulating the role of the Middeck Locker Equivalent (MLE) outfitting increment on ISS (One MLE offers approximately 1/16 of a cubic meter.). NASA’s ISS configuration offers modularity at the International Standard Payload Rack (ISPR) level, with each ISPR offering accommodations for approximately 2 cubic meters of outfitting, and the entire ISS offering accommodations for dozens of ISPRs. One ISPR would constitute a major installation aboard ISS. By comparison, SPACEHAB’s architecture for the Lab-ET expands on the relative scale of standard increments with each “deck” emulating the role of the ISPR in the NASA ISS architecture and operations approach but at a significantly larger scale. Each bay environment in the Lab-ET architecture emulates the role of an ISS module and supports the allocation of bays to commercial users in a similar fashion as the ISS incorporates modules provided by and allocated to the use of the International Partners. 2 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION These modularity concepts promote efficiency in the development, design, marketing and commercial utilization and operations of Lab-ET facilities while reflecting Space Island Group’s vision of significant expansion of commercial activities in low-earth orbit. The modularity is intended to apply not only to habitation and commercial installations in the Lab-ET, but also to facilities infrastructure installations constituting the core systems supporting the entire Lab-ET as a viable orbiting facility. GENERAL INTERIOR SEGMENTATION APPROACH Though not extensively traded in the scope of SPACEHAB’s current design study, various high-level options were considered for segmenting the Lab-ET into discrete regions suitable for recurring modular outfitting approaches. SPACEHAB elected to pursue designs based on segmentation normal to the cylindrical axis of the structure, similar to prior Space Island Group architectures. A modularity concept that emulates the natural design of a bee-hive was selected as the fundamental theme and was applied in various scales within the prescribed Lab-ET diameter to identify the most favorable scale for the cells and related outfitting from the standpoint of packaging efficiency and human scale concerns. The resulting 19-cell deck configuration became the progenitor for many other dimensional aspects of the facility concept. With the cell scale established, pallet proportions were dictated by a requirement for unrestricted outfitting transportability within the facility. This pallet envelope, along with clearance considerations and additional human-scale concerns, resulted in the separation distances between adjacent decks at bay separations (intra-deck regions), and deck-to-deck separation within the bay environments. Recognizing that the Lab-ET primary structure would be a derivative of a Shuttle ET, and therefore may not present identical dimensions or features as the Shuttle ET, SPACEHAB did not expand efforts to optimize these proportions across the entire Lab-ET length, so the ideal total number of decks in a Lab-ET is still to be determined. (See descriptions for Sketches FTE071803.01 and FTE072103.03 and .04 for additional discussion of facility-level scale issues and concepts.) The resulting configurations and concepts are described in detail through the remainder of this paper, offering in-depth information on philosophies and concepts applicable to the architecture represented in those renderings. DEFINITION OF TERMS For purposes of common reference, the following terms are used throughout this document and are offered as standard terms to be adopted in future developments. Lab-ET Orbital Industrial Base (OIB): The Lab-ET Space Island Space Station concept outfitted to support multiple industrial tenants. Thus configured, the OIB may host alternative technology types and processes in distinct and proprietary commercial settings. The OIB can also accommodate installations satisfying habitation and physical plant applications based on the same architecture that supports its commercial tenant facilities. 3 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION Facility Crew: Members of the OIB crew who are dedicated to the maintenance and operation of the Space Island Group facility itself, and who provide facility management and operations support services to the facilities industrial client base and Commercial Crews. Commercial Crew: Members of the OIB crew who are dedicated to the proprietary operations of specific industrial tenants. Commercial crew may be SIG or tenant employees or contractors. Commercial crewmembers are highly trained in the tenant-specific operations, technologies and outfitting and have generic cross training in areas of OIB emergency and contingency procedures and in generic Habitation Bay accommodations and operations. Select members of the Commercial Crew may be specifically trained and skilled in limited areas of expertise: e.g. Production Bay activities or Laboratory Bay activities or maintenance and repair of tenant-proprietary outfitting and systems. Cell: Each hexagonal station on a deck. The typical deck configuration provides 19 cells, any of which may be delegated specific functions and alternately outfitted with modular pallets, closeouts or other facility outfitting. Deck: Each planar array of cells. Decks are designated “nadir” or “zenith”. Row: Designated “A-E”, each row is a side-by-side array of cells. The quantity of cells per row varies from 3 to 5. Column: Designated “1-5”, each column is an array of cells adjacent to each other along a vector 120 degrees from the “row vector”. Recognizing the circular bounds of the decks and the “3-4-5-4-3” quantity of cells in rows, not all rows offer cells in all columns (Rows D and E are mission columns 1 [in row D], 1 and 2 [in row E], respectively). This designation scheme promotes clearly understandable references coordinates throughout the facility. Zenith: The vector in the direction of the primary structures nose cone. (Note that “zenith” typically means whatever direction is opposite to the local direction to the Earth’s center, and “nadir” is the direction toward Earth’s center.) Since the LabET flight orientation is as yet unspecified, these terms (“zenith” and “nadir”) are applied here independent of the Lab-ET’s orbital orientation. Nadir: The vector opposite to zenith. Utility Corridor: Each of six regions running along the inboard surface of the primary structure within which facility-level power, data, fluids and ventilation routing is accommodated. Utility corridors provide physically separated and redundant distribution of services throughout the facility. Utility Corridors may constitute Restricted Access Environments. 4 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION General Access Environment: Regions in the facility that are continuously provided with environmental control and life support services to support continuous occupation and not requiring special equipment or cautionary measures during normal activities. General Access environments present inherently safe outfitting (no sharp edges, hazardous protrusions, pinch points), appropriate lighting and lighting controls and suitable décor. Limited Access Environment: Regions within which specialized measures must be taken to ensure safety of crew and equipment during periods when the crew is present. Measures may include use of protective clothing and/or breathing apparatus. Limited Access Environments may require activation of life support systems otherwise taken off-line during extended unoccupied periods to preserve facility resources. Restricted Access Environment: Regions within which the vehicle design takes liberties in inherent safety characteristics in return for significant savings in cost, mass, and environmental parameters. Said regions may be optionally entered or accessed for specific off-nominal purposes and by select, specially trained and equipped crewmembers. These regions may include the interiors of Utility Corridors and Plenums. Special equipment used in accessing these regions may include protective clothing (gloves, coveralls, head gear, breathing apparatus, Hazardous Materials suits, crew mobility and restraint aids, portable lighting, etc.). Bay: The region between two adjacent firewalls, constituting the open habitable volume between zenith and nadir decks and the plenum regions between the decks and the firewalls. A bay has a gross volume of approximately 212 cubic meters. Bays are designated using sequential Phonetic Alphabet characters (Alpha, Bravo, Charlie, etc.) starting with the upper-most bay (at the forward end of the Lab-ET). Laboratory Bay: A region within which processes and product analyses are conducted by either by crewmembers or by autonomous or semi-autonomous means. The Laboratory Bay is envisioned as a general access environment. Habitation Bay: A region providing crewmember’s living accommodations possibly including personal and common areas, food, hygiene, health and recreational facilities, etc. Habitation Bays are general access environments. Production Bay: The region spanning the distance between adjacent firewalls and within which tenants locate large-scale installations involving multiple special purpose pallets. Production Bays are provided with measures that ensure protection of proprietary operations and outfitting (considering that the OIB may accommodate multiple tenants each desiring to isolate their operations from each other). Production Bays are Limited Access Environments. 5 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION Drone Robot: Multi-purpose robot capable of operating within a typical bay environment and designed to provide crew support functions when operating in proximity to the crew, remote controlled functions and autonomous routines. The Drone Robot is initially envisioned as a tendon suspended robot similar to the CHARLOTTE robot flown as a DTO experiment on STS-63. Electrical Utility Panel: An area or the deck grid adjacent to each cell where facility-to-pallet electrical connections are provided as a standard format array. The degree to which all cells are thus provisioned is TBD. Interfaces support power and data connectivity. Fluids Utility Panel: An area or the deck grid adjacent to each cell where facilityto-pallet fluid connections are provided as a standard format array. The degree to which all cells are thus provisioned is TBD. Intercell Stowage Zone: Regions inbetween two adjacent pallets within which inter-cell soft stowage may be accommodated. These regions typically occur in the space between pallets adjacent to each other on the same ROW. Intercell Soft Stowage: A standard increment of stowage accommodations that fits into the “valley” between adjacent pallets on the same row and deck. Each unit provides approximately .5 x .5 x 1 meter of stowage volume. Pallet: The basic unit of outfitting, a pallet occupies a cell and extends into the Bay free volume and intra-deck volume. The extent of the standard outfitting envelope is that which, when viewed in cross-section, can pass through a standard deck cell opening with approximately 1 inch of clearance between pallet outfitting and cell profiles. Stacked Pallet Configurations: Recognizing that some outfitting will benefit from larger contiguous packaging volumes, the OIB architecture supports installation of one pallet mounted atop a pallet installed in a standard fashion to the deck. This “stacked” pallet option enables direct payload element-to-payload element interfaces to be established that can reduce interconnection distance between payload features. Linked Pallet Configurations: Payload pallets in proximity to each other may provide payload-to-payload interfaces wherein direct system-level interconnections can be established between multiple elements using dedicated jumpers. This offers throughput capabilities that may be unique to the payload elements and would otherwise not be supportable using standard connections at the standard Utility Panels. Linked payloads may be proximal to each other on the same deck surface, or may be proximal but on opposite walls for a bay. 6 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION Bay-To-Bay Payload Interconnections: Tenants may occupy more than one IOB Bay. In cases where tenant installations occupy adjacent Bays, potential exists to directly interconnect payloads in adjacent Bays using jumpers that pass between the payloads and within the Intra-deck airspace. Said connections would penetrate the Bay isolation firewall and might be most easily accommodated if the firewall offers an optionally replaceable panel in the firewall behind each deck cell. Said panels shall be replaceable with payload-specific panels to support Bay-toBay direct payload item interconnections. Intra-Deck Region: The space between decks bounding adjacent bays is designated an “Intra-deck Region”. These regions house distributed utilities that service standard pellet cells, provide a delivery/return plenum for avionics cooling air, accommodate the firewall that isolates bay environments one from another and accommodate the structural elements that strengthen and rigidize the decks. Firewall: Given the large contiguous volume of the Lab-ET and the likelihood that multiple tenants may co-occupy a facility, measures shall be evident in the facility that reduce crossover risk between tenant facilities. One countermeasure involves protection against propagation of fire between adjacent OIB Bays. Back-to-back Decks of adjacent Bays are separated by a firewall to protect against propagation of fire between bays. Contamination Barriers: As with the firewall discussed above, multiple tenants sharing a OIB may pose risks to each other relating to cross-contamination of environments. Considering that the OIB is a “closed” facility, means to isolate and purge or otherwise disinfect/sanitize one bay or OIB region while preserving normal operations in the remaining bays would promote tenant autonomy and security. Contamination Barrier functions will involve contributions from other distributed OIB features, including the intra-deck firewalls and translation paths. Assured Transit Corridor (ATC): The facility, configured as a “stack” of bays each capable of mutual and selective isolation, provides a corridor capable of selective isolation from any or all Bays yet offering transit between bays for crew and equipment. The ATC is the nominal translation route between bays. Service Corridor: A parallel corridor is envisioned in addition to the ATC. This “Service Corridor” is intended to support infrequent passage of large items throughout the OIB. This corridor may be as simple as a series of optionally opened hatches between adjacent facility bays sized to enable transit of standard Pallet assemblies through the resulting airlocks. Each bay-to-bay transit feature would constitute a hinged cover over the opening of a deck cell and opening into the hosting bay. All adjacent bays provide such covers on back-to-back decks/cells. The firewall between decks has a penetration and the through-deck opening is sealed about the six sides of the cell to create a sealed airlock chamber between the decks. Depending on conditions throughout the facility, the Service Corridor may selectively be transited as a series of transfers through 7 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION sealed airlocks (to maintain bay-to-bay isolation control), or hatches may be “thrown open” to present an unobstructed clear passage through multiple decks and bays. The Service Corridor also supports contingency functions such as providing a physically distanced secondary transit path between all points in the OIB. Transportation Bay: As an orbiting facility supported by transportation systems for crew, supplies and equipment, the OIB requires interfaces and facilities that enable efficient visiting vehicle operations and logistics staging/warehousing. Depending on the overall traffic model and tenant activities, the OIB will, at minimum, require transportation of crew-support logistics (food, water, hygiene supplies, medicine). This traffic alone, for a crew of up to twelve members, represents a significant total volume of items. When combined with consumables, equipment and bi-products from tenant operations, the warehousing, material handling and inventory management challenges alone become significant. A properly designed and dedicated Transportation Bay is envisioned within which the entire facility’s needs for payloads staging transfer and management may be addressed. Application of robotics and electronic inventory management systems, along with efficient human factors design of the Transportation Bay and related facility features, will result in greater crew efficiency and reduced overhead costs. Core Systems: Systems supporting basic facility services maybe either centralized or distributed throughout the IOB. Systems include: Electrical power generation, management, and distribution Data management systems Communications systems Thermal Control systems Environmental Control and Life Support systems Caution and Warning systems Optimal allocation of core systems functions between centralized and distributed installations shall reflect considerations for facility-level technical and businessrelated factors, such as the degree of flexibility supported by the design of the generic OIB as a host for tenant operations and installations that may vary widely in their specific resource requirements. At a minimum, the facility’s core systems shall be capable of maintaining the IOB in a ready state to accept variations in outfitting specific to TBD industrial tenants. Standardized and modular distributed enhancements may be installed throughout the OIB to increase or concentrate availability or select resources in particular IOB regions consistent with the specific requirements of the tenants. Exposure Lock: A feature of the OIB primary structure constituting a hexagonal penetration in the exterior wall providing an internally oriented frame interface that emulates a typical cell, said frame having interior and exterior hinged covers between which a cavity is disposed when both doors are closed, said cavity also being sized to accommodate insertion of a typical pallet payload envelope. 8 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION With the interior door open and the external door closed and sealed, a pallet assembly may be affixed and sealed to the internal surface of the frame, and may also be attached to facility services via a connector panel internal to the cavity and on the inboard surface of the installed pallet. With the pallet installed from inside the OIB, the inboard door is closed and sealed (to avoid dependence on the pallet as a critical pressure vessel surface), and the outer door is automatically opened, thereby exposing the outboard aspect of the installed pallet to the space environment. Such installations may be useful for tenant-specific or facility-level installations. Examples may include: Radiator/Pump Package: For instances where a tenant has unique thermal rejection requirements beyond the capability of the baseline OIB TCS, a “stand-alone” radiator/pump package may be installed in an exposure lock located about the perimeter of the tenant’s IOB bay. Once installed, the radiator/pump package would extend a dedicated radiator into space, said radiator having an ability to rotate such that its surface faces deep space. Removal or access for servicing would reverse the process. This example demonstrates the ability to deploy and recover external features while avoiding Extra-Vehicular Activity or installation designs that preserve EVA viability. (Facility-level installations may also utilize this approach.) Experiment Exposure: Presuming a tenant has a particular need to expose features of a payload directly to the space environment, the Exposure Lock may be utilized similarly (as described above). Potential advantages may be optimal exposure for vacuum venting of a payload feature via a dedicated vacuum vent offering required venting rates and abilities to control the utilization of the vent to avoid contamination or to control timing for vent use without regard for other users “piggy-backing” on the same vacuum vent manifold. HIERARCHY OF ENVIRONMENTAL CONDITIONS Recognizing the large volumes associated with the Lab-ET concept, and further recognizing the diverse types of activities and installations envisioned and the high overhead cost to provide and maintain unrestricted occupancy standards throughout spacecraft, a hierarchy of environmental conditions is envisioned to economize on Environmental Control and Life Support System scale, complexity and resource draw; and to offer additional latitude for designing and maintaining “special-use” environments suitable for various commercial activities. The degree to which this approach provides actual economy and useful versatility may be determined over the course of detailed development of the facility and in coordination with the tenants that would utilize the facility. The degree to which environments in a given Lab-ET may be modulated over time to create various levels of conditions suitable for changing utilization modes is another variable, itself representing a degree of system-level complexity that may prove unattractive from a facility development and management perspective. 9 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION Variables that may be manipulated to optimize environments for limited applications include: temperature, humidity control, atmospheric constituents, atmospheric pressure, chemical and biological contaminant monitoring, control, countermeasures and recovery modes; lighting conditions; ventilation conditions; physical hazards; accessibility characteristics; fire detection and suppression techniques; occupancy capacity and duration. Each of these variables represents cost and complexity. Properly balancing these parameters to reflect the actual and limited requirements of several distinct environments will offer significant advantages in development and operations cost at the facility level and for the commercial tenant infrastructure and operations that Space Island Group intends to host. “Shirt-Sleeve” Environment This designation applies to regions of the Lab-ET where crewmembers reside and work on an everyday, unrestricted basis. This type of environment is typical of NASA’s Space Station, providing a terrestrial analog environment for the crew. Conditions maintained include: comfortable temperatures, low humidity, standard atmospheric constituents, comfortable and controllable lighting levels and ventilation provisions, elimination of physical hazards (sharp edges, pinch points, etc.). This level of environment is analogous to terrestrial offices and residences. Limited Access Environment This level of environmental conditions is analogous to terrestrial industrial environments where hard-hats, special protective clothing and special purpose equipment and operational modes may be used to compensate for reduced inherent habitability at the facility level. This level of habitability may be suitable for crew-tended areas of the LabET where automated processes are predominant. Such environments may offer reduced nominal lighting levels, altered atmospheric and temperature control and monitoring parameters, reduced emphasis on inherently safe (hazard-free) outfitting design, reduced restriction on confinement at worksites and other parameters. This level of environment is analogous to special-purpose and limited access terrestrial industrial environments such as: clean rooms, operating rooms, refineries, heavy manufacturing floors, etc. Restricted Access Environment Various regions of the Lab-ET may require very limited access by crewmembers to the degree that the environment may be most economically designed, operated and maintained if requirements are relaxed and restrictions are placed on the manner in which the crew interacts with this environment. Candidate regions where these conditions may appropriately apply include sections of the Lab-ET that host resource storage facilities (e.g. high pressure containers, hazardous materials, etc.), areas hosting inherently hazardous installations (potentially involving high-energy power systems, etc.) and areas hosting systems requiring virtually no normal interaction with the crew. 10 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION Crewmembers operating in these environments may require special garments and equipment to enable their entry into and continued occupancy of these regions. Such equipment may include portable breathing apparatus, hazard-protective clothing, portable task lighting, portable power delivery to support use of tools and portable equipment, special restraint and mobility support equipment for the crewmember and the tools and equipment with which the crewmember is working, etc. This level of environment is analogous to terrestrial restricted access environments such as: submerged worksites, contaminated environments, fire-fighting environments, hazardous materials handling environments, etc. Internal Transitional Environments The Lab-ET, as a facility maintaining particular conditions in discrete regions, provides features that enable crew and equipment to transit between these discrete regions. Transitional environments enable control of exposure of the crew to these environments and further ensure that discrete environments remain discrete. Various factors may drive the need to isolate regions of the Lab-ET. The environments described in the section above may require specific modes of isolation to address and control atmospheric constituents and contaminants. Also, in a Lab-ET that hosts multiple commercial tenants, each tenant may require limited accessibility to their proprietary environments. The current Lab-ET architectural concept proposes a crew-transit corridor to support normal access throughout the facility. This corridor may be isolated from various Bay environments through the use of localized adjacent “airlocks” along the corridor’s path. Said airlocks may provide varying degrees of isolation and may further support specific capabilities and equipment relating to limited or restricted access environments (e.g. local accommodations for environment-specific garments and equipment required in specific regions). In addition to the crew-transit corridor, provisions are made to enable transit of large objects throughout the Lab-ET. The deck and pallet architecture supports transit of pallets through the openings in the deck. A series of corresponding cells on adjacent decks are outfitted such that these cells may be selectively opened to allow insertion of a pallet through the resulting opening in the deck. The “intra-deck” space may incorporate a closure that isolates the transit route from the general intra-deck environment and penetrates the firewall that isolates adjacent decks. The entire Lab-ET shall preserve the capability to transit the largest contiguous outfitting package throughout the facility and through whatever portal is provided to interface with facility-supportive transportation infrastructure. 11 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION Extra-Vehicular and Pressurized/Vacuum Transitional Environments The Lab-ET will most likely employ systems and features external to the pressurized environments. These features may be designed for operations and maintenance supported directly by crew or by robotic devices, or (most likely) a combination of both. NASA’s Space Station provides an example of this type of facility and the activities relating to its operations. The Lab-ET will embody capabilities for crewmembers and equipment to transition from interior to exterior environments. Various forms of airlocks may satisfy particular requirements most efficiently in this role. Transportation Portals Once the Lab-ET is on orbit, nothing arrives or departs without interfacing with some form of transportation portal. The traffic that supports the Lab-ET will include personnel, supplies, consumables and equipment. This traffic will be bi-directional, supporting both delivery to the Lab-ET and departure from the facility. Traffic will involve a spectrum of operational and physical requirements: Urgency of transport and delivery Controlled conditions and availability of services during transport Need to recover material from the Lab-ET back to Earth Need to dispose of material no longer required aboard the Lab-ET but not to be recovered to Earth Nominal and contingency crew transportation NASA’s Space Station development and operation has demonstrated that specific requirements are generally reflected in the design of the specific facilities created in response to the requirements and that failure to define and meet broad-spectrum requirements results in unintended limitations on the versatility and operability of the resultant infrastructure. Space Island Group’s Lab-ET facilities must prepare to host commercial and industrial clientele that will demand versatility at an unprecedented level. A significant factor in preserving such versatility involves the interfacing features of the Lab-ET itself and the transportation infrastructure that services the Lab-ET. Development of these features is not in the scope of SPACEHAB’s current task. Reference to these features is provided to indicate functional relationships with in-scope concepts. 12 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION ORIENTATION MAP This figure provides orientation cues for generic features throughout the Lab-ET Orbiting Industrial Base. The map at left designates features and locations in a manner that allows rapid and accurate reference to particular features and locations throughout the Lab-ET. A typical pallet designation is described by giving its bay, the orientation of the deck upon which the location resides, and the location’s row and column designator, e.g. Alpha Zenith A 1 or Delta Nadir C 3. DESCRIPTION OF FACILITY OUTFITTING CONCEPTS Two finished renderings are delivered with this paper depicting an amalgamation of concepts into single scenes as might be found in the Lab-ET. The following text and sketches offer insight to the design rationale behind the renderings. GENERIC FEATURES: VIGNETTE VIEW DESCRIPTIONS Multiple sketches are described below, each representing concepts potentially applicable to the Lab-ET facility. Sketches are identified by date produced and are described in the order in which they were produced. Various concepts may not be mutually compatible. All features discussed may not be evident in the finished renderings delivered under the current contract. These descriptions are intended as candidate features only. Operational concepts are also described relating to the physical design concepts. 13 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION FTE070803.01 Habitat Deck Layout View of a 19-cell deck with attached deployable walls used to create distinct crew cabins. Each of four cabins shown is identical in configuration. Each provides a door to a common area; said doors opening onto cell C3 (see facility map). Each cabin provides a window offering exterior views for recreation and psychological benefit. The common area on a given deck may accommodate any of several functional installations, including wardroom, galley, exercise and health maintenance equipment, “sick bay” equipment, etc. Whether or not the Pharma-Lab provides identical levels of living accommodations for SIG staff and tenant staff is TBD. Given that facility staff represents overhead expense while tenant staff represents potential revenue, and considering the potential differences in mind-set and in work-shift scheduling for each class of crew, there may be good reasons to differentiate the level of accommodations for facility and tenant crew. SIG prefers that the Pharma-Lab accommodate 12 crewmembers for extended operations. SPACEHAB has projected from that requirement that three crewmembers will be SIG employees dedicated to managing, operating and maintaining the facility itself. This staff will consist of a facility commander and two subservient technicians. The commander acts in the role of ship’s captain and is the resident authority for all SIG and client issues associated with running a safe and reliable facility, including efforts to ensure an uninterrupted flow of resources are provided to the industrial clients consistent with the requirements set forth in their contracts with SIG. Facility staff and other residents will be subject to career limits for time on orbit; said limits reflecting the radiation dosage allowable in the harsh LEO environment. Radiation shielding in high-occupancy rate regions may reduce exposure and result in greater staff longevity. The concept depicted incorporates water-filled panels to construct the walls of crew quarters and other defined spaces. These panels are envisioned as Tisavel structures. Tisavel is a material that uses multi-directional internal fibers between airtight parallel planar fabric walls and configured as closed panel structures. Typically filled with compressed air, these panels achieve rigidity through the interaction of the cross-woven fibers and the rigidized pressure barrier material. The depicted application uses water rather than air to fill the panel, with a small amount of pressurized air injected to result in a semi-rigid panel. Water acts as an effective attenuator for relatively low-energy 14 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION radiation, though high-energy cosmic radiation is less effectively shielded. An additional benefit to dense yet flexible walls is their sound-insulating properties. A crew aboard an isolated station for months may require opportunities to get away from each other and may work in shifts. Either of these cases and more drives the provision of interior surfaces that attenuate noise. Also evident in this view are four of six commonly occurring utility distribution corridors. One corridor is evident adjacent to the window-bearing facet of each crew cabin and two additional corridors flank the common region of the bay. Facility-level utilities are distributed throughout the Lab-ET via these limited access corridors. Access is gained through removable panels on the interior surfaces. Pressure vessel penetrations may occur coincident with these utility corridors through which electrical, fluids and data connections can pass from the exterior to the interior of the Lab-ET. (See additional discussions on sketch FTE071003.02, FTE071003.10, and FTE071703.01.) Lab-ETs housing twelve people might utilize three similar bays, each providing four crew cabins. The relative rotation of these interiors from one deck to another could be rotated such that the common spaces of all three decks partially align with each other. This feature, combined with large openings in the decks between the adjacent bays, would result in greater visual interest and diversity in the environment and a large contiguous common area to host the community activities of the Lab-ET’s population. For more info on inflatable flat panel technologies see: http://www.us-government-torture.com/bighard.htm (Bighard is an outgrowth of Bigelow Aerospace, itself a potential developer of commercial space-based manned infrastructure.) http://www.sciences.univnantes.fr/physique/recherche/LGCNSN/themesrecherche/struct uresgonflables/structur.htm Though this site is in French, it does offer images and text describing the flat panel technology of interest for interior walls with radiation attenuation contributions. 15 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION FTE070803.02 Typical deck outfitting concept This sketch explores the general layout of a facility deck configured as a series of hexagonal cell units. Illustrated is the ability of a typical pallet to pass through the opening of a typical cell. Also illustrated are the utility corridors features of the proposed Lab-ET layout and initial exploration of locations for utility connections between pallets and the hosting deck cells. FTE071003.01 Inter-bay Hatch Concept and Stacked Pallet Concept These sketches depict two concepts potentially applicable to the SIG Lab-ET. The upper image shows a hatch configuration initially conceived for application to a hyperbaric chamber/airlock to have been a part of NASA’s Space Station Freedom. This hatch actuates via a mechanism that enables the hatch to pass through the opening and seal to either side of the port, thereby enabling pressure-assisted sealing regardless of which direction exerts higher pressure. The hexagonal shape of the cells is compatible with this actuation mode. Hatches with this capability may be important aboard the LabET, where the facility might experience off-nominal conditions resulting in a need to isolate particular portions of the facility with pressure-assisted hatch closures. The lower sketch illustrates two pallet assemblies mounted in tandem on a single deck cell. Such a configuration may enable higher density outfitting in sections of the Lab-ET where free-volume between opposing decks is not required for crew activity or where installations must be immediately adjacent to each other. A similar concept is shown in the interior rendering of the “Production Bay” environment but with the distinction of the 2-cubic meter cross-bay payload extending all the way from one standard pallet to the opposing standard pallet. 16 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION FTE 071003.02 Hybrid Payload This sketch illustrates a payload configuration referred to by SPACEHAB as a “Hybrid Payload”: that refers to the payload’s inclusion of an internal element and an external element directly connected to each other by way of facility-provided through-hull connectors. The advantage of a hybrid payload is that only the external component requires the rigorous and challenging effort of designing for the harsh space environment. The inboard (pressurized) element enjoys the conditioned environment of the Lab-ET, which is significantly more amenable to avionics, materials selection, servicing and trouble-shooting by Lab-ET crew working internal to the station. FTE071003.03 Cross-Bay Installation (Shower) and Inter-Bay Airlock In addition to standard pallet installations, various generic installations are viable in the context of the current architectural concept. Two such installations are shown here: one that spans the bay environment and one that spans the deck structures between adjacent bays. Depicted in the upper image is a concept for a full-body shower installed as a crossbay feature. Two typical pallet installations oppose each other, each constituting elements of a full body shower installation. The upper and lower elements are connected to each other by utility lines carrying fluids, power and control signals to coordinate their operations. Also connecting the two pallets is a shower enclosure here envisioned as a multi-element telescoping assembly of clear (probably polycarbonate) material creating the confines of the shower facility. Depicted in the lower image is a trans-deck airlock suitable for isolating adjacent bay environments while enabling passage of crewmembers between the isolated environments of the two habitable bays and the separate environment of the intra-deck region. 17 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION These two concepts illustrate a level of outfitting versatility that is inherent to the architecture. Many additional applications may be derived based on these general configuration themes. FTE071003.04 Pallet Application Concepts: Glove box and MDK pallets The upper sketch shows a typical pallet outfitted as a glove box and illustrates the favorable relationship of the pallet increment to human scale. Similar installations are illustrated in one of the finished renderings accompanying this paper. The lower sketch shows ISS-heritage MDK-format payloads mounted to a standard pallet and illustrates the pallet’s capacity to host up to six such payloads on each of its surfaces. Also shown is a standard stowage increment concept occupying the space between standard pallet installations. Space flight experience has shown that payloads typically require supplemental equipment to support their operations. Provision of dedicated stowage capacity immediately adjacent to all standard pallets addresses this requirement. The proposed architecture offers the planned option to use the spaces between payloads to host storage rather than dedicating pallets themselves to host storage. ISS experience has shown that aisle volume is quickly appropriated to accommodate stowage regardless of whether that use was initially planned in the architectural development of the facility. Recognizing this, the recommended architecture incorporates this use in the original design, which should result in improved operational flexibility while preserving the intended viability of installation designs adjacent to the storage regions. Similar stowage installations are depicted in the context of complete deck outfitting in the renderings accompanying this paper. 18 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION FTE071003.05 Standard Pallet Features This sketch illustrates configuration and interface concepts for the standard pallet. The pallet concept strives to improve significantly on the ISS ISPR in areas of structural efficiency, maintainability and optimization of user and facility interfaces. The structural approach provides a planar structural pallet to which other elements and outfitting are mounted. Flight loads are transmitted between the pallet and deck structures via structurally determinate and de-coupled interfaces at three positions evenly spaced about the perimeter of the pallet. This configuration, depicted in the first image on the following page, offers direct and short load paths from pallet outfitting to the deck structures, especially compared to the convoluted load paths seen in ISS outfitting. A pallet-outfitting envelope is defined that preserves the integrated pallet’s ability to pass through a standard deck cell opening. Environmental closures can attach to both sides of the pallet and their removal reveals internal components for assembly, test, servicing and maintenance to a much-improved degree compared to ISS ISPR racks. Pallet ventilation for internal equipment cooling may be achieved in any of several modes, illustrated by the diagrams along the mid-portion of the image. The intra-deck region constitutes a plenum providing a supply of conditioned cooling air. Pallet-based installations may draw air from this plenum and exhaust that air either back to the plenum or to the cabin. Cabin air may also be drawn upon with exhaust either back to the cabin, or to the intra-deck plenum. These ventilation modes offer versatility to configure payloads to take best and most appropriate advantage of available thermal rejection in a resource-limited setting. 19 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION Additional pallet features evident in the figures include: Truncated corners on enclosures: Each corner has a facet upon which hard point is provided in the form of a threaded insert. These features, when dispersed throughout the interiors, offer versatile interfaces for crew equipment, pallet handling, portable equipment attachment, etc. Utility connections: Power, data and fluid connections between pallets and resources occur at the perimeter of the pallet structure. Their locations on the pallets coincide with the utility provisions at each pallet cell on the deck structures. These locations will be efficiently supplied with resources via distribution lines in the intra-deck regions and the Utility Corridors. FTE071003.06, 7, 8, and 9 IVA Robot Assistant Concepts Intra-Vehicular Activity (IVA) Robot are environed based generally on the design of the CHARLOTTE1 Robot flown as a McDonnell Douglas Development Test Objective (DTO) payload on NASA’s STS-63 mission. CHARLOTTE was the first robotic device to operate concurrently with crewmembers within the cabin of an orbiting spacecraft, its inherently fail-safe design garnering such trust from the crew that one crewmember even slept in the SPACEHAB module while CHARLOTTE was executing its automated test routines. These several sketches explore the CHARLOTTE concept taken to a configuration and scale thought to be appropriate for its role in the Lab-ET setting. The robot as envisioned here would be multi-functional and capable of assisting crew to execute tasks or executing standardized routines autonomously, both roles promising increased performance from the Lab-ET crew and system. In the crew-support role, the robot acts as a crew mobility and restraint aid, providing not only mobility throughout the bay environment, but also providing additional end effectors and manipulator arms to assist 1 CHARLOTTE IVA Robot technology is subject to Intellectual Property limitations relating to limitedscope patents issued to its designers and assigned to McDonnell Douglas Astronautics Company (now The Boeing Company). References to this technology in this paper do not imply that rights to exploit this IP have been coordinated with The Boeing Company. 20 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION the user. The user directs the robot’s motion using foot controls: one foot enables a “activate” switch and the other reacts against a 6-DOF force-torque sensor on the foot platform to drive and fixate the robot wherever the user desires while leaving the operator’s hands free to work. The robot may relieve the crew of many “housekeeping” tasks aboard the Lab-ET, possibly including such mundane activities as cleaning lint from intake filters, sampling and testing utility resources, general facility cleaning, etc. One of the finished renderings delivered with this paper depicts such a robot operating in support of a crewmember in a limited-access environment. As shown in the rendering, the robotic assistant provides two 6-DOF manipulators. Modular end effectors are envisioned stowed on the robot itself to be selectively attached in support of specific tasks that the robot can perform. The robot also is shown with integral task illumination located to project over the shoulders of the crewmember using the robot as a mobile work platform in limited-access or restricted access environments. The robot may also provide interfaces to support services for the crewmember’s controlled environment garb, including breathing air, thermal conditioning fluids, power, data and communications connections. A docking station at a standard cell may host the robot, configured to emulate the interfaces of a standard pallet. The intent of the robot concept is to support operations throughout the facility using identical robots or variations on a common configuration in multiple settings. 21 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION FTE071003.11 Color Scheme An interior color scheme is reflected in this sketch and in the finished renderings delivered with this paper. The approach applies color in a manner that not only enhances the psychological aspect of the interior, but also reinforces crew sense of orientation and location throughout the Lab-ET interior. The general theme attempts to emulate the distribution of colors found in natural environments, and to do so in a way that promotes crew efficiency, safety and comfort. Colors employed represent sky, clouds, sand and grass, in addition to fairly extensive use of white for lighting control purposes. Color distribution reinforces the crewmembers sense of spatial orientation by offering a different predominant color on visible surfaces when the crewmember views the environment in different directions. Colors are applied to Utility Corridor surfaces and to Pallet surfaces and pallet color schemes are typical for all cell locations. Deck structures are one color (sky blue) on decks oriented toward the Lab-ET “zenith”, and “sand” on the opposing deck surface. Surfaces of the hexagonal pallets themselves and the frontal surfaces of the pallet enclosures are white, the letter to contribute to acceptable lighting with limited resources. This scheme not only embodies “comfort colors” from terrestrial environments, it also contributes to productivity and safety by assisting the crew in always knowing which direction they are facing and where emergency corridors are, etc. Graphical/symbolic location cues adjacent to each cell are also envisioned to uniquely identify each deck cell throughout the Lab-ET facility. Location coding concepts are discussed below with sketch FTE071103.01. 22 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION FTE071103.01 Typical Pallet Features and Location Designators The “Orientation Map” concepts discussed earlier in this paper and other features of the pallet architecture were developed through this sketch. Cell row and column designations and orientation/position of pallet utility connections are identified here. Locations on the pallet for primary load paths from pallet to deck are also shown. Fluid and electrical utilities are distributed on the distal side of the deck structures (relative to the Bay environment), with connections for electrical and fluid utilities being physically separated from each other at the upper and lower regions of the pallet perimeters. Connector regions are located to preclude interference with interpallet stowage regions. FTE011703.01 Primary Structure Surface Features This sketch explores the dispersal and functionality of modular features in the primary pressure vessel. Experience has shown that versatile multi-purpose features in a spacecraft’s pressure vessel primary structure enable greater flexibility to outfit and operate the vehicle in response to varying customer requirements. The SPACEHAB module’s rooftop windows offer one example, wherein a feature originally designed to selectively accommodate modular window installations has also proven valuable in supporting hybrid payloads through the replacement of the window with a cover plate providing payload-specific through-hull connectors. A similar example was evident on NASA’s Spacelab, where a penetration was capable of hosting an optically correct window, a scientific payload exposure airlock, or other suitable modular installations. Unique and valuable payload-support capabilities may be economically implemented over time by altering the design of the modular installations while preserving the integrity of the original pressure vessel design. 23 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION For the Lab-ET application, this concept has been expanded to the scale of the typical pallet. An array of hull penetrations is envisioned, each constituting a ring-frame interfacing the cylindrical shell on the frame’s outer perimeter and hosting a planar surface within its perimeter. The planar surface is penetrated by a hexagonal opening to which various modular elements may be installed from the inboard side of the opening. Seals and circumferential fasteners provide pressure integrity. Selectively installed modular elements emulate the general configuration of a standard pallet, thereby ensuring their compatibility with system-wide architectural parameters of the facility (for unrestricted passage, common transportation interfaces, etc.). The sketch represents several bays, each with (up to) six localized pressure vessel discontinuities. The discontinuities may all be of a common design offering modularity options in their purpose-driven outfitting. Or, alternative localized features may be provided among these regularly occurring locations. Though many other modular installations are possible (see EXPOSURE LOCK description earlier in this paper), this sketch represents a distribution of three types of modular features: A window An Exposure Lock A “blank”, or cover plate Two of each feature is indicated as occurring in each bay and features are shown in a 60-degree rotation relative to those of adjacent decks. The relative rotation is intended to orient like interfaces in multiple vectors throughout the Lab-ET, thus maximizing exposure possibilities for all feature types that might be installed. 24 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION FTE071803.01 Deck Structural Concepts This sketch explored the structural design of the Lab-ET decks. (Details of these structures are not evident in the finished renderings accompanying this paper.) Lab-ET deck structures carry significant load from payloads and outfitting during launch, a function that drives the deck’s strength and stiffness and the design of load paths between the deck and the payloads and the deck and the Lab-ET primary structure. (Also see description of Sketch FTE072103.03.) After orbital insertion, these loads never again occur and the deck functions as a static framework for attachment of equipment, a supportive structure for distributed utility lines, a reaction point for induced loads from crew, robots, or payloads and a separation barrier between adjacent bay environments. This sketch shows an intra-deck cross-bracing scheme that provides deck stiffness and appropriately distributed hard points to accommodated loads from pallet outfitting on ascent. (Note that the Lab-ET may offer on-orbit capacity that exceeds its launch capacity. Determination of these limits and the ideal means to optimize the design across ascent and on-orbit operational phases has not yet been explored, but will significantly impact the deck structural design, allocation of payloads for ascent and operational scenario whereby the Lab-ET becomes fully outfitted and operational.) This sketch shows an internal cross-bracing configuration suitable for application between adjacent decks and the firewall in the intra-deck region. The array of internal bracing and the localized reinforcement and strength it provides corresponds with the load transfer paths between the deck and standard pallets such that each hard-point on the deck sustains selective loads from each of three adjacent pallets. The cross-bracing configuration preserves the void regions of each cell location while retaining clear avenues in the intra-deck region for distribution of utility lines. Intra-deck regions may, depending on the conditions provided in adjacent bays, constitute limited- 25 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION access or restricted-access environments. The proportions support crew access to the intra-deck regions, and the bracing design preserves accessibility to enable facility maintenance, repair, and modification as driven by commercial and facility-management requirements. To economize on manufacturing, decks may be fabricated and assembled as complete installable subassemblies that are inserted to the Lab-ET pressure vessel. This approach promotes parallel fabrication, assembly and checkout of primary structures and multiple deck assemblies while reducing work done in confined spaces. These factors can reduce manufacturing schedules and cost. The deck concept uses large numbers of identical component parts, further fostering low design, development and fabrication costs. Commercially available fittings and materials may be used to create the component parts. FTE071803.02 Bay Isolation Airlock Industrial environments such as those envisioned for the Lab-ET are often isolated to control bilateral flow of contaminants. This sketch illustrates a concept for positioning an airlock adjacent to a translation corridor to enable controlled access to a bay requiring isolation from the balance of the Lab-ET. Shown is a translation corridor transiting a series aligned cells. The corridor constitutes a discretely ventilated environment relative to the bays through which it passes. Adjacent to that corridor in a particular bay is positioned a second chamber configured as a cross-bay installation. This chamber can be selectively opened to the transit corridor, or to the hosting bay, with an intermediate state of being closed relative to both adjacent environments. Preferential sequential cycling of filtered air through the selectively isolated airlock enables control of the passage of contaminants between the corridor and the isolated bay environment. Similar features may also be used to isolate sections of a single bay if used to penetrate a barrier spanning between bounding decks. 26 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION This type of feature may be applicable to relative isolation of hazardous activities and/or materials from the crew habitation environment, or to isolate sensitive environments from contaminants originating in the habitable regions of the Lab-ET. FTE 072103.01 and FTE 072103.02 Multi-Cell Installations SPACEHAB recognizes that all installations supporting Lab-ET tenants may not be scalable to the size of a typical pallet. Cross-bay installations and cross-deck installations offer two approaches for installing large contiguous assemblies in the proposed architecture. This sketch explores multicell installation concepts that are viable within the physical constraints of the envisioned Lab-ET design. The operational viability of these concepts and potential applications that might be served are yet to be explored. Shown in the upper figures of FTE072103.01 are concepts for multicell assemblies configured such that the entire assembly may still pass through open deck cells to transit the facility via a service corridor. The orientation of the pallet-outfitting envelope to the pallet’s minimum cross-section, along with the dimensions between the decks bounding the typical bay constrain the maximum size of as assembly capable of transiting the Lab-ET facility via service corridors. Sketch FTE072103.02 shows the largest installations attainable using this configuration can span the entire bay, offering the combined volume of multiple pallets plus the volumes on the bay side and between typical pallet outfitting envelopes. Contiguous installations up to approximately 5 cubic meters may be thus configured. Installation of these maximum size assemblies would require their insertion to the Lab-ET through an opening in the primary pressure vessel directly into the hosting bay. If installed prior to launch, the assembly may be inserted prior to installing the closure to the primary shell opening. Installation of such large assemblies once the Lab-ET is on orbit would be possible through the use of an externally disposed airlock (relative to the Lab-ET shell), possibly taking the form of an inflatable cylinder capable of attaching to the Lab-ET exterior at a typical shell penetration (discussed in Sketch FTE071703.01). 27 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION Installations that may finds this capability/configuration attractive may include large contiguous tanks or containers associated with chemical processes, large pressure vessels holding consumables and instruments and devices that are necessarily driven to large scale by the physics associated with the related processes or technologies, etc. The bottom figure on this sketch diagrams the cross-bay installation previously described. FTE072103.03 Multi-Deck Structural Concept A facility as large as the Lab-ET and intended to launch with pre-integrated payloads will experience extreme environments during ascent. Preserving the structural integrity of the assembly through ascent while designing for minimum structural mass requires that the loads be well distributed throughout the available structures and that load concentrations are avoided. The concepts illustrated here address the mounting of decks within the LabET pressure vessel and the relative fixity of adjacent decks. Shown at the upper right is a typical deck structure designed to act as a viable structure in and of itself. This deck is mounted within the cylindrical Lab-ET shell via a series of wire rope isolators (WRI) at six positions about the deck’s perimeter. The WRIs are capable of transmitting loads while providing a degree of controllable compliance and definitive dynamic response between the adjacent structures. Also shown at the upper right is a tripod of launch-phase struts spanning the bay between adjacent decks. These struts transmit forces between adjacent decks in a manner that preserves each deck’s limited freedom of motion during ascent while also preserving the overall dimensions of the multi-deck assembly mounted within the Lab-ET pressure vessel. Another function of this structural concept addresses the behavior of large pressurized structures in vacuum environments that also 28 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION present strongly directional heating parameters. The Lab-ET structure will respond to non-uniform heating while on orbit by expanding and contracting. Given the facility’s large scale, these thermal responses can result in significant dimensional changes. Unless compliance is designed into the structural assembly, large loads can be experienced at the interfaces between the pressure vessel and the internal outfitting. The structural approach depicted here provides distributed load paths throughout the Lab-ET assembly while preserving compliance. Also found on this sketch is a listing of various generic pallet types that may be required in multiple locations throughout the Lab-ET to satisfy common “housekeeping” functions. Maximizing commonality among standard-function pallets throughout the Lab-ET and in multiple Lab-ETs will promote affordability in design, development, test and certification of these assemblies, reduce crew training for their operations and maintenance, simplify the spares approach and improve system-level redundancy across the Lab-ET. Among the typical pallet types listed are: Oxygen Regeneration, CO2 scrubber, water tank, Toxicity Monitoring and Control system, battery assemblies, high pressure tanks assemblies, power conversion assemblies, Thermal Control System pump packages, etc. FTE072103.04 Non-Standard Deck Configurations Although the Lab-ET concept is based on the geometry of the Space Shuttle External Tank, Space Island Group’s Lab-ET may deviate significantly from the Shuttle-ET design. One area of deviation may involve the elimination of the internal barriers that separate the cryogenic propellants for which the Shuttle ET was designed. If configured as a single contiguous pressure vessel, the Lab-ET’s forward decks in the tapered region may resemble the decks in the constant-cross-section portion of the Lab-ET. This sketch explores the potential capacity of decks of diminishing size, as might apply in the nose of the Lab-ET. These decks exhibit some rather interesting geometric variation that. If applied to the habitation facilities for the Lab-ET crew, might add variation and interest to their living environment. Allocating this architectural variation to the non-commercial potions of the Lab-ET also fosters facility-wide design commonality in the commercial bays. 29 ARCHITECTURAL CONCEPTS APPLICABLE TO THE SPACE ISLAND GROUP LAB-ET SPACE STATION CONFIGURATION FTE072303.01 Robotic Assistant Concepts This sketch expands on the concept of the Robotic Assistant. The robot is depicted with reference to human scale. Also depicted is an array of tendons emanating from the corners of the robot’s housing and running to anchor points in the Lab-ET environment. The robot translates and adjusts its orientation by coordinated variation of the length of these various tendons while maintaining equivalent tension in all tendons. This robotic concept is subject to patent protection, with The Boeing Company having limited rights to variations on this theme which house the reel assemblies internal to the robot’s mobile base. Other patents protect configurations wherein the reel assemblies are at the distal ends of the tendons. Any commercial applications of these concepts by Space Island Group shall be coordinated with the holder of these and other applicable patents. SPACEHAB’s renderings incorporate a depiction of the robotic assistant, but do so without illustrating tendon and tendon control features that are subject to existing Intellectual Property protection. CONCLUSION The descriptions provided throughout this paper demonstrate the viability of SPACEHAB’s architectural concept for the Space Island Group Lab-ET facility as designed to host commercial pharmacological and biological research and production applications. These concepts also seek to apply various lessons learned through NASA’s development of its International Space Station and SPACEHAB’s commercial space flight infrastructure development and operations, especially in areas that might reduce design, development and operations costs and simplify ongoing operations and maintenance. The concepts illustrate the inherent versatility of the Lab-ET architecture developed by SPACEHAB, Inc. for Space Island Group. Many of these concepts may be appropriate for other Lab-ET applications. 30