synthesis of pure α-monoglycerides by continuous process

advertisement

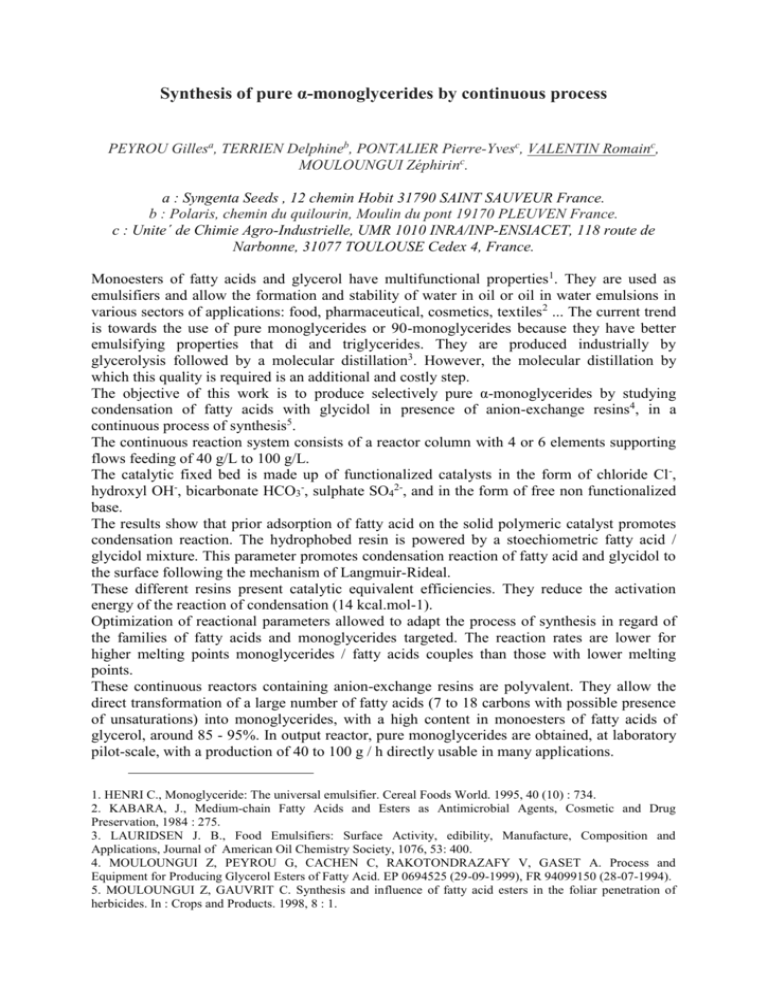

Synthesis of pure α-monoglycerides by continuous process PEYROU Gillesa, TERRIEN Delphineb, PONTALIER Pierre-Yvesc, VALENTIN Romainc, MOULOUNGUI Zéphirinc. a : Syngenta Seeds , 12 chemin Hobit 31790 SAINT SAUVEUR France. b : Polaris, chemin du quilourin, Moulin du pont 19170 PLEUVEN France. c : Unite´ de Chimie Agro-Industrielle, UMR 1010 INRA/INP-ENSIACET, 118 route de Narbonne, 31077 TOULOUSE Cedex 4, France. Monoesters of fatty acids and glycerol have multifunctional properties1. They are used as emulsifiers and allow the formation and stability of water in oil or oil in water emulsions in various sectors of applications: food, pharmaceutical, cosmetics, textiles2 ... The current trend is towards the use of pure monoglycerides or 90-monoglycerides because they have better emulsifying properties that di and triglycerides. They are produced industrially by glycerolysis followed by a molecular distillation3. However, the molecular distillation by which this quality is required is an additional and costly step. The objective of this work is to produce selectively pure α-monoglycerides by studying condensation of fatty acids with glycidol in presence of anion-exchange resins4, in a continuous process of synthesis5. The continuous reaction system consists of a reactor column with 4 or 6 elements supporting flows feeding of 40 g/L to 100 g/L. The catalytic fixed bed is made up of functionalized catalysts in the form of chloride Cl -, hydroxyl OH-, bicarbonate HCO3-, sulphate SO42-, and in the form of free non functionalized base. The results show that prior adsorption of fatty acid on the solid polymeric catalyst promotes condensation reaction. The hydrophobed resin is powered by a stoechiometric fatty acid / glycidol mixture. This parameter promotes condensation reaction of fatty acid and glycidol to the surface following the mechanism of Langmuir-Rideal. These different resins present catalytic equivalent efficiencies. They reduce the activation energy of the reaction of condensation (14 kcal.mol-1). Optimization of reactional parameters allowed to adapt the process of synthesis in regard of the families of fatty acids and monoglycerides targeted. The reaction rates are lower for higher melting points monoglycerides / fatty acids couples than those with lower melting points. These continuous reactors containing anion-exchange resins are polyvalent. They allow the direct transformation of a large number of fatty acids (7 to 18 carbons with possible presence of unsaturations) into monoglycerides, with a high content in monoesters of fatty acids of glycerol, around 85 - 95%. In output reactor, pure monoglycerides are obtained, at laboratory pilot-scale, with a production of 40 to 100 g / h directly usable in many applications. 1. HENRI C., Monoglyceride: The universal emulsifier. Cereal Foods World. 1995, 40 (10) : 734. 2. KABARA, J., Medium-chain Fatty Acids and Esters as Antimicrobial Agents, Cosmetic and Drug Preservation, 1984 : 275. 3. LAURIDSEN J. B., Food Emulsifiers: Surface Activity, edibility, Manufacture, Composition and Applications, Journal of American Oil Chemistry Society, 1076, 53: 400. 4. MOULOUNGUI Z, PEYROU G, CACHEN C, RAKOTONDRAZAFY V, GASET A. Process and Equipment for Producing Glycerol Esters of Fatty Acid. EP 0694525 (29-09-1999), FR 94099150 (28-07-1994). 5. MOULOUNGUI Z, GAUVRIT C. Synthesis and influence of fatty acid esters in the foliar penetration of herbicides. In : Crops and Products. 1998, 8 : 1.