6.0 Trends in Structures for Offshore OG Dev

advertisement

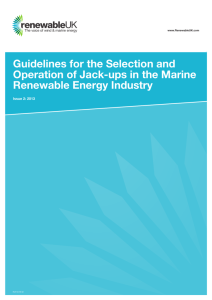

NPA FINAL REPORT – OFFSHORE OIL & GAS 6.0 TRENDS IN STRUCTURES FOR THE OFFSHORE OIL & GAS INDUSTRY Bottom Supported Structures Converted Jack-up Barges Jack-up Rigs Fixed Leg Towers SPARS Semi-Submersible Floating, Production, Storage and Offloading Topsides Mooring Facilities Sub-Sea 24 NPA FINAL REPORT – OFFSHORE OIL & GAS 6.0 TRENDS IN STRUCTURES FOR OFFSHORE OIL & GAS DEVELOPMENTS The marine environment in the area of an offshore hydrocarbons reservoir, largely dictates the type of structure that will be required above the ocean floor for exploitation purposes. In the early days of the offshore oil & gas industry, reserves sufficient to meet market demand were exploitable in relatively shallow and calm waters. A Platform is a generic term used in the Oil & Gas Industry to depict an integrated fixed or anchored facility in the sea, from which drilling and exploitation is made possible. Topsides, as they are known comprise oil or gas handling, treatment and stabilising facilities together with living quarters for operators. The topsides are supported on “jackets” which sit on the sea bed anchored by piles or a floating structure, supporting the mass of the topsides. Bottom Supported Structures The following types of support structures comprise the present day market for offshore fabrication and assembly. Converted jack-up barges – Used only in remote areas and in very shallow waters. Jack-up barges can be constructed very easily in shipyards. Jack-up Rigs – The topsides of the rig has legs which are cranked or winched down to the sea bed, lifting the topsides deck out of the water for drilling or production purposes. The market for new rigs fluctuates year by year, but refitting/upgrading of existing rigs provides a steady source of business for several yards. Fixed leg towers – Can be used in water depths up to 300 meters, although most commonly in depths less than 150 meters. Within this category there are 4-leg, 6-leg and 8-leg towers. Compliant towers are commonly used in the relatively calm waters up to 300metres. Fixed towers of up to 180 meters are to be found in the more hostile environments such as the North Sea or the Southern Coastline of South Africa. 25 NPA FINAL REPORT – OFFSHORE OIL & GAS Within this category are “minimal structures”, whose decks are supported by a single, unbraced or pile braced caisson. Minimal structures are used in water depths less than 50 metres. Tension Leg Platforms – TLP’s are used in water depths greater than 200 metres. They consist of a floating steel deck structure, which is anchored to pile heads on the sea bed by means of long pipes. The pipes are always kept in tension and thus can be flexible without risk of buckling collapse failure. SPARS A SPAR is a vertical floating steel cylinder, attached by means of cables to anchors placed on the sea bed more than a kilometre distant. SPARS are becoming common for very deep water activities. Facilities similar to those required for a jacket assembly are required, potentially without the expense of as many high capacity crawler cranes. 26 NPA FINAL REPORT – OFFSHORE OIL & GAS Floating Structures Floating Structures Semi-submersibles Semi-subs are used both for exploration drilling and as floating production systems (otherwise known as SFPSs). As with jack-ups, the market for new semi-sub drilling platforms is limited, but refits and conversions are ongoing. Fabrication requirements notwithstanding, a South African location for final assembly of a semi-sub, could present some problems, where sufficient water depth, in calm conditions, close to the fabrication yard, yet well clear of shipping channels, might be difficult to find. Saldanha might be an option in such circumstances. Typical Semi-Submersible Drilling Rig 27 NPA FINAL REPORT – OFFSHORE OIL & GAS Floating Production Storage & Offloading (FPSO) The term “FPSO” embraces any type of floating production, storage and offloading system, including purpose built vessels, tanker/barge conversions, semi-submersible platforms, tension leg platforms, and spars. However, the term is used most commonly to describe a ship-shape vessel with on-board process plant and storage capacity, which has been newly constructed or converted from an existing vessel. In the case of a new, purpose built FPSO, the approach to date has been to construct the hull or “ship-shape structure” in shipbuilders yard, and thereafter move the ship to another country location for fitting out with topsides. This location is normally an established module yard, where process and utilities units, living quarters etc have been pre-fabricated and assembled in readiness for arrival of the ship. The same principle is applied to existing hull conversions, although some conversions have been carried out at the same locations as module assemblies. A typical Floating Production Storage and Offloading System Topsides Topsides are best defined as anything above the water line which is supported directly or indirectly by a Jacket, SPAR, TLP, Semi-Sub, or FPSO, including decks, process modules (oil/gas separation etc), utilities modules (power generation, water treatment etc), living quarters, the drilling structure, helicopter pad, flare stack, crane unit. Such topsides are common to virtually every type of offshore installation and will continue to be so regardless of technology developments sub-sea. Most Fabrication Yards will accommodate both structures and topsides. These Yards also assemble modules for onshore oil & gas projects. Decks Deck structures generally sit on top of a jacket, or TLP, or Spar, in turn supporting the modules, living quarters etc. Some decks, or module support frames (MSF’s) as they can be known also contain equipment, tanks, piping etc, effectively becoming modules in themselves. A deck structure might be described as easier to fabricate/assemble and load out than a jacket, or spar, which physically and dimensionally would normally be the case, but materials 28 NPA FINAL REPORT – OFFSHORE OIL & GAS of construction can be of equally high specification and some of the subassemblies equally complex. The Mossgas Deck (MSF) being loaded out in Durban Modules A true module comprises a steel box frame, varying in size, containing pressure vessels, pumps, piping, electrical equipment and cabling, instruments and instrument tubing, forming part of a process or utilities system. A module is engineered and designed to industry standards, the only difference between a unit of modularised plant, and a section of conventional plant, being the compactness, which must be inherent in the design. Similarly, skills required to assemble a module, such as steel erection, equipment installation, piping erection, cabling etc., are no different to the norm, but planning/scheduling of the work has to be of a higher standard than normal. Modules are often inspected, tested and precommissioned whilst still in the Assembly Yard, being transported as ready-to-operate individual units. Mossgas Modules at Charl Malan Quay Port Elizabeth Living Quarters 29 NPA FINAL REPORT – OFFSHORE OIL & GAS Living quarters for an operational offshore facility can be located either on the main processing platform, or on an adjacent structure, interconnected by a bridge. In some cases, permanent accommodation is provided by a semisubmersible nearby, or by a “Flotel”. The latter are used extensively during hook up and commissioning phases. Quarters can comprise either a number of individual modules, of “ski cabin” proportions, each providing a component of living requirements (sleeping, eating, recreation etc) or a full sized module containing all requirements in one unit. Fully integrated living quarter modules are extremely complex, due to the multitude of services and finishes involved, requiring considerable hands-on experience. The Mossgas Accommodation Module Other topsides structures Drilling derricks, flare booms, helicopter decks and bridges to adjacent platforms, together with a miscellany of smaller items, all go into making up topsides and all of which must be fabricated/assembled in a yard somewhere. The Mossgas Drilling Derrick on Load Out 30 NPA FINAL REPORT – OFFSHORE OIL & GAS Mooring Facilities Various types of buoys are required offshore including, other than for mooring purposes, flare buoys, well head control buoys. Sub-Sea With advances in sub-sea completion technology, demand for complex sea bed modules has increased and many companies are specialising in fabrication and assembly of same. 31