2-24-09 ID2692 Revised PIF South Africa S-v6L

advertisement

PROJECT IDENTIFICATION FORM (PIF)

PROJECT TYPE: FULL-SIZED

THE GEF TRUST FUND

S

Submission Date: 11 September 2008

Re-submission Date: 25 November 2008

Re-submission Date: 24 February 2009

PART I: PROJECT IDENTIFICATION

GEFSEC PROJECT ID:

GEF AGENCY PROJECT ID: PIMS 3277

COUNTRY(IES): South Africa

PROJECT TITLE: Market Transformation through Energy

Efficiency Standards & Labelling of Appliances in South Africa

GEF AGENCY(IES): UNDP

OTHER EXECUTING PARTNERS: Dept. of Mines and Energy

GEF FOCAL AREAS: Climate change

GEF-4 STRATEGIC PROGRAM(S): CC-SP1

INDICATIVE CALENDAR

Milestones

Expected

Dates

Work Program (for FSP)

June 2009

CEO Endorsement/Approval

July 2009

GEF Agency Approval

Implementation Start

Mid-term Review

Implementation Completion

Aug 2010

Oct 2010

June 2015

Oct 2015

A. PROJECT FRAMEWORK

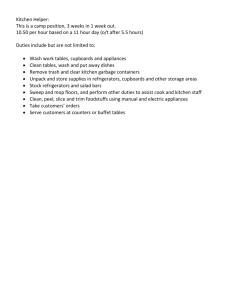

Project Objective: To reduce greenhouse gases (GHG) from the energy consumption by achieving a market

transformation towards high-efficiency appliances through the introduction of energy labels and minimum energy

performance standards.

Project

Components

(UNDP outcome)

1. Energy labelling

Indicate

whether

Invest,

TA, or

STA**

TA

Expected

Outcomes

Increased

awareness and

introduced

energy labels

2. Policy and

regulatory

framework for

labels and

standards

3.Capacity

strengthening

TA

Conducive

policy & policy

instruments on

energy efficiency

TA

Strengthened

capacity of main

stakeholders

4. MEPS

TA

5.Evaluation &

dissemination

TA

Minimum energy

performance

standards

(MEPS) adopted

Monitoring,

feedback,

evaluation

6. Project management

PIF Template, August 28, 2007

Expected

Outputs

1) Specification and

launching of energy

labels for domestic

appliances (voluntary)

2) Awareness creation

and info campaigns for

consumers and other

stakeholders

1) Market and

engineering studies

2) Regulation and

legislation (mandatory)

3) Financial incentives

1) Testing capability

enhanced

2) Enforcement of

standards and labels

3) Strengthened

institutional capacity

Minimum energy

performance standards

(MEPS) adopted for

electric appliances

1) Regular M&E

2) Best practices and

recommendations

Indicative GEF

Financing*

(‘000 $)

%

Indicative Cofinancing*

($)

%

Total ($)

900

15

4,750

35

5,650

1,800

30

3,800

28

5,600

1,800

30

1,450

11

3,250

900

15

2,800

21

3,700

300

5

100

1

400

300

5

600

4

1,000

1

6,000

13,500

19,500

Total project costs

*

List the dollar amount by project components/activities. ** STA = Scientific & technical analysis.

B. INDICATIVE FINANCING PLAN SUMMARY FOR THE PROJECT ($)

GEF Grant

Co-financing

Total

Project Preparation

95,000

135,000

230,000

Project

6,000,000

13,500,000

19,500,000

Agency Fee

609,500

Total

6,704,500

13,635,000

20,339,500

609,500

C. INDICATIVE CO-FINANCING FOR THE PROJECT BY SOURCE ($), IF AVAILABLE

Co-financing Source

Government Contribution

Utility (DSM)2

Private Sector3

Total co-financing

1

2

3

Cash

4,500,0001

4,000,000

2,500,000

11,000,000

In-kind

1,000,000

1,000,000

500,000

2,500,000

Total

6,000,000

4,500,000

3,000,000

13,500,000

This includes the standard and labelling program that DME is currently initiating with the SABS (Bureau of Standards) as

well as budget for energy efficiency promotion

This includes related financing planned under ESKOM’s Accererated Energy Efficiency Plan, which includes national

awareness creation, promoting appropriate legislation preventing the importation and use of inefficient equipment,

collaboration between stakeholders

Including contribution from manufacturers/suppliers for marketing campaigns of energy-efficient appliances and piloting of

consumer credit schemes by retailers.

D. GEF RESOURCES REQUESTED BY FOCAL AREA(S), AGENCY (IES) SHARE AND COUNTRY(IES)*

N/A

PART II: PROJECT JUSTIFICATION

A. STATE THE ISSUE, HOW THE PROJECT SEEKS TO SOLVE IT, AND THE EXPECTED GLOBAL

ENVIRONMENTAL BENEFITS TO BE DELIVERED:

The average efficiency of electrical domestic appliances currently sold in South Africa is significantly

below that of the best products on the market, largely because of customers’ and marketers’ strong

emphasis on first cost at the expense of life-cycle cost considerations, but also because of other policy,

informational and market barriers. The strategy of the proposed project is to address these barriers that

hamper the introduction of standards and labelin. Five outcomes are proposed to help overcome these

barriers

Identified barrier

Project activities planned

Awareness barriers

o Lack of knowledge and understanding

amongst consumers of energy efficiency

improvement opportunities of appliances,

o Uncertainty about market demand of highefficiency models, making manufacturers

reluctant to tie up financial resources

dealer/retailer reluctant to stock energyefficient models.

Information and policy barriers

Raise awareness among manufacturers and policy

decision makers on the benefits of introduction of

S&L programs and in cooperation with these

stakeholders and local utilities (ESKOM) outreach the

importance of energy-efficient (EE) appliances

(Outcome 1) and propose energy labels for selected

appliances (Outcome 1)

PIF Template, August 28, 2007

Detailed market analysis and energy savings potential

2

o Difficulty to take informed decisions and make

appropriate regulation, due to insufficiency of

market data (on supply and energy

consumption of most appliances and on the

potential for improving the energy efficiency);

o Lack of appropriate regulation (allowing

production and import of highly inefficient

appliance); lack of legislation for introduction

of S&L

Capacity barrier

o Insufficient capacity to design and introduce

S&L

o Lack of procedures for compliance checking

of the selected appliances to allow selection of S&L to

be designed and introduced, so that the schemes

proposed will have a high market transformation

aspect (Outcome 2) and formulate a legislative

framework for the introduction of labels (Outcome 2)

and adoption of minimum energy performance

standards (Outcome 4)

Enhance testing capacity of laboratories and

institutional capacity for the effective design of S&L

schemes, consumer, manufacturer and outreach

programs, incentive schemes and for monitoring and

evaluation (Outcome 3 and Outcome 5) and propose

compliance checking and testing procedures

Cost barrier:

Provide adequate information on cost and benefits and

o The low unit price of coal and electricity in design and implement incentives for consumers to

South Africa influences the mind-set of purchase S&L schemes (Outcome 2)

consumers and companies with the argument

that the higher initial investment cost cannot

be justified due to lengthy payback times;

o Low purchasing power of the majority of

South African households

The project is designed around the following five outcomes:

Outcome 1: Awareness creation and introduction of energy labels for electric appliances

- Output 1.1: Specification and launching of energy labels for domestic appliances1

(In 2004 DME decided to introduce the European labelling system. The first group

of appliances include refrigerators, washing machines and cloth dryers, dishwaters,

air conditioners, space heaters and stoves. Progress in implementation has been slow

related to the barriers mentioned above2. Labels will be introduced first on a

voluntary basis to get the general public manufacturers and retailers involved,

starting with refrigerators/freezers and cloth washers in 2005)3.

- Output 1.2: Awareness creation and information campaigns

1

2

3

Current labels may display the energy used as required by the existing South African National Standards (SANS), IEC and ISO

(respectively International Electro-technical Commission and International Standard Organisation) specifications. This is usually

displayed on the model and serial number tag at the back of the appliance and not visibly from the front of the appliance. The marking

does not carry a norm or “bench marked” figure. Therefore, the customer cannot compare the energy efficiency of one make to

another or to a norm for that type of appliance

The norm for labels for refrigerators is now implemented on a voluntary basis in 2004. Other norms for labels (washing machines,

tumble driers and dishwashers) have been postponed for some time and are now planned for 2009-2010. The standard for CFLs is

completed and published; standards for industrial AC motors and Set-Top boxes (for digital TV) are in the later stages for finalization.

The procedure of launching the label will encompass the following steps: (1) Energy data are collected to create a database and a norm

for the label; (2) Consensus to be built among stakeholders in drafting technical parameters; (3) SABS/SANS (SABS has officially

changed name to SANS) safety standards and performance specifications are amended to include the energy label; (4) Design of the

visual format of the label (following the European energy labelling system); (5) Define compliance deadlines (adaptation times, line

changeover schedules, inventory clearing and product availability, based on product development cycles and production). The market

and engineering analysis of output 2.1 will feed into this process.

PIF Template, August 28, 2007

3

(Appliance-specific consumer awareness campaign on labelling will be undertaken.

The campaign will inform the consumers about the label features, the importance

and potential impact of selecting efficient products for their household. In addition,

country-wide massive campaign promoting energy efficiency in general will be

launched, which launched through television, radio, magazine and newspaper

advertisements, which will be an on-going activity until the end of the project4

Outcome 2: Conducive policy and policy instruments regarding energy efficiency

- Output 2.1: Impact of voluntary label schemes (refrigerators/freezers, washing machines).

Market survey and engineering analysis of appliances (a., consumer preferences and

appliances market size, b. appliance energy use study and c. energy efficiency

improvement potential). This is an iterative process throughout the project. A first

analysis will provide the info needed for a voluntary label (air conditioners, stoves,

space heaters). A more detailed analysis will provide the info needed for a

mandatory labels (e.g., refrigerators, washing machines will move from voluntary to

mandatory labels) and eventually the necessary analysis to introduce minimum

energy performance standard (MEPS) for the before-mentioned appliances.

- Output 2.2: Mandatory labelling:

(The labelling scheme will first be introduced on a voluntary basis at first (see

output 1.1). The historically low unit price of energy, coupled with limited

awareness on energy savings potential, may result in only modest success arising

from voluntary measures5 and other non-legislative instruments. For this reason,

South Africa’s Energy Efficiency Strategy aims the voluntary labels go into

mandatory labelling of products (first starting with refrigertor/freezers and washing

machines). This requires that the product performance specification regarding

energy levels of consumption and labels is made compulsary by legislation.

- Output 2.3: Incentives and financial issues:

(The Government will not consider direct subsidies for efficient appliances

Nonetheless, over time some fiscal reforms will be considered (import duties, VAT).

Based on the study done in the PPG phase, pilot innovative mechanisms’ for

financing shall be implemented, such as the utilisation of customer credit schemes

(many customer by on credit at the retailer’s outlet) to equalise cost of poorer and

more efficient equipment (using funds from the Central Energy Fund, CEF) 6. Also,

links with ESKOM’s Demand Side Management (DSM) programme will be made

Outcome 3: Capacity strengthening of main stakeholders

- Output 3.1: Developing a testing capability:

(The process of creating energy testing capability must begin before a labelling of

standards programme is launched. The test procedure describes the method used to

4

5

6

Also, promotion and education are valuable aids to increase the effectiveness of an energy label, such as government promotion of the

program (e.g., annual efficiency awards), manufacturers campaigns (marketing of their energy-efficient products), training of retailers

(shop managers and sales persons), publication of lists of current models on the market (e.g., through easy-accessible brochures and an

Internet site) and educational programmes at schools.

For example, even if South African industry would voluntary adopt the energy efficiency label, importers may bring in goods without

the label at lower prices and poorer performance

To be financed by co-financing

PIF Template, August 28, 2007

4

measure the energy performance of a product and a testing norm that references the

appropriate testing procedures)7.

- Output 3.2: Enforcement of labels and standards

(The policing of the energy label scheme is critical in the implementation and

maintenance of a mandatory energy label system; options consist of self-certification,

in their own or third-party facilities or certification by an independent party; planning

of human and financial resources for verification and enforcement).

- Output 3.3: Capacity strengthening of stakeholders

(Strengthening of the government agency responsible for standards8, codes and

labelling and of the agency responsible for compliance monitoring; Training of

manufacturers, distributor and retailers)

Outcome 4:

Adoption of minimum energy performance standards for electric appliances

(Minimum energy performance standards, MEPS, are usually set to exclude the label

categories with the lowest energy efficiency from the market. Various methods exist

to determine the standards, e.g., statistical consideration, setting energy efficiency

target at the least life-cycle cost level, choosing the top runner model at the threshold

or adopt world’s best energy efficiency practice9. First candidates for which

standards will be introduced directly are refrigerators, geysers, boilers and fixed

stoves)10

Outcome 5:

Monitoring, learning, adaptive feedback and evaluation

(The GEF project would support the: Monitoring of the market towards compliance

and progress towards targets; Regular evaluations of the progress; Programme

evaluation; Review of programme results and, if necessary, revise programme

elements)

B. DESCRIBE THE CONSISTENCY OF THE PROJECT WITH NATIONAL PRIORITIES/PLANS

The project complements and contributes to the ongoing implementation of South African policy on

Energy Efficiency. The final draft of the South African Energy Efficiency Strategy sets a national target for

energy savings of at least 12% to be achieved by the year 2015. The draft strategy covers all economic

sectors, including public and commercial buildings, residential sector, transport, industry and

7

8

9

10

The testing procedure is the foundation for the energy standards and label of a product. Selection (adoption) of existing test procedures

is strongly preferable to inventing the wheel by designing new test protocols, e.g., the International Standards Organisation (ISO) and

International Electrical Commission (IEC) are two international entities responsible for formulating internationally recognised

appliance test procedures. In South Africa, various (commercial) independent testing facilities exist. SABS has a Test House; in

addition there are other test laboratories as well as the in-house test facilities of the manufacturers. One or several test houses should be

accredited under the South African National Accreditation System (SANAS) system to develop energy measurements, so that local

manufacturers can have their products tested and accepted for energy efficiency performance. Accreditation of EE testing procedures

will be sought with ISO and/or IEC

This means, strengthening the capacity of stakeholders other than the test labs. On the policy level, for example, by setting up a

‘Standards and Labelling Unit’ within the Directorate for Energy Efficiency of DME

GEF support is requested to ensure that stakeholder consultations and the necessary engineering and market analyses are carried out in

a systematic way in order to develop a strong standards programme, which could be as follows: (a) Expert and stakeholder

consultations; (b) Identification of product categories and key issues; (c) Engineering analysis to determine life-cycle cost and energy

performance of models;(d) Defining principle and methods for setting the standards (e.g., lowest life-cycle cost); (e) Analysis of

impacts (on manufacturers, consumers, competition, utilities, as well as economic and environmental impacts); (f) Public comments

and stakeholder negotiation; (g) Setting of final standards; (h) Introduction of relevant legislation.

The reason is that these artefacts usually come with the house a consumer buys or rents. For other appliances, such as air conditioners

the introduction of both labels and standards will be considered, while for some other appliance the introduction of labels may suffice

PIF Template, August 28, 2007

5

transportation. The Strategy further mentions that energy efficiency improvements are to be achieved

through a mix of instruments and interventions, including support mechanisms (such as labelling of

appliances; energy standards and building codes; energy audits), financial instruments (such as revisions of

the tax system and linkage with the utility ESKOM’s demand-side management programme) as well as

policy and regulatory instruments (preparation of appropriate legislation to implement the energy

efficiency strategy and implementation of regulatory means where necessary, of efficiency standards and

labels). The DME has introduced voluntary labelling schemes for refrigerators/freezers with the help of the

Bureau of Standards (SABS). Norms for labels for for washing machines tumble driers and dishwashers

were planned to be introduced by the year 2006. This has not happened so far. It is now planned for 20092010, so here the GEF support would be timely.

C. DESCRIBE THE CONSISTENCY OF THE PROJECT WITH GEF STRATEGIES AND FIT WITH

STRATEGIC PROGRAMS:

This project will directly relate to the GEF Focal Area of Climate Change and is addressing the Strategic

Priority on “Energy-Efficient Buildings and Appliances”.

D. OUTLINE THE COORDINATION WITH OTHER RELATED INITIATIVES

The project will work closely with existing programmes undertaken by means players:

South Africa Bureau of Standards and South Africa National Accreditation System (certification and

accreditation, regulation, standards and norms)

ESKOM and utilities (demand-side management programmes)

E. DESCRIBE THE INCREMENTAL REASONING OF THE PROJECT

Business-as-usual

The average efficiency of electrical domestic appliances currently sold in South Africa is significantly

below that of the best products on the market, largely because of customers’ and marketers’ strong

emphasis on first cost at the expense of life-cycle cost considerations, but also because of the other barriers.

In the absence of the proposed GEF-supported Standards and Labelling project, the efficiency of new

energy consuming appliances, equipment and lighting products sold in the South Africa would likely

continue to increase slowly from existing levels. However, the average efficiency of products currently sold

is significantly below that of the best products on the market, largely because of customers’ and marketers’

strong emphasis on first cost at the expense of life-cycle cost considerations, but also because of the other

barriers to energy efficiency in today's marketplace, mentioned above. While the Energy Efficiency

Strategy foresees the introduction of a standards and labelling programme, the challenge for South Africa is

not only to overcome the barriers to the introduction of high-efficient appliances in general, but also to

overcome the barriers to the adoption and implementation of a labelling and standards programme in

particular, such as insufficient institutional capacity and lack of specific expertise for S&L programme

implementation and financing.

The project seeks to develop a full-size grant proposal for submission to GEF funding which will enable

South Africa to address the policy, financial, information and technological barriers that block the

widespread introduction of more energy efficient domestic appliances in general, as well as the introduction

of a standards and labelling programme in particular.

To be able to understand and analyse the barriers in detail, the DME proposes to use GEF funds to set up

comprehensive consumer awareness and information dissemination campaigns and to target retailers who

PIF Template, August 28, 2007

6

play a very important role in influencing the consumer’s purchase decision. Assistance will be provided to

manufacturers in the form of assessment of the technological upgrade and energy efficiency improvement

potential and marketing support. Also, relevant institutional capacity building will be identified and

strengthened by training and technical assistance to formulate standards and labelling policy, planning and

decision-making. Specific attention will be given to addressing financial barrier issues, while potential

funding sources for energy efficiency will be identified and evaluated. The project will support DME in

seeking implementation commitment from the main stakeholders to achieve an effective market

transformation by providing information that assists consumers in making rational decisions based on lifecycle cost rather than initial investment cost. As a complementary tool to appliance labelling, minimum

performance efficiency standards (MEPS) will bring about significant improvements by removing poor

efficiency appliances from the market.

F. INDICATE RISKS, INCLUDING CLIMATE CHANGE RISKS, THAT MIGHT PREVENT THE PROJECT

OBJECTIVE(S) FROM BEING ACHIEVED. OUTLINE THE RISK MANAGEMENT MEASURES,

INCLUDING IMPROVING RESILIENCE TO CLIMATE CHANGE, THAT THE PROJECT PROPOSES TO

UNDERTAKE:

Risk

Risk mitigation

South Africa may choose not to However, the country’s Energy Efficiency Strategy as well as the White

implement

or

delay

the Paper on Energy firmly states mandatory labelling and standards as an

introduction of energy labels and ultimate goal. In addition, the structure for the proposed GEF project is to

MEPS (mandatory minimum first identify and focus on barriers and barrier removal, then to develop a

efficiency standards) for end-use menu of options suited to the specific situation of South Africa and

equipment.

demonstrating these

Manufacturers object to the

implementation of efficiency

labels and standards, fearing that

the implementation of new

regulations resulting in additional

costs

Consumers do not understand

energy efficiency labelling and

avoid purchasing energy-efficient

models owing to higher first

costs.

The proposed project will take into account the financial situation of

manufacturers and is designed to assess this situation as part of any decision

to move forward on the development of labels and MEPS. Also, the project

will be to contribute in generating awareness around business opportunities

related to energy efficient labeling.

While the project cannot eliminate the potential higher first-costs of energy

efficient models to consumers, who have a preference to spend less money

for a less efficient model, label development will be accompanied by

substantial efforts in information dissemination, consumer education, retaildirected educational materials, and other activities to both raise awareness of

the label and to educate consumers

An important barrier to successful An update of the existing market survey will be performed during the PPG

implementation is the maturity of stage to make sure all related barriers are addressed in full implementation.

the market

The FSP design will also be done in consultation with all major stakeholders

to minimize this risk. Finally, the FSP will be monitored closely on the

aspect of market risk to be able to take management decisions early in the

project cycle.

G. DESCRIBE, IF POSSIBLE, THE EXPECTED COST-EFFECTIVENESS OF THE PROJECT

The potential for savings in South Africa through standards and labelling is high in terms of energy

consumption. The Appliance Labelling Study, report no. 2.3.4-05, CaBEERE project, Department of

Mineral and Energy (South Africa, 2003) has made projections of energy savings resulting from phasing in

PIF Template, August 28, 2007

7

energy labels and standards over a 5-year period. A compilation of these projections is presented in table

below. The data will be updated during the PPG phase.

Assuming an economically useful life of 15 years for each appliance (as is done in the CaBEERE study)

this implies direct emission reduction of 2.1 million tCO2. The total potential of savings was estimated at

about 188,000 tCO2, assuming that within 10 years after introduction all appliances would be the more

energy-efficient ones (as is summarised in the table below). Including this post-project impact, total direct

and indirect emission reduction is estimated at 2.8 million tCO2.

Estimated energy and CO2 emission reduction by the project

Estimate of actual energy demand reduction

Potential

energy

demand

reduction

(GWh/yr) Year 1

Refrigerators

- single door

- two door

- freezer

Washing machines

- front load

- top load

Tumble dryer

Dishwashers

Space heating

- air conditioners

- electric heaters

Stoves

- electric stoves

- electric hot plates

Annual carbon

reduction (tonnes

CO2)

@ .96 tCO2/MWh

Annual

Year 2

Year 3

Year 4

Year 5

Total

7.6

26.8

8.6

0.4

1.3

0.4

0.8

2.7

0.9

1.1

4.0

1.3

1.5

5.4

1.7

1.9

6.7

2.1

5.7

20.1

6.4

3.4

1.5

8.1

2.2

0.2

0.1

0.4

0.1

0.3

0.2

0.8

0.2

0.5

0.2

1.2

0.3

0.7

0.3

1.6

0.4

0.9

0.4

2.0

0.5

2.6

1.2

6.0

1.5

4.7

10.9

0.2

0.5

0.5

1.1

0.7

1.6

0.9

2.2

1.2

2.7

3.5

8.1

89.3

32.7

4.5

1.6

8.9

3.3

13.4

4.9

17.9

6.5

22.3

8.2

67.0

24.5

5,472

19,296

6,144

2,496

1,152

5,760

1,440

3,360

7,776

64,320

23,520

-

195.7

9.7

19.7

29.2

39.1

48.9

146.6

140,736

Potential for energy savings and CO2 reduction

Annual savings

Refrigerators

- single door

- two door

- freezer

Washing machines

- front load

- top load

Cloth dryer

Dishwashers

Space heating

- air conditioners

- electric heaters

Stoves

- electric stoves

- electric hot plates

Annual carbon

Money ('000 reduction (tonnes

Rand)

CO2)

@ 0.3/kWh @ .96 tCO2/MWh

# of units

bought

annually

Assumed energy

consumption per

appliance (kWh)

Assumed

energy

reduction of

appliance

Energy

demand

(GWh/yr)

259,170

417,552

316,763

588

1,284

540

5%

5%

5%

7.6

26.8

8.6

2,286

8,042

2,566

244,772

158,382

187,178

71,992

281

192

864

300

5%

5%

5%

10%

3.4

1.5

8.1

2.2

1,032

456

2,426

648

51,834

483,784

1,800

450

5%

5%

4.7

10.9

1,400

3,266

532,738

259,170

3,353

2,520

5%

5%

89.3

32.7

26,794

9,797

7,315

25,735

8,210

0

3,301

1,460

7,763

2,073

0

4,478

10,450

0

85,741

31,349

TOTAL

195.7

58,711

187,875

The total requested GEF contribution is USD 6.04 million, leading to a cost-effectiveness of USD 2.14 per

tCO2 reduced.

PIF Template, August 28, 2007

8

H. JUSTIFY THE GEF AGENCY COMPARATIVE ADVANTAGE

UNDP is mentioned as having a comparative advantage in ‘energy efficiency’ projects in Annex L of the

document GEF/C.31/5 rev.1 (GEF comparative advantage matrix).

PART III: APPROVAL/ENDORSEMENT BY GEF OPERATIONAL FOCAL POINTS AND GEF

AGENCIES

A.

RECORD OF ENDORSEMENT OF GEF OPERATIONAL FOCAL POINT (S) ON BEHALF OF THE

GOVERNMENT(S): (Please attach the country endorsement letter(s) or regional endorsement letter(s)

with this template).

Ms. Pam Yako

Director General

Department of Environmental Affairs and Tourism

Date: (December 20, 2006

B. GEF AGENCY(IES) CERTIFICATION

This request has been prepared in accordance with GEF policies and procedures and meets the GEF

criteria for project identification and preparation.

John Hough

Deputy Executive Coordinator

UNDP/GEF

Date: 24 February 2009

PIF Template, August 28, 2007

J.H.A. van den Akker

RTA a.i. climate change, Eastern & Southern Africa

Project Contact Person

Tel. and Email: +31 6 27424634 / 31 40 2019240

Email: johannes.vandenakker@undp.org

9

ANNEX A. ATTACHMENTS

PIF Template, August 28, 2007

10