formal laboratory report

advertisement

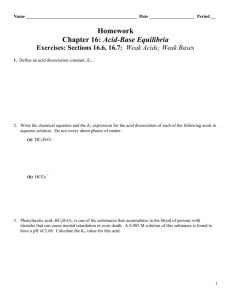

Corra 1 Acetylation of salicylic acid to acetylsalicylic acid Traci Corra Introduction The purpose of this experiment was to synthesis acetylsalicylic acid (aspirin) from salicylic acid and acetic anhydride, to monitor progression of the reaction with thin-layer chromatography and to characterize the product by 1H NMR spectroscopy1. Aspirin is one of the most widely synthesized and consumed drugs in the United States 2 and is an active ingredient in more than one hundred medications. As a non-steroidal antiinflammatory drug (NSAID), aspirin acts as a pain reliever (analgesic), as a fever reducer (antipyretic), to minimize swelling (anti-inflammatory), and to prevent heart attacks and ischemic strokes3. Although salicylic acid produces the same results as aspirin, it irritates the digestive system and must be converted to acetylsalicylic acid to be safely ingested to perform the aforementioned functions4. Proper synthesis of aspirin can be carried out by the acetylation of salicylic acid and acetic anhydride to acetylsalicylic acid. Figure 1 shows the mechanism of this reaction. Figure 1- Mechanism of acetylation of salicylic acid Corra 2 The catalyst, phosphoric acid, initiates the reaction by protonating acetic anhydride. The oxygen of the phenol group of salicylic acid then donates an electron pair to the positively charged carbon of acetic anhydride. The alcohol group attached to the new tetrahedral carbon donates an electron pair to the central carbon and loses the hydrogen to regenerate H3PO4, and then donates an electron pair to the oxygen of the former ester. The positively charged oxygen attached to the benzene ring loses the attached hydrogen to the negatively charged oxygen forming acetic acid and acetylsalicylic acid. This reaction usually does not run to completion and the product is a mixture of acetylsalicylic acid, acetic acid, and small amounts of salicylic acid. To isolate acetylsalicylic acid, vacuum filtration of the recrystallized solid with a Hirsh funnel is used and purity will initially be checked by comparing the observed melting point of the product to the known melting point of acetylsalicylic acid (134º-136ºC 5). To monitor the reaction while it is taking place, thin-layer chromatography (TLC) is used. TLC is a method of chromatography that utilizes a polar solid as the stationary phase and either a single solvent or a combination of solvents to separate two or more compounds. The mobile phase travels up the stationary phase via capillary action and molecules bond with the stationary phase based on individual polarities. The mobile phase is experimentally determined through trials of TLC plates spotted with standards of salicylic acid and acetylsalicylic acid and mobiles phases that vary in ethyl acetate to hexane ratios. The ratio that gives the best separation determined by retardation factors (Rf) values will be used during the reaction. A TLC plate will be spotted every fifteen minutes with salicylic acid, acetylsalicylic acid and the reaction mixture after the reaction begins to determine progression. The first TLC plate should show a co-spot of both salicylic acid and acetylsalicylic acid. A TLC plate showing mostly acetylsalicylic acid and very little salicylic acid indicates near completion of the reaction. Corra 3 Since the reaction does not generally run to completion, further purification of acetylsalicylic acid can be achieved through recrystallization from ethyl acetate1. Proton nuclear magnetic resonance (1H NMR) spectroscopy is the final tool to verify purity of the product after the reaction is completed. NMR utilizes a magnetic field to analyze the nuclei of molecules to provide information about the carbon skeleton and location of functional groups and hydrogens. An impure product would contain salicylic acid. The characteristic peak to distinguish acetylsalicylic acid from salicylic acid is a singlet representing 3 hydrogens between 2.1-2.5 ppm indicating the new methyl group. Multiplets between 6.5-8.0 ppm representing the four hydrogens of the benzene ring would signify pure acetylsalicylic acid and an increase of hydrogrens at said multiplets dictates contamination by salicylic acid. Experimental Determination of Mobile Phase Solvent #1 was 10 mL ethyl acetate and 0 mL hexane and solvent #2 was 9 mL ethyl acetate and 1 mL hexane. Solvents were prepared in 4.0 oz labeled jars, each fitted with filter paper. 2labeled TLC plates were spotted with salicylic acid (1%) and acetylsalicylic acid (2%) and one placed in jar #1, one in jar #2. Plates were removed and marked and Rf values were calculated. A Synthesis Compound, Acetylsalicylic Acid from Salicylic Acid Acetylsalicylic Acid. Salicylic acid (102 mg), acetic anhydride (250 µL) and phosphoric acid (85%, 4 drops) were placed in a 13 X 100 mm test tube. The test tube was capped and shaken, uncapped and placed in boiling water. Every 15 minutes, a TLC was run spotted with salicylic acid, the reaction mixture and acetylsalicylic acid. The liquid phase was 7 mL ethyl acetate 3 mL hexane. Test tube was removed from boiling water after 60 minutes and distilled water was Corra 4 added (700 µL). The mixture was cooled to room temperature and then placed in an ice bath. The product was isolated via Hirsh funnel vacuum filtration. Product was isolated as a white powder (.071 g, 53.4% yield); mp was 129°-130°C (observed). Product was recrystallized with ethyl acetate and isolated as white powder (.027 g, 20.3% yield); mp was 134°-136°C (observed). 1H NMR was run on the recrystallized sample combined with d-chloroform as the solvent. Table 1- Mobile phase of TLC composition to determine solvent 6,7,8 Mobile Phase Mixture number % Ethyl Acetate % Hexane Rf Salicylic acid Rf Acetylsalicylic acid ∆Rf 1 100 0 0.577 0.588 0.011 2 90 10 0.588 0.490 0.098 3 70 30 0.782 0.545 0.237 4 50 50 0.444 0.371 0.073 5 30 70 0.377 0.381 0.004 6 20 80 0.243 0.207 0.036 7 10 90 0.16 0.16 0.00 8 0 100 0.00 0.00 0.00 Table 2- TLC data from synthesis of acetylsalicylic acid at 15-minute intervals Time (min) 15 30 45 60 Rf salicylic Acid 0.54 0.58 0.53 0.55 Rf Acetylsalicylic acid 0.51 0.54 0.52 0.58 Rf reaction mixture 0.40 0.49 0.52 0.43 Corra 5 Table 3- Percent yield for products synthesized from salicylic acid Before Recrystallization 53.4% After Recrystallization 20.3% Table 4- Significant Peaks of 1H NMR of products synthesized from salicylic acid Peak B, C.D.E F G Ppm 7.182-8.082 2.349 0.00 Integral 5 3 NA Theoretical yield of acetylsalicylic acid (ASA) from salicylic acid (SA) 102 mg SA X 1 g SA X 1 mol SA X 1 mol ASA X 1000mg SA 138.12 g SA 1 mol SA Percent Yield Actual Yield X 100%= Percent Yield Theoretical Yield Retardation Factor (Rf) Distance spot traveled = Rf Values Distance solvent traveled 180.2 g ASA= .133 g ASA 1 mol ASA Results and Discussion Data from Table 1 was used to determine the mobile phase of 70:30 ethyl acetate to hexane. This mixture had the largest Rf values difference (0.237) between salicylic acid and acetylsalicylic acid. The TLC plates, summarized in Table 2, did not adequately depict the progress of the reaction. The first plate should have a co-spot of salicylic and acetylsalicylic acid. Each subsequent TLC plate should have progressively less salicylic acid compared to acetylsalicylic acid. The final plate should have minimal amounts of salicylic acid. However, the TLC plates did not show progression of the reaction and each plate was visually similar to the other plates with significant streaking and insignificant separation of the compounds. The product from the synthesis had a 53.4% yield and the melting point was 129°-130°C Although within 5°C of the lower parameter of the theoretical melting point of 134°-136°C for Corra 6 acetylsalicylic acid, the observed melting point bordered the lower limit and the product was recrystallized. Recrystallization decreased the percent yield by 33.1%, to 20.3% and the new observed melting point was the same as the theoretical melting point and the product was deemed pure. These results did not concur with the TLC results and most likely a different mobile phase should have been used. A less polar mobile phase, such as 30:70 ethyl acetate to hexane, may have increased separation of each compound on the TLC plates and may have resulted in more accurate representation of the reaction. The 1H NMR spectrum for the acetylation of salicylic acid to acetylsalicylic acid (Table 4 and Figure 2) shows a reference peak at 0 ppm, a singlet at 2.349 ppm and multiple overlapping multiplet peaks between 7.182 and 8.082 ppm. The peak at 0 ppm, peak g, represents the deuterated chloroform solvent. Peak f corresponds to the three hydrogens labeled f of the methyl group of acetylsalicylic acid. This peak is characteristic of acetylsalicylic acid and shows product was formed. The overlapping peaks labeled b, c, d and e represent the aromatic hydrogens. Pure acetylsalicylic acid would have four hydrogens represented here but Figure 2 shows 5 hydrogrens represented. This difference indicates slight contamination by salicylic acid. The spectrum correlates with the melting point data after recrystallization, signifying acetylsalicylic acid however; the product is not free of contamination. Conclusion To monitor the synthesis of acetylsalicylic acid from salicylic acid, TLC was not a helpful technique. The quick chromatographic scans did not show the progress of the reaction nor did it allow for prediction of the purity of the product. A less polar mobile phase may have corrected this problem, increasing component separation and preventing the observed streaking. Corra 7 Melting point determination showed pure salicylic acid yet the 1H NMR showed acetylsalicylic acid with slight contamination from salicylic acid. The reaction did create the intended product however it was not pure and had a very low final percent yield. To increase the percent yield of pure product in future replications of this experiment, more acetic anhydride could initially be added to completely react with all salicylic acid. Acetic anhydride also hydrolyzes easily when exposed to air and this premature reaction decreases the ability for acetic anhydride to react with H3PO4 and salicylic acid. Extreme care should be taken to minimize any unnecessary hydrolyzation by capping all containers immediately. References 1. Bortiatynski, J. Lab Guide for Chemistry 203, 2011-2012, pp 151-172 2. Schiavino, D.; Nucera, E.; Milani, A.; Del Ninno, M.; Buonomo, A.; Sun, J.; Patriarca, G. The Aspirin Disease. Thorax [Online] 2000, 55, 66-69. http://thorax.bmj.com/content/55/suppl_2/S66.full (accessed April 1, 2012) 3. U.S. National Library of Medicine. http://www.ncbi.nlm.nih.gov/pubmedhealth/PMH0000802/ (accessed April 1, 2012) 4. Kitamura, K.; Ma Jima, R. Determination of Salicylic Acid in Aspirin Powder by Second Derivative Ultraviolet Spectrometry. Anal. Chem. [Online] 1983, 55, 54-56. http://pubs.acs.org.ezaccess.libraries.psu.edu/doi/pdf/10.1021/ac00252a017 (accessed April 1, 2012) 5. Acetylsalicylic Acid; MSDS No A5376 [Online]; Sigma-Aldrich: March 29, 2012. http://www.sigmaaldrich.com/catalog/DisplayMSDSContent.do (accessed Feb 26 2012) 6. Espada, Sergio. Exp #7 Thin-Layer Chromatography, Mobile phase determination data, Feb Corra 8 28, 2012. 7. Gardner, Megan. Exp #7 Thin-Layer Chromatography, Mobile phase determination data, Feb 28, 2012. 8. Harding, Margaret. Exp #7 Thin-Layer Chromatography, Mobile phase determination data, Feb 28, 2012.