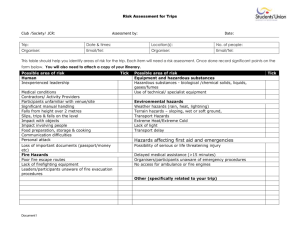

How to assess the risks

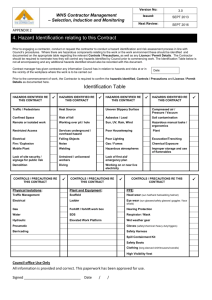

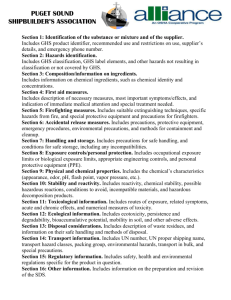

advertisement

The 5 Steps to Risk Assessment This page was originally published by the Health and Safety Executive (ref. INDG163rev1) and Crown copyright is acknowledged. What is risk assessment? A risk assessment is nothing more than a written documentation of a careful examination of what, in your work, could cause harm to people, so that you can weigh up whether you believe you have taken sufficient precautions or must do more to prevent harm. The aim is to make sure that no one gets hurt or becomes ill. Accidents and ill health can ruin lives — and affect your work too if activities are halted, equipment is damaged, or you have to go to court. You are legally required to assess the risks associated with activities you are responsible for when they may cause harm to yourself or others. The important things you need to decide are whether a hazard is significant, and whether you have it covered by satisfactory precautions so that the risk is small. You need to check this when you assess the risks. For instance, electricity can kill, but the risk of it doing so in an office environment is remote — provided that ‘live’ components are insulated and metal casings properly earthed. How to assess the risks Hazard and Risk Hazard: Anything that can cause harm (e.g., chemicals, electricity, working from ladders, etc.). Risk: The chance, high or low, that somebody will be harmed by the hazard. STEP 1: Look for the hazards STEP 2: Decide who might be harmed and how STEP 3: Evaluate the risks and decide whether the existing precautions are adequate or whether more should be done STEP 4: Record your findings STEP 5: Review your assessment and revise it if necessary Don’t be overcomplicated. In most cases the hazards are few and simple. Checking them is common sense, but necessary. You probably already know whether, for example, you have equipment that could cause harm, or if there is a dangerous cliff near where you or others may be working. If so, check that you have taken what reasonable precautions you can to avoid injury. Step 1: Look for the hazards If you are doing the assessment yourself, walk around your laboratory or area of forest where you are working or are intending to work. Consider the machine(s) you intend operating. Look at what could reasonably be expected to cause harm. Ignore the trivial (e.g. unevenness of footpath in forest) and concentrate on significant hazards which could result in serious harm or affect several people. Ask others who might be working with you what they think. They may have noticed things which are not immediately obvious. Manufacturers’ instructions or data sheets can also help you spot hazards and put risks in their true perspective. Examples of hazards: fire (e.g. flammable materials), chemicals, moving parts of machinery (e.g. blades), ejection of material (e.g. when chipping wood), pressurised apparatus, vehicles, electricity (e.g. poor wiring), dust, fumes, manual handling, noise). Step 2: Decide who might be harmed, and how Don’t forget: Machine/ apparatus/ equipment operators young students, overseas students etc., who may be at particular risk; cleaners, visitors, contractors, maintenance workers, etc. who may be unfamiliar with your workplace; members of the public, or people you share your workplace with, if there is a chance that they could be hurt by your activities N.B. lone workers – who may be more vulnerable. Step 3: Evaluate the risks and decide whether existing precautions are adequate or if more must be done Consider how likely it is that each hazard could cause harm. This will determine whether or not you need to do more to reduce the risk. Even after all precautions have been taken, some risk usually remains. What you have to decide for each significant hazard is whether this remaining risk is high, medium or low. First, ask yourself whether you have done all the things that the law says you have got to do. For example, there are legal requirements on prevention of access to dangerous parts of machinery. Then ask yourself whether generally accepted industry standards are in place. But don’t stop there — think for yourself, because the law also says that you must do what is reasonably practicable to keep your workplace safe. Your real aim is to make all risks small by adding to your precautions as necessary. If you find that something needs to be done, draw up an ‘action list’. Give priority to any remaining risks which are high and/or those which could affect the most people. In taking action, ask yourself: can I get rid of the hazard altogether? if not, how can I control the risks so that harm is unlikely? In controlling risks, apply the principles below — if possible in the following order: try a less risky option (e.g. do it a different way); prevent access to the hazard (e.g., by guarding,); organise work to reduce exposure to the hazard (e.g. forbidding access to certain areas) issue personal protective equipment – (e.g. protective eye glasses, dust masks) provide welfare facilities (e.g., washing facilities for removal of contamination, and a good first aid kit). Improving health and safety need not cost a lot. And failure to take simple precautions can cost you a lot more if an accident does happen. But what if the work you do tends to vary a lot, or you or your employees (students) move from one site to another (e.g. a field trip)? In these cases, identify the hazards you can reasonably expect, and assess the risks from them. After that, if you spot any additional hazards when you get to a site, get information from others on site, and take what action seems necessary. But what if you share a workplace? If so, tell the other people there about any risks your work could cause them, and what precautions you are taking. Also, think about the risks to your own work-force (e.g. fellow staff, students) from those who share your workplace (e.g. others who are working in the lab.). But what if you have already assessed some of the risks? If, for example, you use hazardous chemicals and you have already assessed (as you must) the risks to health and the precautions you need to take under the Control of Substances Hazardous to Health Regulations (COSHH), you can consider them ‘checked’ and move on to consider other risks. Step 4: Record your findings and ensure fellow workers or students are aware of the contents of your risk assessment You must record the significant findings of your assessment. This means writing down the significant hazards and conclusions. You must also tell your employees (students) about your findings. Obtain proof that you have shown them the risk assessment (a signed copy of the assessment, or a list of signatures of all members of a field trip). Risk assessments must be suitable and sufficient – not perfect! You need to be able to show that: a proper check was made; you considered who might be affected; you dealt with all the obvious significant hazards, taking into account the number of people who could be involved; the precautions you impose are reasonable, and the remaining risk is low. Keep the written record for future reference or use; it can help you if an HSE inspector asks what precautions you have taken, or if you become involved in any action for civil liability. It can also remind you to keep an eye on particular hazards and precautions. And it helps to show that you have done what the law requires. To make things simpler, you can refer to other documents, such as manuals, the arrangements in the SENR Health and Safety Policy statement, university rules, manufacturers’ instructions, School health and safety procedures, the “Good Chemical Practice” notice displayed in all SENR laboratories, and the arrangements for general fire safety. These may already list hazards and precautions. You don’t need to repeat all that, and it is up to you whether you combine all the documents, or keep them separately. Copies of Risk Assessments must be lodged with the Chief Technician, Mr. John Evans, and also be displayed locally to the area the activity is taking place. Should this be impractical (e.g. forestry work) then a copy of the Risk Assessment must be available for inspection. The School has the right to order the termination of any activity proceeding without a suitable Risk Assessment having been made. Step 5: Review your assessment and revise it if necessary Sooner or later you will use new equipment, procedures and substances which could lead to new hazards. If there is any significant change, add to the assessment to take account of the new hazard. Don’t amend your assessment for every trivial change, but if a new activity introduces significant new hazards of its own, you will want to consider them in their own right and do whatever you need to keep the risks down. In any case, it is good practice to review your assessment from time to time to make sure that the precautions are still working effectively. A risk assessment document could be of the following form: Page 1 of 2 School of the Environment and Natural Resources Risk Assessment Form On completion of this form (including having obtained the signature of supervisor) it is the responsibility of the student to ensure: the contents of this form must be drawn to the attention of all persons directly involved in the activity a copy must be lodged with SENR Head Technician for review by SENR Safety Committee a copy must be retained by the student and be displayed locally to where the activity is performed (e.g. in laboratory) or be available for inspection (e.g. forest, farm activity) a copy must be handed to the SENR Undergrad, M.Sc. or Ph.D. Administrator as appropriate Note. Failure to undertake a risk assessment is considered to be a serious breach of the UK Health and Safety at Work Regulations. Any student failing to complete a risk assessment prior to the commencement of research activity or failing to ensure that the above 4 requirements of SENR Safety Policy are met may be at a later time prohibited from submitting a project, thesis or honours project. This form should be used in conjunction with the document “The 5 Steps to Risk Assessment” included as Appendix 3 in the SENR Safety Policy Activity:………………………………………………………Location:……………………… Persons directly involved in activity (use an additional sheet if needed): Assessment undertaken by: (print name)…………………………… Course:……………….. Signed:…………………………………………………………Date:…………………………. Category of supervision required: (delete as necessary to be completed by supervisor) A: Those where work may not be started without direct supervision. B: Those where work may not be started without the task supervisor’s advice and approval. C: Those with risks (other than categories A & B) where extra care must be observed, but where it is considered that workers are adequately trained and competent in the procedures involved. D: Those where the risks are insignificant and carry no special supervision considerations. Approved by (supervisor): ……………………….…………………………… Date:…………....... N.B. THE COMPLETION OF THE ABOVE ALONE DOES NOT CONSTITUTE A RISK ASESSMENT. THE ATTACHED TABLE, ONCE COMPLETED, TOGETHER WITH THIS PAGE WOULD CONSTITUTE A RISK ASESSMENT Page 2 of 2 Name: …………………………….………..…………….. Significant Hazards People who are at risk from the significant hazards identified Supervisor ……………………………………………….... Existing controls or where relevant information can be found. Risks which are not Action needed adequately controlled regarding risks which are not adequately controlled.