saving oil

advertisement

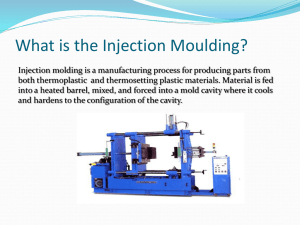

Application Case in Plastics Machinery Industry Case I Energy-saving Transformation of Senlan Inverter on Injection Molding Machine I Energy Saving Analysis of Injection Molding Machine A work piece is machined as per such a process that plastic is heated and absorbed by multi-stage heater in injection molding machine barrel and then agitated and pressurized, injected into mold cavity, pressure maintained and cooled to take shape. For plastic processing, the integrated process is as mold closing – mold locking – injecting – pressure maintaining – cooling – stripping – opening. According to the technique process of the injection molding machine, the relationship diagram between system oil pressure (P) and time (t) is as Fig. 1 below: P Injecting, pressure maintaining, cooling 注射,保压,冷却 Mold locking 锁模 Stripping, 脱模,开模mold opening 模 Mold合closing 间隙期 Interval Workflow of A Work Cycle 一个周期工作流程 Fig. 1 t Relation between System Oil Pressure and Time According to Fig. 1, mold closing, stripping and opening systems require low oil pressure and short time while injecting, pressure maintaining, cooling systems require high oil pressure and long time (generally 40%~60% of a work cycle). Time duration is related to a machined work piece. A shorter interval is also related to the conditions of a machined work piece. Sometimes intervals are not necessary. The Figure above is only a simple approximate representation, thus if injection screw is driven by oil motor, the system oil pressure will be a little higher while injecting. Pressures and times of each stage of process are also different. But oil pump still runs at 50Hz and its oil delivery is constant. The excessive hydraulic oil will flow back to oil tank through relief valve, leading to futile actions and electric power waste. Frequency-conversion speed regulation is thus required for oil pump to modify the fixed delivery pump to have features similar to variable delivery pump. After modified, when system pressure is high, the oil pump motor will run at 50Hz and when system pressure is low, the inverter will decrease the frequency to run. Shaft power output by the motor is proportional to the product of outlet pressure and flow. After oil pump motor speed is decreased, the output shaft power will decrease and effective energy saving can be realized, with a saving rate of 20%~50% in general. II Plan of Frequency-conversion Speed Regulation Energy-saving Transformation of Injection Molding Machine 1 Injection molding machine is classified into vertical type and horizontal type. A vertical injection molding machine of dozens of grams has a gear pump as its oil pump and a motor of a small capacity and a simple electric control circuit. While modifying, connect the inverter with the power supply circuit of the motor, then change the signals of proportional flow valve (0~1A) to signals of 4~20mA or 0~10V and transmit the changed signals to the corresponding port of the inverter. In this way, with the change of the processing, the flow of the hydraulic oil will also change. Injection molding machines of above 60 grams are of horizontal type. An injection molding machine of 60~500 grams may have one or two oil pumps. The transformation of the injection molding machine with one oil pump is the same as the vertical injection molding machine, i.e. take signals of 0~1A from proportional flow valve as the speed regulating signals of the inverter. Speed regulating signals is returned to the inverter by hydraulic circuit elements, but there are no demand signals in the regulating circuit, thus the control is still of open loop control type. In order to save energy, large and medium sized injection molding machines may have more than one oil pump. For example, Mitsubishi 850-MM, 1300-MM, 1800-MM, 2000-MM injection molding machines have three oil pumps. Corresponding to plastic injection process, at the mold closing stage, the system pressure is low and thus only 1# oil pump will run; when the system pressure is high at the mold locking stage, 2# oil pump will run together with 1# oil pump; when the system pressure is the maximum at the injecting stage, all the three oil pumps will run at the same time; when the system pressure is low at the stripping and opening stages, 3# and 2# oil pumps will be stopped respectively. 1# oil pump will always run as long as the machine is started. Intermittent running of three small oil pumps as per different process stages is more effective in energy saving than the continuous running of a large oil pump. How to modify injection molding machines with two or more oil pumps? Now we are taking the transformation of Mitsubishi 1800-MM injection molding machine as the example. Mitsubishi 1800-MM injection molding machine has three 45kW oil pump motors. 1# oil pump motor is driven by one Senlan SB61G+45KW inverter and the regulating signals of the inverter are taken from the proportional flow valve of the injection molding machine. In this way, the frequency of the inverter will change with the change of the hydraulic oil flow of the injection molding machine. The other two oil pump motors are respectively driven by two Senlan SB61G+45KW inverters. However, the two inverters do not regulate the speeds of the motors and only performs two-position controlling, i.e. start and stop. Signals for starting and stopping the inverters are from the start and stop signals of the original oil pump motors. The frequency upper limits of the inverters are set below 50Hz. The specific set values are related to such factors as the size and material of a machined work piece and the temperature of the barrel. If the running frequencies of the converters are less than 50Hz, energy can be saved. In fact, margin is reserved while an injection molding machine is designed and oil pressure will also change with the size and material change of a machined work piece. In this example, the running frequencies of the two converters are 37Hz and the saving rate of the injection molding machine reaches 23%. Case II Energy-saving Transformation of Senlan Inverter on Plastic Film Blowing Machine Film blowing machine is a device for manufacturing plastic film. The plastic processing machine was purchased a few years ago. It is of electromagnetic speed regulating mode. It is 2 known from the principle of electromagnetic speed regulation that it is of an energy-intensive low-efficiency speed regulating mode and its efficiency is only 85% at the highest speed and decreases with the decrease of the speed. In addition, the electromagnetic speed regulation is soft in mechanical property, poor in low speed load capacity and thus can not run at a relatively low speed. In order to save energy, frequency-conversion transformation is performed for film blowing machine as per the following method: Plastic extruder, the wind and the traction of a film blowing machine are driven by a 37kW AC squirrel cage asynchronous motor. The mechanical properties of the extrusion and the wind are all of constant torque load, thus general inverter with constant torque characteristic is selected. In this example, Senlan SB70G37KW inverter is selected. Senlan SB70 Series Inverter is a high-performance vector control inverter, with an overload capacity of 150% of the rated load, an overload maintaining duration of 1 minute and a control mode of keyboard or terminal. Other requirements of film blowing machine on the inverter include stable operation and convenient regulation. The transformation is simple, i.e. connect the inverter with the motor circuit and set that the inverter is operated by external control terminal and its speed regulated by potentiometer. In order to enable steady acceleration and deceleration, acceleration and deceleration time is set as 20s. There are two methods for motor transformation. One is to replace electromagnetic speed regulating motor with common squirrel cage motor and the other one is to regulate the electromagnetic speed regulator at its maximum and still use electromagnetic speed regulating motor to drive. The former is remarkable in energy saving and the latter is 15% less than the former in energy saving. Thus the latter is only a temporary expedient. Case III Application of Senlan Inverter on Plastic Pipe Making Machine Plastic pipe making machine is a device for manufacturing all types of hoses and hard plastic pipes. Its production line mainly consists of three parts, i.e. plastic extruder, cooling tank and traction machine. Plastic pipe making machine requires the inverter to be low in speed and big in torque, stable in speed while running at open loop so as to manufacture hoses and hard plastic pipes with even wall thickness. Moreover, the manufacturing site conditions are not very well, there is much plastic dust, the inverter is contained in a closed control cabinet and the heat dissipation condition is poor, thus the inverter with a little bigger capacity shall be selected, or the ventilation and heat dissipation shall be better carried out and dedusting repair shall be performed regularly to enable the reliable operation of the inverter. Senlan SB70 and SB60G+/61G+ Series Inverters are generally matched with plastic pipe making machine, with capacities ranging from 0.4kW to 1100kW. Each set of plastic pipe making machine is matched with an inverter, with control mode set as terminal control. It is quite simple to apply the inverter to plastic pipe making machine, i.e. regulate the output frequency of the inverter as per process at the beginning of the running and conduct no regulation during manufacturing. It shall be noted that feed screws of all plastic extruders are not allowed to invert and motor is not allowed to be started before the absorption of the heated plastic, because the motor then is at a locked rotor state and if the overcurrent protection function of the inverter is not sensitive, the feed screw may even be broken. While setting the rotation direction of motor under terminal control mode, the rotation direction shall be the same with that under keyboard control mode and both shall be forward to avoid broking feed screw while shifting between terminal control and keyboard control. Case IV 3 Application of Senlan SB70 Series Inverter in Film Winder Common film winding in industry mainly includes cloth, paper, plastic film, etc., which requires high tension accuracy. Roll diameter varies greatly. Tension requirement is variable with the increase of the roll diameter, thus tension taper control is required to prevent reel damage or internal folds. By setting existing functions and fully making use of arithmetic unit and counter, Senlan SB70 Series Inverter can realize the tension control required by film winding. The solution is as follows: Main setting frequency of the corresponding slave machine (winder) is calculated from the running frequency of the master machine (processor) representing film linear speed and the real time roll diameter of the wound film and taken as the feedforward. Meanwhile, PID regulator is used to control the film tension PID output. Setting frequency is continuously modified and the modified frequency is considered as the setting frequency of the winding motor. The control method by combining feedforward and feedback is high in control accuracy and many tension control dedicated inverters uses the method. Part I Calculation of setting frequency of winder Users need to know three values: initial roll diameter, final roll diameter, and paper thickness. Based on the three values, calculate the following values required for parameter setting: If the final roll diameter of film is 1000mm, initial roll diameter of 100mm, and film thickness of 0.05mm, then: Percentage of initial roll diameter, D0=100/1000=10%; Setting value of counter =1000/(0.05×2)=20000; Preset value of counter = 100/(0.05×2)=2000. At this moment, the count value of the counter (with setting count value as 100%) is equivalent to an output signal of a roll-diameter sensor, i.e. real-time roll-diameter value D (with final roll diameter as 100%). Considering the frequency of master machine as F0, frequency of slave machine as F, and current roll diameter as D (with final roll diameter as 100%), we know: F0×D0=F×D; It is able to calculate that: F=F0×(D0/D); First, calculate the value of D0/D through arithmetic unit 3; and then calculate the value of F0 (i.e. AI1) through arithmetic unit 2, which is multiplied by the output of arithmetic unit 3 so as to get the value of F. At this moment, the result of arithmetic unit 2 is just the main setting frequency of the winder, so the frequency setting channel for the winder is set as the setting of arithmetic unit 2. By this, the setting of main setting frequency of winder is complete. Part II Setting Calculation of PID With the method of close-loop tension control, the setting value of PID shall be set as tension value required by users. However, tension value required by users is a value continuously decreasing with the change of roll diameter rather than a constant, i.e. tension has a taper. Refer to Fig. 2. 4 Fig. 2 Tension Taper Sketch Tension taper formula is as: T=T0×[1-K×(1-D0/D)] =T0×(1-K)+T0×K×(D0/D) Wherein, T refers to the actual ideal tension value (with the maximum tension value of the tension sensor as 100%); T0 refers to initial tension value (with the maximum tension value of the tension sensor as 100%); K refers to tension taper parameter, within range of 0-100%; D0 refers to initial roll diameter (with final roll diameter as 100%); D refers to real-time roll diameter (with final roll diameter as 100%); Wherein T0×(1-K) and T0×K are constant. Then calculate the value of T0×K×(D0/D) through arithmetic unit 4, wherein the value of D0/D is the result of arithmetic unit 3 and T0×K is digital setting, and then calculate the value of T through arithmetic unit 1, i.e. T0×(1-K)+T0×K×(D0/D), wherein the value of T0×K×(D0/D) is the result of arithmetic unit 4 and T0×(1-K) is digital setting. At this moment, the result of arithmetic unit 1 is the real-time tension value required by users, and the setting channel of PID is set as the setting of arithmetic unit 1. By this, the setting of setting channel for PID is complete. Arriving here, the design of tension control solution is complete. Site running condition is as: after the master machine begins to start, the slave machine receives the start signal and begins to start and continuously regulate output frequency according to the change of roll diameter and the feedback of tension sensor so that tension sensor can change with the roll diameter change as per tension taper requirement at reference position and the winding motor can always run steadily. During deceleration, tension sensor has no large deflection till the stop. In the whole process, no deformation or relaxation happens. 5