AdebamboKF_0310_eps(1). - Heriot

advertisement

CHAPTER ONE

1.0

Introduction

The Human Immunodeficiency Virus (HIV) belongs to the class of viruses called

retroviruses. This virus causes a weakness of the immune system which results in a

disease called Acquired Immunodeficiency Syndrome (AIDS). The global epidemic of

AIDS has become one of the most pressing public health emergencies of this century.

The first reports of AIDS date back to 1981.1 However, current data suggest that AIDS

has existed for at least several decades.2

While both forms of the human

immunodeficiency virus (HIV), type 1 and type 2, are retroviruses capable of causing

fatal AIDS, a longer incubation period is generally associated with infection with the

latter together with a more indolent course of disease.3 Maternal-foetal transmission of

HIV-2 is limited, and infection with HIV-2 seems to provide natural protection, estimated

to be approximately 70%, against infection with HIV-1 in certain high-risk groups. 2 HIV2, initially endemic to West Africa, also is spreading worldwide.

Over the years, a variety of chemotherapeutic approaches towards the treatment of HIV-1

have been developed; the strategies employed target the key biomolecules which have

been identified to play important roles in the life-cycle of HIV-1 virus. The first class of

HIV-1 drugs approved for used by the United States Food Drugs and Administration

Agency (FDA), were Nucleoside Reverse Transcriptase Inhibitors (NRTIs), for example

AZT(zidovudine), d4T(stavudine). These drugs were found to exert their effect by

inhibiting the reverse transcription process whereby the HIV-1 viral RNA is converted

into viral double-stranded DNA. This is catalysed by the reverse transcriptase (RT)

enzymes. However as resistance of the HIV-1 to these NRTIs emerged, so other drugs

were required. The next generation that were developed also targeted the HIV-1 RT

enzymes.

These compounds are known as Non-nucleoside Reverse Transcriptase

Inhibitors (NNRTIs), example of these compounds are delavirdine, efavirenz, nevirapine.

The difference between NNRTIs and NRTIs is that they bind to the RT enzyme at

1

different binding sites. Unfortunately, the HIV-1 virus has also developed resistance

towards the NNRTIs over time.

Another target which has been exploited in the development of anti-HIV drugs is viral

entry into the host cell (i.e. virus fusion). The fusion inhibitor, enfuvirtide is currently

approved for HIV-1 treatment.4 Disappointingly, the HIV-1 virus developed resistance

towards these drugs. Another drug that targets HIV-1 virus entry is moraviroc developed

by Pfizer Ltd, UK. This drug was approved for use as anti-HIV therapeutic in August

2007.

Another biological target that has been extensively investigated for the development of

anti-HIV drugs is the protease enzyme. This enzyme is responsible for the cleavage of

the viral proteins (Gag and Gag-pol) produced at the end of the HIV-1 life cycle. Thus

several protease inhibitors (PIs) have been prepared and marketed to date, for example,

ritonavir, indinavir, lopinavir and atazanavir. However, like the other drug classes, HIV1 has been shown to develop resistance towards PIs.5

Since drug resistance was commonly observed in patients when taking the individual

anti-HIV-1 drug, another strategy to combat the HIV-1 virus was implemented, the

Highly Active Anti-Retrovirus Therapy (HAART). This is a combination therapy

involving the patient receiving a cocktail of three anti-HIV drugs, typically one PI and

two NRTI or one NNRTI and two NRTI. Although this approach has proved successful

with little side effects,6 HIV-1 viral resistance has been observed and there are

compliance issues for some patients.7

The emerging resistance and side effects produced through the constant administration of

the currently approved HIV-1 drugs means that there is a continuing need for the

development of new anti-HIV drugs, especially those acting on novel biological targets.

Thus, the principal objective of this research project was to prepare and evaluate a series

of novel guanine compounds for potential use as either NNRTIs or integrase (IN)

inhibitors.

HIV-1 integrase is the enzyme that enhances the integration of HIV-1

2

genomic DNA into the host cell. IN has appeared a valid new biological target for antiHIV drug intervention. Although, there are currently no integrase inhibitors on the market

which inhibit this enzyme, there are a few in clinical trials, for example, diketo aryl

(DKA) and catechols. 8 Furthermore, IN is a valid biological target as it has no human

equivalent like RT.

1.1

Global Epidemic of Human Immunodeficiency Syndrome

Since the initial report of HIV-1 in 1981, the United Nation (UN), World Health

Organization (WHO) and other public bodies have intensified their efforts towards

eradicating this deadly disease.

This has been approached from two angles, that is the

preventive approach (involving health education) and the curative approach (through

active research into a cure). The latest statistics on the world epidemic of AIDS and HIV

were published by UNAIDS/WHO in November 2006,9 and are summarised in Table 1

Estimate

Range

(million)

(million)

People living with HIV/AIDS in 2006

39.5

34.1-47.1

Adults living with HIV/AIDS in 2006

37.2

32.1-44.5

Women living with HIV/AIDS in 2006

17.7

15.1-20.9

Children living with HIV/AIDS in 2006

2.3

1.7-3.5

People newly infected with HIV/AIDS in 2006

4.3

3.6-6.6

Adults newly infected with HIV in 2006

3.8

3.5-5.7

Children newly infected with HIV in 2006

0.53

0.41-0.66

AIDS deaths in 2006

2.9

2.5-3.5

Adult AIDS deaths in 2006

2.6

2.2-3.0

Child AIDS deaths in 2006

0.38

0.29-0.50

Table 1: Global HIV/AIDS estimates, end of 20069

3

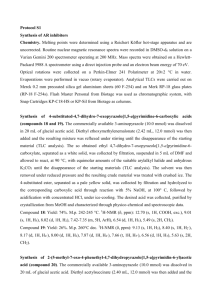

Figure 1 shows the global trend relative to reported cases of HIV-1 infection since 1990

till the end of 2005.10 From this, it can be seen that the number of people in the world

living with HIV-1 has risen from ca. 8 million in 1990 to 40 million by the end of

2005/early 2006 and this number is still growing. Furthermore, of these 40 million

people, 25 million live in sub-Saharan Africa (that is 62.5% of these people reside in

Africa).

(Year)

Figure 1

Global Trend of HIV-110

More than 25 million people have died of AIDS worldwide since 1981. Young people

(under 25 years old) make up half of all new HIV infections reported worldwide with

approximately 6,000 infected with HIV-1 every day. In developing and transitional

countries, 7.1 million people are in immediate need of life-saving AIDS drugs; however,

only 2.0 million (28%) are receiving the appropriate treatments.9

In the UK, the number of reported cases of HIV-1 infection per country between 1991

and June 2007 can be seen in Table 2. The striking feature here is that there was a

marked increase in the number of people diagnosed with HIV-1 between 2000 and 2005.

The reason for this was thought to be due to the fact that an effective health education

programme was no longer being pursued. Thus, a programme of prevention awareness

4

was undertaken. Although there was a decrease in the number of people diagnosed with

HIV/AIDS recorded the following year, it is difficult to ascertain whether this was solely

as a result of the improved prevention education strategy.

Year of

country

diagnosis

England

Wales

N.

Scotland

UK

Ireland

Channel

Isles/Isle

Total

1991

and 17,461

of Man

276

96

1,703

19,536

28

earlier

1992

2,547

50

12

138

2,747

1

1993

2,408

40

12

181

2,641

2

1994

2,373

45

15

157

2,590

8

1995

2,460

45

12

148

2,665

1

1996

2,503

35

17

170

2,725

6

1997

2,542

46

9

167

2,764

8

1998

2,661

29

9

164

2,863

6

1999

2,943

35

15

156

3,149

0

2000

3,661

45

19

159

3,884

1

2001

4,837

63

19

182

5,101

5

2002

5,938

76

27

225

6,266

7

2003

6,916

108

32

279

7,335

4

2004

7,041

107

62

346

7,556

4

2005

7,115

122

63

362

7,662

4

2006

6,595

154

57

287

7,093

2

Until

June 1,849

64

13

124

2,050

0

1,340

489

4,948

88,627

87

2007

Total

81,850

Table 2: New cases of HIV-1 infection reported in UK per annum 9

5

1.2

Viruses

Viruses are tiny infectious agents, which were first noticed by Dmitri Iwanowski on 12th

February 1892 while he was studying a mosaic tobacco disease.11 Extensive research

work in the culture of live cells and some microscopy observation led scientists in the

20th century to eventually observe the structure of virus. A representative structure of

viruses is illustrated in Figure 2.12 Viruses can be viewed as living as they have

reproductive abilities, although only with the assistance of a host organism. Since viruses

themselves do not contain ribosomes, they are unable to synthesise proteins. Thus in

order to translate its viral messenger RNA into viral proteins, the virus makes use of the

ribosomes from the host cells. Furthermore, in general, a virus cannot store or generate

energy; all their energy and metabolic functions have to be derived from the host cell.12

Bilipid layer

Nucleic Acid

Glycoproteins

Envelope

Capsid

Capsomer

Figure 2: General Structure of Viruses.12

6

As shown in Figure 2, the structure of a virus is made up of several components:

(i)

Capsid: The capsid is the viral protein coat, composed of capsomers, which

enclose the viral nucleic acids. The capsid together with its enclosed nucleic acid

is generally referred to as the nucleocapsid. The capsid has three functions: (a) to

protect the viral nucleic acid from enzymatic degradation. (b) to enable viral

binding through special sites on its surface (c) and to facilitate the virion to

penetrate the host cell membrane in order to inject the viral nucleic acids into the

cytoplasm of the host cell. Under the right conditions, viral RNA in a liquid

suspension of protein molecules will self-assemble into a capsid and become a

functional and infectious virus.12

(ii)

Capsomer: This is the morphological unit, one or more of which constitutes the

viral capsid. The capsomer consists of one or more structural unit called

protomers or monomers. 12

(iii)

Envelope: A glycoprotein envelope surrounding the nucleocapsid is common in

many viruses. The envelope is composed of two lipid layers interspersed with

protein molecules (lipoprotein bilayer) and it may contain material from the

membrane of the host cell as well as that of the virus. The virus obtains the lipid

molecules from the membrane of the host cell during the viral budding process.

However, the virus replaces the proteins from the host cell membrane with its

own proteins, creating a hybrid structure of host cell-derived lipids and virusderived proteins. Many viruses also develop spikes made of glycoprotein on their

envelopes which help them to attach to specific host cell surfaces. 12

(iv)

Glycoprotein: This substance is composed of a protein which is covalently linked

to a carbohydrate unit. The main function of the viral glycoprotein is for immune

cell recognition. The viral glycoprotein has three main parts: (1) the external

domain which interacts with the host cell, thereby leading to viral binding to the

host; (2) transmembrane segment, which is the viral envelope membrane, and (3)

the endodomain, which is mainly the internal part of glycoprotein.12

7

(v)

Nucleic Acid: This substance in the virus encodes all the genetic information that

is needed for the biosynthesis of the viral proteins. While double-stranded DNA

is responsible for this in prokaryotic and eukaryotic cells, only a few groups of

viruses actually use DNA. Most viruses house all their genetic information within

single-stranded RNA. There are two types of RNA-based viruses. These are the

plus strand RNA viruses in which the viral m-RNA ultimately produced has the

same base sequence as the original viral RNA The second class type are the minus

strand RNA viruses in which the base sequence of the messenger RNA is

complimentary to the original viral RNA. The latter viruses contain the virion

enzyme, RNA-dependent RNA transcriptase.

This enzyme catalyses the

production of complementary messenger RNA from the virion genomic RNA.12

1.3

Classification of Human Immunodeficiency Virus type 1 Strains

HIV-1 viruses can be sub-divided into three main groups denoted, M, N, and O. Group O

is restricted to West Africa, whereas N was discovered in Cameroon in 1998, although it

has subsequently been found to be very rare. The major group is Group M and this group

has been further sub-divided into nine classes (clades) as shown in Figure 3.13

HIV-1

Group M

A

B

HIV-2

Group N

C

D

Group O

F

G

H

J

K

CRFs

Figure 3: Diagram illustrating the different levels of HIV classifications13

When viruses of different subclasses meet in the cell of an infected person, they share

their genetic materials resulting in the formation of a new strain.

8

Although many of

these strains do not survive very long, those that do and go on to infect other people are

referred to as “circulating recombinant forms” (CRFs).14

The most widely spread CRFs and HIV sub-types are not evenly distributed over the

world. Sub-types B and C are the commonest strains worldwide. Sub-type C is found

mainly in eastern Africa, India, and Nepal, while sub-type B is found in Europe, the

Americas, Japan and Australia. Sub-type A and CRF A/G are common in West and

Central Africa while D is limited to east and central Africa. CRF A/E has been located in

south-east Asia, G and CRF A/G have been observed in western and eastern Africa and

central Europe. Sub-type A has only been reported in Central Africa, J only in Central

America and K only in the Democratic Republic of Congo and Cameroon. 15,16

The geographic preferences of each of these sub-types may have major applications in

the development of suitable drug regimens designed for the treatment of HIV-1

infections. Currently, most of the marketed anti- HIV-1 drugs target sub-type B. Thus, it

has been proposed that the efficacies may be compromised in regions where the strain is

not predominant. This suggestion has not yet been confirmed. To date, it is not known if

the different sub-types respond to antiviral drugs in different ways.

1.3.1 Origin of HIV-1

In 1999, a group of researchers led by Professor Beatrice Hansat the University of

Alabama at Birmingham provided an answer to the mystery surrounding the origin of this

deadly virus.17 During the course of their studies, they sequenced the genome of a new

SIVcpz (Simian Immunodeficiency Virus from chimps) strain. This sequencing was

carried out on the sub-species of all known SIVcpz infected chimpanzees. It revealed

that two chimpanzee sub-species found in Central Africa (P.t troglodytes) and Eastern

Africa (P.t. Schweinfurthii) were the reservoir of SIVcpz. Furthermore, it was deduced

that all HIV-1 strains known to infect man, including the HIV-1 groups M, N, and O

were related to those SIVcpz lineage found in P.t. troglodytes.

9

Therefore, it was

concluded that the primary source of HIV-1 is from chimpanziee sub-species the P.t.

troglodyte, which reside in Central Africa.18

The virus responsible for HIV was first isolated in 1983 by Robert Gallo of the United

States together with the French scientist, Luc Montagnier.19 Since that time, a tremendous

amount of research focusing upon the causative agent of AIDS has been carried out and

much has been learned about the structure of the virus and its typical course of action.

HIV is one of the groups of a typical virus called retroviruses that maintain their genetic

information in the form of ribonucleic acid (RNA). Through the use of a viral enzyme

known as reverse transcriptase (RT), HIV like other retroviruses, produces viral

deoxyribonucleic acid (DNA) from its RNA, upon internalization into a host cell RNA.

The viral DNA is then integrated into the host DNA the genetic information of HIV to

become permanently incorporated into the genome of the host cell.

High-resolution electron microscopy has illustrated that HIV-1 [Figure 4] is an enveloped

virus of about 100 nm in diameter. 20 It contains an outer lipid bilayer, derived from the

host cell during maturation, which consists of two major viral glycoprotein; the external

gp120 and the transmembrane gp41 protein (gp stands for glycoprotein and the number

refers to the mass of protein in kilo Daltons). Immediately inside the outer envelope is

the membrane-associated protein p18, which provides a matrix for the viral structure and

is vital for the integrity of the virion. The matrix surrounds a characteristic dense

cylindrical nucleiod, containing capsid protein p24. Inside the nucleiod are two identical

RNA strands together with the viral RNA-dependent DNA polymerase (pol) p66/p55

(that is RT), nucleoprotein p9, integrase protein p12 and protease p15.

10

Figure 4: Structure of HIV-121

1.3.2

HIV-1 Life Cycle

Figure 5 highlights the various stages in the life cycle of the HIV virus.

Figure 5: HIV life cycle22

11

a.

Viral Entry

The HIV life cycle [Figure 5] begins with high-affinity binding of the gp120 envelope

protein of HIV-1 to the receptor CD4 on the surface of the host cell.23 The CD4 receptor

is a protein molecule which is found predominantly on a subset of T-lymphocytes

responsible for the helper, or inducer function in the immune response. The binding of

the viral glycoprotein to the CD4 receptor of the host is followed by the binding of the

HIV-1 gp120 to one of the host cell surface co-receptors. There are two main types of

co-receptors on the cell surface of the host,24 the CCR-5 co-receptor, a C-C chemokine

(Chemoattractant cytokines) co-receptor, which mediates the entry of non-syncytiuminducing (NSI), or monocytotropic, strains of HIV-1 and the CXCR-4 co-receptor. This is

a C-X-C chemokine co-receptor, also known as fusin, and is expressed on the surface of

T-lymphocytes.

The complete binding of the HIV-1 glycoprotein to both the CD4

receptor and either CCR-5 or CXCR-4 co-receptor triggers conformational changes in the

viral envelope.

This exposes the hydrophobic fusion domain of gp41 and enables

complete fusion of the viral envelope with the cell membrane of the host [Figure 6].

Figure 6: HIV-1 entry mechanisms25

12

CCR-5 using viruses are the early viruses isolated in an HIV infected individual. This

isolation suggested that HIV may be selective in its choice of binding to the co-receptor,

but this does not rule the other co-receptor out completely. This might be another source

of resistance in future, should HIV-1 develop a strain that binds to the CXCR-4 co

receptor.

b.

Reverse Transcription

Following binding, the fusion of virus with the host cell membrane occurs via the gp41

envelope molecules, and the HIV-1 genomic RNA is uncoated and internalised into the

host cell. Subsequently, the viral enzyme RT copies the viral genomic RNA into doublestranded viral DNA. Human immunodeficiency virus type 1 reverse transcriptase (RT)

was discovered in 1970 by Baltimore et al.26 This enzyme [Figure 7] is a heterodimer

composed of a 560 residue subunit (p66) and a smaller subunit (p51) that contains the Nterminal 440 residues of p66. The C-terminal portion of p66 forms the RNase H domain,

while the N-terminal portion is the polymerase domain. Only p66 has a functional

polymerase action site and a DNA-binding cleft formed by the p66 fingers, palm and

thumb sub-domains. The role of p51 appears to be primarily structural.27,28

Figure 7: HIV-1 Reverse Transcriptase Structure

13

RT is used by retroviruses to transcribe viral single-stranded RNA genomes into singlestranded DNA, to construct the Watson-Crick complementary DNA strand, and

ultimately yield the double-stranded DNA required for integration into the host’s

chromosomes. Production of double-stranded DNA is primed by the host cell lysinetRNA which partly unfolds and anneals to the 5'-end of the viral genomic RNA. This is

extended by the polymerase function of the RT to give a DNA-RNA hybrid. The RNA

component of this hybrid is degraded by the RNase H function of RT once it has been

copied. The polymerase function of RT is then able to synthesise the second strand of

DNA, possibly primed by a rump of the viral RNA.29

c.

Viral Integration

The viral DNA migrates to the host cell nucleus where it is integrated into the

chromosome of the host cell through the action of another virally-encoded enzyme,

integrase (IN). The incorporation of this “provirus” into the cell genome is permanent.

The provirus may either remain transcriptionally inactive (latent) or manifest a high level

of gene expression with active production of the HIV-1 virus.30

Incorporation of viral double-stranded DNA into the genome of the host cell forms the

basis of life-long infection. Therefore, this biochemical event, catalysed by IN, is a

pivotal step in the HIV-1 life cycle and as such is worthy of investigation in the

development of new anti-HIV chemotherapies. Analysis of the structure if HIV-1 IN has

revealed that it is composed of three domains [Figure 8] and the structures of each of

these domains have been individually determined by X-ray crystallography and NMR

studies.31

14

Core

N-terminus

Catalyses

Polynucleotidyl

Transfer

Multimerization

212

50

1

HTH Fold

HH CC

Dimer(NMR)

Binds zinc

DNA binding

RNAseH

D

D

Fold

35 E

Dimer (X-Ray)

Binds Mg2+

288

SH3 Fold

Dimer (NMR)

Binds DNA

Figure 8: Three domains of HIV-1 IN

The catalytic core domain contains the invariant triad of acidic residues, Asp64, Asp116

and Glu152 (the DDE moiety).32 These catalytic residues are in close proximity and coordinated to a divalent metal ion typically magnesium. Approximately 40-100 IN are

packaged within each HIV-1 particle.28 The main function of IN is to catalyse the

integration of the viral cDNA into the genome of the infected cells. However, it has also

been postulated that it may function as a co-factor for reverse transcription.30

Although the core domain of IN is clearly responsible for catalysis, the functional roles of

the other two domains are less clear. The structure of the catalytic core domain (CCD) of

HIV-1 integrase consists of a central five-stranded β-sheet with six surrounding helices.

Three amino acids in the CCD are highly conserved among retrotransposon and retroviral

integrase.33 Mutation of these residues generally leads to a loss of all catalytic activities

of these proteins, and they are therefore thought to be essential components of the

integrase active site. Two of these amino acids in HIV-1 Integrase are Asp64 and

Asp116. The third conserved residue, Glu152, lies near the other two in a 13-residue

disordered region (not visualized by X-ray crystallography) bordered by residues 140 and

154.33

15

Studies in vitro have indicated that functional HIV-1 integrase is a multimeric protein,

but the number of monomers in a functional enzyme has not been determined with

certainty. Examination of the crystal structure shows two contacts between CCD

monomers, one of which suggests a dimeric model for functional integrase. In this

contact, the two monomers are related by a dyad axis, with a large, solvent-excluded

surface (1300 Å2/monomer).

The interaction between core domain monomers can be

compared to the interactions involved in antibody binding of protein antigens, which

generate solvent excluded interfaces of ~800 Å2 for each molecule.34

The C-terminal domain of IN binds DNA non-specifically. The N-terminal domain of

HIV-1 contains a conserved pair of His and Cys residues, a motif similar to zinccoordinating residues of zinc fingers. Although this domain does indeed bind zinc35 its

structure is totally different from that of conventional zinc finger proteins. It consists of a

bundle of three α-helices36 and has an SH3 fold, although there is no known functional

responsibility with SH3 domains of other proteins.

Retroviral integration occurs through a series of DNA cleavage and joining reactions.37,38

The integration process is illustrated in Figure 9. In the first step (3'-end processing), IN

removes 2 nucleotides from the 3'-end of each strand of linear viral DNA so that the viral

3'-ends terminate with a conserved cystine-adenosine (CA) dinucleotide. The second step

(3'-end joining) is a concerted cleavage-ligation reaction during which IN makes a

staggered cut in target DNA at the cleavage site. The product of this reaction is a gapped

intermediate. The last step is 5'-end joining. The integration process is completed by

removal of the 2 unpaired nucleotides at the 5'-ends of the viral DNA and repair of the

gaps between the viral and target DNA. This interaction produces the short direct repeats

that flank the provirus. The latter step is likely performed by host DNA repair enzymes;

thus, inhibition of either of the first 2 steps is likely to inhibit viral integration and

subsequent replication.

16

Figure 9: Schematic illustration of IN-mediated 3'- end processing of viral DNA and

nucleophilic attack on host DNA. HIV IN first removes 2 nucleotides from each 3'-end of

long terminal repeat (LTR) leaving terminal CA dinucleotide. This processed genome

undergoes nucleophilic attack on host chromosomal DNA (strand transfer) catalyzed by

IN. The resulting product is repaired, likely mediated by host repair machinery.39

d.

Viral Maturation/ Cleavages

Once the viral DNA enters the nucleus, where it is integrated into the genetic material of

the cell by HIV-1 IN, the activation of the host cells results in transcription of the viral

DNA into messenger RNA, which is then translated into viral proteins. HIV-1 protease

(PR), the third virally-encoded enzyme is now required at this stage to cleave the viral

polyprotein precursor into viral proteins.40 Protease enzymes are responsible for the

cleavages of gag protein (the protein of the nucleocapsid envelope around the RNA of the

retrovirus) and gag-pol proteins to produce structural and functional viral proteins.

17

HIV-1 PR is a 99 amino acid aspartyl protease which functions as a homodimer with only

one active site which has C2-symmetry in the free form.40,41 PR carries out its catalytic

process by:

(a)

making use of activated water molecules to attack the amide bond carbonyl of the

scissile bond of the substrate [Figure 10], the water molecule can be activated by

either the zinc cation (zinc metalloproteinase) or by the two aspartyl β-carboxyl

groups at the active site (the aspartate proteases).40

(b)

using the nucleophillic atom of an amino acid side chain to initiate amide

hydrolysis. This is done by the activation of the hydroxyl group or thiol by

another amino acid side chain. This activated nucleophile attacks the carbonyl of

the scissile amide bond [Figure 10] to form an ester or a thioester acyl

intermediate. Eventually, this acyl enzyme intermediate is hydrolysed by a water

molecule to the corresponding hydrolysis products.40

Scissile bond

S1

S3

N

H

Figure 10:

P1

P3

O

S'2

P2'

O

H

N

N

H

O

O

H

N

O

N

H

P2

P1'

S2

S'1

H

N

O

N

H

O

P 3'

S'3

The nomenclature P1…Pn, P1’…Pn’ designate amino acids residues of

peptide substrates. The corresponding binding sites on the protease are

referred to as S1…..Sn; S1’……Sn’

18

Based on the fact that HIV-1 PR enzyme can be classified as an aspartic protease,

Suguma et al. [Figure 11]42 proposed a mechanism for the action of HIV-1 PR in the life

cycle of HIV-1 virus. They proposed that the Asp. group that is closer to the nucleophilic

water molecule was assigned negative charge [Figure 11], and the water molecule that is

held between the catalytic aspartates is activated by the negative aspartate side chain. The

activated water molecule then attacks the carbonyl group in the substrate scissile bond to

generate a tetrahedral intermediate. The protonation of the scissile amide N atom and

rearrangement result in the break down of the tetrahedral intermediate to the hydrolysis

products.43

P1

P1

H

N

H

N

O

O

H H

H O

P 1'

O

H

H

O

O

O

O

O

O

D

O

D

D

D

T

G

P 1'

OH

T

T

T

G

G

G

P1'

O

+ H 2N

OH

P1

O

H

O

O

O

D

D

T

T

G

G

Figure 11: Catalytic mechanism for aspartic protease proposed by Suguma et al.42

19

Furthermore, Jaskolski et al.44 proposed a new model for HIV-1 PR; in this mechanism

[Figure 12], the hydrolysis reaction is viewed as a one-step process during which the

nucleophillic water molecule and the acidic proton attack the scissile peptide bond in a

concerted manner.44

Figure 12: Concerted catalytic mechanism for HIV-1 protease enzyme suggested by

Jaskolski et al.44

The activation of the provirus from the latent state by selective and constitutive host

transcription factors, notably from the NF-Кβ family of DNA enhancer binding proteins,

leads to the sequential production of various viral m-RNAs. These m-RNAs are

subsequently translated into the regulatory proteins, Tat, Rev and Nef. The viral core is

formed by assembly of these proteins, enzymes, and genomic RNA at the plasma

membrane of the cells. Budding of the progeny virion occurs through the membrane of

the host cell, where the core acquires its external envelope. During the final budding

process, cleavage of the gag-pol polyprotein precursor by HIV protease occurs, which

leads to morphological maturation of virions.30

20

1.4

Common Chemotherapy of Human Immunodeficiency Virus Type 1

Infection

As shown above in section 1.3, the replicative cycle [Figure 5] of HIV-1 presents several

viable biological targets that have been and still are being exploited in the development of

current and future anti-HIV drugs. These are:

(i)

Viral entry

(ii)

Reverse transcription

(iii)

Viral Integration

(iv)

Gene expression

(v)

Cleavage agents

(vi)

Virion maturation.

By inhibiting any of these stages, HIV-1 can be prevented from spreading throughout the

cell. 45

1.4.1 Viral Entry Inhibitors

A number of compounds have been designed to block the interaction of HIV-1 virus with

the CCR-5 co-receptors. Examples include: vicriviroc 146, aplaviroc 2 and moraviroc 3

[Figure 13]. The subsequent problem of high liver toxicity47 has since led to the

termination of the use of aplaviroc and vicriviroc. Moraviroc, which was developed by

Pfizer, was reviewed on April 24, 2007 by United States Food Drug and Administrations

and it was recommended for approval, on August 6, 2007.48

21

Figure 13: HIV-1 viral entry inhibitors

Another compound which targets the entry mechanism of HIV-1 is fuzeon 4 (Enfuvirtide,

or T-20), Fuzeon is a peptide-based drug [Figure 14]. Fuzeon inhibits formation of the

initial entry interaction between the HIV-1 gp41 and the CD4 receptor of the host.

Fuzeon blocks the virus before the cell fusion process, therefore it has no effect on the

intracellular process of the host.

Gp41 of the HIV-1 virus consists of cytoplasm,

transmembrane and extracellular domains.49 There are four major functional domains in

the extracellular domain of gp41. These regions are: fusion peptide (FP), N-terminal

heptad repeat (NHR1 or NHR2), the C-terminal heptad repeat (CHR2 or CHR1) and a

22

triptophan-rich (TR) region. These regions were considered as potential targets for

designing HIV-1 drugs.

CH3CO-Tyr-Thr-Ser-Leu-Ile-His-Ser-Leu-Ile-Glu-Glu-Ser-Gln-Asn-Gln-Gln-Glu-LysAsn-Glu-Gln-Glu-Leu-Leu-Glu-Leu-Asp-Lys-Trp-Ala-Ser-Leu-Trp-Asn-Trp-Phe-NH2

4

Figure 14: The amino acid sequence of Fuzeon

Fuzeon exerts its anti-viral effect by preventing changes in the conformation of gp41 that

are required by the HIV-1 virion to enter the host cell.50,51 Figure 15 illustrates this

inhibition process in more detail.

NH2

HR1

HR2

COOH

2

1

Fuzeon

Figure 15: Inhibition process of fuzeon

Fuzeon binds to Heptad Repeat (HR1) of the gp41 glycoprotein, thereby preventing HR1

from interacting with Heptad Repeat (HR2,) and so inhibiting the formation of the coiledcoil bundle necessary to initiate fusion of HIV-1 to the host cell.52,53 Liu et al. 25 observed

that the inhibition of fusion takes place by interacting with the gp41 NHR to form stable

six-helix bundles (6-HB) and blocking gp 41 from forming a fusogenic core between

viral gp41 NHR(N-terminal Heptad repeat) and CHR(C-terminal Heptad Repeat). The

principal problem associated with the use of Fuzeon is that HIV-1 has found a way to

produce mutations in the heptad repeat 1(HR1).

23

1.4.2

Reverse Transcriptase Inhibitors

HIV-1 reverse transcriptase inhibitors can be divided into two major classes: The

nucleoside (NRTIs) and non-nucleoside reverse transcriptase inhibitors (NNRTIs).

1.4.2.1

Nucleoside Reverse Transcriptase Inhibitors (NRTIs)

Nucleoside reverse transcriptase inhibitors (NRTIs) are nucleoside analogues and they

exert their effects by binding to RT and inhibiting viral DNA synthesis, thus preventing

the virus from replicating.54 Examples of some common NRTIs are AZT (3′-azido-2′, 3′dideoxythimidine, or retrovir zidovudine) 5, d4T (stavudine) 6, and ddc (zalcitabine) 7

[Figure 16]. During the inhibition process, the NRTIs are first converted into their active

triphosphate forms by a process known as phosphorylation (Scheme 1). This

biotransformation is an enzyme-catalysed process. The enzymes commonly employed

are thymidine kinase, deoxycytidine kinase or inosine phosphotransferase. These

enzymes initially convert the NRTIs into their corresponding monophosphates which are

subsequently triphosphorylated. Once in their triphosphate form, they can be incorporated

into the ss-DNA by RT during the reverse transcription process. However, since the

NRTIs lack the 3′-OH present in natural nucleotides, subsequent elongation of the chain

is prevented and thus DNA synthesis terminates.55

O

CH3

HN

HO

CH3

HN

N

O

NH2

O

O

HO

N

O

N

HO

N

O

O

N3

5

AZT(Zidovudine)

7

6

d4T(Stavudine)

ddC(Zalcitabine)

Figure 16: Structure of some current NRTIs

24

Scheme 1: Incorporation of nucleoside analogues into elongating viral component

DNA47

25

1.4.2.2 Non-nucleoside Reverse Transcriptase Inhibitors (NNRTIs)

The other major family of small ligand inhibitors of HIV-1 RT are the non-nucleoside

reverse transcriptase inhibitors (NNRTIs).

Non-nucleoside reverse transcriptase

inhibitors are non-competitive inhibitors; this is because their binding position is quite

different from the DNA binding site. The NNRTIs share a number of properties which

distinguish them from the previously described NRTIs. They are highly specific, they

present little cytotoxicity and they do not require activation through intracellular

metabolism and phosphorylation to exert their effect.35 NNRTIs bind allosterically to the

enzyme, thereby leading to an alteration in the conformation and functions of the

enzyme. NNRTIs interact with the RT enzyme at a hydrophobic pocket located near to

the polymerase active site of the enzyme. This binding site is called the non-nucleoside

binding site (NNBS).56

There are four key amino acid residues present in the

hydrophobic pocket, Phe 227, Trp 229, and Leu 234 from the “palm” region of the

binding site and Tyr 319 from the “thumb” region [Figure 7, page 13].

These four

residues are conserved throughout the HIV-1 strains (wild-type and mutants).57

The first generation of NNRTIs introduced in 1990s and approved by USA FDA for

clinical use are nevirapine 12, delavirdine 13, and efavirenz 14 [Figure 17].58

26

Efavirenz

14

Figure 17: Structures of some NNRTIs

The NNRTIs primarily bind to hydrophobic pocket in the RT which is located in the p66

subunit.59 Although efavirenz, nevirapine and delavirdine bind in the same general area

of the hydrophobic pocket, some differences exist in their specific interactions. As a

result, on virologic failure some NNRTI mutations are more likely to occur with certain

NNRTIs. K103N, for example, is typically associated with initial efavirenz resistance,

while Y181C is associated with initial nevirapine resistance. These mutations, although

considered to be drug specific, can still lead to significant cross-resistance among the

three first generation NNRTIs.

These first generation NNRTIs suffered set backs because the HIV-1 virus was able to

develop resistance to these compounds.

A single mutation in the amino acids in the

binding site eliminates the effectiveness of these compounds. In addition to the multidrug resistance developed by the virus, some side effects such as deadly toxicities have

27

been reported for efavirenz 14 and nevirapine 12 and this is a major limitation to the use

of first generation NNRTIs.

In order to overcome the multi-drug resistance problem of the first generation NNRTIs,

rilpivirine 15 and etravirine 16 [Figure 18] were developed by Tibotech Pharmaceuticals

and are currently in their different stages of clinical trials. These compounds are classed

as second generation NNRTIs. They were designed in order to overcome the resistance

mechanisms through “conformational flexibility”; both etravirine and rilpivirine are able

to alter their shape and position in order to bind to the NNBS in the enzyme RT.60,61

Figure 18: Structures of some second generations NNRTIs

Structural studies of etravirine, a diarylpyrimidine (DAPY) analogue,59,62 indicate that it

possesses several characteristics that enable it to bind in the hydrophobic pocket of the

reverse transcriptase enzyme using multiple conformations.

These characteristics include:

*

the ability to bind in at least two conformationally distinct modes,

*

the ability to exercise torsional flexibility and develop alternative conformational

variants, and

*

the ability to reposition itself within the hydrophobic pocket to promote better

binding, this is as a result of its compact nature.63

28

Ripilvirine is well tolerated with less CNS disturbance than efavirenz, and has nonteratogenic potential.64

1.4.3

Resistance

of

HIV-1

Reverse

Transcriptase

Enzymes

to

Reverse

Transcriptase Inhibitors

The tolerance of HIV-1 RT to non-standard base pairs and modified ribose units is very

high. The high tolerance made it easier for the reverse transcriptase enzymes to develop

a great rate mutation in the HIV-1 genome. It has been observed that about 10 bases

mutate in the HIV-1 genome per replication cycle.65 Numerous toxic effects such as

lactic acidosis and hepatic steatosis have been associated with the use of NRTIs. The

reason for their toxicity has been linked to the inhibition of mitochondrial DNA

synthesis.66,67

The emergence of one or more HIV-1 strains with altered RT genes leads to resistance of

the HIV-1 to nucleoside analogue drugs. A novel NNRTI resistance-conferring mutation,

M230L, which was identified in NNRTI-experienced patients, has been associated with

dose-dependent stimulation of HIV replication.68

This mutation can dramatically

decrease susceptibilities to NNRTI drugs. Pharmaceutical companies are still working on

new categories of NNRTIs such as benzophenones and diaryl pyrimidines (DAPYs).

1.4.4 Highly Active Anti-Retroviral Therapy

As highlighted earlier, due to resistance of HIV-1 towards the current approved FDA

drugs when administered individually, there was a need for the investigation of a multidrug or combination therapy (this type of drug therapy is known as HAART). HAART,

which was developed in 1996, is now the standard treatment for HIV-1. Typically,

HAART consists of one protease or non-nucleoside reverse transcriptase inhibitor

(NNRTIs) being given in combination with two nucleoside reverse transcriptase

inhibitors (NRTIs). This combination regime has been found to effectively suppress HIV-

29

1 replication thereby leading to the restoration of the immune system of an HIV-1

infected patient.69

However, there are several limitations to HAART. Firstly, it is often not well tolerated

by the patients. Furthermore, long term exposure of patients to PI-containing HAART

has been shown to result in several side effects such as hyperbilirubinaemia, insulin

resistance, hyperlipidaemia, body fat redistributions, osteopenia, and osteoporosis.70

Thus, HAART requires discipline, is expensive and can lead to the development of multidrug resistance if the regimen is not adhered to correctly.71,72 Based on these problems,

additional therapies are needed especially those which act on another site in the HIV-1

virus life cycle. The requirement to find alternative drugs has led to the evaluation of

another target in the HIV-1 virus for drug interaction. This target is the third viral

enzyme, HIV-1 integrase.

1.4.5 Integrase Inhibitor Compounds

The first IN inhibitor was reported about ten years ago.73 Although there are no IN

inhibitors yet on the market, some have now reached the early stages of clinical trials.

The IN inhibitors are discussed under the following headings.

1.4.5.1 The Diketo Aryl Compounds

The most clinically advanced IN inhibitor recorded to date is compound 17 [Figure 19]

developed by Merck and GSK-Shionogi. This compound belongs to the diketo aryl

(DKA) class of compounds which act by selectively inhibiting the strand-transfer process

catalysed by IN.

30

17

Figure 19: Structure of a DKA

The characteristic of DKA is selective inhibition of the integrase strand-transfer step at

nanomolar concentrations.74 Inspite of the selective strand-transfer properties of DKAs,

they have also been found to have some remarkable effects on 3′-processing at 30-70 fold

higher concentrations.75 Another of Shionogo’s DKA compounds 5ClTEP 18 proved to

be important because it was co-crystallised with the CCD of IN in close association with

the catalytic DDE triad.76 Further development in the use of DKA IN inhibitors led to the

discovery of naphthyridine carboxamides 22. This is considered to be a DKA-like

molecule because it contains a β-hydroxyl ketone and it shares a similar IN inhibitory

mechanism to DKAs (selectively inhibits the strand transfer process). Another DKA

derivative, 19 [Figure 20], has also reached clinical trials.

For adequate binding of DKA to HIV-1 integrase, a divalent metal ion is necessary. For

example, it was found that 17, through the carboxylate functionality, bound to both Mg2+

and Mn2+ effectively, but 5ClTEP, 18 [Figure 20], showed better inhibitory properties in

the presence of Mn2+ than

Mg2+.

Therefore, the replacement of tetrazole by a

carboxylate markedly increases the inhibitory activity of the hybrid compound in Mg2+.77

The carboxylate, therefore, might be important for metal chelation.78 The carboxylate

portion is, however, not required for binding to the integrase complex. SAR studies have

revealed that the presence of an aromatic ring in the drug is an important requirement for

the potency and for strand-transfer selectivity of the IN inhibitors. It has been shown that

the aromatic groups can be functionalised with a wide range of substituents including an

azido group 23.79 The azido functionality of azido-DKAs contributes to reduced toxicity

and has a direct role in metal chelation. 79

31

Figure 20: Chemical structures of antiviral integrase inhibitors

The functional diketo or β-hydroxy-keto groups are known to have metal-chelating

functions and metal-dependent inhibition by DKAs and DKA-like compounds has been

32

interpreted as indicating a direct interaction of these drugs with the divalent metal in the

enzyme catalytic site.79 The metal coordination could also be important for shaping the

catalytic pocket of integrase and therefore the DKA-binding site.79, 74

Figure 21 shows the interaction of the integrase (IN) 3′- processing inhibitor, 5CITEP,

bound to HIV-1 IN. 5CITEP is drawn with an orange carbon backbone while the donor

DNA-interacting amino acid residues are represented as sticks. The putative metal ions

within the IN active site are shown as yellow spheres.

Finally, the possible hydrogen

bonding interactions between 5ClTEP and the active site amino acid residues are

indicated as dashed lines.80

Figure 21 Possible binding mode of integrase inhibitor 1880

The binding of DKAs to integrase has been a focus for researchers because of the

importance of DKAs and DKA-like derivatives as antiviral lead compounds and their

unique mechanism of action. The proposed mechanism of action of DKAs is illustrated

in Figure 22.

33

Figure 22: Proposed mechanism of action of DKAs

The model above [Figure 22] shows that DKAs inhibits integrase at the interface with

viral DNA and divalent metal ion. The model shows that:79

34

(a)

integrase has two binding sites, namely the donor site of the viral DNA (blue

colour) and the acceptor site for the host DNA (red colour).

(b)

after 3′-processing, the integrase-DNA undergoes structural changes that render

the acceptor-site competent for binding the host DNA.

(c)

binding of the host (acceptor) DNA to the donor site leads to strand transfer.

(d)

the DKA inhibitor (grey colour) can only bind to the acceptor site after 3′processing.

(e)

the hypothetical binding of DKAs, for example MA-DKA, at the interface of the

integrase-DNA-divalent metal complex. The processed viral 3′-DNA end (blue

colour) is bound to integrase (the three acidic catalytic residues are shown in red),

ready to attack a host DNA phosphodiester bond.

A proposition has been made that DKAs chelate the metal in the integrase catalytic site

and stabilize the macromolecular integrase-DNA complex at the 3′-processing step of the

reaction. 79

Recently, raltegravir 24, a β-diketo acid compound, has been reported to inhibit HIV-1

integrase.81 This compound was approved by the FDA on October 12, 2007 for use with

another anti-HIV agent in the treatment of HIV-1 infection; it is the first IN inhibitor to

be approved by the FDA. Raltegravir has been found to inhibit the strand-transfer

process of HIV-1 IN and to exhibit a potent in vitro activity against both wild type and

more importantly, a wide range of drug-resistant HIV-1 clinical trials isolates. 82

35

24

Figure 23: Structure of raltegravir

1.4.5.2 Catechol Derivatives

Catechol derivatives are another class of possible HIV-1 integrase inhibitors that have

been reported.83 The biological activities of catechol derivatives have been attributed to

the presence of bis-aryl moieties in their scaffold, and this is a very significant structural

component in many of the potent catechols derivatives. These compounds are made up

of two aryl units, one of which contains 1,2-dihydroxy substitution and separated from

the other aryl unit by the linker.

Among this class of compounds is caffeic acid

83,84,85

[Figure 24]. Compound 25 was reported to exhibit

phenethyl ester (CAPE) 25

good inhibition against isolated HIV-1 IN, but due to dose limiting toxicities in in vitro

studies, it could not be further investigated.

This, therefore led to the investigation of

other IN inhibitors such as, compounds 26 (1-methoxyoxalyl-3,5-dicaffeoyl quinic acid,

DCQAs) 83 and compound 27 L-chicoric acid (7-decaffeoyltartaric acid) in an attempt to

overcome the problem of toxicities. These compounds were found to inhibit HIV-1

replication and integration. In another studies to overcome the toxic effects of catechols

in cell culture,83 which might be related to the cross reactivity of metal-dependent

requiring enzymes or covalent protein modification, a new class of HIV-1 IN 28 was

synthesised. These catechol isosteres inhibit HIV-1 IN enzymes in vitro. 83

36

Figure 24: Structures of some catechol derivatives

However, it has been postulated that catechol derivatives elicit their effects by interfering

with the co-ordination of metal ions required for phosphoryl transfer rather than directly

binding to IN itself.83

37

1.4.5.3 Other Integrase Inhibitors

29

30

Figure 25: Structures of other IN inhibitors

Compounds 29 and 30 [Figure 25] are promising anti-integrase agents because they have

a favourable pharmacokinetic profile. This is because their oral bioavailability is >60%

and half life of about 5 h in rhesus macaques.86 Compound 29 and 30 have reached

clinical trials.87

Other potential IN-specific inhibitors [Figure 26] have been investigated. The antiviral

activity of compound 31 has been demonstrated to reduce the effect of viraemia as well

as chronic infections in rhesus macaques infected with simian immunodeficiency virus.

Compound 32 has been shown to inhibit HIV-1 IN in vitro, but its antiviral target has not

yet been established in HIV-1 infected cells.79

Figure 26: Structures of other potential IN inhibitors

38

1.4.6

Protease Inhibitors

It has been reported that budding immature viral particles that contain a catalytically

inactive form of HIV-1 PR cannot undergo maturation to afford an infective form of the

HIV-1 virus.40 Based on this premise, a number of HIV-1 PR inhibitors (PIs) have been

designed to make sure that PR enzymes are rendered inactive.

Therefore, PIs were

designed in such a way that the hydrolysable peptide linkage has replaced by the nonhydrolysable hydroxyethylene group.

HIV-1 PIs act by blocking HIV-1 aspartyl

protease, a viral enzyme that cleaves the HIV-1 gag and gag-polyprotein at nine specific

cleavage sites to produce shorter, functional proteins.

Three of the nine cleavage

reactions occur between phenylalanine or tyrosine and a proline residue.40

In general, PIs show only slight side effects and a tolerable toxicity profile. 40 However,

one of the main complications of PIs is that there is a risk of lipodydstrophy. This

symptom encompasses a wide range of manifestations such as insulin resistance,

hyperlipidaemia and body fat redistribution. This manifested in PIs interfering with the

metabolism of fat through cytochrome P450 enzymes in the liver.

There is also an increased risk of HIV patients developing cardiovascular diseases with

PI therapy. Some widely used PIs [Figure 27 and 28] include saquinavir88 33 which was

developed by Hoffman-La Roche (kί = 0.12 nM), amprenavir 34 was discovered by

Vertex pharmaceuticals (kί = 0.6 nM),89 Lilly and Agouron reported nelfinavir 35 (kί = 2

nM),90 indinavir 36 (kί = 0.56 nM)91 developed by the Merck group, while Abbott

laboratories marketed ritonavir 37 (kί = 0.01 nM)92and lopinavir 38 (kί = 0.003 nM).

Unfortunately, due to the high polymorphism of HIV-1, the virus rapidly selects for

variant PI-resistant strains. This kind of resistance has often been observed for HIV-1

positive patients after treatment with PIs approved for clinical use.40

39

Figure 27 FDA approved protease inhibitors

40

Figure 28 Other FDA approved protease inhibitors

1.5

Guanine-Derived Compounds as Novel HIV-1 Therapeutics

The research reported in this thesis is based on the investigation of novel guanine

compounds as HIV-1 therapeutics. Therefore, this section will focus on the various

attempts that have been reported to develop HIV-1 drugs bearing guanine scaffolds.

1.5.1 Guanine-Derived Compound as RT Inhibitors

The first carbocylic guanine compound to show potential as a therapeutic agent for

HIV/AIDS was carbovir (carbocyclic-2′,3′-didehydro-2′,3′-dideoxyguanine) 39 [Figure

29].93

41

39

Figure 29: Structure of carbovir

Both the racemic form of carbovir and its (-)-enantiomer have been synthesised and

evaluated in various cell lines.94 (-)-Carbovir (EC50 = 0.31 μg/mL in MT-4 cells) was

found to be approximately two-fold more potent than the racemic version (EC50 = 0.52

μg/mL in MT-4 cells), indicating that most of the anti-HIV activity of racemic carbovir

resides in the (-)-carbovir.95 Carbovir is believed to exert its anti-HIV-1 effect by the

same mechanism as other dideoxy nucleosides, such as AZT and ddC.96

Analogues of carbovir, compounds 40 and 41 [Figure 30], have recently been synthesised

and their anti-HIV-1 activities have been evaluated.97 Both of these compounds were

synthesised in their racemic forms. The carbocyclic oxetanocin98 40, and the adenosine

analogue 41 were found to have an EC50 of 0.2 μg/mL in the MT4-cell line; however, the

IC50 of 40 was 40 μg/mL. The oxetanocin hypoxanthine 40 was found to have the highest

selectivity index of all the oxetanocin-purine tested.

42

40

41

Figure 30: Structure of analogues of carbovir

Cyclobutyl G, compound 42 [Figure 31], is another guanine-containing compound that

has been found to be very active against HIV-1 as well as other viral diseases such as

herpes simplex virus (HSV-1 and HSV-2) and hepatitis B. This compound has been

found to be resistant to phosphorolytic cleavage by pyrimidine nucleoside phosphorylase

enzymes due to the absence of a furanose ring oxygen.97,99 The therapeutic activity of

carbocyclic nucleosides has been attributed to their conformational mobility, the distance

separating the hydroxymethyl oxygen and pseudo-glycosidic nitrogen, the presence of

lipophilic groups and the absolute and relative configurations of these molecules.100

42

Figure 31: Structure of Cyclobutyl G

Guanosine prodrugs have been successfully used in improving the pharmacokinetics of

already potently-active, guanosine NRTIs.101

For example, the 6-oxopurine ring

substituent in dioxolane guanosine (DXG) 43 and carbovir [Figure 32] has been replaced

with an amino group to afford diaminopurine dioxolane 44 and abacavir 45 respectively.

43

The presence of the amino functionality in these guanosine analogues improves their

lipophilicity, solubility and oral bioavailability. The presence of the cyclopropyl

substituted secondary amine in abacavir 45 improved its absorption into the central

nervous system. 102

Figure 32: Structures of guanine prodrugs

Compound 45 is currently in Phase I/II of clinical development for the treatment of HIV1. Compound 45 exerts its biological effect by first being deaminated by adenosine

deaminase. The resulting dioxolane guanine (DXG) is then further metabolised to its 5′triphosphate form (DXG-TP) by host cell enzymes.103 Subsequently, DXG-TP acts as a

potent substrate inhibitor of the HIV-1 RT.104 The incorporation of DXG 5′-triphosphate

(DXG-TP) into nascent DNA results in chain termination. It has been shown that a virus

harbouring HIV-1 RT mutations which are resistant to AZT, abacavir and efavirenz

remained sensitive to inhibition by DXG. 105

44

Acyclovir 46 [Figure 33] is another example of a guanine-containing compound that has

antiviral activity.106 Acyclovir is able to carry out its inhibitory activity because it has

greater affinity for the HSV viral form of thymidine kinase than the human equivalent.

Thymidine kinase converts acyclovir into acyclovir monophosphate which is then further

transformed into its corresponding diphosphate by another cellular enzyme, guanylate

kinase. Finally, upon being transformed into its triphosphate form, it binds to HSV RT

and terminates the replication cycle of the HSV virus. 107

46

Figure 33: Structure of acyclovir

Furthermore, guanine derivative 47 [Figure 34] has been found to show comparable

activity with that of PMEA 48 against HIV-1 and HIV-2 in MT4-cell cultures and against

clinical HIV-1 isolates from peripheral blood mononuclear cells.108 The anti-retroviral

activities of PMEG 49 and compound 47 in cell culture were found to have EC50 values

of 0.26 μM and 17.7 μM respectively.

45

Figure 34: Structures of other antiviral purine compounds

1.5.2 Guanine-Derived Compounds as IN Inhibitors

Recently, a family of G-tetrad-forming oligonucleotides has been developed as potential

anti-HIV therapeutic drugs.109

The G-tetrad (G-quartet) DNA structure was first

determined by Gellert et al.110 G-tetrads are multi-stranded structures held together by

square planes of four guanines interacting by forming Hoogsteen hydrogen bonds.111

Each G-base makes two hydrogen bonds to its neighbouring G-bases (N1 to O6 and N2

to N7) [Figure 35].112 G-tetrad formation is the fundamental driving force for a large

number of G-rich DNA and RNA oligomers to form highly ordered structures. These

oligomers have been found to be involved in human genomes and telomerases.113 They

have also shown promising applications in nanotechnology. Inhibition of integrase

activity in vitro strongly depends on the stability of the G-quartet. When associated with

K+ ions [Figure 36], they form symmetrical and compact intramolecular G-tetrads and the

folded loop domains greatly increase their structural stability.114 This highly stable and

46

compact structure enhances the permeability of the guanosine tetrad-forming

oligonucleotides into cells and their ability to resist nuclease digestion. The structural

features of the G-tetrad induced by K+ ions are essential for the inhibition of the HIV-1

integrase activity.114

The most potent inhibitors of HIV-1 integrase were found to be T30695,

5′g*ggtgggtgggtggg*t-3′ and T30177, 5′-g*tggtgggtgggtggg*t-3′(where * shows that

there is a phosphorothioate linkage at the two end g residues.).109

IC50 values of

inhibition for HIV-1 integrase 3′-processing and strand transfer, obtained from a gelbased method, were 47 and 24 nM for T30695 and 79 and 49 nM for T30177.109 NMR

and kinetic data have been used to demonstrate that, in response to K+ binding, T30695

folded into a stable and symmetric G-tetrad. The folding was shown to be a two-step

process, and is dependent on the nature of the alkali metal ion added. The first step of the

process involved the coordination of one K+ ion, which competes with a Li+ ion to bind

within the core of two G-tetrads. The second step involves the binding of two additional

K+ ions to the loop domains. NMR and optical analysis have shown that the second

binding step is associated with substantial ordering of the oligonucleotides fold.109 NMR

data and molecular modelling have determined that T30695, in the absence of K+ and

presence of Li+ ions, forms an intramolecular G-tetrad with opened loop structures. Upon

coordination with three K+ ions, the loop structure is rearranged, and the bases of loops

are folded onto the underlying G-quartets. The structure of T30695 in the presence of K+

becomes symmetric and compact. The inhibition of HIV-1 integrase activity was found to

greatly increase upon K+ binding to the loops. Thus, the folding of the loop domains of

these oligonucleotides plays an important role in the function of G-tetrad forming

oligonucleotides.115

47

dR

H

N

N

H

N

H

H

N

N

H

O

O

H

H N

N

N

H

H

N

O

N

N H

O

N

dR

N dR

N

H

H

N

H

N

N

N

N

N

dR

H

H

Figure 35: Four G-bases associate through Hoogsteen hydrogen bonding to form a cyclic

structure 115

dR

H

N

N

N

H

N

N

H

H N

K+

O

O

N

N

H

N

dR

N

H

N dR

N

N

H

N

H

O

O

H

H

H

H

N

N H

H

N

N

N

N

dR

H

Figure 36: Assembly of four guanine nucleobases into a G-tetrad stabilized by a central

potassium ion.116

1.6

Peptide Nucleic Acids

Peptide nucleic acids [PNAs] [Figure 37] are DNA mimics which were originally

developed by Nielsen et al. in 1991.117 In order to overcome some of the limitations

associated with natural or other oligonucleotides analogues which had been developed at

the time. These include poor cellular uptake and nuclease stability. PNAs contains an

uncharged pseudo-peptide backbone in place of the normal sugar-phosphate backbone,

which is isomorphous with the DNA backbone [Figure 38].118,119,120,121 The nucleobases

48

of peptide nucleic acids are attached to the pseudo-peptide backbone via a methylene

carbonyl linker. Peptide nucleic acids are able to mimic DNA and RNA perfectly,

because they contain an achiral backbone and they are relatively flexible.117

Figure 37: Peptide Nucleic Acid

49

NH2

A

N

N

N

N

O

U

HO

O

O

NH

N

OH

O P

O

O

NH2

O

N

O5'

NH2

N

N

HO

O

OH

N

P O

O

3'

T

O

P

N

OH

O

G

O

N

O

O

NH

O

O

O-

N

N

O

A

C

NH

N

NH2

O

-

O

N

O

O

P

O

O

O

O

N

P

O

O

P

O

N

N

O

O

O

P

OH

O-

O-

O

O3'

O

N

-

O

O

C

O

5'

RNA

NH2

G

NH

N

NH2

O

-

O

DNA

O

O

P

O-

O-

Figure 38: Structures of DNA and RNA

1.6.1 Properties of Peptide Nucleic Acids (PNAs)

PNAs and DNA have no functional groups in common except the nucleobases and as a

result of this they have completely different chemical stability. For example, DNA

depurinates on treatment with strong acids while PNAs are acid stable. This is the major

reason why it is possible to synthesise PNAs using the standard protecting groups from

50

peptide chemistry which requires cleavage with trifluoromethanesulphonic acid or

anhydrous HF.122

PNAs bind with higher affinities to complementary nucleic acids than their natural

counterparts. A mixed purine-pyrimidine PNA hybridizes to complementary ssDNA and

RNA oligomers in a sequence specific manner by the formation of anti-parallel double

helices in compliance with the Watson-Crick base pairing rule (A binding to T and C

binding to G).123 PNA backbones, unlike DNA and RNA, are uncharged. The presence

of the uncharged PNA backbone gives relative stability to the complexes formed by

PNAs, either with itself or with DNA or RNA, because there is no electrostatic repulsion

when PNA hybridizes to its target nucleic acid sequence.122,124,125

For example,

PNA:ssDNA hybrids are more stable than the corresponding DNA:DNA complexes and

this results in an increase in the melting temperature (Tm) of approximately 1 °C/base.

The formation of PNA: DNA duplexes have been investigated using the pentadecamer HTGTACGTCACAACTA-NH2.126 This oligomer forms a duplex with complementary

antiparallel DNA with a Tm of 69.5 °C, whereas the corresponding DNA: DNA duplexes

have a Tm of 56.1 °C.

PNA: RNA complexes are even more stable showing an increase

in about 1.5 °C/base compared to DNA: RNA hybrids. Homopyrimidine PNAs form

extremely stable (PNA)2/RNA triplexes with target RNA and shown similar Tm values to

their corresponding (PNA)2/DNA triplexes.

The most interesting aspect of the PNA: DNA duplex is its dependence on ionic strength.

According to Tomac et al.127 the Tm of DNA: DNA hybrids were shown to increase by

more than 20 °C for a 10-mer with increasing salt concentrations, whereas the Tm of

PNA: DNA duplexes decreased. The contrasting effect of ionic strength on duplex

formation can be explained by the association of counter ions in the case of DNA: DNA

duplex formation and by displacement of counter ions in the case of PNA: DNA duplex

formation.128

Furthermore the formation of (PNA)2/DNA triplexes has been observed when

homopyrimidine PNAs or PNAs with a high pyrimidine:purine ratio bind to

51

complementary DNA using both Watson-Crick and Hoogsteen base pairing in a 2:1

stoichiometry [Figure 39].

The thermal melting (Tm) obtained for these types of

complexes has been found to be greater than 70.0 °C for decamer hybrids. However, the

length of the oligomer has been observed to be an additional contributory factor to the

stability of the triplex formed. For example, an increase in Tm of ca. 10 °C per base pair

has been observed.129,130

Figure 39

These triple helices are much more stable than their corresponding DNA duplexes. For

example the Tm value of the hybrid of the PNA “10-mer” H-(T)10 with its Watson-Crick

complementary deoxyribose (dA)10 was measured as 73 °C whereas the corresponding

(dT)10:(dA)10 is less than 23 °C.

The high stability of (PNA) 2/ DNA triplexes enables strand displacement to occur upon

targeting double-stranded DNA. During strand displacement, the homopyrimidine PNA

oligomers displace the pyrimidine strand of the complementary dsDNA targets to form a

(PNA) 2/DNA triplex with the homopurine strand. This type of displacement gives rise

to a P-loop.

The formation of the P-loop during strand invasion has been visualized

using electron microscopy.133

For example when a linear dsDNA target containing

d(A) 98/d(T) 98 insert was challenged with PNA H-T10-LysNH2, a P-loop of 90-100 bases

in length were was observed.131 ,132 ,133 Homopurine PNAs also invade dsDNA but fail to

form triplexes and their invasion complexes are less stable.134 With a few exceptions,135

52

strand displacement using mixed sequence PNAs has not been observed; presumably this

is because their strand invasion complexes are even less stable. Figure 40 below gives a

summary of the three binding modes of PNA with dsDNA.136, 126 ,137

D loop

PNA

PNA

PNA

dsDNA

Nucleobases

dsDNA

Nucleobases

A

Triplex

dsDNA

Nucleobases

PNA

B

C

Triplex

Duplex

invasion

Invasion

Figure 40: Complexes of PNA with dsDNA128

Finally, PNAs can also form extremely stable duplexes with another strand of

complementary PNA. For example a duplex formed by the PNA decamer H-gtagatcact(L)-Lys-NH2 and the complementary sequence H-agtgatctac-(L)-Lys-NH2 has a Tm of 67

°C compared to a Tm of 33.5 °C reported for the corresponding DNA/DNA duplex.138

1.6.2

PNAs as a Potential Anti-HIV-1 Therapeutics

Peptide nucleic acids manifest high biological stabilities.139 They have high resistance

against cell nucleases, proteases and peptidases.140 Another advantage of PNA is that they

generally exhibit low toxicity and they are not prone to non-specific binding to cellular

proteins.130 However, a slight draw back to their use is that PNA oligomers may undergo

very slow enzymatic hydrolysis in both cell extracts and in vivo.133

53

Peptide nucleic acids can inhibit the transcriptional process because of their ability to

form a stable triplex structure with DNA.

This type of complex formed creates a

structural hindrance which affects the working of the RNA polymerase.141,142

However, despite their numerous advantages, PNAs possess a number of limitations.

Since pure PNAs are neutral compounds with a tendency for self-aggregation and limited

water solubility, they show poor bioavailability.143 In addition, they cannot be delivered

into the cell by conventional cationic formulations such as liposome (as well as

lipofectin, lipofectamine, e.t.c) or microspheres.137 However, the introduction of charged

groups, for instance a C-terminal lysine amide, can greatly improve their solubility.

Another difficulty is that PNA aqueous solubility drops with increasing length and

purine: pyrimidine ratio.144

The higher the purine content, the higher the aqueous

solubility of the PNA. Homoadenine PNA polymer has been found to be highly watersoluble.

Positive charges have also been introduced by modifying the PNA backbone,

for instance by replacement of the glycines by lysines.137 The incorporation of only two

such groups was found to greatly increase the solubility of the oligomers. Alternatively,

negative charges can be introduced into the oligomers, such as by preparing PNA-DNA

chimeras. These too showed enhanced water solubility.134

1.7

Aims and Objectives of the Research

Currently, there are about twenty one antiretroviral drugs approved for the treatment of

HIV-1 infections,145 but the problems of cost, toxicity, viral suppression and drug

resistance still persist. Therefore, there is a need to synthesise new compounds with

antiretroviral activity and to exploit novel drug targets.

From section 1.4, it is clear that two major classes of RT inhibitors have been

investigated (the NRTIs and NNRTIs). It has been shown that NNRTIs have a number of

specific properties which distinguish them from the NRTIs. The NNRTIs are highly

specific, present little cytotoxicity and do not require activation through intracellular

metabolism and phosphorylation to exert their effect. Furthermore, it has also been

54

shown that the first generation of NNRTIs suffered a set back because the HIV-1 virus

was able to develop resistance to these compounds. The resistance of HIV-1 virus to the

first generation NNRTIs was as a result of the way they bind to the amino acids in

NNBS. A single mutation in the amino acids in the NNBS affects the binding of the first

generation NNRTIs to the NNBS. Hence, there is a need to discover another generation

of NNRTIs which will be able to overcome this resistance mechanism. Based on this

resistance problem, another generation of NNRTIs is being investigated; notable among

these second generation NNRTIs are etravirne and riplivirine. These compounds are able

to overcome the resistance mechanism through their conformational flexibility.

Upon closely examining the structure of the second generation NNRTIs, it was clearly

seen that, these compounds bear desirable features (aromatic substituents and hydrogen

bond donor) which are required for binding in NNBS. Based on these desirable features,

it was reasoned that the proposed guanine compounds were worthy of examination as

potential NNRTIs.

Since guanine-rich natural oligonucleotides T30695, 5′g*ggtgggtgggtggg*t-3′ and

T30177, 5′-g*tggtgggtgggtggg*t-3′ have been shown to be potent HIV-1 integrase

inhibitors, it was reasoned that PNA analogues of T30695 and T30177 would also be

potential HIV-1 integrase inhibitors. The stability advantages of PNAs towards nucleases

and proteases mean that these guanine-rich PNA compounds will be more stable than the

natural oligonucleotides in the cell.

In order to synthesise these guanine-rich PNA oligomers using conventional peptide

synthesis, the synthesis of protected guanine-PNA monomers 48 and 49 [Figure. 41] in

high yield was first required.

55

Figure 41: Guanine PNA monomers

The challenges in the synthesis of 48 and 49 were that guanine molecules are notoriously

insoluble in aprotic organic solvents and there is a problem of non-reactivity of the 2amino group on the purine ring. Therefore, one of our aims was to design a high yielding

route to the synthesis of Cbz- and Boc-protected guan-9-ylacetic acids. The classical

carbamate peptide protecting groups Cbz and Boc were the groups of choice since it is

known that these moieties would remain intact during the peptide synthesis protocol but

could be readily removed at the end of solid phase synthesis of PNA oligomers.

Therefore, the aims of research work were:

1

To develop a high yielding route for the synthesis of Cbz-and Boc-protected

guan-9-ylacetic acids.

2.

To synthesise guanine PNA monomers 48 and 49 [Figure 41], which would be

used subsequently in the construction of guanine-rich PNA oligomers.

3

To biologically evaluate the guanine derivatives synthesised as HIV-1 reverse

transcriptase and integrase inhibitors.

56

4

To initiate structure-activity studies on active compounds.

5

To explore the solution phase synthesis of guanine dimers.

6

To investigate solid phase synthesis of guanine-rich PNA oligomers i.e the PNA

analogues of T30695 and T30177.

57

CHAPTER TWO

RESULTS AND DISCUSSION

CHEMICAL SYNTHESIS OF GUANINE-CONTAINING COMPOUNDS

As outlined in section 1.7, one of the aims of this research was to design reproducible and

high yielding routes to the synthesis of N2-Cbz- and N2-Boc-protected guan-9-ylacetic

acid. These compounds, once synthesised, would be coupled to the “traditional” PNA