Syllabus - California University of Pennsylvania

advertisement

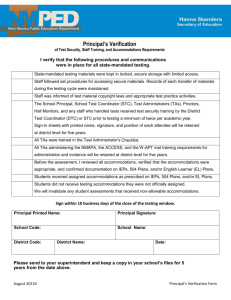

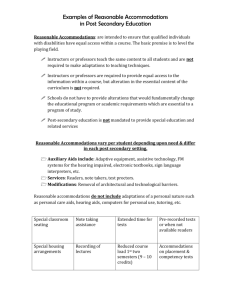

California University of Pennsylvania University Course Syllabus Approved: Department of Applied Engineering and Technology A. Protocol Course Name: Course Number: Credits: Prerequisites: LABORATORY DESIGN AND MAINTENANCE TED 476 3 Upper Class Standing B. Objectives of the Course Upon completion of this course, the student should be able to: 1. Review a variety of laboratory facilities and evaluate their adequacy as an educational environment to teach technology curriculum and activities. 2. Redesign an existing laboratory so that it would have an educational environment conducive to the teaching of technology curriculum and activities. 3. Design a technology laboratory that has multi-purpose capabilities. 4. Evaluate the safety aspects related to technology-based activities and how they influence the design of a laboratory and the equipment contained in that facility. 5. Review an existing laboratory using a safety evaluation checklist to determine if that facility is up to code. 6. Develop a maintenance system for a technology laboratory. 7. Develop a routine maintenance program for the equipment in a technology laboratory based on the information contained in the service manuals for the equipment. 8. Troubleshoot and diagnose problems with equipment and make recommendations for repair. C. Catalog Description This is an advanced placement course designed to further prepare students who are about to begin teaching in a technology-based laboratory or who are already teaching in one. The course will have three main focuses. It will examine the requirements of a technology-based laboratory and contrast it with the needs of an industrial arts-based facility. Secondly, it will look at the safety requirements of such a facility and its associated activities. Finally, the course will present information on routine laboratory maintenance, maintenance systems, troubleshooting and machine repair. This course consists of three hours of lecture/laboratory per week for 15 weeks. D. Outline of the Course 1. Technology Education Facility Design a. Industrial Arts facility requirements i. Curriculum ii. Activities iii. Laboratory size requirements iv. Laboratory space v. Laboratory structure vi. Utilities vii. Safety viii. Special needs students b. Technology Education facility requirements i. Curriculum ii. Activities iii. Laboratory size requirements iv. Laboratory space v. Laboratory structure vi. Utilities vii. Safety viii. Special needs students 2. 3. Technology Education Facility Safety a. Systems approach to safety b. Safety systems components c. Environmental factors d. Human factors e. Tools and equipment f. Processes g. Materials h. Outside influences Laboratory Maintenance a. Maintenance system design b. Routine maintenance schedules c. Basic maintenance information d. Specific tool information e. Troubleshooting and diagnosing equipment problems f. Laboratory maintenance service contracts E. Teaching Methodology This course consists of three hours of lecture/laboratory per week for 15 weeks. A variety of teaching methods will be employed including but not limited to: lecture/demonstrations, laboratory activities, field trips, guest speakers, audio-visual materials, and computer applications. Students will gain practical experience in evaluating and developing laboratories appropriate for technologybased activities. Students will also gain an understanding of the safety requirements and applications for such a facility. Additionally, students will develop skills necessary to maintain and repair the equipment appropriate for a technology-based facility. F. Texts DeLuca, W. & Haynie, J. (1989). Safety system design for technology education. International Technology Education Association: Reston, VA. Irwin, D. (1971). Power tool maintenance. McGraw-Hill: New York. Polette, D. (1991). Planning technology teacher education learning environments. Council on Technology Teacher Education: Reston, VA. Pennsylvania Department of Education (2002). Pennsylvania safety guide for technology education and elementary science and technology education. (electronic media). Pennsylvania Department of Education: Harrisburg, PA. G. Assessment Activities Student assessment will be based upon exams, activities and assignments. Students will be expected to satisfactorily complete a facility evaluation in an actual school setting. They will need to evaluate the facility in terms of its appropriateness for use in teaching technology education content and associated activities, maintenance plan/program, and safety system compliance. H. Accommodations for Students with Disabilities Students with disabilities: Reserve the right to decide when to self-identify and when to request accommodations. Will register with the Office for Students with Disabilities (OSD) each semester to receive services. Will present the OSD Accommodation Approval Notice to faculty when requesting accommodations. Might be required to communicate with faculty for accommodations which specifically involve the faculty. Office for Students with Disabilities Requests for approval for reasonable accommodations should be directed to OSD. Approved accommodations will be recorded on the OSD Accommodation Approval notice and provided to the student. Students are expected to adhere to OSD procedures for self-identifying, providing documentation and requesting accommodations in a timely manner. The OSD is located in Keystone Education Building – Room 112 and the phone number is (724) 938-5781. I. Supportive Instructional Materials, e.g. library materials, Internet access, etc. The Internet will be the primary source for supportive instructional materials. Additionally, equipment manuals are available in the technology laboratories and will be used by the class. Web Sites: International Technology Education Association: www.iteawww.org Technology Education Association: www.teap-online.org Technically Speaking: http://www.nap.edu/books/0309082625/html/ The Basics of Power Tool Maintenance: http://www.toolnewz.com/november2001/maintenance.html Maintaining Power: http://www.facilitiesnet.com/ms/Apr02/apr02engineeringc.shtml Periodicals: Advanced Materials & Processes. Incorporating - Metals Progress. American Machinist & Automated Manufacturing. Design Engineering. Fine Woodworking. Modern Metals. Modern Plastics. Plastics Technology. Professional Safety. TEAP Journal. Technology Teacher. Wood and Wood Products. Cunningham, B. (1974). Woodshop tool maintenance. Glencoe-Bennett & McKnight: Mission Hills, CA. DeLuca, W. & Haynie, J. (1989). Safety system design for technology education. International Technology Education Association: Reston, VA. Irwin, D. (1971). Power tool maintenance. McGraw-Hill: New York. Kibbe, R. (1987). Machine tool practices. Wiley and Sons: NY. Long, R., Graham, C. & Ulrich, A. (1988). Facility planning guide. Pennsylvania Department of Education and the Technology Education Association of Pennsylvania: Harrisburg, PA. Paxton/Patterson (1993). Technology education facilities planning guide. Paxton/Patterson: Chicago, IL. Pennsylvania Department of Education (2002). Pennsylvania safety guide for technology education and elementary science and technology education. (electronic media). Pennsylvania Department of Education: Harrisburg, PA. Polette, D. (1991). Planning technology teacher education learning environments. Council on Technology Teacher Education: Reston, VA.