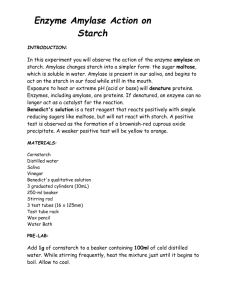

Amylase in saliva

advertisement

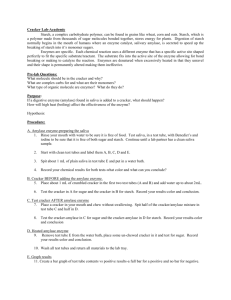

-1 Enzymes and Macromolecules Macromolecules are large molecules made up of small, relatively simple, subunits that are strung together. During the process of anabolism, macromolecules are made. Catabolism is the process of breaking them down. Most of the chemical reactions that must occur to either make or break down a macromolecule do not happen spontaneously under normal conditions. For example, starch is a macromolecule made up of many glucose subunits (monomers) joined together. Even when left out in the oxidizing atmosphere, starch will not break down to glucose. Unless subjected to extreme conditions (ie high temperatures etc.) the shelf life of commercial products like corn starch is very long. When eaten by an animal however, starch is readily broken down to glucose and used as an energy source. This does not require high temperatures or other conventional methods of breaking chemical bonds. Enzymes are the biological catalysts that allow the chemical reactions necessary for metabolism to occur without under relatively mild conditions. All enzymes are composed primarily of proteins, so they themselves are macromolecules made up of many amino acid subunits. Along with the protein, some enzymes may also require cofactors. These cofactors may be either metal ions or complex organic molecules. Vitamins are organic cofactors that are not naturally produced by the human body. Frequently these cofactors are involved in temporarily holding electrons or functional groups during chemical reactions. By acting as electron acceptors or donors, holding molecules in very specific orientations, and stressing specific bonds in a molecule, enzymes lower the energy of activation of chemical reactions. The net result is that reactions that naturally proceed in a certain direction with a net release of energy (-ΔG) require much less activation energy (energy to get the reaction started). This is the trick that enzymes do when they cause normally very slow reactions to occur rapidly. They can not change the direction in which a reaction will proceed, but they can lower the activation energy enough to increase the rate of the reaction manyfold. Enzymes are typically very specific as to the reactions they speed up. For example, 2 H 2 O2 _2 H 2 O + O2 the enzyme catalase detoxifies hydrogen peroxide (H2O2) in the following reaction: But catylase will not breakdown other peroxides or molecules similar to hydrogen peroxide like water. When enzymes stop working, the results may be dramatic. Many poisons destroy the activity of specific enzymes resulting in illness or death. For example, some insecticides prevent the enzyme acetylcholine esterase from working properly. This results in loss of control of muscles and consequently the random buzzing of wings and twitching of limbs seen in dying insects. Strychnine has a similar effect on vertebrates. All of the factors that result in denaturation of proteins will typically destroy enzyme activity. These include changes in temperature, pH, salt concentration, and osmolarity of the enzyme's environment. Many enzymes have other more specific effects. These effects fall into two categories: 1) Allosteric inhibition involves binding of the inhibitor to somewhere on the enzyme other than the active site (the place where reactions actually take -2 2) place). This may result in changes in the shape of the enzyme so that the active site is no longer available and consequently catalysis stops. Competitive inhibition usually involves chemicals that resemble in some way the normal substrate for the enzyme. These analogous of the normal substrate bind to the active site and as a consequence, it is not available for the normal substrate so catalysis does not occur. Each type of inhibition results in different effects on the rate of reactions catalyzed by the enzyme. If enough substrate is present so that the active site of the enzyme is occupied by substrate essentially 100 % of the time, the rate of the reaction is limited by the concentration of enzyme not substrate. When this limit is met, the reaction will go no faster even if more substrate is added. Allosteric inhibition lowers the effective concentration of the enzyme so that the maximum rate of the reaction is reduced and adding more enzyme will not result in a higher rate of reaction. In competitive inhibition, the situation is somewhat different, the inhibitor and normal substrate are in a competition for the active site of the enzyme, but the effective concentration of the enzyme is not changed. This means that if the concentration of substrate is increased and the concentrations of enzyme and inhibitor are left constant, the rate of the reaction will increase until it reaches its limit due to enzyme concentration. The limit will be reached at a much higher substrate concentration than in the absence of inhibitor. What is happening here is that the enzyme active site can be occupied by either substrate or inhibitor so that if substrate is in a high concentration, it is much more likely to occupy the active site and thus the reaction is more likely to occur. In today's laboratory we will be looking at salivary amylase found in human saliva. Salivary amylase As with most enzymes, the function of salivary amylase can be deduced from the name. "Salivary" refers to the fact that it is found in saliva. Amylose is a kind of starch in which glucose monomers are joined by α(14) linkages. It is commonly found in many foods particularly in the form of amylopectin, a starch that includes α(16) linkages on some glucose monomers thus allowing branching at those points. The suffix "ase" is usually added to the end of enzymes as an indication that the name refers to an enzyme. If you ever see a word with "ase" at the end, it is probably a good guess that it is the name of an enzyme. Salivary amylase is very specific in the way it breaks down starch to glucose. It inserts a water molecule at the α(14) linkage closest to the end of the amylose molecule thus releasing a glucose molecule. When an α(16) linkage is encountered at a branch point, the enzyme cannot break it, so a resistent end is left. In the digestive system, α(16) linkages are broken by another enzyme called an α(16)-glucosidase. This enzyme is not found in saliva so the ends of all the glucose chains are digested off leaving a resistant core with α(16) linked glucose at the end of each branch. This resistent "core" is called a limit dextrin, a substance that forms the base for mucilage (library paste). Another example of the specificity of salivary amylase is the fact that it will not digest the β(14) linkages found in cellulose even though cellulose is chemically very similar to starch in that it is a polymer of -3 glucose monomers. Exercise 1 1. Take a slice of bread and chew on it until you begin to taste some sweetness. This sweetness is glucose that has been produced during the digestion of starch by salivary amylase in your saliva. Exercise 2 Test for enzyme activity 1. Collect 3 ml of saliva in a 10 ml graduated cylinder. Do not include bubbles as part of your volume. 2. Transfer the saliva to 2 1.5 ml microcentrifuge tubes and centrifuge at top speed for 5 min. This step removes cells and food debris that may be in your saliva. 3. Transfer the supernatant to a fresh 1.5 ml microcentrifuge tubes being careful not to disturb the pellet at the bottom of the centrifuged saliva. Discard the old tube and the pellet. 4. Test for amylase activity by taking 4 clean 5 ml test tubes and number them 1-3. Into each test tube place the following: Test Tube 1 2 3 4 5 Supernatant ml 0.2 0.2 0 0.2 0.2 Buffer Starch Glucose ml ml 0.6 0.2 0.6 0 0.6 0.2 0.6 0 0.6 0 dH20 ml 0 0 0 0.2 0 ml 0 0.2 0.2 0 0 Note: Only test tube 1 is checking for enzyme activity, the other test tubes are controls. Test tube 2 is a positive control, as no starch is added, it should show us what results to expect if all the starch is digested. Test tube 3 is a negative control, as no enzyme was added, the starch should not be digested and thus should be present when starch is tested for. Test tube 4 is another kind of negative control that ensures that the reaction products do not produce a positive result with the test we are using for starch. Test tube 5 is for use in Exercise 4, put it aside for later use. 5. After 5 min. at room temperature, test each test tube for the presence of starch by placing 1 drop of Lugol's solution (potassium diiodide IKI) together with 5 drops from each test tube into spot plate wells. In the presence of starch, IKI produces a -4 blue black color, in its absence it is yellow. Save these results as you will want them to compare with the result obtained in Exercise 4. DO NOT DISCARD THE CONTENTS OF THE TEST TUBES. YOU WILL NEED THEM IN EXERCISE 3. Exercise 3 Test for reaction products This exercise is checking for the presence of reducing sugars following starch digestion. In Exercise 2 only starch was tested for and you should have observed that starch was digested. In this exercise, we are looking for the products of starch digestion by salivary amylase. The test used is called the Benedicts test. While this is not a definitive test for glucose, as other reducing sugars exist, it does provide supporting evidence for the presence of glucose. This test takes advantage of the fact that the carbinol group on glucose will reduce copper III (Cu+++) to copper. The result of this reduction is that the Benedicts solution in the presence of glucose, or any other reducing sugar, goes from blue to red/brown (copper color). BE CAREFUL NOT TO BURN YOURSELF OR YOUR COLLEAGUES. IF YOU ARE BURNED, IMMEDIATELY PLACE THE BURNT AREA UNDER COLD RUNNING WATER AND INFORM YOUR LAB INSTRUCTOR. 1. Start a boiling water bath by placing approximately 2 cm of water in the bottom of a 500 ml beaker and placing it on a hot plate turned to high. 2. Add 0.5 ml of Benedicts reagent to each test tube prepared in Exercise 2, mix, then place the test tubes into boiling water for 5 min. 3. Check the color of each tube. NOTE: The roles of each tube in this exercise are different than in Exercise 2. Test tube 4 is now a positive control as we know that it contains glucose and so should give a positive result. Test tubes 2 and 3 are negative controls as in the absence of enzyme or substrate, glucose should not be present. Test tube 1 remains our experimental tube. Exercise 4 Test of effect of boiling on enzyme activity The secondary, tertiary, and quaternary structure of proteins is maintained by hydrogen bonds. These relatively weak bonds can be broken at elevated temperatures. Water boils at 100 oC because its hydrogen bonds are broken at that temperature. As -5 enzymes are made up primarily of proteins, they can be affected by heat. Typically, boiling causes the structure of enzymes to unwind, a process called "heat denaturation." Because proteins do not usually refold themselves to regain their original structure following heat denaturation, most (but there are some interesting exceptions) enzymes loose their activity following boiling. We will see if this is the case following heat denaturation of salivary amylase. 1. Place test tube 5, prepared during Exercise 2, in boiling water for 5 min. 2. Remove test tube 5 from boiling water and cool to room temperature. 3. Add 0.2 ml of 0.2 % starch solution to test tube 5 and set aside for 5 min. 4. Test for the presence of starch using Lugol's solution as you did in Exercise 2. 5. Test for the presence of glucose using Benedicts reagent as you did in Exercise 3. Exercise 5 Test for optimal pH As you learned in the pH and buffers laboratory, pH can have an effect on biological molecules. Most enzymes have an optimal pH at which their activity is greatest. If you checked the pH of your mouth during the pH laboratory, you may want to refer to your notes from that lab. If you did not do that, check the pH of your mouth right now using pH paper. Based on this information, what would you predict the optimal pH for salivary amylase activity to be? 1. Dilute 1 ml of saliva supernatant 6 x by combining 1 ml of supernatant with 5 ml of distilled water. This step is necessary with most individuals saliva or else the reactions proceed so fast that they can not be easily measured. The final dilution factor will be 10 x as the final volume will be made up with buffers and starch solution. NOTE: Salivary amylase activity varies widely from individual to individual and may also vary according to the time of day. Because of this, dilution may not be necessary, or greater dilution may be needed. Unfortunately, you will not know until you have done the following steps. If things don't work out well with this dilution, you may need to repeat using a different dilution. This is why you should have plenty of saliva supernatant in reserve. 2. 3. Obtain 4 clean spot plates and arrange them in such a way that there is an array of wells with 8 columns and 6 rows of wells. Place 3 drops of the saliva diluted with buffer solution in each well. -6 4. Number the eight columns starting with 3 and ending with 10, then place 1 drop of the corresponding buffer solution into each well of each column. 5. The following events may become a little hectic, so it is important that you organize your group now. One person will be designated as the timer, one as the recorder, and one as the dropper. The reaction will be started by adding substrate, the 0.2 % starch solution at time 0. Following this, at 2 min intervals, one row of wells will be tested for the presence of starch. Row 1 will be tested as near to time 0 as possible, row 2, two min later, row 3, four min after substrate was added and so on until row 6 is tested 10 min after substrate was added. The column in which all the starch was digested first is at the optimal pH for salivary amylase. The test for starch will be the Lugol's solution test used in Exercise 2. The timer's task is to indicate when 2 min intervals are up. The dropper's tasks are the most complicated and involve first adding one drop of starch solution to each well, then adding the lugol's solution at time 0 and 2 min intervals there after. The recorders job is to check that the other two are doing things right and also to record the results. Now that you are organized and know what you are going to do, proceed to step 6. 6. Start timing and immediately add one drop of 0.2 % starch solution to every well then add 1 drop of Lugol's solution to all the wells in row 1. When adding solutions, always work from left to right in the rows, this helps keep the timing as consistent as possible. 7. Wait 2 min then add Lugol's solution to all the wells in row 2. 8. Repeat step 7, and add Lugol's solution to all the wells in row 3. Keep repeating until all the rows have Lugol's solution added. 9. Evaluate your results. If several columns tested negative after 2 min you will not be able to determine the optimal pH. The best thing to do here is to increase your dilution factor and repeat the exercise. If starch was still present in all the wells following 10 min, decrease the dilution factor and repeat. Sometimes, two or three columns may turn at the same time, lets say after 6 min columns 3, 4, and 5 have all completely digested the starch. In this case it may be best to repeat, but as you know that the ideal pH is one of these three, it is only necessary to recheck these three pHs. In addition you know that they all complete digestion between 4 and 6 min. You may want to start checking at 30 sec intervals starting 3 min after addition of the substrate. This greater time resolution should allow you to distinguish which pH is best of the three. Exercise 6 -7 For A students only Design you own experiment using salivary amylase. Here are some suggestions: 1) Check to see if salivary amylase will digest cellulose, 2) See if cellulose is similar enough to starch to inhibit the activity of salivary amylase, 3) Try altering the salt concentration and see how that affects salivary amylase activity, 4) See what effect temperature has on the rate of reactions catalyzed by salivary amylase ie. does running the reaction on ice slow the rate? 5) See what effect high glucose concentrations have on the rate of the reaction. Materials: Equipment Beakers, 500 ml Centrifuge tubes, 10 ml (or more) Centrifuges, table top Graduated cylinders, 10 ml Hot plates Pipettes, 1 ml (with 0.1 ml increments) and Pasture pipettes for dropping Spot plates Pasture pipets with bulbs Chemicals Benedicts reagent Buffer solutions, pH 3 - 10 Cellulose solution, 0.2 % Prepared by placing 1 g of cellulose in distilled water and boiling for 5 min. Glucose solution, 0.2 % 1 g of glucose in 500 ml of distilled water. Lugol’s solution (IKI) pH paper Phosphate buffered saline solution Starch solution, 0.2 % Prepared by placing 1 g of amylopectin (corn starch) in distilled water and boiling for 5 min. Water, distilled Consumables White bread