Module 22: Simulation of a Methane Steam

advertisement

CACHE Modules on Energy in the Curriculum

Fuel Cells

Module Title: Simulation of a Methane Steam Reforming Reactor

Module Author: Jason Keith

Author Affiliation: Michigan Technological University

Course: Kinetics and Reaction Engineering

Text Reference: Fogler (4th edition), Sections 4.7, 4.8, 4.9

Literature References: J. Xu and G. Froment, AIChE J., 35, 88 (1989), J. Xu and G.

Froment, AIChE J., 35, 97 (1989), F. A. N. Fernandes and A. B. Soares, Lat. Am. Appl.

Res., 36(3) 155 (2006).

Concepts: Develop a numerical model to predict the conversion and hydrogen yield

within a steam reforming reactor.

Problem Motivation:

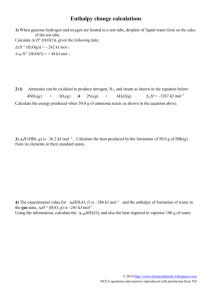

Fuel cells are a promising alternative energy conversion technology. One type of fuel

cell, a proton exchange membrane fuel cell (PEMFC) reacts hydrogen with oxygen to

produce electricity (Figure 1). Fundamental to a hydrogen economy powered by fuel cells

is the generation of high purity hydrogen.

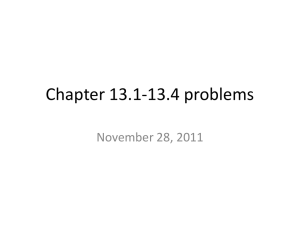

Consider the schematic of a compressed hydrogen tank (2000 psi, regulated to 10 psi)

feeding a proton exchange membrane fuel cell, as seen in Figure 2 below. The focus of

this module is hydrogen generation by steam reforming of methane to fill the compressed

tank.

-

-

e

e

H2

H2O

O2

H+

H2

H2O

H2

O2

O2

H+

H2

Computer

(Electric

Load)

Pressure

regulator

H2 feed line

Air in

H2

H2

H2

H2

H2

H2O

H2O

+

H

H+

O2

Anode

Cathode

Electrolyte

Figure 1. Reactions in the PEMFC

H2 out

H2 tank

Fuel Cell

Air / H2O out

Figure 2. Diagram for fueling a laptop.

1st Draft

2nd Draft

J.M. Keith

Page 1

October 14, 2008

March 20, 2009

Background

Natural gas has been proposed as a source of hydrogen for fuel cell vehicle applications

because of the existing infrastructure. In a process known as steam reforming, natural gas

and steam are reacted into mostly carbon monoxide and hydrogen with some carbon

dioxide also produced. There can also be excess water in the reformate stream.

The steam reforming reaction is given as:

CH4 + H2O ↔ 3 H2 + CO

(1)

In the steam reformer, the water gas shift reaction also takes place as:

CO + H2O ↔ H2 + CO2

(2)

Adding together the steam reforming and water gas shift reactions gives the overall

reaction:

CH4 + 2 H2O ↔ 4 H2 + CO2

(3)

The equilibrium constants can be expressed in terms of partial pressures (in atm) and

temperature in degrees Kelvin as [J. R. Rostrup-Nielsen and K. Aasberg-Petersen,

“Steam Reforming, ATR, Partial Oxidation; Catalysts and Reaction Engineering,” Ch. 14

of Handbook of Fuel Cells: Fundamentals, Technology, and Applications, Vol 3., W.

Vielstich, A. Lamm, H. A. Gasteiger, eds., Wiley, 2003]. The subscript on the following

equilibrium constants refers to the equation number given above:

K1

PH3 2 PCO

exp( 30.42 27106 / T )

PCH 4 PH 2O

(4)

K2

PH 2 PCO 2

exp( 3.798 4160 / T )

PCO PH 2O

(5)

PH4 2 PCO 2

K3

exp( 34.218 31266 / T )

PCH 4 PH2 2O

(6)

In the reactor, methane (CH4) and water (H2O) are fed as reactants and carbon dioxide

(CO2), carbon monoxide (CO), and hydrogen (H2) are produced over a nickel catalyst on

an alumina support.

In laboratory experiments, a nonreacting inert gas such as helium (He) may also be

present. In the most general form, the governing conservation equations for each of these

species is given below, where Fi denotes the molar flow rate of species i in mol/h, W

1st Draft

2nd Draft

J.M. Keith

Page 2

October 14, 2008

March 20, 2009

denotes the catalyst weight in g, and Ri denotes the reaction rate of equation i in units of

mol/(g-h):

dFCH 4

0

( R1 R3 ) with FCH 4 (W 0) FCH

4

dW

(7)

dFH 2O

( R1 R2 2 R3 ) with FH 2O (W 0) FH0 2O

dW

(8)

dFH 2

(3R1 R2 4R3 ) with FH 2 (W 0) FH0 2

dW

(9)

dFCO

0

( R1 R2 ) with FCO (W 0) FCO

dW

(10)

dFCO 2

0

( R2 R3 ) with FCO 2 (W 0) FCO

2

dW

(11)

dFHe

0

0 with FHe (W 0) FHe

dW

(12)

The reaction rates are given by:

R1

k1

PH2.25

PH3 2 PCO

P

P

CH 4 H 2O

K1

DEN 2

(13)

PH 2 PCO 2

k2

PCO PH 2O

K2

PH 2

R2

DEN 2

R3

k3

PH3.25

(14)

PH4 2 PCO 2

2

P

P

CH 4 H 2O

K3

DEN 2

(15)

DEN 1 K CH 4 PCH 4 K CO PCO K H 2 PH 2

K H 2O PH 2O

PH 2

(16)

Furthermore, the coefficients in Equations 13-16 are given by the Arrhenius relationships

as:

1st Draft

2nd Draft

J.M. Keith

Page 3

October 14, 2008

March 20, 2009

k1 4.22 1015 exp( 240100 / RT )

(17)

k 2 1.96 10 6 exp( 67130 / RT )

(18)

k 3 1.02 1015 exp( 243900 / RT )

(19)

K CH 4 6.65 10 4 exp( 38280 / RT )

(20)

K H 2O 1.77 10 5 exp( 88680 / RT )

(21)

K H 2 6.12 10 9 exp(82900 / RT )

(22)

K CO 8.23 10 5 exp( 70650 / RT )

(23)

Note that in the above expressions, R = 8.314 J/(mol-K) is the gas constant.

The reaction stoichiometry suggests that the number of moles will increase with the

distance down the reactor. Thus, for a negligible pressure drop in the reactor, the gas

expands by increasing the volumetric flow rate. The partial pressure of a chemical species

is calculated from the total pressure and the number of moles of that species.

Pi P

Fi

Ftot

1st Draft

2nd Draft

(24)

J.M. Keith

Page 4

October 14, 2008

March 20, 2009

Example Problem Statement: Consider a feed of 10000 mol/h CH4, 10000 mol/h H2O,

and 100 mol/h H2 to a steam reforming reactor that operates at 1000 K and a 1 atm feed

pressure. Determine the molar flow rates of CH4, H2O, CO2, CO, and H2 as a function of

catalyst weight up to 382 g. Also, determine the overall methane conversion.

Example Problem Solution:

Step 1) A numerical model can be made to simulate Equations 7 – 12 with the

coefficients determined in equations 4 – 6 and 13 – 23. Using a simple Euler

discretization of the equations we have:

FCH 4,i 1 FCH 4,i W ( R1 R3 )

(25)

FH 2O ,i 1 FH 2O 4,i W ( R1 R2 2 R3 )

(26)

FH 2,i 1 FH 2,i W (3R1 R2 4 R3 )

(27)

FCO ,i 1 FCO ,i W ( R1 R2 )

(28)

FCO 2,i 1 FCO 2,i W ( R2 R2 )

(29)

FHe,i 1 FHe,i

(30)

subject to the initial conditions FCH 4,0 FH 2O ,0 10000 mol/h and FH 2, 0 100 mol/h.

The other chemicals have zero initial molar flows: FCO 2,0 FCO ,0 FHe,0 0 mol/h.

These equations can be solved iteratively until the end of the reactor is reached. The

procedure is as follows:

1) Calculate the rate constants k1, k2, k3, KCH4, KH2O, KCO, KH2 and use them to

compute the reaction rates R1, R2, R3 at the feed conditions (location 0, total

catalyst weight W = 0).

2) Calculate chemical flow rates (location 1, catalyst weight = W) using Equations

25 – 30.

3) Calculate the total and partial pressures using Equation 24.

4) Calculate the rate constants k1, k2, k3, KCH4, KH2O, KCO, KH2 and use them to

compute the reaction rates R1, R2, R3 at the feed conditions (location 1, total

catalyst weight W = W).

5) Repeat steps 2-4 as you progress down the length of the reactor.

The system is simulated using a step size of W = 0.1 g. For more detail please see the

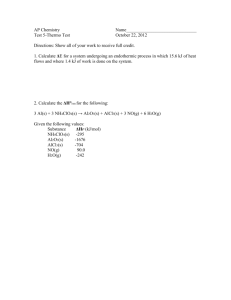

MATLAB code at the end of the example problem solution. A plot of the species molar

flow rates as a function of catalyst weight is shown in Figure 3 below. There are some

observations to be made from this plot. First of all, as there is no helium present in the

1st Draft

2nd Draft

J.M. Keith

Page 5

October 14, 2008

March 20, 2009

feed the molar flow rate is zero everywhere in the reactor. Secondly, both the CO and

CH4 are shown as solid lines. The molar flow rate of CH4 decreases with catalyst weight,

while the molar flow rate of CO increases with catalyst weight. We also note that if W

=0.01 g the results are nearly identical.

Figure 3. Species molar flow rates as a function of catalyst weight.

Step 2) The exit CH4 molar flow rate is about 2400 mol/h. This corresponds to a CH4

conversion of:

X

FCH 4, 0 FCH 4,exit

FCH 4, 0

10000 2400

76%

10000

(21)

Summary: After a quick change in the first g of catalyst (see the H2O molar flow rate),

there is a slow approach towards equilibrium in the reactor.

Matlab Code: Following is the Matlab code for this example problem.

%

% steam reforming plug flow model

% includes water-gas shift reaction and overall reaction

%

% this is an isothermal model with no pressure drop!

1st Draft

2nd Draft

J.M. Keith

Page 6

October 14, 2008

March 20, 2009

%

% CH4 + H2O <-> CO + 3H2 rxn 1

% CO + H2O <-> CO2 + H2 rxn 2

% CH4 + 2 H2O <-> CO2 + 4 H2 rxn 3

%

% feed conditions

% a = CO

% b = H2O

% c = CO2

% d = H2

% e = He

% f = CH4

%

clear

figure(1)

close

%

Fa0=0; %mol/hr

Fb0=10000;

Fc0=0;

Fd0=100;

Fe0=0;

Ff0=10000;

%

Ftot0=Fa0+Fb0+Fc0+Fd0+Fe0+Ff0;

%

% partial pressures in atm

Ptot0 = 1;

Pa0 = Ptot0*Fa0/Ftot0;

Pb0 = Ptot0*Fb0/Ftot0;

Pc0 = Ptot0*Fc0/Ftot0;

Pd0 = Ptot0*Fd0/Ftot0;

Pe0 = Ptot0*Fe0/Ftot0;

Pf0 = Ptot0*Ff0/Ftot0;

%

% temperatures in K

T0 = 1000;

%

% set up numerical model

dw=1e-1;

w(1)=0;

%

Fa(1)=Fa0;

Fb(1)=Fb0;

Fc(1)=Fc0;

Fd(1)=Fd0;

Fe(1)=Fe0;

Ff(1)=Ff0;

%

Pa(1)=Pa0;

Pb(1)=Pb0;

Pc(1)=Pc0;

Pd(1)=Pd0;

Pe(1)=Pe0;

Pf(1)=Pf0;

%

1st Draft

2nd Draft

J.M. Keith

Page 7

October 14, 2008

March 20, 2009

for i=1:382/dw+1;

w(i+1)=w(i)+dw;

%

K1=exp(30.420-27106/T(i));

K2=exp(-3.798+4160/T(i));

K3=exp(34.218-31266/T(i));

%

KCH4=6.65e-4*exp(38280/8.314/T(i));

KCO=8.23e-5*exp(70650/8.314/T(i));

KH2=6.12e-9*exp(82900/8.314/T(i));

KH2O=1.77e5*exp(-88680/8.314/T(i));

%

kin1=4.2248e15*exp(-240100/8.314/T(i));

kin2=1.955e6*exp(-67130/8.314/T(i));

kin3=1.0202e15*exp(-243900/8.314/T(i));

%

DEN=1+KCH4*Pf(i)+KCO*Pc(i)+KH2*Pd(i)+KH2O*Pb(i)/Pd(i);

r1=kin1/Pd(i)^2.5/DEN^2*(Pf(i)*Pb(i)-Pd(i)^3*Pa(i)/K1);

r2=kin2/Pd(i)/DEN^2*(Pa(i)*Pb(i)-Pd(i)*Pc(i)/K2);

r3=kin3/Pd(i)^3.5/DEN^2*(Pf(i)*Pb(i)^2-Pd(i)^4*Pc(i)/K3);

%

Fa(i+1)=Fa(i)+(r1-r2)*dw;

Fb(i+1)=Fb(i)-(Fb0/Ff0)*(r1+r2+2*r3)*dw;

Fc(i+1)=Fc(i)+(r2+r3)*dw;

Fd(i+1)=Fd(i)+(3*r1+r2+4*r3)*dw;

Fe(i+1)=Fe(i);

Ff(i+1)=Ff(i)-(r1+r3)*dw;

Ftot=Fa(i+1)+Fb(i+1)+Fc(i+1)+Fd(i+1)+Fe(i+1)+Ff(i+1);

%

Pa(i+1) = Ptot0*Fa(i+1)/Ftot;

Pb(i+1) = Ptot0*Fb(i+1)/Ftot;

Pc(i+1) = Ptot0*Fc(i+1)/Ftot;

Pd(i+1) = Ptot0*Fd(i+1)/Ftot;

Pe(i+1) = Ptot0*Fe(i+1)/Ftot;

Pf(i+1) = Ptot0*Ff(i+1)/Ftot;

%

end

%

figure(1)

plot(w,Fa)

hold on

plot(w,Fb,'r--')

plot(w,Fc,'g-.')

plot(w,Fd,'k:')

plot(w,Fe,'c')

plot(w,Ff,'b')

xlabel('Catalyst Weight, g')

ylabel('Molar Flow Rate mol/hr')

legend('CO','H_2O','CO_2','H_2','He','CH_4')

1st Draft

2nd Draft

J.M. Keith

Page 8

October 14, 2008

March 20, 2009

Home Problem Statement: Consider a feed of 10000 mol/h CH4 and 100 mol/h H2 to a

steam reforming reactor that operates at 900 K and a 2 atm feed pressure.

a) Determine the molar flow rates of CH4, H2O, CO2, CO, and H2 as a function of

catalyst weight up to 382 g for H2O feed flow rates of 20000 mol/h, 30000 mol/h, 40000

mol.h. For each water molar flow feed rate, determine the methane conversion and the

exit hydrogen molar flow rate.

b) If the water feed flow rate is 20000 mol/h, determine the best choice for reactor

pressure and temperature to give a minimum of 90% methane conversion.

1st Draft

2nd Draft

J.M. Keith

Page 9

October 14, 2008

March 20, 2009