I. Introduction - Virginia Commonwealth University

advertisement

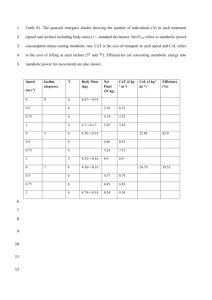

Investigation of Thermobifida fusca as a Novel Biofuel Agent Joe Alvin Dr. Stephen Fong Dr. Ana Estevez Bioinformatics and Bioengineering Summer Institute Virginia Commonwealth University St. Lawrence University August 5th, 2008 I. Introduction The dependence on fossil fuels has brought first world and developing countries to the cusp of energy economies. Cellulosic ethanol—one of many biofuels—is regarded as a likely source for renewable energy in the future 1. Cellulose is the most abundant carbohydrate polymer on the Earth and is found in all plant matter 2. It is normally degraded by saprophytes via enzymes and then fermented into a number of by-products. The second most abundant—chitin and chitosan—are found in terrestrial and marine animal exoskeletons 3. These polymers constitute a vast pool of energy hitherto untapped for lack of means or efficiency 3. Current common practice involves a treatment of the polymer in acid and enzymes—breaking hydrolyzing the bonds—followed by fermentation by yeast (ie. Saccharomyces cerevisiae) 1. In order to increase process efficiency, one organism couples both enzymatic interactions and fermentation, such as Thermobifida fusca. Thermobifida fusca’s genome has been sequenced and the annotation provides a bright outlook for T. fusca’s metabolism in the biofuel industry4. However, T. fusca’s physiology and metabolism have not been studied in vivo in detail; many studies have cloned cellulase genes into other organisms such as Escheria coli or Bacillus megaterium 5, 6 . Recently, the cellulases found in T. fusca have shown non-specific catabolism of chitin/chitosan 3. Known for its highly active cellulases and potential to ferment digested biomass into fuel, our laboratory is investigating T. fusca’s potential as a biofuel producer 7, 8 . Metabolic engineering allows further enhancement through organisms designed with increased enzyme activity and product yield. In the past, metabolic engineering has been a time-consuming, hit-or-miss method of genetic modification. New methods combining genome annotation and in silico metabolic flux analysis provide a working model for the organism 9. In silico models enhance the process’ effectiveness by eliminating experiments that are unfavorable to pursue in vitro 10, 11. Flux-balance analysis (FBA) of an annotated genome involves a matrix of reactions, metabolites and flux. The model is solved for a solution space of growth rate and the desired product based on the model’s constraints (substrate, moles etc.). FBA of T. fusca will provide ample information about the organism’s metabolic pathways and the applicability of genomic engineering for biofuel production 12. In addition, the FBA will elucidate the best genes and pathways for metabolic engineering. II. Progress and Future Work a. Metabolic Flux-Balance Analysis of Thermobifida fusca The annotated genome provided by the Integrated Microbial Genomes project (IMG) database listed proteins connected with the Kyoto Encyclopedia of Genes and Genomes. These proteins were cross-referenced for their individual reactions and metabolites. All of these were compiled using MetModel software to generate a matrix of reactions and metabolites to be solved with a biomass equation. The model currently contains 320 unique metabolic, enzyme-catalyzed reactions that occur in T. fusca and 4,447 metabolites. This is an estimated 50% of the true reactions and metabolites within the cellular model. Future work will finalize the model: integrating fatty acid and lipid syntheses, determining and adding the appropriate biomass reaction. This work will be continued over the 08/09 academic year at St. Lawrence University with help from Dr. Seth Roberts, Chris Gowen and Dr. Paul Brooks. However, The working model will not be sufficient proof for the potential of metabolic FBA in biofuel research. When a working model is built with the software, single or double deletions of proteins will be made in silico and evaluated for efficiency. The model will need to accurately predict the final phenotypes of individual pathway as per the genomic modification. If the model fails to predict the phenotype, sequencing the anomalous strain will help identify the shortcomings in the model or organic mutations that prevented proper evolution. When several potential modifications to the metabolic pathways have been identified, the knockout strains will be created. The model will then be proven with experimental evidence based on identical deletions and resulting phenotypes. This facet of my research is the most time-consuming, yet minimal in terms of equipment and supplies, therefore, in this area that I will likely progress the most over the 08/09 academic year. b. Investigation of Chitin/Chitosan substrates Deng Yu and I collaborated on research concerning the use of chitosan as a fermentable carbon source for T. fusca. Pre-cultures containing 1% D-glucose and essential nutrients were incubated for 36h. Two replicates of a 0.5% and 1% chitosan where evaluated for their growth (determined by protein assays) and compared to those on D-glucose and cellobiose media; both known to support normal growth of T. fusca. The first experiment did not provide definitive results with error attributed to insufficient culture density after pre-culture. A second experiment—including identical replicates and an additional bioreactor component—was designed and carried out. T. fusca’s growth rate and phylogenic expression have been known to vary depending on the environmental conditions. The results indicate a slow growth rate on chitosan as a carbon source. Few resources are necessary to assay the substrates’ carbon source efficiencies and thus minimal experimentation could be completed at St. Lawrence University. Requirements are chitosan samples, proper incubation facilities, and total protein assay kits. c. Alternative Biofuel Production/Efficiency A pathway to potentially generate additional biofuels (presently uncharacterized) was uncovered, during the metabolism review for MFBA. This alternate product in question was verified by HPLC and GC results. The samples were obtained from an experiment that varied growth conditions to determine variety in growth rates and metabolite secretion. The product has potential use in the biofuel industry and has not been categorized in T. fusca and as such, a provisional patent is being written to secure he intellectual property. Therefore, little information about this particular project can be released. Experiments were carried out—using the growth/product secretion rate data—in an attempt to discover environmental parameters that generate the maximum amount of product. Two parameter settings were chosen from previous experiments—yielding maximum product secretion—and used in the bioreactor fermentation. The results showed decreased yields with the combination of settings when compared to the maxima of the independent settings. Due to the lack of proper facilities at St. Lawrence University, most of the future experimentation will be completed at Virginia Commonwealth University’s laboratories. Limited experimentation may be possible depending on the environmental factors (bioreactor vs. flask). References 1. Wackett, L. P. Biomass to fuels via microbial transformations. Current Opinion in Chemical Biology 12, 187-193 (2008). 2. Yang, C., Yang, S. & Liu, W. Production of xylooligosaccharides from xylans by extracellular xylanases from Thermobifida fusca. JOURNAL OF AGRICULTURAL AND FOOD CHEMISTRY 55, 3955-3959 (2007). 3. Xia, W., Liu, P. & Liu, J. Advance in chitosan hydrolysis by non-specific cellulases. Bioresour. Technol. 99, 6751-6762 (2008). 4. Lykidis, A. et al. Genome sequence and analysis of the soil cellulolytic actinomycete Thermobifida fusca YX. JOURNAL OF BACTERIOLOGY 189, 2477-2486 (2007). 5. Yang, C. & Liu, W. Cloning and characterization of a maltotriose-producing alphaamylase gene from Thermobifida fusca. JOURNAL OF INDUSTRIAL MICROBIOLOGY \& BIOTECHNOLOGY 34, 325-330 (2007). 6. Posta, K., Beki, E., Wilson, D., Kukolya, J. & Hornok, L. Cloning, characterization and phylogenetic relationships of cel5B, a new endoglucanase encoding gene from Thermobifida fusca. JOURNAL OF BASIC MICROBIOLOGY 44, 383-399 (2004). 7. Wilson, D. Studies of Thermobifida fusca plant cell wall degrading enzymes. CHEMICAL RECORD 4, 7-82 (2004). 8. Kim, Y. et al. Phenolic extraction from apple peel by cellulases from Thermobifida fusca. JOURNAL OF AGRICULTURAL AND FOOD CHEMISTRY 53, 95609565 (2005). 9. Schilling, C., Edwards, J., Letscher, D. & Palsson, B. Combining pathway analysis with flux balance analysis for the comprehensive study of metabolic systems. BIOTECHNOLOGY AND BIOENGINEERING 71, 286-306 (2000). 10. Fong, S. et al. In silico design and adaptive evolution of Escherichia coli for production of lactic acid. BIOTECHNOLOGY AND BIOENGINEERING 91, 643648 (2005). 11. Hua, Q., Joyce, A. R., Fong, S. S. & Palsson, B. Ø. Metabolic analysis of adaptive evolution for in silico-designed lactate-producing strains. Biotechnol. Bioeng. 95, 992-1002 (2006). 12. Hong, S., Moon, S. & Lee, S. Prediction of maximum yields of metabolites and optimal pathways for their production by metabolic flux analysis. JOURNAL OF MICROBIOLOGY AND BIOTECHNOLOGY 13, 571-577 (2003).