Novel Oxygen Optrode withstanding Autoclavation: Technical

advertisement

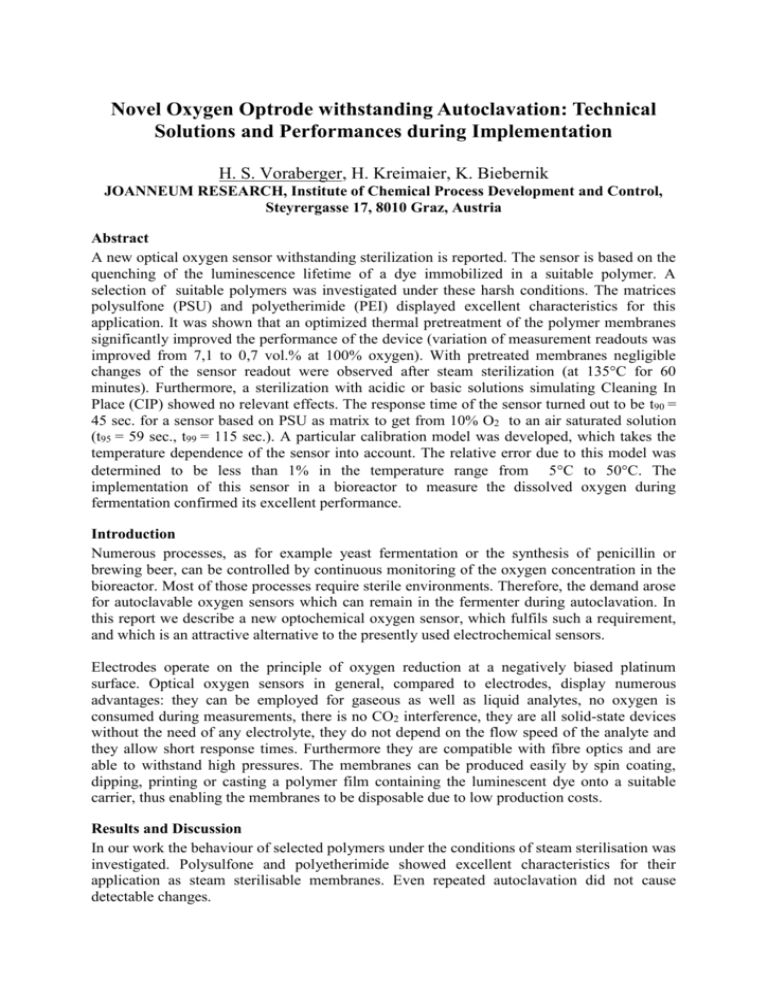

Novel Oxygen Optrode withstanding Autoclavation: Technical Solutions and Performances during Implementation H. S. Voraberger, H. Kreimaier, K. Biebernik JOANNEUM RESEARCH, Institute of Chemical Process Development and Control, Steyrergasse 17, 8010 Graz, Austria Abstract A new optical oxygen sensor withstanding sterilization is reported. The sensor is based on the quenching of the luminescence lifetime of a dye immobilized in a suitable polymer. A selection of suitable polymers was investigated under these harsh conditions. The matrices polysulfone (PSU) and polyetherimide (PEI) displayed excellent characteristics for this application. It was shown that an optimized thermal pretreatment of the polymer membranes significantly improved the performance of the device (variation of measurement readouts was improved from 7,1 to 0,7 vol.% at 100% oxygen). With pretreated membranes negligible changes of the sensor readout were observed after steam sterilization (at 135°C for 60 minutes). Furthermore, a sterilization with acidic or basic solutions simulating Cleaning In Place (CIP) showed no relevant effects. The response time of the sensor turned out to be t90 = 45 sec. for a sensor based on PSU as matrix to get from 10% O2 to an air saturated solution (t95 = 59 sec., t99 = 115 sec.). A particular calibration model was developed, which takes the temperature dependence of the sensor into account. The relative error due to this model was determined to be less than 1% in the temperature range from 5C to 50C. The implementation of this sensor in a bioreactor to measure the dissolved oxygen during fermentation confirmed its excellent performance. Introduction Numerous processes, as for example yeast fermentation or the synthesis of penicillin or brewing beer, can be controlled by continuous monitoring of the oxygen concentration in the bioreactor. Most of those processes require sterile environments. Therefore, the demand arose for autoclavable oxygen sensors which can remain in the fermenter during autoclavation. In this report we describe a new optochemical oxygen sensor, which fulfils such a requirement, and which is an attractive alternative to the presently used electrochemical sensors. Electrodes operate on the principle of oxygen reduction at a negatively biased platinum surface. Optical oxygen sensors in general, compared to electrodes, display numerous advantages: they can be employed for gaseous as well as liquid analytes, no oxygen is consumed during measurements, there is no CO2 interference, they are all solid-state devices without the need of any electrolyte, they do not depend on the flow speed of the analyte and they allow short response times. Furthermore they are compatible with fibre optics and are able to withstand high pressures. The membranes can be produced easily by spin coating, dipping, printing or casting a polymer film containing the luminescent dye onto a suitable carrier, thus enabling the membranes to be disposable due to low production costs. Results and Discussion In our work the behaviour of selected polymers under the conditions of steam sterilisation was investigated. Polysulfone and polyetherimide showed excellent characteristics for their application as steam sterilisable membranes. Even repeated autoclavation did not cause detectable changes. By a thermal pre-treatment of the oxygen sensors (i. e. polymer and dye), a further improvement of the sensor stability could be achieved. During a thermal pre-treatment, remaining solvent and water are removed and therefore stress is reduced. This was revealed by infrared spectroscopy. Stern-Volmer-plots of sensors pre-treated under different conditions were established. Fig. 1 shows the improved performance of a pre-treated membrane compared to a membrane without pre-treatment. The plots A and B were recorded before and after autoclavation. Plot B clearly shows, that autoclavation had no significant influence on the performance of the pre-treated sensor membrane. The variation of measurement readouts was improved from 7,1 to 0,7 vol.% at 100% oxygen. 1.8 1.6 1.6 0/ 1.8 0/ 1.4 1.4 1.2 1.2 1.0 1.0 0 20 40 60 Oxygen / vol.% A 80 100 0 B 20 40 60 80 100 Oxygen / % Fig. 1: Stern-Volmer plots of optical oxygen sensors before (black dotted line) and after steam sterilisation (grey line). Plot A refers to an untreated PSU film, plot B refers to a thermally pre-treated PSU film. air saturation / % The measured phase shifts and the Stern-Volmer parameters are strongly dependent on the temperature of the sensor membrane. For many applications a constant temperature cannot be guaranteed and therefore the temperature has to be measured and to be compensated in a calibration model. So a calibration function valid and tested for the temperature range from 5° to 50°C was developed. The performance of an optical oxygen Escherichia Coli Fermentation sensor membrane, which was inserted 100 Mettler electrode in a bioreactor and compared to a JR Sensor conventional electrochemical device 80 measuring the dissolved oxygen, is 60 displayed in Fig. 2. A cultivation of Escherichia Coil for production of 40 enzymes was monitored. It can be 20 seen, that with both sensor types 0 similar results were obtained. Therefore polymer based optical 0 2 4 6 8 10 12 14 16 18 20 22 24 time / hours oxygen sensors are a good alternative to electrochemical sensors. Fig. 2: Comparison of the performances of a conventional electrochemical oxygen electrode and the JOANNEUM RESEARCH Optical Oxygen Measuring Device. Acknowledgements We wish to thank the Institute for Biotechnology at the University of Technology, Graz, Austria, for access to their fermenters and electrochemical O2 electrodes, Christian Konrad for his contribution to the temperature compensation experiments and Stephanus Leibl and his co-workers at Wissenschaftlich-Technische Werkstätten GmbH, 82362 Weilheim, Germany, for providing essential mechanical parts.