26 27 26 Wiring Devices

advertisement

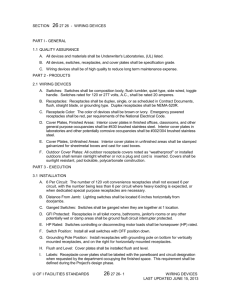

MPS Master SECTION 26 27 26 WIRING DEVICES PART 1 - GENERAL 1.01 A. SUMMARY Section Includes: 1. Provide new wiring devices in each outlet indicated on Drawings. 2. Provide all devices from one manufacturer. 3. Allowances for relocating wiring and technology device locations. 4. Wiring devices in this Section include the following: a. b. c. d. B. Related Sections: 1. 2. 1.02 A. Outlets Switches Device Plates Pilot Lights Section 26 00 00: Electrical. Section 26 05 26: Grounding and Bonding for Electrical Systems. REFERENCE STANDARDS General: 1. 2. 3. 4. Current Edition of the National Electrical Code Underwriters‘ Laboratories NEMA WD1-3, WD1-4 for General and Specific Purpose Wiring Devices Current Edition of ICC/ANSI (A117.1-2003) PART 2 - PRODUCTS 2.01 A. MANUFACTURERS Acceptable Manufacturers: Subject to compliance with requirements of the Contract Documents, acceptable manufacturers are as follows: 1. Switches and Receptacles: a. b. c. Hubbell Pass & Seymour Leviton 2. Hubbell catalog numbers are used to specify type and quality required. 3. Device wall plates shall be compatible with devices and Article 2.06. 26 27 26 - 1 Wiring Devices MPS Master SECTION 26 27 26 2.02 A. 2.03 A. DEVICE COLOR General Requirements: Catalog numbers are for standard brown or ivory color devices to match existing in remodeling projects. SWITCHES General Requirements: 1. 2. 3. 4. 5. 6. 7. Switches, except as noted, shall be rated 20 Ampere, 120/277 Volt, AC, ”Quiet“ Toggle Switch Meet Federal Specification WS896-E and NEMA WD1 Standards UL Listed Side and Back Wiring Options Single Pole Switches: No. 1221 3-Way Switches: No. 1223 4-Way Switches: No. 1224 B. Switches Controlling Loads Under 5 Amperes: Where loads do not exceed 5 ampere, switches of same series above but rated only 15 amperes may be used. C. Momentary Contact Switches: Switches shall be 20A, double throw, 3-position toggle switches, with center return No. 1557 or equal, mounted in matching wall plate. D. Key Switches and Double Pole Switches: Hubbell or Owner approved equal of type specified above. Where key operated switches are called for in Science classrooms to control gas valves, the device shall be by ”Spectrol“ consisting of: 1. 2. 3. 4. 5. ”Locknetics“ 643-0505 Engraved Locknetics Plate Red Neon Lamp SPDT 10A Relay 4-Point Terminal Strip Gas solenoid valve is provided by Division 23 and installed by Division 26. Rough-in height for key switch shall be at 42 inches. Electrical Contractor shall provide all necessary mounting hardware brackets to building structure for a secure installation. Unit shall be Chemetron Medical Products, No. 669201-64. E. Switches in Door Frames: Pass & Seymour No. ACD-201 or ACD-203 as required, complete with mounting straps and narrow stainless steel plates. F. Switches with Pilot Light Toggle: Pilot light on with load on, No. NBL 1221 PLC for single pole and NBL 1223 PLC for 3-way. 2.04 A. CONVENIENCE OUTLETS Duplex Receptacles: 1. 2. 3. Meet Federal Spec WS596G Standards UL Listed 1-Piece Brass Strap with Integral Ground Contacts, except GFI Receptacles 26 27 26 - 2 Wiring Devices MPS Master SECTION 26 27 26 4. 5. 6. 7. 8. Heavy Duty High Impact Nylon Face "Bypass" Patented Design Constant Contact Pressure Power Contacts Side and Back Wiring Options NEMA 5-20R Configuration; rated for 20 amperes at 125 volts, unless noted otherwise Interior duplex receptacles, except within 6 feet of sinks, shall be No. . B. Rough-Use Receptacles: High grade 0.050-inch thick brass alloy, 1-piece mounting strap and grounding system, glass reinforced nylon base, triple wipe contacts, and nylon face, No. 5362. C. GFI Receptacles: All receptacles located in bathrooms, kitchens, and on rooftops shall be GFI type. Units shall be No. GF-5362, 20 ampere self-contained type with reset and test buttons, and shall be equipped with a ground fault interrupter which will automatically detect a ground fault current and de-energize receptacle when fault currents exceed 5 milliamps. 1. Feed-through feature shall not be used, except where specifically noted on Drawings. 2. GFI receptacles shall be same color as other receptacles and installed as follows: a. b. c. D. 3. All duplex receptacles within 6 feet of sinks shall be GFI type as specified. 4. Receptacle covers shall, in all cases, meet NEC code requirements for outdoor receptacles with attachment plug caps inserted and cover closed. Emergency Power Receptacles: 1. E. Where installed within building, receptacles shall be mounted in standard device plates as specified. Where installed on roof or in other areas requiring surface mounted outlets, GFI receptacles shall be installed in weatherproof cast boxes with a hinged locking in use weatherproof cover. Where installed on exterior walls of building, receptacles shall be mounted vertically with hinged locking weatherproof covers. Covers shall be listed for wet locations and be complete with holes for Owner's padlock. For circuits connected to emergency generators, provide red devices as indicated on Drawings. Special Purpose Receptacles: 1. Single Receptacles: Hubbell No. 5351 grounding type, rated 20 amperes, provided only where so noted on Drawings. a. Water Cooler Receptacles: Exact location of receptacle shall be coordinated with Mechanical Contractor. 2. Single Receptacles: Hubbell No. 2320 grounding type, twist-lock rated 20 amperes as noted on Drawings. 3. Special Combination Receptacles: Receptacles shall be No. 5290 (NEMA 5-15R/6-15R), with (1) 15 ampere, 208 volt circuit. 26 27 26 - 3 Wiring Devices MPS Master SECTION 26 27 26 4. Special Combination Receptacles: No. 5451 (NEMA 6-20R), 20 ampere, 208 volt, single phase receptacle mounted in 1 gang of a 2-gang plate with a duplex 120 volt receptacle in second gang. 5. 30 Ampere (Dryer) Receptacles: No. 9430 (NEMA 14-30R), 125/250 volt, 3 pole, 3-wire type complete with flush plate. a. 6. 50 Ampere (Range) Receptacles: No. 7450 (NEMA 14-50R), 125/250 volt, 4 pole, 4-wire type complete with flush plate. a. 7. Furnish and connect (1) No. 9339-5, 3-wire, 5-foot long cord set to Owner's dryer at each outlet. Furnish and connect (1) 4-wire cord set to Owner's range at each outlet. 50 Ampere (Welding) Receptacles: Provide 250 volt, 3-wire grounding type complete with flush plate to match cords and plugs on Owner's units. a. Where Owner does not have existing units to match, provide No. 9367 (NEMA 6-50R) receptacles in flush plates. 8. Air Conditioning Receptacles: Pass & Seymour No. 5890 combination type, with (1) 20 ampere, 120 volt circuit and (1) 15 ampere, 220 volt circuit. 9. Childproof Receptacles: Pass & Seymour No. 8300-SG, 15 or 20 ampere type. 10. 3 Phase, 208 Volt Receptacles: Provide 3 pole, 4-wire grounding type complete with flush plate to match cords and plugs on Owner's units. a. b. c. Where Owner does not have existing units to match, provide No. 2420-A (NEMA L15-20R), twist lock type receptacles in flush plates. Engrave each plate "208V - 3 Phase". Furnish (1) No. 2421 attachment plug for each 2420-A outlet. 11. Isolated Ground Receptacles: No. IG5362, rated 20 amperes. 12. 3 Phase, 480 Volt Receptacles: No. 2430 (NEMA 116-20R), 3 pole, 4-wire grounding type complete with flush plate. a. b. Engrave each plate "480V - 3 Phase". Furnish (1) No. 2431, plug for each outlet. 13. Single Phase, 277 Volt Receptacles: Receptacles shall be No. 34760 (NEMA 17-15R), 2 pole, 3-wire grounding type complete with flush plate. a. b. Engrave each plate "277 Volts". Furnish (1) No. 4770C, nylon plug for each outlet. 14. Ceiling service reel receptacles shall be recessed single reel service, with a 120 volt, single phase Hubbell No. 23002G, twist lock receptacle with 20-foot, 3 #16 cable per reel. All branch circuits shall be protected with GFI receptacles or Leviton 23030. 26 27 26 - 4 Wiring Devices MPS Master SECTION 26 27 26 2.05 A. CORD CAPS AND PLUGS 15 and 20 Amp Straight Blade and Locking Plugs and Connectors: 1. 2.06 Water Tight Devices: Leviton "Wetguard" or Owner approved equal. DEVICE PLATES A. General Requirements: Plates shall have rounded, smooth edges and be common for each group of devices mounted adjacent to each other unless otherwise noted on Drawings. All plates shall be Sierra, Type S, or Hubbell. Plates with beveled edges shall not be acceptable. B. Wall Plates: Except where special finishes are called for, shall be 302 stainless steel. C. Special Plates: Plates in swimming pool areas shall be high strength plastic. D. Special Screws: Where so indicated, device plates shall be complete with special tamperproof spanner oval head screws. Provide Owner with (3) special screw drivers for spanner head screws. E. Engraved Plates: Printed tape or glued-on name plates are not acceptable. Engraved plates shall have letters as required, 1/8 inch minimum letter height, and black filling. Verify all engraving text with Owner prior to work. Engrave plates as follows: F. 1. Engrave all wall plates as indicated on Drawings. 2. Engrave all switch wall plates controlling any lights which are out of sight of switches. 3. Engrave all switch plates controlling motors. 4. Engrave all switch plates with (4) or more gangs, to indicate lighting fixtures served. Weatherproof Plates for Public Area: Weatherproof plates for public areas include exterior of building: 1. G. Weatherproof Plates for Work Area: Weatherproof plates for work areas include roofs: 1. H. A. Pass & Seymour 3723-FS or Owner approved equal "While in Service" Plates: 1. 2.07 Pass & Seymour 4600-26 with 4609 Key or Owner approved equal Pass & Seymour WIU10 Series, or Owner approved equal, with Padlock-able Capability PILOT LIGHTS General Requirements: Hubbell No. 1201-PL, or Owner approved equal, neon red jewel type mounted in separate gangs of switch plates. Pilot lights shall be wired from load side of motor disconnect switch so that pilot cannot light when disconnect is in open position. Where pilot lights are required, provide switches with handle lighted when switch is ”On”. 26 27 26 - 5 Wiring Devices MPS Master SECTION 26 27 26 PART 3 - EXECUTION 3.01 A. INSTALLATION OF DEVICES General Requirements: Install wiring devices in compliance with manufacturer=s instructions, applicable requirements of NEC and NECA’s ”Standards of Installation“, and in accordance with recognized industry practices. All devices shall conform to mounting heights required by ADA (Americans with Disabilities Act). 1. B. Other Requirements: Special heights are required above casework. Devices mounted above casework shall be mounted horizontally so that dimensions from openings and switch handles are accessible. 1. C. Ensure that wiring device boxes are free of debris. Wiring work shall be completed before devices are installed. All painting shall be completed before device wall plates are installed. Special coordination shall be completed with Architectural Drawings and manufacturer's installation drawings and instructions for all disciplines. Device Heights: 1. 2. 3. 4. 5. Switches: 48 Inches Convenience Outlets: 18 Inches Telephone Outlets: 18 Inches Weatherproof Receptacles (Above Grade): 24 Inches Non-Adjustable Thermostats: 60 Inches D. Mounting Height: Heights are given from center of outlet box to finished floor directly below outlet. Other miscellaneous device mounting heights are given in their respective sections of the Specifications or on Drawings. E. Outlets Added to Existing Surfaces: Carefully cut and patch to match adjacent finishes and materials. 3.02 A. INSTALLATION OF RECEPTACLES Location: 1. Coordinate with all trades before installing receptacles. 2. Special coordination required with Mechanical Contractor for locating devices in outside walls to determine size and location of wall hung radiation. Where conflicts are apparent, Contractor shall notify Architect/Engineer. 3. Receptacles alongside of switches in janitor closets, storage rooms, and mechanical spaces shall be in 2-gang boxes, with switch in first gang and receptacle in second gang. 4. Switches near doors shall be located on side opposite the hinges (verify door swings with Architectural Drawings before installation) and close to door trim. Edge of switch plate shall be within 4 inches of door frame. 26 27 26 - 6 Wiring Devices MPS Master SECTION 26 27 26 B. Circuit Identification: Label inside of plates of all receptacles with panel and circuit number with permanent marker. END OF SECTION 26 27 26 - 7 Wiring Devices