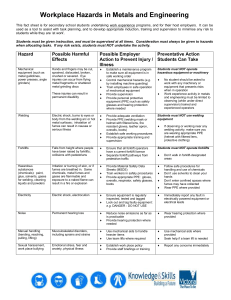

welding proforma

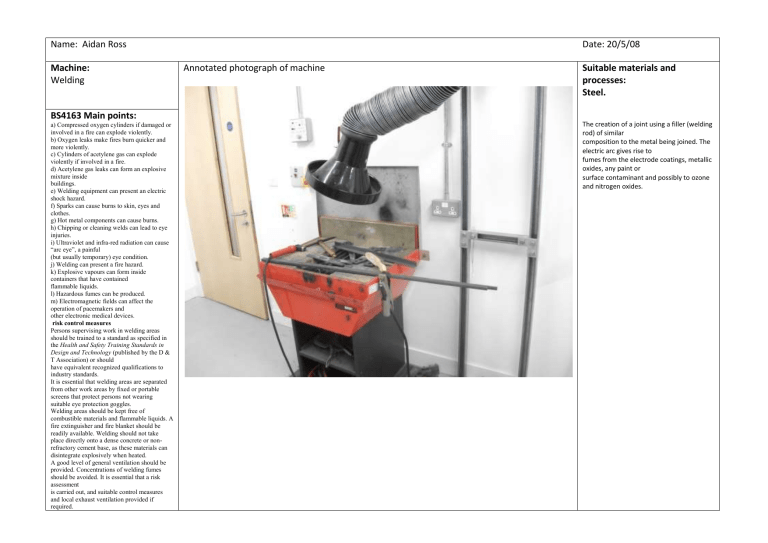

Name: Aidan Ross

Machine:

Welding

BS4163 Main points: a) Compressed oxygen cylinders if damaged or involved in a fire can explode violently. b) Oxygen leaks make fires burn quicker and more violently. c) Cylinders of acetylene gas can explode violently if involved in a fire. d) Acetylene gas leaks can form an explosive mixture inside buildings. e) Welding equipment can present an electric shock hazard. f) Sparks can cause burns to skin, eyes and clothes. g) Hot metal components can cause burns. h) Chipping or cleaning welds can lead to eye injuries. i) Ultraviolet and infra-red radiation can cause

“arc eye”, a painful

(but usually temporary) eye condition. j) Welding can present a fire hazard. k) Explosive vapours can form inside containers that have contained flammable liquids. l) Hazardous fumes can be produced. m) Electromagnetic fields can affect the operation of pacemakers and other electronic medical devices.

risk control measures

Persons supervising work in welding areas should be trained to a standard as specified in the Health and Safety Training Standards in

Design and Technology (published by the D &

T Association) or should have equivalent recognized qualifications to industry standards.

It is essential that welding areas are separated from other work areas by fixed or portable screens that protect persons not wearing suitable eye protection goggles.

Welding areas should be kept free of combustible materials and flammable liquids. A fire extinguisher and fire blanket should be readily available. Welding should not take place directly onto a dense concrete or nonrefractory cement base, as these materials can disintegrate explosively when heated.

A good level of general ventilation should be provided. Concentrations of welding fumes should be avoided. It is essential that a risk assessment is carried out, and suitable control measures and local exhaust ventilation provided if required.

Annotated photograph of machine

Date: 20/5/08

Suitable materials and processes:

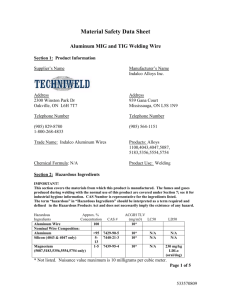

Steel.

The creation of a joint using a filler (welding rod) of similar composition to the metal being joined. The electric arc gives rise to fumes from the electrode coatings, metallic oxides, any paint or surface contaminant and possibly to ozone and nitrogen oxides.

Users of welding equipment, and observers, should be protected against glare and sparks by appropriate goggles or shields. Goggles or shields should also be utilized when chipping or cleaning welds. Suitable protective clothing

(gloves, aprons and substantial footwear) should be worn to minimize risks of spark burns and clothing damage. Protective clothing should be kept free of oil and grease.

In the educational environment, the welding, cutting or any other heat processes on tanks should not be undertaken.

Welded materials should be put in a safe place to cool, in order to minimize the risk of burns

.

CLEAPSS Main Points:

Toxic Ozone is likely to be present with traces of nitrogen oxides unless a totally inert shielding gas is used.

Particles of freshly-formed metallic oxides may also be present to give the possibility of ‘metal fume fever’. (See Further Information overleaf.)

Irritant Irritation of the respiratory tract, caused by gases or fine particles.

RISK ASSESSMENT

The OES for ozone is 0.2 ppm (15 min ref period)1, while that for nitrogen dioxide is 5 ppm (15 min ref period). Neither is likely to be exceeded if welding is very occasional but, even in MIG welding, the ozone concentration can reach the limit quite quickly.

Zinc oxide fumes, commonly emitted when galvanised steel is welded, have an OES of 10 mg/m3 (15 min ref period) (under review).

This operation will not be routine in a school workshop but may be required for an occasional repair which can be done outside.

Welding through painted surfaces, particularly those containing lead compounds, also produces hazardous fumes.

Cases of ‘metal fume fever’ are rare.

The oxide particles are mainly responsible for this risk.

Common Problems:

Welding and cutting can produce hazards such as sparks, spatter, radiation (infrared, ultraviolet, and blue light), slag, heat, hot metal, fumes and gases, and even electric shock. Since these hazards may cause burns, injury, or death, it is important to wear proper PPE at all times.

PPE:

Eye, face, head, ear and hand protection

I have used this machine to:

Common Misconceptions: