FM SHE 005 Protection from Hazardous Substances

advertisement

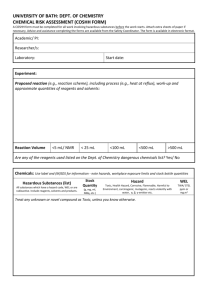

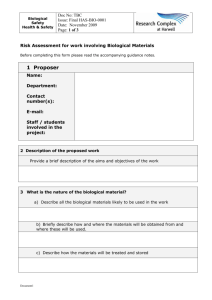

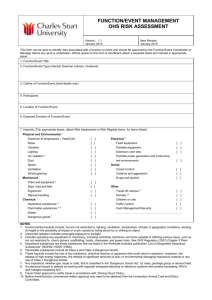

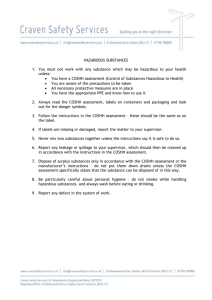

Document1 Safety, Health & Environment Section FM SHE 005 Procedural Guidance for Protection from Hazardous Substances November 2014 Version 2.0 Document review due: November2016 Please Note: This is a controlled document, please ensure you are using the most recent version. SHE Intranet Page 1 of 13 Document1 Section Contents 1.0 Introduction 3 2.0 Scope 3 3.0 Purpose 3 4.0 Definitions 3 5.0 Legal Requirements The Management of Health & Safety at Work Regulations Control of Substances Hazardous to Health Regulations The Ionising Radiations Regulations 5 Hazards 5 6.1 Routes of entry into the body 5 6.2 Contaminated areas and equipment 6 6 7.1 7.2 Procedure Identification of Hazardous Substances contaminated equipment and areas COSHH Risk assessment 7.3 Decontamination 7 7.4 Isolation 7 7.5 Communication 7 7.6 Emergency Arrangements 8 Glossary 8 APPENDICES Equipment/Articles Decontamination Clearance Certificate Area Decontamination Clearance Certificate 10 5.1 5.2 5.3 6.0 7.0 8.0 1 2 Page 5 5 5 6 6 12 Page 2 of 13 Document1 1.0 Introduction Many hazardous substances are used within the University. They range from chemical, radiological and biological agents used in laboratory experiments to cleaning and fumigation substances. Instances may occur where people are exposed to these hazards where the risks of exposure need to be controlled. This procedure details the safe systems of work to be followed in order to prevent injuries and ill-health to people when working with hazardous substances. 2.0 Scope This guidance applies to all hazardous substances used on University premises that pose a risk to employees, contractors, students, visitors and members of the public. 3.0 Purpose The purpose of this guidance is to: Provide procedural guidance for Managers and Supervisors so that employees, contractors, visitors & students are not injured through exposures to hazardous substances. Ensure a safe system of work is in place for the decontamination of equipment and areas prior to maintenance or repair work being undertaken. Clearly define individual responsibilities for the control of risks when work on contaminated equipment is carried out. 4.0 Definitions The following table illustrates the labels likely to be displayed on containers and gives brief definitions of the corresponding hazard. Chemical Hazard Information for Packaging and Supply Regulations 2000 (CHIP) (note: CHIP is being replaced by the European CLP Regulation and will be revoked from 1 June 2015.) require labels to be affixed to containers by the supplier to indicate hazard classification for the end user. The Carriage of Dangerous Goods and Use of Transportable Pressure Equipment Regulations 2009 (CDG) requires labels to be affixed to containers and vehicles by the supplier to indicate transport hazards. CHIP CDG None Hazard Classification HARMFUL - May cause death or acute/chronic damage to health. Lethal dose > 250 mg/kg of body weight. Category 3 carcinogens, mutagens and toxic for reproduction are also labelled as harmful. IRRITANT - Immediate, prolonged or repeated contact with the skin or mucous membrane may cause inflammation. TOXIC – A substance, which in low quantities causes death or acute/chronic damage to health. Lethal dose < 250 mg/kg. Category 1 & 2 carcinogens, mutagens and toxic for reproduction are also labelled as toxic. VERY TOXIC – Lethal dose < 50 mg/kg. CORROSIVE - will destroy living tissue on contact. Can cause full thickness dermal burns. Page 3 of 13 Document1 CHIP CDG Hazard Classification FLAMMABLE - substance having a flash point of <21 oC EXTREMELY FLAMMABLE – substance having a flash point <0 oC and boiling point below 35 oC. OXIDISER - substance which gives rise to an exothermic reaction when in contact with other substances. Generally they react with most organic substances, usually resulting in a fire. None None None DANGEROUS FOR THE ENVIRONMENT - A substance, which were it to enter into the environment, would present or may present an immediate or delayed danger for one or more components of the environment. INFECTIOUS SUBSTANCE / BIOLOGICAL AGENT - These are classified as any micro-organism, cell culture or human endoparasite, including those that have been genetically modified, which may cause infection, allergy, toxicity or otherwise cause hazard to human health. IONISING RADIATION – Gamma rays, X-rays and corpuscular radiations capable of producing ions either directly or indirectly. The Globally Harmonised System (GHS) for labelling will eventually replace the CHIP symbols detailed above. This transition will take place over several years so users will need to be familiar with both sets of labels during this time. GHS Health Hazard: Respiratory sensitisation, germ cell mutagenicity, carcinogen, reproductive toxicity, specific target organ toxicity following single and repeated exposure, aspiration hazard. Acute toxicity (oral, dermal, inhalation) category 4 Acute toxicity (oral, dermal, inhalation) categories 1,2,3. Skin corrosion, serious eye damage. Flammable gases, aerosols, liquids, solids. Self-reactive substances and mixtures, pyrophoric liquids and solids, self-heating substances and mixtures Oxidising gases, liquids and solids. Page 4 of 13 Document1 GHS Acute and chronic hazard to the aquatic environment 5.0 Legal requirements 5.1 Management of Health and Safety at Work Regulations 1999 A suitable and sufficient assessment of the risks for all work activities is required for the purpose of deciding what measures are necessary to ensure safety. 5.2 Control of Substances Hazardous to Health Regulations 2002 Control of Substances Hazardous to Health (COSHH) is all about controlling the exposure of persons to substances hazardous to health with the aim of preventing illness or injury. The COSHH Regulations hinge around the process of ‘risk assessment’ where the employer (or self-employed person) has to decide whether the exposure levels in the workplace are likely to cause risks to health and safety. The assessment process is based on a number of factors including: Who is being exposed; What substances are being used; How long people are being exposed for; What levels they are being exposed to; A hierarchy of control measures must be followed in order to limit the exposure to such substances. The control measures must either eliminate the exposure or reduce it to an acceptable level. These control measures must be properly used and maintained in efficient working order. 5.3 Ionising Radiations Regulations 1999. These regulations detail the requirements for the protection of persons against ionising radiation from any work activity. Protection measures include; Notification of certain work. Restriction of exposure. Dose limits. Designation of controlled and supervised areas and classified persons. Appointment of Radiation Protection Advisers and Radiation Protection Supervisors. Local rules. Medical surveillance and monitoring. Personal protective equipment and washing facilities. Contingency plans. Decontamination procedures. 6.0 Hazards 6.1 Routes of entry into the body. The areas where hazardous substances may be absorbed into the body are through; The outer skin surface; The tissues covering the surfaces of the respiratory tract; The tissues covering the surface of the gastrointestinal tract; Page 5 of 13 Document1 The four main routes of entry are via; Inhalation. The lung is the most vulnerable part of the body, as it can readily absorb gases, soluble dusts and fumes. Absorption (Skin contact). The skin is the next most vulnerable area, as it can be in contact with hazardous substances which may be solid, liquid or gaseous and in very high concentrations in terms of quantity of substance to skin area. Ingestion. The gastrointestinal tract is the least vulnerable area of the body since the possibility of solid or liquid toxicants being ingested is limited. Injection. Sharp objects may break the protective surface of the skin leaving the area vulnerable to penetration by biological and chemical agents. 6.2 Contaminated areas and equipment. Contamination may be present; On equipment that has been used to handle or contain hazardous substances. In areas where hazardous substances have been stored, handled or used. In pipe-work that has been used to transport hazardous substances, or become inadvertently contaminated. Hazardous substances may be present in either gas, solid or liquid form and may not be visibly detectable, this will almost certainly be the case for biological and radioactive hazards. Some substances may pose a significant hazard in very small, or even trace quantities. 7.0 Procedure 7.1 Identification of Hazardous Substances, Contaminated Equipment and Areas. ALL containers of hazardous substances must be clearly labelled at all times, including containers hazardous substances are decanted into. The label must include a name or description of the contents, the hazard classification and the appropriate hazard pictogram. Prior to working in any area or on any equipment; Assess the historical use. This may give a good indication of any likely contamination. Look for any signage or warning labels that may indicate that a hazard is present. (See section 4.0). Pipe-work may be colour coded in line with BS 1710 – Pipeline identification markings. Talk to staff and students from the area, or who have control over the equipment that is to be worked on. They will be able to indicate if any contamination of a hazardous nature is present. Visually inspect the area or equipment for obvious signs of contamination. It is the responsibility of all staff to notify others of hazards arising out of their activity. 7.2 COSHH Risk Assessment A COSHH risk assessment shall be carried out and recorded prior to any work where there is a risk of exposure to a hazardous substance. It is the responsibility of the relevant supervisor(s) or manager(s) to ensure this COSHH risk assessment is Page 6 of 13 Document1 undertaken. In shared areas communication and co-operation may be necessary when undertaking the COSHH assessment and developing safe systems of work. COSHH Risk Assessment Forms can be found at the following: (https://intranet.uclan.ac.uk/ou/fm/Pages/Health-and-Safety-COSHH.aspx) 7.3 Decontamination Any decontamination must be carried out by a suitably competent person. The level of expertise will vary according to the task and level of risk. Simple decontamination involving the cleaning of oils/greases will require a relatively low level of expertise. More complex procedures and expertise will be necessary when decontaminating areas or equipment contaminated with biological or radiological hazards. It is the responsibility of the relevant supervisor(s) or manager(s) in charge of the area and equipment to ensure that sufficient decontamination is carried out by a person who is suitably qualified and experienced for the task. A test, validating the level of decontamination should be carried out where reasonably practicable and a Decontamination Clearance Certificate completed (see section 7.5 and appendices 1 & 2) 7.4 Isolation Where there is a need to break into potentially contaminated pipe-work, or where there is a risk of material ingress into a pipe while work is being undertaken, then isolation shall be carried out. Isolation may be carried out by the following methods: Physical disconnection Closing valves and securing in the closed position by means of a lock Fitting blanking flanges into pipe-work Sometimes it may be appropriate to flush or purge pipe-work with a suitable agent prior to work starting. Water or nitrogen are the preferred option for purging as they are less likely to pose a pollution/disposal problem. An assessment of all used flushing agents must be undertaken and the appropriate disposal route identified. Additional hazards, such as flooding and asphyxiation, may be introduced during purging. Control of these additional risks must be addressed in the COSHH risk assessment. 7.5 Communication The University operates a Decontamination Clearance Certificate system for declaring when equipment or areas are clean and safe to work on. Copies of these forms can be found in Appendices 1 and 2 of this procedure. It is the responsibility of the relevant supervisor(s) or manager(s) in charge of the area or equipment to ensure all necessary decontamination is carried out and to complete the relevant Decontamination Clearance Certificate. For work on University premises involving University Maintenance Staff or External Contractors, a Permit-to-Work form should be utilised. It is the responsibility of the relevant supervisor(s) or manager(s) in charge of the area or equipment to ensure all necessary decontamination is carried out and the Permit-to-Work completed. Page 7 of 13 Document1 7.6 Emergency Arrangements. Arrangements must be in place to deal with any contamination accidents, loss of containment or a fire. Where contamination involves radioactive materials, the Local Rules must be strictly adhered to and the Radiation Protection Supervisor (RPS) and Radiation Protection Officer (RPO) informed immediately. Some emergencies would require the Radiation Protection Adviser (RPA) to be notified. Emergency arrangements may include some or all of the following: Presence of a First-Aid trained member of staff. Presence of other key personnel (e.g. RPS, Senior Technician). First-aid equipment. Emergency showers. Procedures for contacting the Emergency Services. How other members of staff / students will be notified of the emergency. Evacuation procedures. Spillage equipment. Cleaning equipment. Fire extinguishers of the appropriate type. Personal protective equipment and respiratory protective equipment. 8.0 Glossary CDG CHIP COSHH Flash Point GHS mg/kg RPA RPO RPS Carriage of Dangerous Goods Regulations. Chemical Hazard Information for Packaging and Supply Regulations The Control of Substances Hazardous to Health Regulations 2002 The minimum temperature at which the vapour above the surface of a liquid will ignite, if impinged upon by a source of ignition Globally Harmonised System (labelling of hazardous chemicals) Milligrams per kilogram of body weight. The unit of measure for a lethal dose of a toxic substance Radiation Protection Adviser Radiation Protection Officer Radiation Protection Supervisor Page 8 of 13 Document1 APPENDIX 1 Page 9 of 13 Document1 University of Central Lancashire – Equipment/Articles Decontamination Clearance Certificate To: From: Works are required to be carried out in your area containing the following equipment/articles: (Model/Serial/Batch No.) Please certify by signing below that the above equipment/article has so far as reasonably practicable been decontaminated in accordance with the relevant risk assessment prior to inspection, service, repair or disposal and is radiologically, chemically and biologically clean. Name Date: Job Title If the equipment/article cannot be fully decontaminated please state the nature of the risk and safety precautions necessary: Please return to sender once the above is completed. Page 10 of 13 Document1 APPENDIX 2 Page 11 of 13 Document1 University of Central Lancashire Area Decontamination Clearance Certificate To: From: The following works are required to be carried out in your room/area: Please certify by signing below that the above Room/Area is free from the following hazards: Biological* name job title Date: Chemical* Date: Radiological* Date: * Where there has been no material used which represents a hazard, please write ‘N/A’ in the appropriate signature column. PLEASE PROVIDE ANY ADDITIONAL INFORMATION THAT MAY BE RELEVANT TO POTENTIAL CONTAMINATION IN AREAS SUCH AS PIPEWORK AND DUCTING ON THE REVERSE OF THIS SHEET. WHERE NECESSARY, APPEND APPROPRIATE MSDS SHEETS. Please return to sender once the above is completed. TO BE COMPLETED BY PROJECT MANAGER Please certify by signing below that the above Room/Area is free from the following hazards: *Asbestos (Asbestos Clearance Certificate attached) Date: (Project Manager) Page 12 of 13 Document1 Additional hazard/safety information Action taken by the School/Department Potential hazards Control measures First Aid Measures Fire Extinguishing Media Risk Assessment Page 13 of 13