section 772 highway traffic signals 772.01 description

advertisement

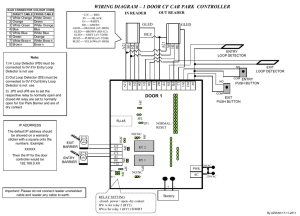

NOTE: New Items: Underlined Changed Items: AGC Comment balloon added SECTION 772 HIGHWAY TRAFFIC SIGNALS 772.01 DESCRIPTION This work consists of furnishing and installing flashing beacons and traffic signals. 772.02 EQUIPMENT Reserved. 772.03 MATERIALS A. General. Item Class AE Portland Cement Concrete Grout Highway Traffic Signals Section 802 806.01 896 The Department defines words and phrases as defined in Section 1 “Definitions” of the National Electrical Manufacturer’s Association (NEMA) Standard Publication No. TS 2 Traffic Control Assemblies with NTCIP Requirements and Part 1 “Definitions” of NEMA Standards Publication TS-1 Traffic Control Systems to interpret these Specifications B. Work Drawings. Submit work drawings a maximum of 50 days after the date of award of contract. Provide the following with the work drawings, provide: The dimensions; Type of material; The functional characteristics of the equipment to be installed; and Any manufacturer warranties and guarantees listing the Department as the owner. Submit work drawings for the following listed items: 1. 2. 3. 4. Conductors; Pull Box; Saw Slot Sealant; Feed Point Equipment including: a. Safety switch and lightning protection device; b. Flasher; c. Time Clock; and d. Cabinet. 5. Traffic Signal Standards including all necessary calculations and drawings used in designing these poles; 1 6. Combination Standards including all necessary calculations and drawings used in designing these poles; 7. Traffic Signal Heads; 8. Beacon Heads; 9. Pedestrian Signal Heads; 10. Pedestrian Push Button; 11. Detector Cabinet; 12. Traffic Signal Controller with all components including, when required: a. Controller; b. Flashers; c. Conflict Monitor; d. Coordination Equipment; e. External Logic Unit; f. Solid State Load Switches; g. Detector Amplifier; h. Lightning Protection Device; and i. Cabinet. 13. Emergency Vehicle Pre-Emption Equipment; and 14. Painting method and type. C. Certificate of Compliance Submit a certificate of compliance for conduit. Submit a certificate of compliance that states all components of the LED signal modules meet the Institute of Transportation Engineers standards. E. Wiring Diagrams. At the time the cabinet and control equipment is delivered, furnish two traffic signal cabinet wiring diagrams showing all circuits and parts in detail. Place one wiring diagram in the signal cabinet and submit the other to the Engineer. Provide wiring diagrams that contain all the control equipment and their associated connecting cables and termination points. Identify each wire in each connecting cable on the wiring diagram as to its function and terminal number. List on each terminal on the wiring diagram, the cable designation and connector letter or number of the wire terminated at that point. Include as part of the wiring diagram the location of all control equipment, terminals, etc., within the cabinet as well as an intersection layout showing the location of vehicle signal faces, pedestrian signal indications, loop detectors, pedestrian push buttons, etc., all labeled as shown on the plans. Include in the main cabinet wiring diagram the logic (schematic) diagram of the following as required: 1. 2. 3. 4. 5. 6. 7. 8. In and Out Flash Circuitry; Detector Paralleling Circuitry; Detector Time Delay Circuitry; Calling Detector Circuitry; Coordination Interface Circuitry; Not Adding Initial During Non-Automatic Circuitry; Actuated Permissive Yield Period Circuitry; All other logic diagrams contained in the external logic assembly unit; and 2 9. Emergency Vehicle Pre-Emption Circuitry and Interface Points. F. Service Manuals. At the time the cabinet and control equipment is delivered, furnish two service and operating manuals for the traffic signal controller unit and emergency vehicle pre-emption controller. Place one manual in the signal cabinet and submit the other to the Engineer. Furnish service manuals that include the following minimum information: 1. 2. 3. 4. Detailed description of operation and instructions for initial set-up; Recommended servicing and service hints; Complete parts list; and Recommended spare parts list. 772.04 CONSTRUCTION REQUIREMENTS A. General. Perform all work to meet the requirements of the National Electric Code, the North Dakota State Electrical Board, the local utility company, and the ordinances established by the local municipality. All electrical installations must be either performed by or supervised by a licensed electrician. Provide and bear all costs for the electrical service necessary to operate and maintain the traffic signal system until the system is accepted as specified in 722.04 P.4, “Final Acceptance”. B. Concrete Foundations. Construct concrete Foundations that meet Section 770.04 B “Concrete Foundations”. Place concrete foundations to provide the greater minimum horizontal and vertical clearances between the signal standards/mast arms/appurtenances and power lines required by the National Electric Code (NEC), or as specified in Table 772-1 for the indicated power line voltages: Table 772-1 Power Line Horizontal Vertical Voltage Clearance Clearance (V) (ft) (ft) 0 - 22,000 5 6 Greater than 22,000 5 + 0.033 per kV 6 + 0.033 per kV greater than 22 kV greater than 22 kV Do not adjust the plan foundation locations without the approval from the Engineer. C. Conduit. Install conduit as specified in Section 770.04 D “Conduit”. Install an additional 2 inch conduit in each traffic signal standard foundation and traffic signal controller as directed by the Engineer. Place a label on the additional conduits indicating the cardinal direction the conduit runs. 3 D. Conductors and Cables. 1. General. Pull all cables through conduit by hand without causing strain to the cable or conduit. Install wire entrance fittings. Use rubber sleeves fittings with clamps to protect the wire through the wire entrances on the signal standards and mast arms. Splicing is only permitted in traffic signal standards, pull boxes, and feed points. Perform only compression type splices. Only terminate cables at meter box, signal standards, or other equipment. Connect cables with sufficient slack to prevent any strain on the cable or connections. Install additional cable quantities to provide for slack and the wiring of controllers, feed points, and signal heads as follows: a. b. c. d. e. f. Nine feet at the controller; Fifteen feet at post-mounted and pedestal-mounted vehicular signal heads; Twelve feet at post-mounted and pedestal-mounted pedestrian signal heads; Eight feet at each pedestrian push button; Fifteen feet at each flashing beacon sign support; Twenty-three feet at each signal pole with mast arm plus the length of the mast arm; g. Ten feet at the feed point; h. Five feet at each foundation for each incoming and outgoing pedestrian and signal head control circuit; i. Six feet at pull boxes where connections are made; and j. Three feet at each foundation for each incoming and outgoing circuit which passes through the foundation with no connection being made. Ground all bases, signal standards, control cabinets, feed points, and any exposed metal parts. Provide bolted pressure connectors to all ground rods. Protect cable from moisture during installation. Identify the function of each cable and label each cable accordingly. Make all necessary wiring connections. 2. Traffic Signal Control Circuits. a. Install unspliced, No. 16 AWG, two-conductor cable from each pedestrian push button to the controller. b. Install control cables running from the terminal block in each traffic signal standard base to each traffic signal head. Install No. 12 AWG, three-conductor cable for each two-section pedestrian head, No. 12 AWG, five-conductor cable for each three-section vehicular head and No. 12 AWG seven-conductor cable for each five section vehicular head. c. Provide terminal blocks for connections of control circuits in signal standard bases. 4 d. Do not splice traffic signal control circuits. 3. Loop and Loop Lead-In Conductor. For preformed loop detectors, seal the conduit end inside the pull box to prevent water from entering the conduit. E. Pull Box. Install pull boxes as specified in Section 770.03 F, “Pull Box”. F. Installation of Loop Detectors. 1. General. Install the road loop in a manner that will interrupt the normal flow of traffic the minimum amount of time. Do not begin work until all material, equipment, and personnel are at the site. 2. Layout. The Engineer will mark the loop detector locations before installation. 3. Pull Box Install conduit from the pull box to the gutter or roadway edge. Install a separate conduit for the pull box entry for each loop. Make the excavation from the saw slot at the gutter or roadway edge by means of a punch or drill type tool, rather than by usual excavating methods. Do not cut the visible portion of the gutter for conduit installation. Install the conduit to directly receive the loop wire in line and not at an angle. Use the same sealant over the conduit as the sealant used to close the saw cut. Install the conduit and the pull box at the same time. 4. Saw Cut. Saw the pavement slot with a self-propelled power saw equipped with a depth gauge and alignment guide. Ensure the pavement slot is cut cleanly without uneven or jagged edges. Clean slots immediately after the cutting operation. Place wooden strips in the cut or place a durable cover to prevent slot shrinkage or damage before the wire is installed. 5. Cleaning of Saw Cut. Do not leave any cutting dust, dirt, oil, moisture, or other contaminants in the saw cut. Remove all cutting dust, dirt, oil, moisture, and deleterious material by air blasting the slots. Use a 90 psi air compressor that provides moisture and oil free compressed air to clean the slots. 6. Wire Installation. Install the wire loops in a clean and dry slot. Use a constant connection scheme for the color-coded, shielded loop lead-in wire throughout the intersection. Coil a minimum of 6 feet of slack for loop wire pairs and leave it in the pull box. Do not use a sharp-pointed tool to install the wire. Hold the wire in place with short strips of polyethylene foam sealant backing placed over the wire at approximately every 2 feet. Leave these strips in place while the sealant is poured. 7. Saw Cut Seal. Install sealer according to the manufacturer’s instructions. 5 Pour the sealer into the slot to 1/2 depth without air bubbles or material pileup. Then fill the slots to roadway level without air bubbles or material pileup. Do not form a trough or a mound with sealer. Allow sufficient time for the sealer to harden according to the manufacturer’s recommendations, before allowing traffic to move over the area. 8. Testing. Before pouring the sealer, perform the continuity, inductance, and insulation resistance tests in the presence of the Engineer. a. Continuity Test. Perform the continuity test to each loop detector circuit at the following locations: The continuity of the lead-in cable must be less than 0.5 ohms at the pull box before splicing; or The continuity of the lead-in cable must be between 0.5 and 5.0 ohms at the traffic signal controller cabinet or detector cabinet after splicing in the pull box. b. Inductance Test. Perform the inductance test to each loop detector and lead-in cable at the traffic signal controller cabinet or detector cabinet. The inductance must be between 50 to 500 microhenries. c. Insulation Resistance Test. Perform the insulation resistance test using 500 volts direct current at the traffic signal controller cabinet or at the detector cabinet between one loop detector lead-in conductor and the cabinet ground rod. The insulation resistance must be greater than 100 megaohms. After sealing the saw slots, repeat the continuity, inductance, and insulation resistance tests in the presence of the Engineer and record the results. Submit the test results to the Engineer and include the following information: Project Number; Intersection; City; Loop Detector Location; Dimensions, both length and width; Number of turns; Continuity at all locations Inductance; and Insulation resistance. 9. Loop Detector System Ensure the loop detector system is moisture-proof. a. Loop and Lead-In Conductor. Install the loop lead-in conductor unspliced from the pull box to the controller. 6 Use a wood lath or other nonmetallic material to hold up the loop and lead-in conductor in the pull box so that the conductor does not touch the bottom of the pull box. Hold up the splice area at the top of the conductor holding device. b. Splices. If splicing the detector feeder cable or loop lead-in conductor, use one of the following: a. Uraseal; b. 3M Underground Splice Kit; or c. Approved equal. G. Feed Point. The local utility company will furnish and install the required single phase voltage service connection and any required meter. H. Traffic Signal Standards and Combination Signal and Light Standards. 1. Paint the base, pole, and mast arm as specified in Section 772.03 P, “Signal Painting”. Galvanize the luminaire mast arm. 2. Use leveling nuts to plumb standards. 3. Install and tighten the anchor bolts as specified in Section 754.03 D.4, “Overhead Sign Structures”. 4. Provide a rigidly-mounted terminal block in the base of each standard for the connection of control circuits. Terminal blocks are not required for Type I bases. Install the luminaire fuses in the base of combination signal and light standards. 5. Provide rodent protection using wire mesh with a maximum size opening of 1/4 inch for all anchor base installations. Place the wire mesh continuously around the inside of the lower plate to prevent rodents from entering the base through the space between the concrete foundation and the lower plate. Secure the mesh to the anchor bolts and lower plate. I. Traffic Signal and Pedestrian Heads. 1. General. Mount pedestrian signals vertically and within 2 inches of the pole. Provide back plates with a 1 inch yellow retroreflective sheeting border. Use sheeting specified in Section 894.02 D, “Type IX Retroreflective Sheeting”. Cover all heads with a material that allows the signal heads, when lighted, to be seen dimly by personnel testing the signals. Leave the hoods in place until the Engineer authorizes operation of the signal. The Engineer will determine when the installation is to be put into operation. Position the heads to provide the best possible view for the traffic to be controlled. 2. Pole Mounted Attach the signal and head to signal poles using brackets that have threaded pole plates or pole clamps that accept the 1-1/2 inch standard steel pipe. Mount the traffic signal and 7 pedestrian head on 1-1/2 inch standard steel pipe and fittings. Use pole plates that are held to the pole by means of banding material. 3. Pedestal Mounted. Mount pedestal-mounted traffic signals and pedestrian heads mounted on a post top slip fitter that attaches rigidly to the signal pole. J. Traffic Signal Controller. Connect the signal, interconnect, detector, power, and other circuits to the terminals as shown on the manufacturer’s wiring diagram. When setting the cabinets directly on concrete foundation, set them on a sealant and seal with caulking inside and outside of the concrete base. Arrange the field leads in an orderly arrangement of wires in the cabinet. Do not cut field leads shorter than the furthest terminal for the same function in the cabinet. K. Emergency Vehicle Pre-Emption (EVP). Install EVP equipment when specified in the contract. Program the time settings established by the local municipality. L. Uninterruptible Power Supply (UPS). Install UPS equipment when specified in the contract. Equip the traffic signal controller with an “on-line” type UPS that provides power in both normal and backup mode. The UPS shall incorporate full power management and diagnostic function, and provide backup power to the system for a minimum of: 2 hours in full signalized mode; and 8 hours in flash operation. The UPS shall have aux contacts to put the system into flash operation. M. Interim Traffic Signals. Furnish and install new LED signal lamps. The power company will make the final service connections to the feed points. N. Remove Existing Equipment. 1. General. Before work begins, contact the local utility company and arrange a time for the power to be disconnected. The local utility will remove the meter. Remove the existing foundations to a depth of 2 feet below the ground line and the surface restored to match adjacent areas. 2. Removal of Signal Heads. If no new signal heads are to be installed, disconnect the circuits at the controller terminal strip. Tape the wires together and place them in the bottom of the controller cabinet. 3. Remove Flashing Beacon System. 8 After the local utility removes the meter, disconnect and remove the flashing beacon system. 4. Remove Traffic Signal System. Disconnect and remove conductor and standard. Remove the controller, traffic signal heads, and mounting brackets from the standards. Remove the signal heads from the mounting brackets. Remove and dispose of the traffic control cable and concrete foundation. 5. Remove Traffic Signal Controller. Remove and dispose of the concrete foundation. 6. Remove Feed Point. After the local utility removes the meter, disconnect and remove switch box, meter trim, and conduit. O. Signal Painting. Factory paint all new mast arms standards, combo mast arm signal standards, 4 inch signal standards, pedestrian push button posts, and the base and lower 12 feet of the light standard with attached pedestrian signal heads with two-part epoxy primer and acrylic top coat. Finish the light standard as specified in section 896.07 C.5. Use color No. 13538 of the Federal Standard No. 595. Prepare all areas requiring touch up paint as follows: 1. Completely remove all rust and loose paint; 2. Sand all areas to be painted with 40 grit paper; 3. Wash down with “no rinse pre-paint cleaner” as recommended by the manufacturer; 4. Prime bare metal as recommended by the manufacturer; and 5. Top coat with paint supplied by the original pole manufacturer. P. Tests and Acceptance. 1. General. The Engineer will provide the following at the preconstruction conference: Inspection checklist; Conflict monitor test form; and Ground test form. At a time designated by the Engineer, conduct an operating test when the installation of the system is complete. Furnish all instruments and personnel required for testing and record test results. If a subcontractor performed electrical work, ensure the subcontractor is present during testing and inspection. The Engineer will perform the initial and final inspections when: Winds are 30 mph or less; Ambient temperature is 15°F or greater; and It is not raining or snowing. 9 a. Conflict Monitor Test. Before uncovering the signal heads, perform a conflict monitor test. Record and submit the test results on the conflict monitor test form. b. Ground Test. Before opening to traffic, perform a ground test. The maximum allowable resistance at the controller cabinet is 10 Ohms. The maximum allowable resistance at each traffic signal standard is 25 Ohms. Record and submit the test results on the ground test form. 2. Initial Inspection. Complete and submit the checklist and forms after signal system is operational and open to traffic and before scheduling the initial inspection of the system. Include the vertical clearances for each signal head with the checklist. Include a written statement certifying that all signals or flashing beacons under the Contract are operational and the checklist work and tests are complete. After submitting the checklist and forms, submit a request to schedule the initial inspection. The system must be fully operational for a minimum of 15 days before the Engineer will perform the initial inspection. 3. Final Inspection. After correcting all items identified during the initial inspection, submit a request to schedule the final inspection. The Engineer will perform the final inspection between 30 and 60 days of receipt of the request. 4. Final Acceptance. The Engineer will accept the system after all items identified in the final inspection have been corrected and the system has been operating for 14 consecutive days without interruption from defective equipment or improper workmanship. If the system fails within the 14 days, make the necessary repairs. Once the repairs have been made, request another inspection and the Engineer will perform an inspection as specified in Section 772.04 T.3 “Final Inspection”. The Engineer will accept the system after all items identified in the final inspection have been corrected and the system has been operating for 14 consecutive days without interruption from defective equipment or improper workmanship. 772.05 METHOD OF MEASUREMENT The Engineer will measure, completed and in place, as specified in Section 109.01, “Measurement of Quantities” and as follows: The Engineer will not measure conduit that is placed in concrete foundations, feed points, overhead and sign-mounted flashing beacons, interim flashing beacons, and traffic signals foundation, feed points, and overhead or bridge sign structures. The Engineer will include the additional conductor lengths in the measurement of the conductor. 10 772.06 BASIS OF PAYMENT Pay Item Pay Unit Saw Slot Cable Trench Conduit ____ Size Underground Conductor Linear Foot Linear Foot Linear Foot Linear Foot Loop Lead-in Conductor and Conductor Cable Linear Foot Concrete Foundations Pull Box Feed Point Signal Standard, Combination Mast Arm Signal, and Light Standard Flashing Beacon One-Way, 2-Section Pedestrian Signal Detector Cabinet Controller Interim Traffic Signals One-Way Number of Units in Section Head Signal Adapter Beacon Head Pedestrian Push Button Post Revise Concrete Foundation Remove Signal Heads Remove Flashing Beacon System Remove Interim Traffic Signals Remove Traffic Signal System Remove Traffic Signal Controller Remove Feed Point Emergency Vehicle Pre-Emption Unit Microloop (Single) probe Microloop (Double) probe set Microloop (Triple) probe set Performed Loop Detector Controller Type 1 Controller Type 2 Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Each Such payment is full compensation for furnishing all materials, equipment, labor, and incidentals to complete the work as specified. 11