GaInP NW p-n junction Wallentin Supplementary Material revised v2

advertisement

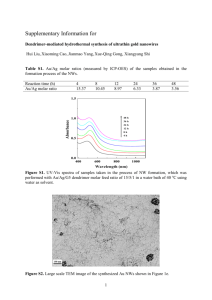

Supplementary Material for “Single GaInP nanowire p-i-n junctions near the direct to indirect bandgap crossover point” Jesper Wallentin1*, Laura Barrutia Poncela1, Anna Jansson1, Kilian Mergenthaler1, Martin Ek2, Daniel Jacobsson1, L. Reine Wallenberg2, Knut Deppert1, Lars Samuelson1, Dan Hessman1, Magnus Borgström1 1 Solid State Physics, Lund University, Box 118, S-221 00, Lund, Sweden Polymer & Materials Chemistry/nCHREM, Lund University, Box 124, S-221 00, Lund, Sweden 2 * jesper.wallentin@ftf.lth.se Methods details NWs were grown from 80nm gold aerosols at a density of 4 μm-2, on InP (111)B substrates, using phosphine (PH3), trimethylgallium (TMG) and trimethylindium (TMI). The phosphine molar fraction was held constant at χPH3 = 6.3x10-3. Hydrogen chloride (HCl) was used to control radial growth. Hydrogen sulfide (H 2S) and diethyl zinc (DEZn) were used for doping, at molar fractions of χH2S = 2.5x10-5 and χDEZn = 1.8x10-6. The NWs were grown in a low-pressure (100 mbar) metal organic vapor phase epitaxy (MOVPE) system with a total flow of 6 l/min using hydrogen as carrier gas. To desorb surface oxides, the samples were first annealed at 550 ºC for 10 min under a PH 3/H2 gas mixture. The reactor was then cooled to 420 ºC, at which temperature InP NW growth was initiated by adding TMI (χTMI = 1.1x10-5). After a 15 s nucleation time HCl was added, χHCl = 1.0x10-5. After 5 min, TMI and HCl were switched off and the temperature raised to 460 ⁰C. A GaP barrier for improved PL was grown for 2 min by adding TMG (χTMG = 6.8x10-6) and HCl (χHCl = 3.3x10-6, lower than for InP growth). GaInP NW growth was initiated by adding TMI (χTMI = 1.1x10-5) and any dopant precursor. Undoped and homogenously H2S-doped GaInP NWs were grown for 30 min, while homogenously DEZn-doped GaInP NWs were grown for 90 min. The p-i-n NWs were grown with 30 + 10 + 10 min of DEZn-doped, undoped and H2Sdoped GaInP, respectively. For NW-FETs and diodes, NWs were mechanically transferred to a degenerately doped silicon substrate. The substrate was covered with 100 nm silicon oxide and 10nm of HfO 2. The position of the nanowires was measured in an optical microscope, and after resist deposition contacts were created to selected nanowires by electron beam lithography (EBL) and metal lift off. The NWs were etched with with H 3PO4:H2O 1:9 for 2 min, then with H2SO4:H2O 1:3 for 1 min, and finally passivated with NH 4Sx for 10 min. A Pd/Zn/Pd/Au (10/10/20/70 nm) metal combination was used for p-type contacts, and Ti/Pd/Au (10/10/80nm) was used for n-contacts. For pi-n devices, p-type contacts were used for both ends to save one EBL step. No annealing was used. The NWs were investigated using scanning electron microscopy (SEM; FEI Nova Nanolab 600) and transmission electron microscopy (TEM; JEOL 3000F), both instruments equipped with a field emission gun and operated at 15 and 300 kV respectively. High resolution TEM (HRTEM) was performed for detailed examination of NW crystal structure and x-ray energy dispersive spectrometry (XEDS) analysis carried out in scanning mode was used out to obtain information about NW composition. TEM samples were prepared by mechanically transferring the NWs onto lacey carbon Cu TEM-grids. For the micro-PL measurements the NWs were mechanically transferred to a thin gold layer on a silicon substrate. For the optical excitation a frequency doubled solid state laser was used emitting at 532 nm. The laser was focused on the nanowires creating a laser intensity of up to ~6000 W/cm2. The sample was mounted in a cold-finger cryostat and all measurements were done at liquid helium temperature. Power-dependent photocurrent measurements were made with the same focused 532 nm laser. Photocurrent spectroscopy measurements were performed using a supercontinuum source based on a pulsed laser and a high nonlinearity optical fiber supercontinuum generator SC450. The laser has a wavelength of 1060 nm and creates laser pulses of approximately 4 ps. Due to the high power of the pulses and the nonlinearity of the fiber, the light experience large spectral broadening, creating a spectrum from 450 nm (2.76 eV) to 1750 nm (0.71 eV). The light from the supercontinuum light source was then coupled into a grating spectrometer with computer controlled wavelength setting. The light from the spectrometer showed a peak width of about 10 meV. The light was directed down to the sample through a microscope and focused with a 100x objective. A lock-in amplifier was used to improve the signal to noise ratio. Electrical characterization of homogenously doped NW-FETs Figure S1: (a), (b): n-doped NW-FET, (c), (d): p-doped NW-FET Electroluminescence images Figure S2: Microscope images of a GaInP NW p-i-n diode device under forward bias. The device is not the same as shown in Fig 2. The left image shows the device under white light illumination, and the right image shows the device in dark. The shift in position is due to drift in the system.