02/11/2010Meeting MinutesEDMS 1102711 Access and ventilation

advertisement

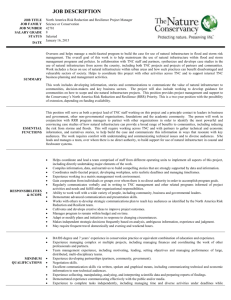

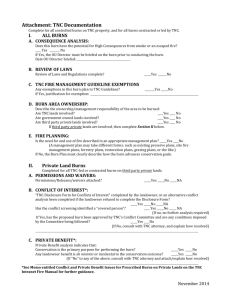

02/11/2010 Meeting Minutes EDMS 1102711 Access and ventilation doors in HiRadMat. Present: André Coin; Didier Vaxelaire; Luca Bruno; Marc Tavlet; John Pedersen; Thijs Wijnands; Chris Theis; Philippe Trilhe; Sebastien Evrard; Ilias Efthymiopoulos; Guillaume Gros; Paul Pepinster; Ans Pardons; CC: Helmut Vincke; ... Meeting structure: 1. 2. 3. 4. 5. Introduction (IE, AC) Discussion ventilation door “TNC” (all) Ventilation System presentation(PP) Repositioning of access gate PPG 12058 (IE) Conclusion and actions Meeting Minutes 1. Introduction (IE, AC) Ilias shows introductory slides summarizing the operational parameters of the future HiRadMat facility. The slides are available at EDMS 1102711. The HiRadMat facility will see a maximum of 1016 protons per year, divided over a maximum of 10 experiments per year. The total amount of protons per experiment will be distributes over a maximum of 100 pulses, with several observation/analysis/modification pauses in between the pulses. Luca remarks that all test objects must be contained to avoid contamination of the area. Ilias and Chris reply that each user will be requested to have a container to ensure there will be no loss of containment. Experiments will need to pass a selection committee (including the DSO and representatives from RP, SPS operation and PS operation) before obtaining beam time. This committee will impose all measure necessary to guarantee safety during the test beam (e.g. request double containment). The TNC volume (former WANF target cavern) must be kept at an under pressure of 40Pa to avoid radioactive air from TNC leaking into the neighbouring volumes. The escape route to building 846 will have a separate ventilation system. The ventilation door “TNC” was originally foreseen to be placed at the junction between the TNC and TJ7 caverns. The original request from G. Roy was to contain the TNC volume as much as possible while separating the TNC volume completely from the access path to TI2 (via TJ7). In this case, access to TI2 does not depend time needed to clean the air in the TNC volume, therefore access to the LHC injection line is never delayed because of the HiRadMat volume flushing time. Page 1 of 6 02/11/2010 Meeting Minutes EDMS 1102711 However, this configuration (“Project 1”) is difficult to put in place because of the following requirements: The overhead crane needs to be able to pass through this door (operating ~20 times per year) and permanent opening must be foreseen for the crane rails. The door needs to be airtight in order to guarantee the 40Pa under pressure in TNC The only way to possibly ensure both tightness and crane passage is a complex system of clamps, mounted around the crane rail, that need to be dismounted manually at each use of the crane and remounted before sending beam to HiRadMat. While the feasibility of such a complex assembly still needs to be proven, it surely comes at a high cost, both in radiation dose to the intervening personnel as well in loss of flexibility and ease of operability of the facility. Additionally, several service and control cables to the experimental area will need to pass through the ventilation door, as it is placed between the cables’ patch panel (TJ7) and the experimental area. This means that, whenever a cable is added following specific user needs or a faulty cable needs to be replaced, the air tightness of the door needs to be broken en re-established. André has studied the design of a ventilation door between TNC and TJ7 and shows a 3D model (see Figure 1) to indicate the difficulties in realizing this door, which are increased by the limited space available between the frame of the overhead crane and the tunnel wall. Figure 1: 3D sketch of a ventilation door that foresees a dismountable part around the crane rails (blue) and a section that needs to be dismounted or pushed downstream to allow the crane to pass (red) Page 2 of 6 02/11/2010 Meeting Minutes EDMS 1102711 Therefore, the alternative solution (Project 2) proposes to move the “TNC” ventilation door into the TA7 gallery, such adding the TJ7 volume (and a small part of the TA7 volume) to the “TNC volume”, i.e. the volume that will see the radioactive air from the experimental area. This solution lets the overhead crane move freely in the TNC volume and allows the ventilation door (now in TA7) to be less complex and completely airtight. The “Project 2” solution is shown in Figure 2. Figure 2: Proposed position (“Project 2”) of the ventilation doors (red) enclosing the TNC air volume 2. Discussion ventilation door “TNC” (all) André mentions that a ventilation door of the WANF-era is present in TA7 and can be used (after modification and renovation) as “TNC” ventilation door at this location. Marc remarks that the opening directing of the door needs to be inversed (i.e. needs to open towards the elevator) in order to be compatible with safety requirements and with the under pressure in TNC. It is agreed that the “Project 2” solution guarantees a 100% airtight separation of TNC (as opposed to “Project 1”) and thus increases safety of the HiRadmat operation. The solution is therefore preferable, though its impact on the ease of access to TI2 needs to be assessed. Paul states that the time needed to flush the TNC area (including TJ7 and a small part of TA7) in order to allow access to the area and, as such, to the LHC injection line TI2 is about 1 hour. Ilias adds that the time needed by the operators to switch from a “HiRadMat” injector cycle to a LHC-cycle takes at least Page 3 of 6 02/11/2010 Meeting Minutes EDMS 1102711 half an hour. Additionally, the area of concern (TT61) contains very few beam elements (5 magnets and 1 TBC) and the probability of a failure, especially one requiring immediate access, is extremely low. Ilias adds that, in case of fire or other emergency needing immediate access, the fire-fighters add under “emergency conditions” (breathing apparatus etc.), such that flushing is not needed in that case and the additional flushing delay is not relevant. André mentions that details of the “Project 2” solution still need to be studied and designed, in particular the “guillotine” that ensures the air tightness at the lower part of the door. However, existing systems can be extrapolated to fit the HiRadMat application. 3. HiRadMat ventilation system (PP) Paul shows the different ventilation scenarios (RUN, RUN with dehumidification, FLUSH, ACCESS, ... ) of the HiRadmat facility (see Figure 3 and Figure 4). During beam mode, there is only the leak ventilation, needed to guarantee the 40Pa under pressure in the TNC area. John asks whether the release air will be filtered. Paul replies that there is the possibility to send the release air over filters, though this will depend on RP measurements. In response to a remark from Luca, Paul ensures that the dehumidification unit underground (renovated WANF equipment) can be started remotely by hand but will also starts automatically based on monitoring of humidity in the tunnels. Figure 3: The HiRadMat ventilation system infrastructure schematics Page 4 of 6 02/11/2010 Meeting Minutes EDMS 1102711 Figure 4a,b,c and d: Schematics and airflow during different ventilation modes Paul explains that the exact position of the ventilation door in TA7 has very little effect on the behaviour of the system. The work needed to put the “project 2 “ solution in place consists of the installation of additional pulsing grates in TJ7 and an a posterior CFD calculation to calculated the slightly modified flushing times, now that TJ7 will also be part of the total volume to be flushed before access. Chris adds that, while calculations give an estimate flushing time, the decision when to give access will be based on real time monitoring results. 4. Repositioning of access gate PPG 12058 (IE, DV, PT) Ilias explains that the service and control cables will start from a rack in or around the surface building BA7 and descend along the pit until a patch panel in TJ7. From TJ7 on, the cables will be radiation resistant and two possibilities are still considered for their routing to the experimental area: a passage through TJ7, TT61 and (through a core drilling between TT66/TNC and TT61) to the test area, or from TJ7 directly to TNC, running along the right hand wall and crossing the TNC tunnel in a structure that will still allow transport vehicles to pass. The first of these two proposals would require frequent access to the TT66 tunnel. With the existing sectors, access to TT61 would mean that a patrol needs to be carried out Page 5 of 6 02/11/2010 Meeting Minutes EDMS 1102711 in the entire TT61 tunnel. Moving the sectorisation gate PPG 12058 downstream for about 40m would avoid the extra patrolling work (see Figure 5). Figure 5: Proposed new location for the PPG.012058 door (blue), as well as the ventilation doors containing the TNC air volume (red) Didier will give a cost estimate for this modification. Thijs mentions that the general logic of sectorisation implies that LHC, SPS and HiRadMat areas are separated. Moving the PPG 12058 downstream is not following this logic, as a part of TT61 will now be in the same sector as TCC6. 5. Conclusion and Actions (all) The “Project 2” proposal is accepted by all present, meaning that the “TNC” ventilation door can be moved from its originally foreseen position (junction TJ7-TNC) to TA7, at the position of the former WANF ventilation door. Modifications and renovation of the door need to be studies (Action: André) The minutes of this meeting and all related documents will be placed on EDMS and sent for approval to all people involved (Action: Ilias, Ans) A decision on the moving of PPG 12058 remains pending and will depend on the cost estimate and the decision on the routing of the cables for the experimental area between TJ7 and TNC/TT66. Ans Pardons, 03/11/2010 Page 6 of 6