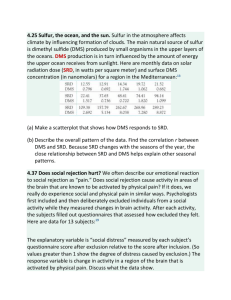

18664_2

advertisement