Program Area Inspection Checklist

P a g e | 1 of 4

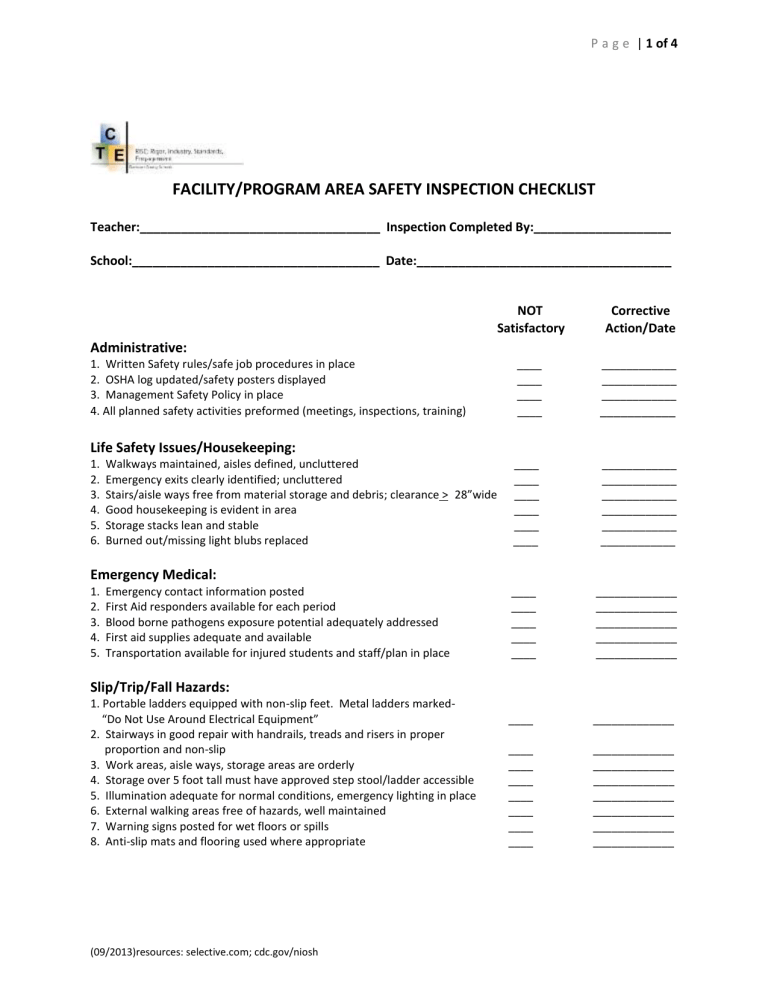

FACILITY/PROGRAM AREA SAFETY INSPECTION CHECKLIST

Teacher:___________________________________ Inspection Completed By:____________________

School:____________________________________ Date:_____________________________________

NOT Corrective

Satisfactory Action/Date

Administrative:

1. Written Safety rules/safe job procedures in place ____ ____________

2. OSHA log updated/safety posters displayed

3. Management Safety Policy in place

____ ____________

____ ____________

4. All planned safety activities preformed (meetings, inspections, training) ____ ___________

Life Safety Issues/Housekeeping:

1. Walkways maintained, aisles defined, uncluttered

2. Emergency exits clearly identified; uncluttered

____ ____________

____ ____________

3. Stairs/aisle ways free from material storage and debris; clearance > 28”wide ____ ____________

4. Good housekeeping is evident in area

5. Storage stacks lean and stable

____ ____________

____ ____________

6. Burned out/missing light blubs replaced ____ ____________

Emergency Medical:

1. Emergency contact information posted

2. First Aid responders available for each period

3. Blood borne pathogens exposure potential adequately addressed

4. First aid supplies adequate and available

5. Transportation available for injured students and staff/plan in place

____ _____________

____

____

____

____

_____________

_____________

_____________

_____________

Slip/Trip/Fall Hazards:

1. Portable ladders equipped with non-slip feet. Metal ladders marked-

“Do Not Use Around Electrical Equipment”

2. Stairways in good repair with handrails, treads and risers in proper

proportion and non-slip

7. Warning signs posted for wet floors or spills

8. Anti-slip mats and flooring used where appropriate

____

____

_____________

_____________

3. Work areas, aisle ways, storage areas are orderly ____ _____________

4. Storage over 5 foot tall must have approved step stool/ladder accessible ____ _____________

5. Illumination adequate for normal conditions, emergency lighting in place ____

6. External walking areas free of hazards, well maintained ____

_____________

_____________

____

____

_____________

_____________

(09/2013)resources: selective.com; cdc.gov/niosh

P a g e | 2 of 4

NOT Corrective

Satisfactory Action/Date

Hand Tools/Appliances:

1. Power tools/appliances properly grounded/have safety power switch

2. Defective tools/appliances are removed from service (no frayed, cut or

____

____

_____________

_____________

damaged electrical cords)

3. Proper guards are provided, tools electrically grounded or double insulated ____

4. There is a preventive maintenance/inspection program

_____________

____ _____________

5. Students/staff are trained in the safe use of hand tools/appliances ____ _____________

_____________________________________________________________________________

Fire Safety:

1. Portable fire extinguishers or proper type are mounted properly, accessible,

and inspected (nothing stored/obstructing within a 3 ft. perimeter) ____

2. Approved safety containers are used for flammable liquids ____

____________

____________

3. Combustible debris disposed of regularly i.e. oily/greasy rags stored in

a covered metal container

____ ____________

4. Compressed gas cylinders capped and chained ____ ____________

5. Sprinkler system functional/inspected/documented

6. Smoke/heat detectors functional and inspected

7. Minimum 18” clearance below sprinkler heads

8. Sprinkler valves locked open

9. Safe clearance around heaters/heat source (nothing stored/obstructing

within a 3 ft. perimeter)

____

____

____

____

____________

____________

____________

____________

____ ____________

Electrical Hazards:

1. Machinery and equipment are grounded

2. Electrical panels clear for 36” access

3. Electrical panels clearly marked (nothing stored/obstructing

within 3 ft. perimeter)

4. Outlets, switches and boxes have covers

5. Permanent wiring in place-no extension cords

6. Exposure of overhead electrical lines controlled

7. Emergency stops and critical electrical controls are identified

____

____

____

____

____

____

____

8. Appropriate electrical systems designed for hazardous locations have been

Installed in spray booths and flammable liquid storage rooms ____

9. Three (3) pronged grounded extension cords used (ground prong in place) ____

Mechanical and Manual Material Handling and Storage:

1. Hoist chains, cables, and slings are inspected regularly and documented

2. Storage piles are stable and secured from falling or collapse

3. Load limits are displayed on all hoists

4. Manual handling aids available and used

5. Weight limits set for manual lifting, carrying, pushing, pulling

6. Student/staff trained in proper lifting techniques/ergonomics

____

____

____

____

____

____

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

____________

___________

____________

(09/2013)resources: selective.com; cdc.gov/niosh

P a g e | 3 of 4

NOT Corrective

Satisfactory Action/Date

Machinery:

1. Lockout/tagout program in place, locks available, students/staff trained

2. Hazardous areas painted bright colors

3. Guards are provided for “point of operation” of machinery

4. Clothing and hair restrictions in place to prevent entanglement in machinery ____

5. Power transmission guards are in place ____

6. Noise exposures adequately addressed

7. Warnings displayed in obvious locations

____

____

8. Compressed air systems are not used for cleaning clothing.

9. Welding equipment in good condition

10. Compressed gas cylinders are secured to prevent falling

____

____

____

____________

____________

____________

____________

____________

____________

____________

____ ____________

____ ____________

____ ____________

11. Overhead hazards from equipment, conveyors, and process pipes, are

guarded below 7 ft. from floor ____ ____________

Chemicals:

1. Hazardous materials containers labeled (incompatible chemicals must

be stored separately)

2. Materials Safety Data Sheet (MSDS)/(SDS) available

3. Hazard Communication Training program in place

4. Chemical absorption spill control kit available

5. Eyewash/emergency shower available and functional

6. Eyewash/emergency shower flushed weekly (chart available)

7. Proper ventilation available and operational

____ ____________

____

____

____

____

____________

____________

____________

____________

____ ____________

____ ____________

Personal Protective Equipment:

1. PPE assessment performed—PPE requirements in place

2. Students/staff trained in the use and maintenance of PPE—

training documented

3. Hard hat areas designated and enforced

4. Hearing protecting utilized in required areas

5. Face/eye protection in place where needed

6. Safety foot protection required where appropriate

7. Protective clothing, gloves, aprons, boots, face shields, and

goggles are used when handling hazardous materials

8. First aid kit available

____ ____________

____

____

____________

____________

____ ____________

____ ____________

____ ____________

____ ____________

____ ____________

Inspectors Comments:

Inspector Signature:_____________________________________________Date:___________________

Teacher Signature:______________________________________________Date:___________________

(09/2013)resources: selective.com; cdc.gov/niosh

P a g e | 4 of 4

(09/2013)resources: selective.com; cdc.gov/niosh