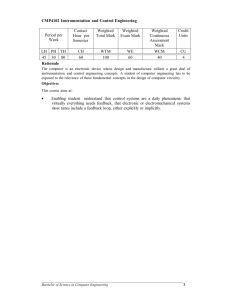

simmerdeep.k

advertisement

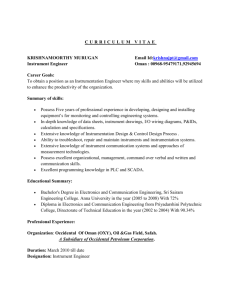

M MO OHHAAM MM MAADD BBAALLAALL Contact: +91 8002820613, +91 657-2363385 Email Id: mohd.balal@gmail.com Address: R.No. 02, H.No. 09, KGN Colony, Old Purulia Road, Zakirnager, Mango, Jamshedpur-832110, Jharkhand (India) JOB OBJECTIVE Seeking assignments in Instrumentation & Control / Maintenance / Services /Projects & Commissioning with an organization of repute in Manufacturing/Engineering industry. PROFILE SNAPSHOT B.Tech. (Instrumentation & Control) with over 5 years of experience in: Maintenance & Operations Troubleshooting Instrumentation and Automation Commissioning Documentation Currently associated with CMI Automation Industry Private Limited, Acid Regeneration Plant (Roaster Type), Jamshedpur as Assistant Manager-Services (Instrumentation) Proficient in handling site maintenance, operations and accountable for quality service & timely completion of projects Adept at carrying out various tests & inspection for various processes, checking the quality, proactively identifying & resolving problems and ramping up project activities on time Skilled in documenting the record of preventive and corrective maintenance including calibration of various pneumatic & electronic field and panel instruments namely, pressure, flow, level, temperature & process analyzer instruments Experienced in commissioning, operations, & maintenance of wide range of sophisticated instruments with proficiency in reducing downtime & enhancing operational effectiveness of equipment, ISO documentation, Why-2 analysis/root cause analysis, and MTTR & MTBF An effective communicator with creative, time management, convincing, learning, problem-solving, and interpersonal skills CORE COMPETENCIES Selecting control schemes, identifying appropriate control system, handling enquiry specification preparation and opting instruments based on type of application: developing logic flow charts/ interlock diagrams as per requirement of process operations Managing the process measurement, control instrumentation and services to monitor the operations Executing process measurement & control instrumentation & services to optimize manufacturing processes, configuring and programming of various plant equipment Implementing testing, calibration, maintenance & operations of all process control related instruments viz. Shut-Off Valves, Control Valves, Load Cells, Solenoid Valve, etc. Carrying out erection & commissioning; conducting tests & inspections to ensure operational effectiveness of plant & utilities Troubleshooting all the issues & problems in process control system, instruments, machines, drives & automation for delay time minimization for healthy production achievement Preparing various project reports for identifying areas of obstruction / defects and conducting troubleshooting, service and repair to rectify the equipment. EMPLOYMENT DETAILS Since Mar’12 CMI Industry Automation Private Limited (CMI Group), Jamshedpur (Jharkhand) As Assistant Manager-Services (Instrumentation) Key Result Areas Dealing with testing, troubleshooting, calibration & installation of gauges & transmitters (temperature, pressure, level), flow meters (electromagnetic), thermocouple and RTD Participating actively in Plant Start-up Activities Driving efforts for loop & logic checking of instruments & instrument protected systems during the commissioning of the plant Finding out areas of bottlenecks / breakdowns; taking steps to rectify through application of troubleshooting tools like root cause analysis Monitoring the Spare Parts, Indenting, Burner Systems (BCU 480/Krome Schroder) and Bag Filling Station Commencing the turnaround efforts for execution of Control & instrumentation including Installation and commissioning and maintenance activities Initiating well chalked out program of condition monitoring and rectifying the defects of critical machinery identified through it Accountable for plant operation covering entire engineering and management aspects to realize generation and efficiency objectives of the unit Carrying out systematic failure analysis and implemented patent resolution of the issue to prevent recurrence and ensured maximum equipment availability, meticulously reviewed the Process & Instrumentation Diagram and Cause / Effect Diagram Supporting in scheduling, planning & implementing preventive & defect maintenance to ensure smooth functioning of all equipment in power plant and reducing the consumable cost of maintenance by emphasis on preventive / predictive maintenance Drafting & developing cost & energy saving techniques / measures and modifications to achieve substantial reduction in O&M expenditures and work within the budget Highlights Guided the team to ensure compliance of all safety norms to minimize/achieve zero accidents through appropriate fire protection system & safety equipment Sept’08 to Mar’12 As Engineer - Maintenance (Instrumentation) Adhunik Alloys and Power Limited, Kandra, Jamshedpur, India Key Result Areas Managed the loop checking & functional checking of instrumentation as well as logic checking & troubleshooting of all instrument related process & instrumentation breakdowns Executed the test procedures for equipment and handled Condition Based Monitoring (CBM) Took care of spares management, indented & followed up with the Purchase Department to ensure availability of materials & contractors’ billing Précised the details of essentials for procurement of the instrument items for any project and maintained respective technical documentation Executing the maintenance, troubleshooting & calibration of; Weigh Feeder (Schenck Jenson & Nicholson), Belt Weigher (Schenck Process, Indus Automation), De-dusting Systems (Macawber Beekay) Worked on AC Drives along with Parameterization (Power Flex 700 (Rockwell),Siemens: MM 430 & MM 440), Gauges & Transmitters (Temperature, Pressure, Level), Thermocouple, RTD (testing and installation as well) Monitored and managed the Operations & Maintenance of all process control related Instruments, Nucleonic Density Gauge, Solenoid Valves, Opacity Monitor, ESP Electronic Control Panels and Rapper Panels TECHNICAL PURVIEW PLC Systems (Siemens S7/400,Rockwell) Field Instruments like Flow Meters, Level Transmitters, Temperature Sensors, Pressure Gauges, Transmitters, Pneumatic Control Valves, I/P Converters, Solenoid Valves, Switches, Air Regulators, Position Transmitters, etc. LT Motors, Weigh Bridge, etc. SAP for Departmental Applications Weigh Feeder, Belt Weigher & Weigh Bridge i.e. Weighing Automation Load Cell Testing & Checking , Opacity Monitor SAT/ FAT procedures for PLC, DCS MCC & PCC Panels & Feeders IT SKILLS Operating System: Software: Application: Windows 98/2000/XP SAP–MM MS Office & Internet Applications TRAININGS ATTENDED Completed 8 days training on TIA Basic with Simatic S7 300 & Step 7 from Siemens Authorized Training Centre, Kolkata, India Undergone 4 weeks training module on PLC Programming (Simatic S7/200) from Indo Danish Tool Room (IDTR), Jamshedpur, Jharkhand, India in the year 2007 ACADEMIC QUALIFICATIONS Bachelor of Technology (Instrumentation & Control) from Academy of Technology, Kolkata, West Bengal University of Technology in 2008 with 7.05 DGPA PERSONAL DETAILS Date of Birth: Sex : Passport No : 15th November, 1985 Male G9905253 Languages Known: English, Hindi, Urdu and Bengali