Supporting Information

advertisement

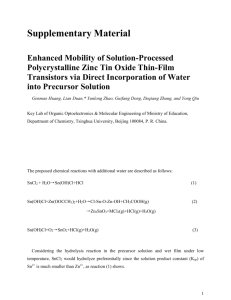

Supporting Information Hierarchically Structured Zn2SnO4 Nanobeads for High-Efficiency Dye-Sensitized Solar Cells Daesub Hwang, Jun-Su Jin, Horim Lee, Hae-Jin Kim, Heejae Chung, Dong Young Kim, Sung-Yeon Jang*, and Dongho Kim* Table of Contents Experimental Methods ............................................................................................................... 2 Fig. S1. Schematic illustration of the preparation process ......................................................... 5 Fig. S2. Schematic diagram of the process for preparing the colloidal dispersions .................. 6 Fig. S3. Schematic showing the electrospraying method .......................................................... 7 Fig. S4. Absorbance of (A) SJ-T1, (B) SJ-ET1, and (C) N719 as a function of the dye loading time. ............................................................................................................................................ 8 Fig. S5. Synthesis procedures and chemical structures ........................................................... 10 Fig. S6. Calculated oscillator strengths and major contributions of the transitions................. 16 Fig. S7. Cyclic voltammograms ............................................................................................... 17 Fig. S8. Dependence of performance on film thickness of the DSSC-ZTO-Bs ...................... 18 Fig. S9. Dependence of performance on film thickness of the DSSC-ZTO-NPs .................... 19 Fig. S10. J-V characteristics of a DSSC-ZTO-NP based on a photoelectrode prepared using the doctor blade method. .......................................................................................................... 22 Fig. S11. Electrochemical impedance spectroscopy results..................................................... 23 Fig. S12. Equivalent electrical circuit of the fabricated DSSCs. ............................................. 25 Fig. S13. Results of the intensity-modulated photoelectron analysis ...................................... 26 Table S1. Calculated transition energies and major contribution in SJ-T1 ............................ 14 Table S2. Calculated transition energies and major contributions in SJ-ET1 ........................ 15 Table S3. Photophysical and electrochemical characteristics of SJ-T1 and SJ-ET1. ............. 17 Table S4. Photovoltaic properties of the DSSC-ZTO-Bs ....................................................... 20 Table S5. Photovoltaic properties of the DSSC-ZTO-NPs ..................................................... 21 1 Table S6. EIS parameters of the DSSC-ZTOs ......................................................................... 23 Experimental Methods Preparation of ZTO films for photoelectrodes and their characterization: The dispersion containing 10 wt% ZTO was loaded into a plastic syringe, which was connected to a high voltage power supply (BERTAN SERIES 205B), and the dispersion was electrosprayed directly onto the conducting FTO substrates (10 cm 10 cm). The feed rate was controlled by a syringe pump to 20–30 µl min-1. In order to ensure that the thickness of the film was uniform over a large area, the nozzle and the substrate were placed on the motion control system using a microprocessor. The ZTO nanoparticles-based photoelectrodes (ZTO-Ps) were prepared using the doctor blade method. The porosity of the electrodes was controlled by adding 20 wt% poly(ethylene glycol) (Aldrich, average MW = 10,000 g mol-1) and 20 wt% poly(ethylene oxide) (Aldrich, average MW = 100,000 g mol-1) to the ZTO colloidal solution. The morphologies of the e-sprayed ZTO-B electrodes were investigated using fieldemission scanning electron microscopy (FESEM) (Hitachi S-4100), performed at an accelerating voltage of 15 kV, and high-resolution transmission electron microscopy (HRTEM) (FEI Tecnai G2), performed at an accelerating voltage of 200 keV. The surface areas and pore distributions of the photoelectrodes were measured using a Sorptomatic 1990 specific surface area analyzer and the Brunauer-Emmett-Teller (BET) method, while their pore volumes and size distributions were determined by the Barrett-Joyner-Halenda (BJH) method using the adsorption branches of the respective isotherms. In order to measure the surface concentration of the dye in the ZTO electrodes, the dye was desorbed into a 0.1 N solution of NaOH in distilled water, and the absorption spectrum of the desorbed-dye solution was measured using a UV-Vis spectrophotometer (Hewlett-Packard 8452A). Device fabrication: To fabricate the working electrodes, the ZTO films were rinsed with water and then sintered at 450°C for 30 min to remove any impurities present. After being 2 cooled to 80°C, the ZTO electrodes were immersed into SJ-T1, SJ-ET1, or a purified 3 × 10-4 M solution of cis-di (thiocyanato)-N,N′-bis (2,2′-bipyridyl-4-carboxylic acid-4′- tetrabutylammonium carboxylate) ruthenium(II) (N719, Solaronix) at room temperature. To fabricate the counter electrode, the FTO plates were drilled using a microdrill, washed with a 0.1 M solution of HCl in ethanol, and subsequently cleaned in an ultrasonic bath with water and ethanol for 15 min. The counter electrode, which was of Pt, was prepared by drop casting a 5 mM solution of H2PtCl6 in isopropyl alcohol onto the washed FTO plates and sintering them at 400°C for 20 min in air. The dye-adsorbed ZTO electrodes were rinsed with ethanol and dried in a flow of nitrogen. The dye-adsorbed ZTO electrodes were then assembled and sealed with the counter electrode; a thermal adhesive film (Surlyn, Dupont 1702, 25-µmthick) was used as the spacer to produce sandwich-type cells. The liquid electrolyte used consisted of 0.7 M 1-propyl-3-methylimmidazolium iodide (PMII), 0.03 M iodine (I2), 0.1 M guanidinium thiocyanate (GSCN), and 0.5 M 4-tert-butylpyridine (TBP) in a mixture of acetonitrile (ACN) and valeronitrile (VN) (85/15 v/v). The electrolyte was introduced through a hole drilled in the counter electrode. Finally, the holes were sealed with a hot-melt film and covered with glass. Photovoltaic and Photoelectrical measurements: The photovoltaic characteristics of the DSSCs were determined by applying an external potential bias to the cells and measuring the generated photocurrent using a Keithley Model 2400 source meter. An AM 1.5 solar simulator, which had a 450 W Xe lamp, was also used. The intensity of the simulated light was calibrated using a Si reference solar cell equipped with a BK7 filter for approximating the AM 1.5 global radiation. The photovoltaic performances were measured using pieces of black tape with an aperture area of 0.25 cm2. The IPCE values were measured as functions of wavelengths ranging from 400 nm to 800 nm using a specially designed IPCE system for dyesensitized solar cells (PV Measurement, Inc.). A 75 W Xe lamp was used as the light source 3 for generating a monochromatic beam. The system was calibrated using a National Institute of Standards and Technology (NIST)-calibrated silicon photodiode as the standard. The IPCE values were measured at a low chopping rate (5 Hz). The electrical impedance spectra were measured using an impedance analyzer (Solatron 1260) at an open-circuit potential under AM 1.5 full sun illumination (100 mW cm-2). The frequency range was 0.1–105 Hz, and the magnitude of the alternating signal was 10 mV. The impedance parameters were determined by fitting the impedance spectra using the software Z-plot. The electron-transport times and electron-recombination lifetimes were measured using intensity-modulated photocurrent spectroscopy (IMPS) and intensity-modulated photovoltage spectroscopy (IMVS). A diode laser with variable power and modulation control (Coherent CUBE diode laser, 40 mW, 445 nm) was used as the light source for these experiments. The illumination was always incident on the working-electrode side of the solar cells. The illumination intensity was measured using a calibrated Si photodiode. The output of the solar cells was connected directly to a lock-in amplifier (Solatron 1260 Impedance/Gain-Phase Analyzer). IMPS was performed by connecting the solar cell via a current amplifier (EG&G PAR 273) to the lock-in amplifier. During the IMVS and IMPS measurements, the cell was illuminated with sinusoidally modulated light having a small ac component (10% or less of the dc component). 4 Preparation of Zn2SnO4 nanoparticles Fig. S1. Schematic illustration of the process for synthesizing the ZTO nanoparticles (diameter of ~ 20 nm) and a TEM image of a primary ZTO nanoparticle. Zn(CH3COO)2∙2H2O (12.8 mmol, 50 mL) and SnCl4 (6.4 mmol, 50 mL) were added slowly (30 μL min-1, 15 μL min-1) to a solution of (CH3)4NOH (50 mmol, from a 25% aqueous solution) dissolved in 50–60 mL of MilliQ MilliPore water under vigorous stirring. The final mole ratio of Zn2+/Sn4+/(CH3)4NOH was 2:1:8. Upon the addition of (CH3)4NOH, the Zn2+ and Sn4+ ions reacted, leading to the formation of a white precipitate. After 30 min of stirring, the solution was transferred to an autoclave, heated at 220 °C for 30 h, and then allowed to cool naturally to room temperature. The precipitated product was centrifuged, rinsed several times with MilliQ water, and finally rinsed with ethanol. 5 Fig. S2. Schematic diagram of the process for preparing the colloidal dispersions of the amphiphilic ZTO nanoparticles by a sol–gel hydrothermal synthesis process. (A) Synthesis process and postulated mechanism of the growth of the ZTO nanoparticles, (B) photograph of a dispersion of conventional hydrophilic ZTO nanoparticles in ethanol, and (C) photograph of a dispersion of the fabricated amphiphilic ZTO nanoparticles in ethanol. 6 Electrospraying Methods & Hierarchically structured ZTO beads The electrostatic spraying (e-spraying) technique is now being used as a cheap and simple method of directly depositing thin films of materials from their colloidal solutions. During the e-spraying deposition process, the colloidal solution is mechanically atomized into droplets, and the surfaces of the droplets are charged because of the electric field. The electric field causes an electric charge to accumulate on the surfaces. This charge remains on the droplets even when they have been ejected from the jet. The magnitude of the charge on an individual droplet is given by following relation: QR = 2π(16σlε0r3)1/2, where σl is the tension of the liquid surface, ε0 is the dielectric permittivity of free space, and r is the radius of the droplet. The deposition efficiency of the charged droplets is usually much higher than that of the uncharged droplets. As a result, the adhesion between the deposited material and the substrates is better. The e-spraying process can be performed at room temperature under atmospheric pressure; this reduces equipment costs significantly. Fig. S3. Schematic showing the electrospraying method used to prepare the hierarchically structured ZTO-B photoelectrodes. 7 Dye Loading Time Fig. S4. Absorbance of (A) SJ-T1, (B) SJ-ET1, and (C) N719 as a function of the dye loading time. The corresponding amounts of the adsorbed dye molecules are also shown (see the yaxis on the right). The fitted adsorption rates (k) determined assuming a first-order reaction are shown in (A-1) to (C-1). The thickness of the Zn2SnO4 beads-based photoelectrodes was ~5 μm. 8 DSSCs based on the Zn2SnO4 beads were fabricated using the procedure discussed in the Experimental Section, and the effect of dye loading on cell performance was determined. To study the dye-loading process, the UV-vis absorption spectra of the organic dyes and N719 adsorbed onto the Zn2SnO4 beads were measured. The amounts of dye adsorbed could be calculated using the extinction coefficients of SJ-T1, SJ-ET1, and N719, which were 4.8 × 107, 4.2 × 107, and 1.4 × 107 mol−1 cm2 at wavelengths of 488, 495, and 535 nm, respectively. Fig. S4 shows the plot of the dye absorbance versus the dye loading time; the amounts of dye adsorbed are shown on the y-axis on the right in the same fig.. It can be seen clearly that the amount of dye adsorbed increased rapidly in the first few hours but then the adsorption rate decreased, increasing only slightly afterwards. The adsorption process can be described using the following equation (Ref. Lee, C.-R.; Kim, H.-S.; Jang, I.-H.; Im, J.-H.; Park, N.-G. ACS Appl. Mater. Interfaces 2011, 3, 1953−1957). (1) where θ is the extent of dye coverage, κ represents the reaction constant, and n is the reaction order. We fitted the adsorption data using Eq. (1) and different values of the reaction order, n (= 0, 1, and 2). We found that the reaction described by Eq. (1) could be best represented as a first-order reaction. Fig. S4 (A-1 to C-1) shows the fitting results for n = 1; ln(1- θ) exhibited a linear dependence on the dye-loading time, t. From this result, the reaction constant, κ, could be calculated, and was found to be 0.0156 min-1 for SJ-T1, 0.0192 min-1 for SJ-ET1, and 0.004 min-1 for N719, respectively. 9 Synthesis and characterization of organic dyes (SJ-T1 and SJ-ET1) The synthetic routes of SJ-T1 and SJ-ET1 are outlined in Scheme S1 and the details are described as follows. (2-1) (3-1) SJ-T1 (2-2) (3-2) SJ-ET1 (1) Fig. S5. Synthetic procedures and chemical structures of organic sensitizers of SJ-T1 and SJET1. (i) 2-ethylhexyl bromide, K2CO3, Acetonitile; (ii) 4-bromoaniline, CuCl, 1,10phenanthroline, KOH, toluene; (iii-a) 2-(tributylstannyl)thiophene, Pd(PPh3)4, anhydrous toluene; (iii-b) 2-(tributylstannyl)-3,4-ethylenedioxythiophene, Pd(PPh3)4, anhydrous toluene; (iv) POCl3, DMF; (v) cyanoacetic acid, piperidine, chloroform. Materials for the synthesis: All the chemicals were obtained from commercial sources and used without purification, unless noted otherwise. 4-bromo-N,N-bis(4-(2- ethylhexyloxy)phenyl) aniline (1) was synthesized by modifying the previously published procedures for similar molecules.[1] [1] Xu, M., R. Li, et al. "Energy-Level and Molecular Engineering of Organic D-π-A Sensitizers in Dye-Sensitized Solar Cells." J. Phys. Chem. C 2008, 112(49), 1977019776. 10 Synthesis of 4-(2-ethylhexyloxy)-N-(4-(2-ethylhexyloxy)phenyl)-N-(4-(thiophen-2-yl) phenyl)aniline (2-1). (1) (0.7 g, 1.24 mmol), 2-(tributyl-stannyl)thiophene (0.46 g, 1.24 mmol), Tetrakis(triphenylphosphine)-palladium (0.29 g, 0.25 mmol) and 5 ml of anhydrous THF were refluxed for 22 h under nitrogen atmosphere. The mixture was extracted with dichloromethane. The organic phase was washed with water and dried over anhydrous magnesium sulfate. After removal of the solvent under reduced pressure, the crude was purified on silica gel column (hexane/chloroform : 8/2) to yield a yellowish brown oil (0.42 g, 58 % yield). 1H NMR (500 MHz, CDCl3,) δ: 7.40 (d, 2H), 7.18 (m, 2H), 7.05 (m, 5H), 6.92 (d, 2H), 6.83 (d, 4H), 3.83 (d, 4H), 1.72 (m, 2H), 1.53 (m, 8H), 1.32 (m, 8H), 0.88 (m, 12H) Synthesis of 4-(2,3-dihydrothieno[3,4-b][1,4]dioxin-5-yl)-N,N-bis(4-(2-ethylhexyloxy) phenyl)aniline (2-2). n-BuLi (0.29 g, 3.87 mmol) was added to 3,4-(ethylenedioxy)thiophene (EDOT, 0.5 g, 3.52 mmol) in 5 ml of anhydrous THF at -78 °C and stirred for 1hr. And then tributyltin chloride (1.49 g, 4.57 mmol) was dropped into the solution under nitrogen atmosphere. The reaction solution was stirred for 4 h at room temperature. The mixture was extracted with diethyl ether and water and dried over anhydrous magnesium sulfate. After removal of the solvent, the product was identified by NMR spectroscopy. 2 (0.96 g, 1.66 mmol), 2-(tributylstannyl)-3,4-(ethylenedioxy)thiophene (1.53 g, 2.48 mmol), Tetrakis (triphenylphosphine)-palladium (0.19 g, 0.16 mmol) and 15 ml of anhydrous toluene were refluxed for 20 h under nitrogen atmosphere. The mixture was extracted with dichloromethane. The organic phase was washed with water and dried over anhydrous magnesium sulfate. After removal of the solvent under reduced pressure, the crude was purified on silica gel column (dichloromethane/petroleum ether: 1/1) to yield a brown oil (0.6 g, 57 % yield). 1H NMR (500 MHz, CDCl3,) δ: 7.55 (d, 2H), 7.09 (d, 4H), 6.97 (d, 2H), 6.86 (d, 4H), 6.24 (s, 1H), 4.25 (t, 4H), 3.86 (d, 4H), 1.77 (m, 2H), 1.53 (m, 8H), 1.45 (m, 8H), 0.99 (m, 12H). 11 Synthesis of 5-(4-(bis(4-(2-ethylhexyloxy)phenyl)amino)phenyl) thiophene-2-carbaldehyde (3-1). Phosphoryl chloride (0.15 g, 0.98mmol) was added to (2-1) (0.42 g, 0.72 mmol) dissolved in dimethylformamide (5 ml) at 0 °C. The reaction solution was heated to 90 °C and stirred overnight. The mixture was extracted with chloroform and washed with a saturated sodium acetate solution. The organic phase was dried over anhydrous magnesium sulfate. After removal of the solvent under reduced pressure, the crude was purified on silica gel column (toluene) to yield a yellow oil (0.39 g, 89 % yield). 1H NMR (500 MHz, CDCl3,) δ: 9.82 (s, 1H), 7.67 (d, 1H), 7.43 (d, 2H), 7.25 (d, 1H), 7.07 (d, 4H) 6.87 (m, 6H), 3.83 (d, 4H), 1.72 (m, 2H), 1.48 (m, 8H), 1.33 (m, 8H), 0.93 (m, 12H). Synthesis of 7-(4-(bis(4-(2-ethylhexyloxy)phenyl)amino)phenyl)-2,3-dihydrothieno[3,4-b] [1,4]dioxine-5-carbaldehyde (3-2). Phosphoryl chloride (0.11 g, 0.70 mmol) was added to (22) (0.3 g, 0.47 mmol) dissolved in dimethylformamide (4 ml) at 0 °C. The reaction solution was heated to 90 °C and stirred for 6 h. The mixture was dissolved in chloroform and washed with a saturated sodium acetate solution. The organic phase was dried over anhydrous magnesium sulfate. After removal of the solvent under reduced pressure, the crude was purified on silica gel column (n-hexane/ethyl acetate : 7/3) to yield a yellow oil (0.22 g, 71 % yield). 1H NMR (500 MHz, CDCl3,) δ: 9.89 (s, 1H), 7.58 (d, 2H), 7.07 (d, 4H), 6.86 (m, 6H), 4.37 (t, 4H), 3.82 (d, 4H), 1.71 (m, 2H), 1.54 - 1.31 (m, 16H), 0.93 (m, 12H). Synthesis of (E)-3-(5-(4-(bis(4-(2-ethylhexyloxy)phenyl)amino)phenyl)thio-phen-2-yl)-2cyanoacrylic acid (SJ-T1). Piperidine (0.25 g, 2.90 mmol) was added to a solution of (3-1) (0.25 g, 0.41 mmol) and cyanoacetic acid (0.07 g, 0.83 mmol) in chloroform (10 ml). The reaction solution was refluxed for 22 h under nitrogen atmosphere. After cooling to room temperature, the mixture was acidified with 2 M hydrochloric acid solution (10 ml) and extracted with chloroform. The organic phase was dried over anhydrous magnesium sulfate. 12 After removal of the solvent under reduced pressure, the crude was purified on silica gel column (chloroform/EtOH : 9/1) to yield a scarlet powder (0.18 g, 64 % yield). 1H NMR (500 MHz, DMSO) δ: 8.04 (s, 1H), 7.65 (d, 1H), 7.53 (d, 2H), 7.42 (d, 1H), 7.05 (d, 4H), 6.94 (d, 4H), 6.78 (d, 2H), 3.83 (d, 4H), 1.67 (m, 2H), 1.42 – 1.29 (m, 16H), 0.90 (q, 12H). Synthesis of (E)-3-(7-(4-(bis(4-(2-ethylhexyloxy)phenyl)amino)phenyl)-2,3-dihydrothieno [3,4-b][1,4]dioxin-5-yl)-2-cyanoacrylic acid (SJ-ET1). Piperidine (0.25 g, 2.9 mmol) was added to a solution of (3-2) (0.28 g, 0.42 mmol) and cyanoacetic acid (0.07 g, 0.84 mmol) in chloroform (10 ml). The reaction solution was refluxed for 22 h under nitrogen atmosphere. After cooling to room temperature, the mixture was acidified with 2 M hydrochloric acid solution (10 ml) and extracted with chloroform. The organic phase was dried over anhydrous magnesium sulfate. After removal of the solvent under reduced pressure, the crude was purified on silica gel column (methanol/chloroform : 1/9) to yield a dark red powder (0.21 g, 67 % yield). 1H NMR (500 MHz, DMSO) δ: 8.04 (s, 1H), 7.52 (d, 2H), 7.04 (d, 4H), 6.92 (d, 4H), 6.79 (d, 2H), 4.38 (d, 4H), 3.83 (d, 4H), 1.70 – 1.64 (t, 2H), 1.48 – 1.23 (m, 16H), 0.89 (q, 12H). 13 Table S1. Calculated Transition Energies, Oscillator Strength and Major Contribution of Transitions in SJ-T1. 14 Table S2. Calculated Transition Energies, Oscillator Strength and Major Contribution of Transitions in SJ-ET1. 15 Fig. S6. Calculated oscillator Strength and major contribution of transitions in SJ-T1 and SJET1. 16 Electrochemical properties & HOMO and LUMO 0.10 SJ-T1 SJ-ET1 0.05 -0.05 0.03 0.266 (SJ-T1, onset) Current / mA Current / mA 0.00 -0.10 0.00 -0.15 0.309 (SJ-ET1, onset) -0.03 -0.20 0.0 0.3 Potential / V (vs Ag/AgNO3) -1.0 -0.5 0.0 0.5 1.0 1.5 0.6 2.0 Potential / V (vs Ag/AgNO3) Fig. S7. Cyclic voltammograms of TiO2 films onto which SJ-T1 (blue dash line) and SJ-ET1 (red solid line) were loaded. Table S3. Photophysical and electrochemical data of SJ-T1 and SJ-ET1. Sensitizer λabsa [nm] (ε/M-1cm-1) 𝒐𝒏𝒔𝒆𝒕 b 𝒐𝒏𝒔𝒆𝒕 c 𝐄 𝒐𝒙 𝒐𝒏𝒔𝒆𝒕 d 𝐄 𝒐𝒙 + [V] vs. Ag/Ag [V] vs. Fc/Fc 𝐄 𝒐𝒙 + [eV] E0-0 e [eV] 𝒐𝒏𝒔𝒆𝒕 𝐄 𝒐𝒙 - E0-0 [eV] SJ-T1 480 (48000) 0.31 0.24 -5.04 1.93 -3.11 SJ-ET1 495 (42500) 0.27 0.19 -4.99 1.96 -3.03 a Absorption spectra and emission spectra were measured in DMF solution. b The oxidation potentials of dyes on TiO2 film were measured in acetonitrile with 0.1 M (n-C4H9)4NPF6 with a scan rate of 50 mV/s (vs. Ag/Ag+). c E1/2 of Fc/Fc+ is 0.068 V vs. Ag/Ag+ d The oxidation potentials are converted to Vacuum energy levels through previous papers e E0–0 was determined from the wavelength at 10 % maximum absorption intensity. 17 Thickness Effect Fig. S8. Dependence of DSSC-ZTO-B performance on film thickness with SJ-T1 (blue), SJET1 (red), and N719 (yellow), respectively: (A) open-circuit voltage; (B) short-circuit current density; (C) fill factor; and (D) overall light-to-electricity efficiency. All cells were under 1 sun AM 1.5 illumination. 18 Fig. S9. Dependence of DSSC-ZTO-NP performance on film thickness with SJ-T1 (blue), SJET1 (red), and N719 (yellow), respectively: (A) open-circuit voltage; (B) short-circuit curren ensity; (C) fill factor; and (D) overall light-to-electricity efficiency. All cells were under 1 sun AM 1.5 illumination. 19 Table S4. Photovoltaic properties of the DSSC-ZTO-Bs based on SJ-T1, SJ-ET1, and N719 Dye Thickness (μm) VOC (mV) JSC (mA/cm2) FF Eff. (%) 1.5 0.712 4.3 0.695 2.1 3 0.708 7.5 0.716 3.8 5 0.714 12.2 0.717 6.2 7 0.698 11.8 0.695 5.7 9 0.674 11.2 0.684 5.2 12 0.669 10.5 0.673 4.7 1.5 0.703 3.7 0.671 1.7 3 0.701 6.4 0.684 3.1 5 0.697 11.3 0.694 5.5 7 0.685 10.4 0.683 4.9 9 0.663 10.1 0.672 4.5 12 0.653 9.7 0.664 4.2 1.5 0.812 3.8 0.598 1.8 3 0.804 4.3 0.631 2.2 5 0.794 4.8 0.639 2.4 7 0.745 5.7 0.64 2.7 9 0.724 6.4 0.647 3.0 12 0.718 6.1 0.638 2.8 SJ-ET1 SJ-T1 N719 20 Table S5. Photovoltaic properties of the DSSC-ZTO-NPs based on SJ-T1, SJ-ET1, and N719 Dye Thickness (μm) VOC (mV) JSC (mA/cm2) FF Eff. (%) 1.5 0.685 3.4 0.623 1.5 3 0.674 6.5 0.634 2.8 5 0.642 8.6 0.637 3.5 7 0.645 7.4 0.635 3.0 9 0.632 6.5 0.615 2.5 12 0.629 6.1 0.609 2.3 1.5 0.665 3.3 0.616 1.3 3 0.643 4.9 0.623 1.9 5 0.645 7.5 0.624 3.0 7 0.636 6.8 0.621 2.7 9 0.625 5.9 0.624 2.3 12 0.621 5.7 0.602 2.1 1.5 0.783 2.7 0.596 1.3 3 0.776 3.6 0.587 1.6 5 0.764 3.7 0.573 1.6 7 0.724 4.5 0.591 1.9 9 0.717 5.1 0.602 2.2 12 0.715 5.3 0.608 2.3 SJ-ET1 SJ-T1 N719 21 IV curve Fig. S10. J-V characteristics of a DSSC-ZTO-NP based on a photoelectrode prepared using the doctor's blade method. The cell was tested under simulated AM 1.5G solar radiation at 100 mW cm-2 and used SJ-ET1 as the sensitizer (A) and normalized IPCE value (B). 22 Electrochemical impedance spectroscopy (EIS) analysis Fig. S11. Electrochemical impedance spectroscopy (EIS) results of the DSSCs in the opencircuit condition under simulated AM 1.5G illumination: (A) Nyquist plot for frequencies ranging from 1 Hz to approximately 1 105 Hz and (B) the corresponding Bode phase plots. Table S6. EIS parameters of the DSSC-ZTOs, as determined by fitting the experimental data to the equivalent circuit shown in Fig. S7. DSSC RS RPt 2 RCT 2 RD 2 Rtotal 2 2 (Ω∙cm ) (Ω∙cm ) (Ω∙cm ) (Ω∙cm ) (Ω∙cm ) DSSC-ZTO-B 3.8 7.4 13.6 0.2 25.0 DSSC-ZTO-NP 4.2 7.6 26.5 0.3 38.6 23 Electrochemical impedance spectroscopy (EIS) was performed following the models proposed by Adachi et al.,[1] who showed the equivalence of the models developed by Kern et al.[2] and Bisquert.[3] The AC impedance measurements yielded information on the fundamental properties of the cells, including on the material quality and the interfacial phenomena, and were used to determine the reason for the improvement in the FF and PCE of the fabricated DSSCs. The complex impedance of a typical DSSC is the sum of the components Z0, Z1, Z2, and Z3. These components are the contact impedance, Z0, which is usually equal to the real-phase component RS; the counter electrode impedance, Z1; the complex impedance, Z2, which represents the interface between the dye-attached semiconductors as well as that between the semiconductor and the electrolyte; the impedance owing to the diffusion of the triiodide ions (Warburg), Z3. Thus, the total Z (Z′+ iZ″) is equal to the sum Z0 + Z1+ Z2 + Z3, as shown in Fig. S2A. An idealized plot of the real part of Z, Z′(ω), versus the imaginary part of Z, Z″(ω), over a wide frequency range for a particular set of conditions is shown in Fig. S2B. In general, three semicircles are observed clearly over the measured frequency range of 0.1 to 100 kHz. The internal series resistance (RS) in the highfrequency region is the electrolyte/FTO glass interface resistance, whereas the resistances R Pt, RCT, and RD are related to the charge-transfer resistance of the electrolyte at the counter electrode surface in the higher-frequency region (RPt), the resistance reflecting the photoinjected electrons within the TiO2 in the intermediate-frequency region (RCT), and the resistance corresponding to Nernst diffusion within the electrolyte in the low-frequency region (RD). 24 Fig. S12. (A) Equivalent electrical circuit of the fabricated DSSCs. (B) Ideal impedance plane plot for a DSSC, showing the real parts of the impedances RS, RPt, RCT, and RD. [1] M. Adachi, M. Sakamoto, J. Jiu, Y. Ogata and S. Isoda, J. Phys. Chem. B, 2006, 110, 13872. [2] R. Kern, R. Sastrawan, J. Ferber, R. Stangl and J. Luther, Electrochim. Acta, 2002, 47, 4213. [3] J. Bisquert, J. Phys. Chem. B, 2001, 106, 325. 25 IMPS / IMVS Analysis Fig. S13. Results of the intensity-modulated photoelectron analysis of the DSSC-ZTOs: (A) Intensity-modulated photocurrent spectroscopy (IMPS) and (B) intensity-modulated photovoltage spectroscopy (IMVS). 26