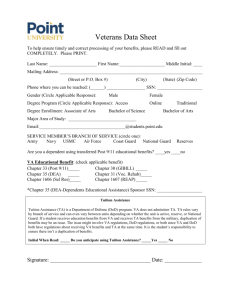

DoD ELAP Accreditation Checklist

advertisement