LordiPresentation

advertisement

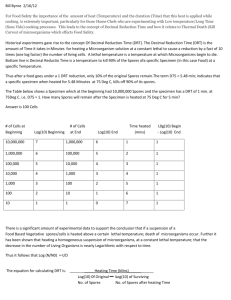

Research and Development Discussion What is it ? Who pays, who does it ? Why do it ? How to do it ? Case Topics Study Start up company based on university research ( Technology transfer) NASA Technology Readiness Levels Percentage of Budget by Agency Government Percent Agency DOD 55.5 HHS (NIH) 21.1 NASA 8.2 DOE 6.3 NSF 3.0 DHS 0.7 DOT 0.6 Source: AAAS Why Do It? Innovation drives new technologies /products Technology Push vs. Product Need Better mouse trap? Answer may depend on TRL Basic vs. applied research How To Do It ? Specific technical answer depends on field. Good reference for new methods and tools: R & D magazine (www.rdmag.com) IP/Patent Search as important as literature review See www.scientific.thomson.com for patent management Case Study: Startup Company from UB Research Buffalo BioBlower Technologies startup based on research project in MAE Dept. Research on compressive heating of gases led to Air Purification device. Application to destruction of airborne biological hazards demonstrated. Funding obtained from DOD for Collective Protection system development. NYSTAR funding obtain to study transition to healthcare Steps in Buffalo BioBlower (B3) Startup Seed money from UB for POC experiments Brief DOD and Congressional Staffers DOD COLPRO funds further experiments Receive WNY BDF investment funds Participate in COLPRO Technology Readiness Evaluation Congressional appropriation received in 2006 DOD budget for further development BioBlower concept -uniform, instantaneous volumetric heating (25oC 300oC) -one-step mechanism, same pump moves the airstream & kills the pathogens Compressive heating of an airstream with a rotary mechanical pump can be used to destroy ANY & ALL airborne biotoxins adapting conventional Roots Blower technology History of MultiRecompressive Heating MRH based on compressive heating of gases using Roots-type mechanism ’76-’81: LLNL Project ’94: Calspan IR&D on Applications ’96-’02: CUBRC funded studies Temperature ratio (abs) ’67-69: MRH concept developed for Calspan Hypersonic Test Facility Extended Operation of Roots Blower Pressure ratio ’02-present: BioBlower University Experimental Protocol 9 x 108 CFU/mL computer interface controls process parameters sampling of .35% of total air flow out of Bio-Blower injection of constant flow of test spores, Bacillus globigii, aerosol by nebulization into the Bio-Blower impinger traps spores in growth media for culture analysis Initial Proof of Concept Testing, ‘04 - experiments performed @ - biotesting supported by heat treated Bacillus globigii (Bg) spores are continuously injected upstream of blower, then sampled downstream SEM (Scanning Electron Microscopy) of biomaterial which passed through the BioBlower at room temperature, 20oC at >200oC temperature 3-4 orders log kill, 99.9% dead in a single pass through BioBlower How it works ! (we think…) 5 ms pressure oscillations + temperature kill pathogens -pathogens are in device on ms time scale -achieve kills at much lower temperatures -SEM’s show little or no debris, spores exploded DOD interest in BioBlower existing systems use passive filtration for biological agent protection, a logistic nightmare! Over 400 suppliers of HEPA filter systems to the military BioBlower offers improvements in effectiveness, logistics, operations and power consumption. Kill pathogens on site! No replaceables needed BioBlower does NOT use : filters/UV lights/toxic chemicals S&T Funded BioBlower Testing, ‘05 Objectives Develop Collection System to Obtain More Quantitative Measure of Kill Effectiveness Obtain data at 240o, 270o and 300oC Assess effects of organic bioload and dry spores Further objective Demonstrate blower operation at 300oC and 50 CFM Observe 6.5 log kill, in a single pass Filter Collection System Developed to Significantly Increase Spore Count Glass fiber filters difficult to use in flow environment Experiments run at 240o, 270o and 300o C Successful data collection at 240o C 99.9999% killed in single pass 25oC , 1,000,000 spores collected glass fiber 240oC , 1 spore collected Bst spores filter housing Current Status of Company University files patent application based on POC results B3 formed and obtained exclusive IP rights from university First generation prototype tested in TRE, device performed well DOD 2006 funding being used to build and test next generation prototype Advanced development/ technology demonstration funding being sought for 2008 Key Steps in Start-Up Process Proof of Concept IP Protection Patent application Licensing agreement Securing Investment BDF investment ($200K for 20% share) DOD S&T funding ($200K + $50K UB match) Congressional DOD appropriation ($1.5M)