jssc3909-sup-0001-SupMat

advertisement

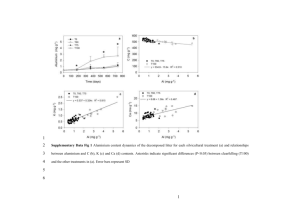

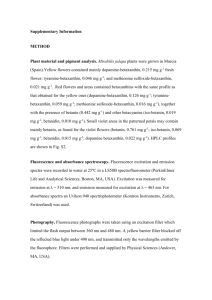

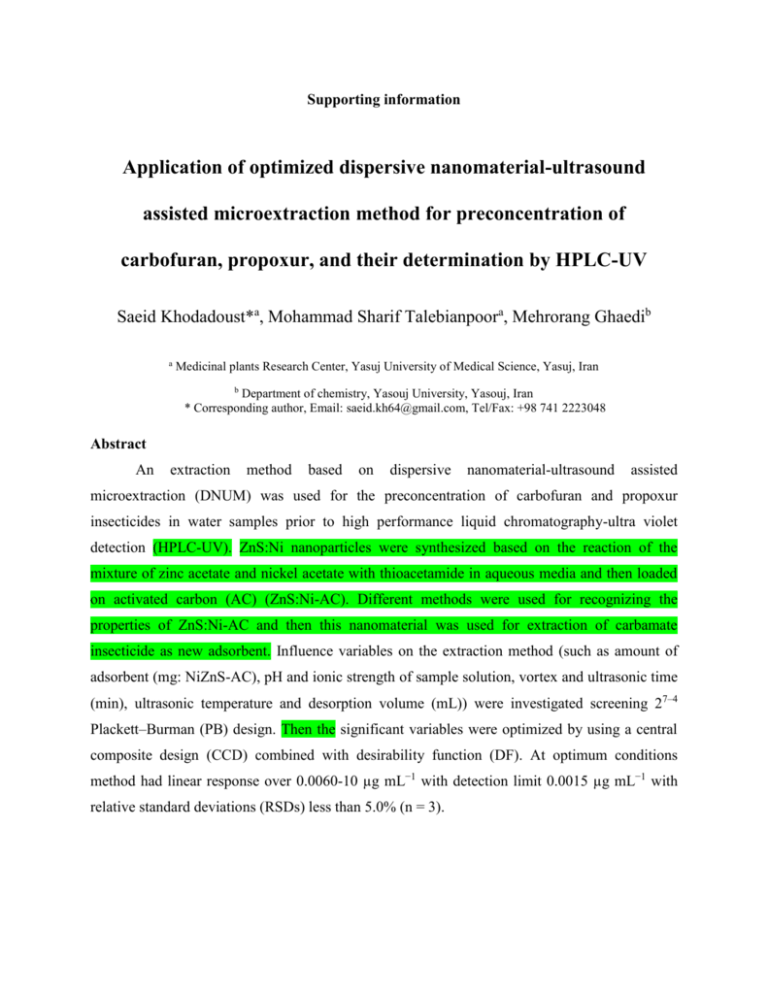

Supporting information Application of optimized dispersive nanomaterial-ultrasound assisted microextraction method for preconcentration of carbofuran, propoxur, and their determination by HPLC-UV Saeid Khodadoust*a, Mohammad Sharif Talebianpoora, Mehrorang Ghaedib a Medicinal plants Research Center, Yasuj University of Medical Science, Yasuj, Iran b Department of chemistry, Yasouj University, Yasouj, Iran * Corresponding author, Email: saeid.kh64@gmail.com, Tel/Fax: +98 741 2223048 Abstract An extraction method based on dispersive nanomaterial-ultrasound assisted microextraction (DNUM) was used for the preconcentration of carbofuran and propoxur insecticides in water samples prior to high performance liquid chromatography-ultra violet detection (HPLC-UV). ZnS:Ni nanoparticles were synthesized based on the reaction of the mixture of zinc acetate and nickel acetate with thioacetamide in aqueous media and then loaded on activated carbon (AC) (ZnS:Ni-AC). Different methods were used for recognizing the properties of ZnS:Ni-AC and then this nanomaterial was used for extraction of carbamate insecticide as new adsorbent. Influence variables on the extraction method (such as amount of adsorbent (mg: NiZnS-AC), pH and ionic strength of sample solution, vortex and ultrasonic time (min), ultrasonic temperature and desorption volume (mL)) were investigated screening 27–4 Plackett–Burman (PB) design. Then the significant variables were optimized by using a central composite design (CCD) combined with desirability function (DF). At optimum conditions method had linear response over 0.0060-10 µg mL−1 with detection limit 0.0015 µg mL−1 with relative standard deviations (RSDs) less than 5.0% (n = 3). Table S1. Properties of NiZnS-AC obtained from BET data. Single point surface area at p/p° 1009.485 m² g-1 BET Surface Area 1012.752 m² g-1 Langmuir Surface Area 1380.726 m² g-1 t-Plot Micropore Area 476.042 m² g-1 t-Plot External Surface Area 536.710 m² g-1 BJH Adsorption cumulative surface area of pores between 17.000 Å and 3000.000 Å width 133.041 m² g-1 BJH Desorption cumulative surface area of pores between 17.000 Å and 3000.000 Å width 157.046 m² g-1 Single point adsorption total pore volume of pores less than 1190.518 Å width at p/p° 0.552 cm³ g-1 t-Plot micropore volume 0.214 cm³ g-1 BJH Adsorption cumulative volume of pores between 17.000 Å and 3000.000 Å width 0.155 cm³ g-1 BJH Desorption cumulative volume of pores between 17.000 Å and 3000.000 Å width 0.162 cm³ g-1 Adsorption average pore width (4V/A by BET) 21.798 Å BJH Adsorption average pore width (4V/A) 46.510 Å BJH Desorption average pore width (4V/A) 41.292 Å Surface Area Properties of NiZnSAC Pore Volume Pore Size Table S2: Variables, codes, low and high levels in 27–4 Plackett–Burman design matrix. Factors Levels (X1) Adsorbent (mg: NiZnS-AC) (X2) pH of sample solution (X3) Ionic strength (NaCl % (w/v) (X4) Vortex time (min) (X5) Ultrasonic time (min) (X6) Ultrasonic temperature ( ˚C) (X7) Desorption volume (mL) Run 1 2 3 4 5 6 7 8 9 (C) 10 (C) X1 -1 +1 -1 +1 -1 +1 -1 +1 0 0 C: center point X2 -1 -1 +1 +1 -1 -1 +1 +1 0 0 X3 -1 -1 -1 -1 +1 +1 +1 +1 0 0 X4 +1 -1 -1 +1 +1 -1 -1 +1 0 0 Low (-1) Center point (0) High (+1) 5.0 3.0 2.0 2.0 1.5 20.0 0.5 10.0 7.0 5.0 4.0 3.0 30.0 1.0 15.0 11.0 8.0 6.0 4.5 40.0 1.5 X5 +1 -1 +1 -1 -1 +1 -1 +1 0 0 X6 +1 +1 -1 -1 -1 -1 +1 +1 0 0 X7 -1 +1 +1 -1 +1 -1 -1 +1 0 0 ER % 57.73 70.97 53.36 70.29 54.43 70.02 40.64 77.13 64.79 65.54 Table S3. Design matrix for the 23 central composite designs. Factors (X1) Adsorbent NiZnS-AC (mg) (X2) Vortex time (min) (X3) Ultrasonic time (min) Low (−1) Levels Central(0) High(+1) 7.0 3.0 3.0 12.0 5.0 5.0 17.0 7.0 7.0 Star point -α +α α=1.682 3.6 20.4 1.6 8.4 1.6 8.4 Runs X1 X2 X3 ER % 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15(c) 16(c) -1 -1 -1 -1 1 1 1 1 -1.682 1.682 0 0 0 0 0 0 -1 -1 1 1 -1 -1 1 1 0 0 -1682 1.682 0 0 0 0 -1 1 -1 1 -1 1 -1 1 0 0 0 0 -1.682 1.682 0 0 50.24 57.11 57.64 72.31 74.18 70.62 76.48 85.35 45.53 78.81 59.67 82.34 68.84 83.21 87.67 88.93 C: center point Table S4. Comparison of DNUM-HPLC-UV with other extraction methods for determination of carbofuran and propoxur. Method LOD (µg mL−1) SPME–HPLC– UV MSA-DLLME– HPLC–DAD G-Fe3O4-HPLCDAD DNUM-HPLCUV RSD (%) 0.001 Linear range (µg mL−1) 0.005–10 Reference 1.7–5.3 Extraction time (min) 25 0.0004 0.002–1.0 4.0-5.0 5 [47] 0.00002 0.0001–0.05 3.0-5.0 15 [48] 0.0015-0.0020 0.0060-10 0.0070-10 3.8-4.5 12 Present work [46] Figure S1. A schematic diagram of the extraction process. Figure S2. a) Plot of predicted value vs observed value for extraction recovery of carbofuran and propoxur. b) Plot of residuals versus predicted response for extraction recovery of carbofuran and propoxur.