AHA #11 FOR DRAINAGE IMPROVEMENT PROJECT

advertisement

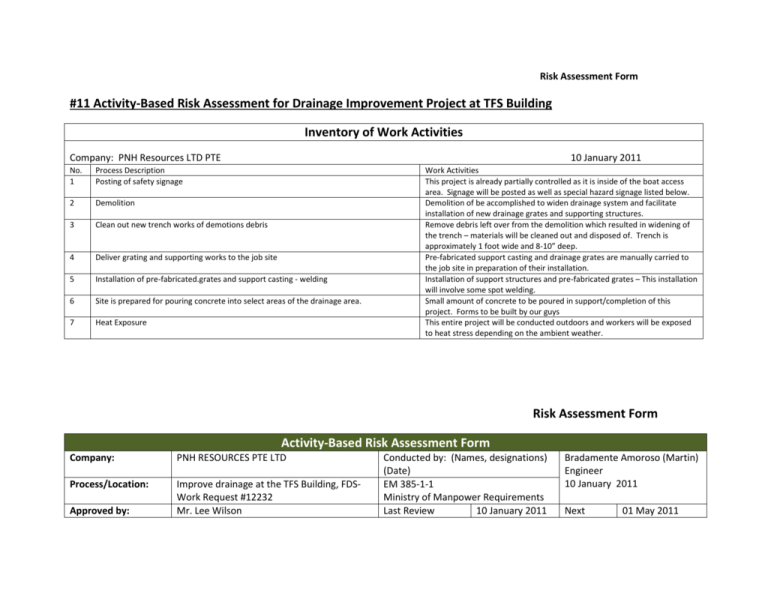

Risk Assessment Form #11 Activity-Based Risk Assessment for Drainage Improvement Project at TFS Building Inventory of Work Activities Company: PNH Resources LTD PTE 10 January 2011 No. 1 Process Description Posting of safety signage 2 Demolition 3 Clean out new trench works of demotions debris 4 Deliver grating and supporting works to the job site 5 Installation of pre-fabricated.grates and support casting - welding 6 Site is prepared for pouring concrete into select areas of the drainage area. 7 Heat Exposure Work Activities This project is already partially controlled as it is inside of the boat access area. Signage will be posted as well as special hazard signage listed below. Demolition of be accomplished to widen drainage system and facilitate installation of new drainage grates and supporting structures. Remove debris left over from the demolition which resulted in widening of the trench – materials will be cleaned out and disposed of. Trench is approximately 1 foot wide and 8-10” deep. Pre-fabricated support casting and drainage grates are manually carried to the job site in preparation of their installation. Installation of support structures and pre-fabricated grates – This installation will involve some spot welding. Small amount of concrete to be poured in support/completion of this project. Forms to be built by our guys This entire project will be conducted outdoors and workers will be exposed to heat stress depending on the ambient weather. Risk Assessment Form Activity-Based Risk Assessment Form Company: PNH RESOURCES PTE LTD Process/Location: Improve drainage at the TFS Building, FDSWork Request #12232 Mr. Lee Wilson Approved by: Conducted by: (Names, designations) (Date) EM 385-1-1 Ministry of Manpower Requirements Last Review 10 January 2011 Bradamente Amoroso (Martin) Engineer 10 January 2011 Next 01 May 2011 (Name, designation) Senior Safety Manager (Date) 10 January 2011 1. Hazard Identification Date: 2. Risk Evaluation 1a 1b 1c 1d 2a No Work Activity Hazard Existing Risk Control (if any) 1 Secure the safety aspects of the site. The site is already semi-controlled as it is inside of the TFS control area although access is not strictly controlled all of the time. 2 Demolition of existing floor in support of new installation of pre-fabricated drainage equipment and to facilitate better drainage Ensure that there is adequate signage to alert traffic through the area this is a construction area and trip hazards may exist, some sharp objects may be present at different stages and some welding will be done here. Musculoskeletal including strains, sprains and back injuries Possible Accident/ Ill Health & Persons at Risk Workers in the area (1 – 3) from PNH and ancillary foot traffic from people assigned to this unit. Sight Hazards from flying debris Personnel actually performing these functions Personnel involved in the demolition or Review Date: 3. Risk Control 2b 2c 2d 3a 3b Severity Liklihood Risk Level Additional Risk Control Action Officer Designation Control of the construction work zone and traffic areas. Minor Remote Low Pre-construction and routine safety briefs should alert workers of the hazards associated with this project and the need to protect personnel routinely transiting through this work zone. Senior Safety Manager Training regarding good lifting techniques and how to recognize your own limitations. Minor Remote Low Where possible utilize mechanical means to move large material Senior Safety Manager Team work if it looks like two or even three workers would do the job more effectively and safer than one, then that is probably true. All PNH workers have been provided with Studies have shown that the use of back belts have little to no effect and may even place workers at greater risk as it gives them a false sense of security. Minor Remote Low Stress good lifting techniques during pre-construction briefs and tool box talks prior to and during this project. This training should include lifting with the legs while keeping the back straight and keeping the load as close the body as possible. Ensure that a sight conservation brief is conducted for all workers involved in this phase of the project prior to Senior Safety Manager other ancillary personnel in the vicinity of this work. Personnel involved in the actual cleanup sight protection. All PNH workers have been provided with sight protection. Minor Remote Low Training regarding good lifting techniques and how to recognize your own limitations. Minor Remote Low 3 Clean/remove debris that resulted from the demolition works. Sight Hazards from flying debris 4 Deliver new fabricated grating and associated support works to the jobsite at the front of the TFS Building Two workers are involved in physically carrying individual pieces from the staging area at the muse facility (where the contractor delivered these pieces, the pieces were actually fabricated out in town. Two workers who are carrying these pieces from the muse to the front of the TSF Building a distance of approximately 150 meters. 5 Installation of the support casting and metal grates installation of the support casting will involve some spot welding Welding fumes Two workers in the vicinity of this phase of the project with one individual primarily assigned to do the welding and the other serves as an observer and fire watch 6 Concrete is to be poured to fill in the drainage Exposure to concrete - eye Workers in the vicinity of the pouring of the Team work if it looks like two or even three workers would do the job more effectively and safer than one, then that is probably true. Hot work chit is in force and is updated as required. Welding is a spot type of work and is conducted outdoors and is not expected to create any occupational hazards to workers. All PNH workers have been provided with beginning work. Training should include a review of the current condition of worker eye protection Ensure that a sight conservation brief is conducted for all workers involved in this phase of the project prior to beginning work. Training should include a review of the current condition of worker eye protection Where possible utilize mechanical means to move large material Senior Safety Manager Senior Safety Manager Studies have shown that the use of back belts have little to no effect and may even place workers at greater risk as it gives them a false sense of security. Minor Remote Low Minor Remote Low Stress good lifting techniques during pre-construction briefs and tool box talks prior to and during this project. This training should include lifting with the legs while keeping the back straight and keeping the load as close the body as possible. Ensure that welding equipment is inspected prior to each use. Report any material deficiencies to the Senior Safety Manager Mr. Lee Wilson or to Mr. Ghopal (acting Indian Safety Representative while Mr. Kumar is on leave). Ensure that a sight conservation brief is conducted for all workers involved in this phase of the project prior to Senior Safety Manager Senior Safety Manager system around metal support equipment and serve as a foundation for drains. 5 Working outdoors – Heat Stress – This entire project is slated to be performed where workers are exposed to the ambient work environment concrete Exposure to concrete - Skin hazard – burns from skin coming in contact with concrete Heat Cramps Heat Rash Heat Syncope Heat Exhaustion* Heat Stroke** Personnel involved in the receiving of the fresh concrete Personnel performing lawn care work *If not treated properly can progress to heat stroke. **Life Threatening and is a real medical emergency. Definitive medical assistance must be summoned. Heat Stress (Color) Green Yellow Red Black Condition I II III IV Heat Stress WBGT Temperature 82-84.9 85-87.9 88-89.9 Above 90 sight protection and this sight protection should be used during this phase of the project. All PNH concrete workers are provided with protective rubber boots, long sleeve shirts and gloves. Tool Box Talk Training concerning heat stress, clean drinking water at all job sites, sufficient rest periods for workers in accordance with NAVMED P-5010 and Ministry of Manpower Recommendations beginning work. Training should include a review of the current condition of worker eye protection Minor Remote Low Pre-construction training should include a reminder of the potential hazards associated with dermal exposure to concrete materials. Senior Safety Manager Moderate Remote Low Continue emphasis on heat injuries whenever safety stand downs, events, tool box talks etc.. are planned. Ensure that drinking water is always available for crews working in heat stress conditions. Ensure that workers have a good working knowledge of the Heat Stress Program employed at Sembawang and what the color system indicates as follows: Safety Manager Activity Level Discretion is required when planning heavy exercise for acclimatized personnel. Strenuous exercise and activity for new and un-acclimatized personnel during the first 30 days of heat exposure. Strenuous exercise should be curtailed for personnel with less than 12 weeks of training in hot weather. Physical training and exercise should be curtailed for all personnel (operational commitments excluded). Heat stroke likelihood is high under conditions of high exertion. Calculations: WBGT = WB X 0.7 + DB X 0.1 + GT X 0.2 Meter calibration should be manually verified every 3 months. Manual calculation must be 0.2 + the meter WBGT readout