Supplementary Information (20151004)

advertisement

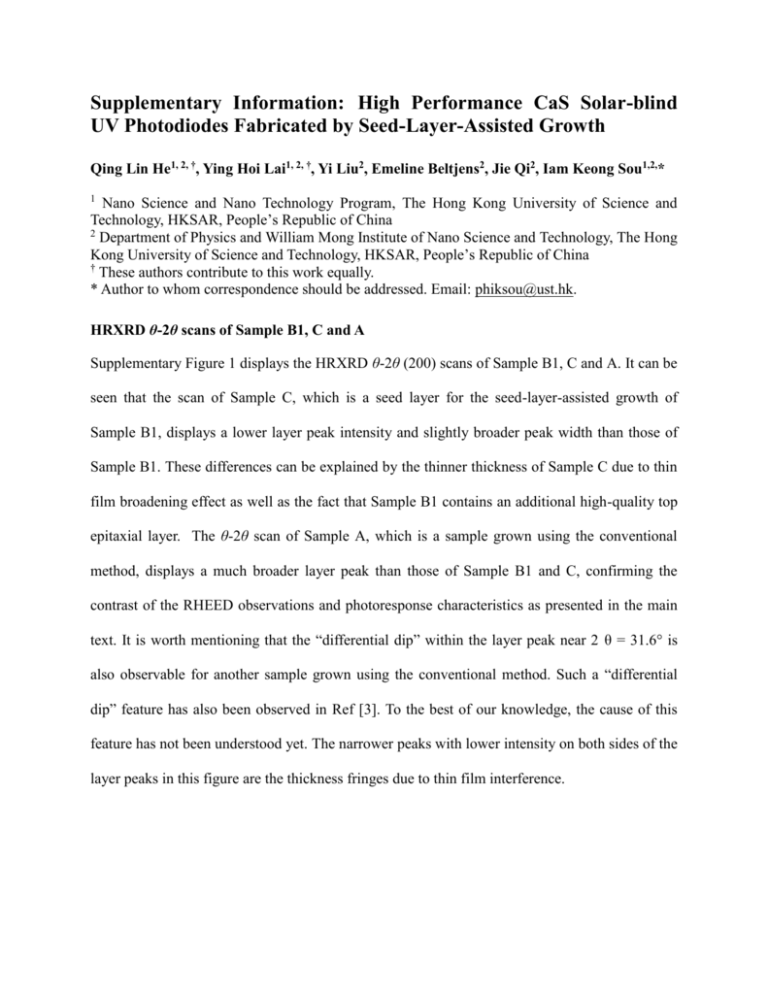

Supplementary Information: High Performance CaS Solar-blind UV Photodiodes Fabricated by Seed-Layer-Assisted Growth Qing Lin He1, 2, †, Ying Hoi Lai1, 2, †, Yi Liu2, Emeline Beltjens2, Jie Qi2, Iam Keong Sou1,2,* 1 Nano Science and Nano Technology Program, The Hong Kong University of Science and Technology, HKSAR, People’s Republic of China 2 Department of Physics and William Mong Institute of Nano Science and Technology, The Hong Kong University of Science and Technology, HKSAR, People’s Republic of China † These authors contribute to this work equally. * Author to whom correspondence should be addressed. Email: phiksou@ust.hk. HRXRD θ-2θ scans of Sample B1, C and A Supplementary Figure 1 displays the HRXRD θ-2θ (200) scans of Sample B1, C and A. It can be seen that the scan of Sample C, which is a seed layer for the seed-layer-assisted growth of Sample B1, displays a lower layer peak intensity and slightly broader peak width than those of Sample B1. These differences can be explained by the thinner thickness of Sample C due to thin film broadening effect as well as the fact that Sample B1 contains an additional high-quality top epitaxial layer. The θ-2θ scan of Sample A, which is a sample grown using the conventional method, displays a much broader layer peak than those of Sample B1 and C, confirming the contrast of the RHEED observations and photoresponse characteristics as presented in the main text. It is worth mentioning that the “differential dip” within the layer peak near 2 θ = 31.6° is also observable for another sample grown using the conventional method. Such a “differential dip” feature has also been observed in Ref [3]. To the best of our knowledge, the cause of this feature has not been understood yet. The narrower peaks with lower intensity on both sides of the layer peaks in this figure are the thickness fringes due to thin film interference. Sample B1 Sample C Sample A 11 10 9 Intensity (A.U.) 10 GaAs (200) CaS(200) 7 10 5 10 3 10 1 10 -1 10 30.0 30.5 31.0 31.5 32.0 32.5 2 (Degree) Supplementary Figure 1 θ-2θ scans of Sample B1, C and A Data fitting for saturation current I0 and ideality factor n For a Schottky barrier diode with assumption that the current is due to thermionic emission, the relation between the applied forward bias and current can be expressed as [1-2], 𝐼 = 𝐼0 exp ( 𝑞𝑉 −𝑞𝑉 ) [1 − 𝑒𝑥𝑝 ( )] 𝑛𝑘𝑇 𝑘𝑇 (S1) that (S1) for 𝑉 > 3𝑘𝑇/𝑞 can be written as 𝐼 = 𝐼0 exp ( 𝑞𝑉 ) 𝑛𝑘𝑇 (S2) where n is the ideality factor, T is the temperature in Kelvin, q the electronic charge, k is the Boltzmann constant and I0 the reverse saturation current which can be extracted by extrapolating the straight line of lnI to intercept the axis at zero voltage. Supplementary Figure 2 displays the I-V characteristics of Sample B1 and its data fitting result based on the above approach, yielding I0 =5.5nA and n =3.3. 2500 2000 I-V Data for Sample B1 Fitted Curve Current (nA) 1500 1000 500 0 0.0 0.1 0.2 0.3 0.4 0.5 0.6 Applied Voltage (V) Supplementary Figure 2 I-V characteristics of Sample B1 and its data fitting Results of response speed measurement Supplementary Figure 3 displays the results of the response speed measurements performed on Sample B1. Decay time: 31.9ms -100 Voltage (A.U.) Voltage (A.U.) Rise time: 30.4ms -50 0 Time (mSec) 50 100 -100 -50 0 Time (mSec) 50 100 Supplementary Figure 3 (Left) Rise-time for Sample B1. (Right) Decay time of Sample B1 Seed-layer-assisted growth of Rocksalt CaTe thin film and a CaTe/SnTe/CaTe quantum well structure The seed-layer-assisted growth approach developed in this work can be applicable to the growth of other materials in rocksalt phase with high crystalline quality. Rocksalt CaTe has a lattice constant of 6.36Å (PDF#39-1494), resulting an even larger lattice misfit of around 12.6% with zinc-blende GaAs, as compared with the CaS/GaAs system. The growth of a CaTe thin film on a GaAs (100) substrate was carried out with similar procedures as those used for Sample B1. Two effusion cells of elemental Ca and Te were used with optimized cell temperatures at 485℃and 290℃ respectively. The seed layer was firstly grown at substrate temperature of 200℃. The sample was then subjected to thermal annealing under the flux of both Ca and Te to the target temperature of 300℃. The growth of the CaTe thin film on the resulting seed layer was then proceeded by lowering down the substrate temperature to 230℃. RHEED patterns of the resulting CaTe thin film show bright and streaky lines, demonstrating that successful application of the seed-layer-assisted growth approach can be extended to other rocksalt/zincblende systems besides the CaS/GaAs system. A high crystalline quality CaTe thin film can find an important application as being the buffer layer for the growth of rocksalt SnTe and Pb1-xSnxTe thin films and related nano-structures, which have been recently demonstrated to be a class of exotic materials named topological crystalline insulator [4, 5]. In this study, the seed-layer-assisted growth approach was also successfully applied to fabricate a CaTe/SnTe/CaTe quantum well structure, which enjoys a small lattice mismatch of only 0.47% between CaTe and SnTe, the latter has a lattice constant of 6.33 Å (PDF#46-1210). The growth of this quantum well structure started with the growth of the bottom CaTe layer using the seed-layer-assisted growth approach followed by epitaxial growths of the SnTe quantum well and the CaTe cap layer. Figure 5 shows the RHEED patterns of the three layers of which display bright and streaky lines, indicating the quantum well indeed exhibits high crystalline perfection. Supplementary Figure 4 RHEED patterns of a CaTe/SnTe/CaTe quantum well structure recorded in [110] (upper) and [100] (lower) directions: (a) The bottom CaTe layer, (b) the middle SnTe layer, and (c) the top CaTe layer. References: [1] E.H. Rhoderick, Metal– Semiconductor Contacts, Clarendon, Oxford, 1988. [2] Somayeh Gholami and Meysam Khakbaz, International Scholarly and Scientific Research & Innovation, Vol: 5, No: 9, 1007-1010 (2011). [3] Jihwey Park, Yeong-Ah Soh, and G. Aeppli, S. R. Bland, Xie-Gang Zhu, Xi Chen, Qi-Kun Xue, and Francois Grey, Appl. Phys. Lett. 101, 221910 (2012). [4] Y. Tanaka, Z. Ren, T. Sato, K. Nakayama, S. Souma, T. Takahashi, K. Segawa, and Y. Ando, Nature Physics 8, 800 (2012). [5] Su-Yang Xu, Chang Liu, N. Alidoust, M. Neupane, D. Qian, I. Belopolski, J.D. Denlinger, Y.J. Wang, H. Lin, L.A. Wray, G. Landolt, B. Slomski, J.H. Dil, A. Marcinkova, E. Morosan, Q. Gibson, R. Sankar, F.C. Chou, R.J. Cava, A. Bansil, and M.Z. Hasan, Nature Communications 3, 1192 (2012)