Suppl.Mater.,Rev

advertisement

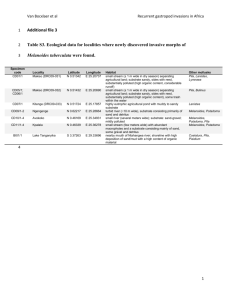

Supplemental Material Physically and Chemically Stable Ionic Liquid-Infused Textured Surfaces Showing Excellent Dynamic Omniphobicity Daniel F. Miranda,1 Chihiro Urata,1 Benjamin Masheder,1 Gary J. Dunderdale,1 Makoto Yagihashi2 and Atsushi Hozumi1* 1 National Institute of Advanced Industrial Science and Technology (AIST), 2266-98, Anagahora, Shimo-Shidami, Moriyama-ku, Nagoya, Aichi 463-8560, Japan 2 Nagoya Municipal Industrial Research Institute, Rokuban, Atsuta-ku, Nagoya 456-0058, Japan Corresponding Authors E-mail: a.hozumi@aist.go.jp 1. Materials. 1,3,5,7-tetramethylcyclotetrasiloxane (D4H) was obtained from Gelest. (3aminopropyl)triethoxysilane (APTES) was obtained from Tokyo Chemical Industries Co. A high boiling point polyphenyl ether synthetic oil, S3105, was obtained from Moresco Techno Co., LTD. Probe liquids (diiodomethane, iodobenzene, n-hexadecane, and n-decane) for contact angle (CA) measurements and common solvents were obtained from Wako Pure Chemicals. The ionic liquid (IL), 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide ([EMI][TFSI]) was obtained from Sigma-Aldrich and dried under vacuum at ~100 Pa overnight prior to use. All 1 other chemicals were used as received. Silicone (Si) substrates (15 x 30 x 0.5 mm3) were cut from n-type wafers, and cleaned by UV/ozone treatment. 2. Film Preparation. Microtextures were prepared on UV/ozone-cleaned Si substrates by a chemical vapor deposition method (CVD). The cleaned substrates were placed into 60 mL perfluoroalkoxy (PFA) containers, along with 3.5 mL glass vials containing ~400 L 4 H in air with ~30 % relative humidity. The container was sealed and then heated for 2~3 days in an oven maintained at 180~200 °C. Afterwards, the substrates were rinsed with acetone and isopropanol, then blown dry with N2 gas. Next, the samples were irradiated by 172 nm vacuum UV (VUV) light generated from an excimer lamp (Ushio Inc., UER20-172V; λ = 172 nm and 10 mW/cm2) at 103 Pa for 30 min. Lastly, the VUV-irradiated samples were modified by exposure to a vapor of APTES in the PFA containers under a dry N2 atmosphere (<5 % relative humidity) for 3 h at 100 °C. Finally, [EMI][TFSI] was spin-coated on the APTES-modified microstructured substrate at 1000 rpm for 10 sec and 2000 rpm for 20 sec at room temperature in ambient air. 3. Film Characterization. The surface morphology of the samples was observed by scanning electron microscopy (Hitachi, Model S-4300). To prevent charging, the un-infused surfaces were covered with a thin layer of gold. Micrographs of infused films were obtained via optical microscopy (Nikon, Model Eclipse ME600). Photographs of VUV-irradiated films were obtained by digital camera. Shown below is a typical cross-sectional SEM image of the dry particulate D4H film (Figure S1a), as well as a top-view SEM image (Figure S1b) and an optical micrograph (Figure S1c) of 2 an [EMI][TFSI]-infused film. The resulting surfaces appear smooth except for some occasional defects. Figure S1. Typical SEM images of (a) cross-sectional view of the dry particulate film and (b) top-view of the particulate film after infusion with [EMI][TFSI], and (c) optical micrograph of a top-view of the same sample as shown in (b). CA measurements were performed using a contact angle goniometer (Kyowa Interface Science Co., LTD, Model CA-V150). Static (S), advancing (A) and receding (R) CAs were collected using Milli-Q water (10-18 Ω/cm), diiodomethane, iodobenzene, n-hexadecane, and ndecane at room temperature (~25 °C). S was measured by placing a small probe liquid drop (2-3 L) onto a sample surface. A and R were determined by gently adding (A) and removing (R) probe liquid from the surface-bound drop. Minimum substrate tilt angles (TAs) required to set 5 3 L drops into continuous motion were measured using a TA goniometer (Kyowa Interface Science Co., LTD, Model DM-SA). Liquid drop motion down an inclined surface was recorded by video camera. A heating stage (Kyowa Interface Science Co., LTD, Model TC-401) was used to obtain substrate TA measurements at elevated temperatures. For measurements using the S3105 probe liquid, due to its high viscosity a small vial containing the oil was pre-heated in a 100 °C oven for ~5 min before being applied to the films. All reported CAs and substrate TAs are the average of at least four measurements over two to three films. In addition to the photographical evidence of n-decane facile dewetting in Figure 2, we have also provided photographs showing a very low CA hysteresis ( [EMI][TFSI]-infused textured films (Figure S2). As before, and substrate TA are very low for this probe liquid, despite the low overall CA magnitudes (A = 49.7°, R = 47.4°). (a) (b) Figure S2. Typical photographs of advancing (a) and receding (b) water probe liquid drop on the [EMI][TFSI]-infused textured films. For additional confirmation of the IL lubricant’s stability against the probe liquids, ten substrate TA measurements were carried out for water, n-hexadecane, diiodomethane, and iodobenze, each on a single film. For each probe liquid, the substrate TA changed very little over the course of the measurements: for water, the substrate TA was consistently between 5° and 7° (5.8° ± 0.8°), between 2° and 3° (2.2° ± 0.4°), and for iodobenzene and iodomethane the drop rolled immediately upon inclination (substrate TA = 1.0°) for all ten measurements. 4 4. Stability under high temperature conditions. Several of the [EMI][TFSI]-infused textured films were placed into an oven maintained at a temperature of 250 °C for approximately 12 h. Then, the samples were removed and allowed to cool to room temperature over 1-2 h. After this time, A/R, CA hysteresis, and substrate TAs for water, diiodomethane, iodobenzene, nhexadecane, and n-decane were measured using the previously described procedures. 5. Droplet velocity measurement. Using the previously described substrate TA measurement apparatus, the velocity of droplets in the process of dewetting was estimated as follows. A clear plastic ruler was superposed between the video camera and sample to establish a known scale. The stage was preset to a specified fixed inclination, and then a 10 L droplet of probe liquid was placed onto the film surface. Video of the droplet motion was obtained using the IC Capture software. Using still shots from the video at known times, along with the Quicktime and ImageJ software, the droplet velocity was estimated from measurements of droplet displacement between each still shot. The reported velocity is the averaged from measurements on each of three separate films, with 5-7 measurements per film. For velocity measurements at elevated temperatures, the same heating stage was used as for the TA measurements. Full video of the droplet motion at room temperature is provided as videos in figures S3-S6. (Multimedia view) 5 Figure S3. Motion of a 10 μL n-decane droplet on the [EMI][TFSI]-infused textured film surface, at a substrate inclination of 5°. (Multimedia view) Figure S4. Motion of a 10 μL H2O droplet on the [EMI][TFSI]-infused textured film surface, at a substrate inclination of 5°. (Multimedia view) Figure S5. Motion of a 10 μL H2O droplet on the [EMI][TFSI]-infused textured film surface, at a substrate inclination of 50°. (Multimedia view) Figure S6. Motion of a 10 μL S3105 droplet on the [EMI][TFSI]-infused textured film surface, at a substrate inclination of 5°, and heated to 250 °C. (Multimedia view) 6. Stability of the samples under high vacuum conditions and VUV irradiation. To test the stability of [EMI][TFSI]-infused textured films under high vacuum conditions, some of the 6 samples were placed in a vacuum chamber maintained at 0.7 Pa for 24 h. After this, A/R, CA hysteresis, and substrate TAs were measured using four probe liquids (water, diiodomethane, iodobenzene, n-hexadecane,). In addition, some of the samples placed in the same vacuum chamber were exposed to VUV light for 5~30 min at 103 Pa. Changes in A/R, CA hysteresis and substrate TAs of the samples before and after VUV irradiation were measured using the identical four probe liquids (Table S1). 7 Table S1. CA (s, A, R) values, CA hysteresis (), and minimum substrate TAs required for 5 L droplet motion on [EMI][TFSI]-infused textured films after exposure to VUV irradiation (for varying times at 103 Pa). R (°) (°) Substrate TA (°) VUV irradiation for 5 min Water 48.7 ± 0.7 Diiodomethane 51.2 ± 2.9 Iodobenzene 30.9 ± 2.1 n-Hexadecane 34.1 ± 5.6 45.0 ± 1.4 41.1 ± 0.7 27.6 ± 2.6 29.7 ± 7.8 3.7 ± 1.8 10.1 ± 3.4 3.3 ± 1.3 4.4 ± 3.2 2.2 ± 1.3 1.8 ± 1.0 1.8 ± 1.0 2.7 ± 0.6 VUV irradiation for 10 min Water 46.1 ± 1.7 Diiodomethane 54.7 ± 0.9 Iodobenzene 33.6 ± 1.1 n-Hexadecane 37.3 ± 4.6 41.7 ± 2.4 51.9 ± 1.6 29.6 ± 1.9 32.7 ± 3.8 4.4 ± 1.1 2.8 ± 1.1 4.0 ± 2.4 4.6 ± 4.6 4.2 ± 1.2 1.5 ± 0.6 1.5 ± 0.6 4.3 ± 1.2 VUV irradiation for 15 min Water 48.5 ± 1.8 Diiodomethane 58.7 ± 1.4 Iodobenzene 35.5 ± 3.7 n-Hexadecane 39.9 ± 1.7 43.2 ± 1.2 54.9 ± 2.1 32.0 ± 2.6 31.9 ± 2.6 5.3 ± 2.5 3.8 ± 2.3 3.5 ± 3.6 8.0 ± 3.2 5.3 ± 2.1 1.3 ± 1.0 2.0 ± 1.0 7.0 ± 2.0 VUV irradiation for 20 min Water 48.0 ± 1.6 Diiodomethane 62.6 ± 4.7 Iodobenzene 38.6 ± 3.8 n-Hexadecane 43.7 ± 3.2 42.7 ± 3.1 56.6 ± 2.1 34.5 ± 2.6 34.2 ± 2.6 5.3 ± 4.2 6.0 ± 4.2 4.1 ± 1.9 9.5 ± 3.5 3.7 ± 2.5 1.0 ± 0.0 1.0 ± 0.0 4.3 ± 1.2 VUV irradiation for 30 min Water 49.1 ± 2.3 Diiodomethane 68.4 ± 7.2 Iodobenzene 38.6 ± 6.6 n-Hexadecane 48.7 ± 3.2 38.9 ± 7.3 56.6 ± 2.4 34.5 ± 4.0 25.6 ± 6.5 10.2 ± 7.1 11.4 ± 6.0 4.1 ± 3.7 23.1 ± 9.4 5.6 ± 3.9 3.8 ± 1.7 1.0 ± 1.3 59.3 ± 5.9 Probe liquid A (°) Below are photographs of the VUV-irradiated films (Figure S7). Discoloration and dewetting of the IL is observed even for the shortest exposure time of 5 min, and becomes quite severe for 20 and 30 min. However, despite these effects, the lubricant films retain their dewetting 8 characteristics for all four probe liquids up through the 20 min exposure time, and for all probe liquids except n-hexadecane through 30 min of exposure, as seen in Table S1. Figure S7. Photographs of VUV-irradiated [EMI][TFSI]-infused films. The films are between 1.4 and 1.7 cm long on each side. 9