HYDRAULIC EVALUATION

OF LEVEE REPAIR TECHNIQUES

A Project

Presented to the faculty of the Department of Civil Engineering

California State University, Sacramento

Submitted in partial satisfaction of

the requirements for the degree of

MASTER OF SCIENCE

in

Civil Engineering

by

Syada Iffat Ara

SPRING

2012

© 2012

Syada Iffat Ara

ALL RIGHTS RESERVED

ii

HYDRAULIC EVALUATION

OF LEVEE REPAIR TECHNIQUES

A Project

by

Syada Iffat Ara

Approved by:

__________________________________, Committee Chair

Saad Merayyan, Ph.D.

____________________________

Date

_______________________________, Second Reader

Kevin Flora, P.E.

__________________________

Date

iii

Student: Syada Iffat Ara

I certify that this student has met the requirements for format contained in the University format

manual, and that this Project is suitable for shelving in the Library and credit is to be awarded for

the Project.

__________________________, Graduate Coordinator

Cyrus Aryani, Ph.D., P.E., G.E.

Department of Civil Engineering

iv

___________________

Date

Abstract

of

HYDRAULIC EVALUATION

OF LEVEE REPAIR TECHNIQUES

by

Syada Iffat Ara

This project presented the techniques of levee erosion repair and their hydraulic

evaluation. For the project purpose a site located at San Joaquin River at River Mile 71.5,

Right Bank (SJR RM 71.5R) has been selected. The site is located at as outside bend of a

tight meander and is subjected to severe erosion. In this study, a simulation model using

HEC-RAS hydraulic model has been performed to determine the existing hydraulic

characteristics for the project design flow and 100-year flow and another simulation

model has been performed to determine the impact of the repair to the existing system.

The design of the erosion site involved alternative analysis and selection of most

appropriate repair alternative, determining site existing hydraulic characteristics,

determining repair cross-section using hydraulic characteristics, and evaluating impact of

the repair on existing system. For alternative analysis, four alternatives have been

considered and analyzed, and most feasible alternative – waterside repair (rock slope

protection) has been selected as a repair option. Hydraulic characteristics of the River

have been determined by using HEC-RAS hydraulic model. Using hydraulic

characteristics and physical parameters of the site, the minimum required rock size for the

v

site has been determined by using CHNL PRO software. The repair section for the

erosion site has been determined by D50 rock size.

As the repair is a waterside repair and is going to encroach into the available

conveyance area, a hydraulic analysis is required to evaluate the impact of the repair to

the existing system. Once the repair section of the site has been finalized, the impact of

the repair to existing system has been analyzed by using HEC-RAS hydraulic model. The

results of the analysis show that the repair has very little or insignificant impact on the

existing system. If there were any adverse impact on the existing system due to the

waterside repair, another alternative other than waterside repair would be considered as a

remedy of the erosion problem.

_______________________, Committee Chair

Saad Merayyan, Ph.D.

_______________________

Date

vi

ACKNOWLEDGEMENTS

I am heartily thankful to my advisor, Professor Saad Merayyan for allowing me to

pursue this work and for his support and guidance throughout the completion of the

project.

I would also like to thank Department of Water Resources (DWR) for letting me

use the data for the project.

Lastly, I offer my gratitude to my husband, Muhammad Waliullah for his support

and encouragement during the completion of the project. Finally and above all, Rohaan

and Liyana (my two little kids), this is all for you.

vii

TABLE OF CONTENTS

Page

Acknowledgements ................................................................................................................ vii

List of Tables ............................................................................................................................ x

List of Figures .......................................................................................................................... xi

Chapter

1. INTRODUCTION ……………. ……………………………………………………….. 1

1.1 Background ............................................................................................................ 1

1.2 Purpose .................................................................................................................. 2

2. GENERAL DESCRIPTION OF THE STUDY AREA ...................................................... 3

2.1 Location ................................................................................................................. 3

2.2 Levee Geometry and Erosion Description ............................................................. 4

3. ALTERNATIVE ANALYSIS ............................................................................................ 7

3.1 Introduction............................................................................................................ 7

3.2 Alternatives ............................................................................................................ 7

3.2.1 Alternative 1 - No Action ...................................................................... 7

3.2.2 Alternative 2 – Waterside Repair........................................................... 8

3.2.3 Alternative 3 – Setback Levee ............................................................. 12

3.2.4 Alternative 4 – Relief Channel ............................................................ 15

3.3 Recommended Alternative................................................................................... 19

4. DESIGN PARAMETERS FOR FEASIBLE ALTERNATIVE ....................................... 20

4.1 Data Gathering and Processing ............................................................................ 20

4.2 Hydraulic Analysis .............................................................................................. 21

4.2.1 Calibration of the Model ...................................................................... 25

4.2.2 Simulation Run .................................................................................... 28

4.3 Riprap Design ...................................................................................................... 32

4.3.1 Stone Shape.......................................................................................... 33

4.3.2 Stone Size and Weight ......................................................................... 33

4.3.3 Layer Thickness ................................................................................... 33

4.3.4 Side Slope Inclination .......................................................................... 34

viii

4.3.5 Channel Roughness, Shape, Alignment and Gradient ......................... 34

4.3.6 Selection of Rock Size ......................................................................... 34

4.3.7 Gradation of Riprap ............................................................................. 37

4.4 Repair Section Design.......................................................................................... 38

4.4.1 Launch Rock ........................................................................................ 39

4.4.2 Riparian Bench .................................................................................... 39

4.4.3 Rock Slope Protection ......................................................................... 39

5. EVALUATION OF REPAIR IMPACT ON EXISTING RIVER

HYDRAULICS ................................................................................................................. 46

5.1 Introduction.......................................................................................................... 46

5.2 Hydraulic Analysis .............................................................................................. 46

6. CONCLUSIONS AND RECOMMENDATIONS ........................................................... 56

6.1 Conclusions.......................................................................................................... 56

6.2 Recommendations ................................................................................................ 57

Appendix A Site Photographs .............................................................................................. 58

Appendix B CHANLPRO Program – Input and Output....................................................... 62

Appendix C CDEC Data – Summer Water Surface Elevation Calculation .......................... 65

Appendix D HEC-RAS Output ............................................................................................. 70

Appendix E Compact Disk (CD) – HEC-RAS Model .......................................................... 73

References ............................................................................................................................... 74

ix

LIST OF TABLES

Tables

Page

1.

Table 2.2.1 – Standard Levee Prism Geometry ..................................................... 5

2.

Table 3.2.2.1 – Soft Costs ...................................................................................... 10

3.

Table 3.2.2.2 – Design Estimate Considerations for Alternative 2 ................... 11

4.

Table 3.2.2.3 – Cost Estimate for Alternative 2.......................................................... 11

5.

Table 3.2.3.1 – Design Estimate Considerations for Alternative 3............................. 14

6.

Table 3.2.3.2 – Cost Estimate for Alternative 3.......................................................... 15

7.

Table 3.2.4.1 – Design Estimate Considerations for Alternative 4............................. 18

8.

Table 3.2.4.2 – Cost Estimate for Alternative 4.......................................................... 18

9.

Table 4.2.1.1 – Manning’s n-Value ............................................................................ 27

10.

Table 4.2.2.1 – HEC-RAS Output .............................................................................. 29

11.

Table 4.3.7.1 – Gradation Table ................................................................................. 38

12.

Table 5.2.1 – Manning’s n-Value for Post Repair Condition ..................................... 47

13.

Table 5.2.2 – Comparison of WSE and V for Existing Condition and Post

Repair Condition ......................................................................................................... 52

x

LIST OF FIGURES

Figures

Page

1.

Figure 2.1 Location Map of SJR RM 71.5R........................................................... 3

2.

Figure 2.2 Vicinity Map of SJR RM 71.5R ............................................................ 4

3.

Figure 2.3 Erosion Progression at SJR RM 71.5R ................................................ 6

4.

Figure 3.2.2.1 Alternative 2 Repair Footprint ........................................................ 9

5.

Figure 3.2.2.2 Typical Repair Section ................................................................... 10

6.

Figure 3.2.3.1 Alternative 3 Repair Footprint ...................................................... 13

7.

Figure 3.2.3.2 Typical Repair Section ................................................................... 14

8.

Figure 3.2.4.1 Alternative 4 Repair Footprint ....................................................... 17

9.

Figure 3.2.4.2 Typical Cross-Section .................................................................... 18

10.

Figure 4.2.1 Presentation of Terms in the Energy Equation (Gary W.

Brunner, 2010) .......................................................................................................... 22

11.

Figure 4.2.2 HEC-RAS Conveyance Subdivision Method (Gary W.

Brunner, 2010) .......................................................................................................... 24

12.

Figure 4.2.1.1 HEC-RAS Channel Alignment ..................................................... 26

13.

Figure 4.2.1.2 Location of VNS Gauging Station ............................................... 27

14.

Figure 4.4.1 Typical Cross-Section ....................................................................... 41

15.

Figure 4.4.2 Repair Footprint – Plan 1 of 3 .......................................................... 42

16.

Figure 4.4.3 Repair Footprint – Plan 2 of 3 .......................................................... 43

17.

Figure 4.4.4 Repair Footprint – Plan 3 of 3 .......................................................... 44

xi

18.

Figure 4.4.5 Full Repair Footprint ......................................................................... 45

19.

Figure 5.2.1 – Cross-Section with Repair on Existing System with 100-Year

Water Surface Elevation (From River Station 71.59 to 71.486) ................................. 49

20.

Figure 5.2.2 – Water Surface Profile for 100-Year and Design Flow for Existing

and Post Project Condition.......................................................................................... 50

21.

Figure 5.2.3 – Velocity Profile for 100-Year and Design Flow for Existing and

Post Project Condition ................................................................................................ 51

22.

Figure D.1 – Cross-Section with Repair on Existing System with 100-Year

Water Surface Elevation (From River Station 71.66 to 71.625) ................................. 71

23.

Figure D.2 – Cross-Section with Repair on Existing System with 100-Year Water

Surface Elevation (From River Station 71.451 to 71.35) ........................................... 72

xii

1

Chapter 1

INTRODUCTION

1.1 Background

The purpose of this project is to repair erosion site at the right bank of the San

Joaquin River, River Mile 71.5R (SJR RM 71.5R). The SJR RM 71.5R is located in

Reclamation District 2064 (RD 2064). RD 2064 is located in San Joaquin County and

includes approximately 11.5 miles of levee along the right banks of San Joaquin and

Stanislaus Rivers. Levees along the San Joaquin and Stanislaus Rivers provide direct

protection to adjacent agricultural land within Reclamation District No. 2064.

A levee can be defined as an earthen embankment which protects a region of

floodplain from the floodwaters of a river. A levee offers complete protection until either

the embankment fails or is overtopped. Levees are the primary method of flood

protection along many rivers where floodplains are used primarily for agriculture or are

inhabited. An erosion site is defined as a site that is at risk of failure by erosive forces

during floods and/or normal flow condition. This study, involved analyzing alternatives

to determine the most feasible solution to address the problem, determining hydraulic

characteristics of the existing system, designing the most feasible alternative for the

erosion site using hydraulic parameters, and finally finding impact of the repair on water

surface elevation and velocity of the existing river system. In order to determine the most

suitable gradation of the rock material to be used in repair application software called

CHANLPRO has been used, and the HEC-RAS has been used to define the hydraulic

2

parameters of the river’s existing condition and to evaluate the impact of repair to the

system.

1.2 Purpose

The purpose of this study is to determine the most appropriate scour

countermeasure and its impact to existing river hydraulics. This study will provide the

procedures to be followed in erosion repair and will assess the impact of the erosion

repair on the hydraulic performance of the existing system. Based on the levee repair

technique, the objective of this study has been group into three different phases.

Phase 1:

Alternative analysis

Phase 2:

Design parameters for feasible alternative

Phase 3:

Evaluate hydraulic impact of the selected alternative to the existing system

Chapter 2

3

GENERAL DESCRIPTION OF STUDY AREA

2.1 Location

The project site is located along the right bank of the San Joaquin River; about 8

miles southwest of Ripon and 9 miles south of Lathrop, in San Joaquin County,

California. The site can be accessed via a County Road off of South Airport Way, 200

feet south of the intersection with Division Road. See Figure 2.1 – location map of the

SJR RM 71.5R.

Figure 2.1 - Location Map of SJR RM 71.5R

4

The Reclamation District 2064 levees provide flood protection to the Durham

Ferry Educational Facility as well as to agricultural and rural residential uses in the

vicinity. See Figure 2.2 – vicinity map of the SJR RM 71.5R.

Figure 2.2 – Vicinity Map of SJR RM 71.5R

2.2 Levee Geometry and Erosion Description

The levee in the project area is generally 10 to 14 feet in height, with a 14 to 15

feet wide crown. The waterside slope is approximately 3H: 1V (horizontal: vertical),

while the landside slope is generally 2H: 1V. Maintenance access ramps exist at the

north end, mid-section, and south end of the proposed repair, allowing for access to the

5

levee crown. According to United State Army Corps of Engineers (USACE), standard

levee prism geometry should follow Table 2.2.1 below.

Table 2.2.1 – Standard Levee Prism Geometry

Levee Location

Crown Width

(feet)

Riverside Slope

(feet/feet)

Landside Slope

(feet/feet)

Freeboard

(feet)

River and

Tributary Levees

20

3H:1V

2H:1V

3

Bypass Levees

20

4H:1V

3H:1V

6

The crown width of the levee in the project area does not match with USACE’s standard

levee prism geometry but for this project purpose only erosion problem will be addressed

and no work will be done on levee prism.

SJR RM 71.5R is located at an outside bend of a tight meander (Radius of

Curvature/Channel Width < 2). The direction of flow of the San Joaquin River changes

from northeasterly to due west through the course of this bend. Consequently, the right

bank of this river bend is subject to significant erosional forces as flows are redirected to

the west. During 2006 and 2011 flood seasons, the portion of this repair site was about to

fail and emergency placement of revetment were required to protect the levee.

The eroded bank is typically 8 to 12 feet in height with slope gradients ranging

from 0.5H:1V to vertical. Overhanging (undercut) zones are also locally present and

commonly lead to tension cracks and caving of tall, narrow wedges. The tall vertical

height and mode of failure are indicative of sandy soils, which are exposed in the bank.

Photographs of the eroded bank are in Appendix A.

6

Aerial photographs from November 23, 2004 and May 5, 2009 (five flood

seasons) show ongoing erosion throughout the majority of the proposed repair site (see

Figure 2.3). Based on these photographs, erosion rates vary along the proposed reach

from a minimum of about 2 feet per year to a maximum of about 10 feet per year. Along

the downstream reach the average erosion rate is about 8 feet per year.

Figure 2.3 – Erosion Progression at SJR RM 71.5R

7

Chapter 3

ALTERNATIVE ANALYSIS

3.1 Introduction

Analysis of Alternatives is the analytical comparison of multiple alternatives to be

completed before committing resources to one project. The practice of comparing

multiple alternative solutions has long been a part of engineering practice. It can be done

by proposing a single alternative and justify this option or proposing multiple options

with the goal of choosing the best one. For this project purpose four alternatives have

been evaluated and the best alternative has been selected as a repair for the erosion site.

The best alternative will be able to mitigate the on-going erosion, will have minimum

environmental impact, will require minimum maintenance and minimum real estate land

acquisition, will have minimum impact on existing infrastructure and will comparative

cheaper than other alternatives.

3.2 Alternatives

3.2.1 Alternative 1 - No Action

Alternative 1 consists of no present action. Under this alternative, erosion will

continue along the exposed bank and into the already compromised levee prism.

Catastrophic failure is possible during a single storm or flood water event. Emergency

flood fighting efforts and repairs would be anticipated, as required during the 2006 flood

event and the 2010-2011 high water event. In addition, further erosion will remove the

existing vegetation as the bank migrates landward.

8

Alternative 1 requires no present expenditure. Future costs to implement

Alternatives 2 or 3 will likely escalate relative to their present costs due to on-going

erosion and the inflation of construction costs.

3.2.2 Alternative 2 – Waterside Repair

Alternative 2 consists of armoring the eroding bank of approximately 2,000 lineal

feet (including transitions) with rock slope protection (RSP). Specifications for the rock

have been presented later in this report based on site’s hydraulic and physical

characteristics. Figure 3.2.2.1 illustrates the extend and location of repair of Alternative

2. For this analysis, it has been considered that a minimum 2 feet thick rock slope

protection will be provided above summer mean water surface elevation at 2H: 1V slope,

10 feet wide riparian bench will be provided on 2 feet above summer mean water surface

elevation and launch rock (discussed later in this report) will be provided below summer

mean water surface elevation at 1.5H: 1V slope. 0.75 foot thick agricultural soil will be

provided on top of upper rock slope protection to help growth of vegetation. Typical

repair section for this alternative has been presented in Figure 3.2.2.1, and soft costs,

design estimate considerations and cost estimate for alternative 2 have been presented in

Table 3.2.2.1, Table 3.2.2.2 and Table 3.2.2.3 respectively. Alternative 2 mitigates ongoing erosion and enhances the stability of the existing stream bank. Real estate costs and

impacts on existing infrastructures and improvements are anticipated to be minimal under

this alternative. Maintenance cost associated with this Alternative is expected to be

minimal. Under this Alternative the levee height remains as originally constructed and no

additional protection is provided for flood/storm events greater than design flow.

9

Figure 3.2.2.1 - Alternative 2 Repair Footprint

The estimated cost for Alternative 2 is about $4.2 million a total and about $2,000.00 per

linear feet.

10

[Type aFigure

quote 3.2.2.2

from the

document

or theSection

summary of an interesting point. You can

– Typical

Repair

position the text box anywhere in the document. Use the Text Box Tools tab to change

the formatting

of theCosts

pull quote text box.]

Table

3.2.2.1 - Soft

Escalation to bid-point of construction

5%

Change order reserve

5%

Design and Engineering (Pre-Bid)1

10%

Design Contingency (Post-Bid)

3%

Engineering Support During Construction

2%

Permitting and Legal2

5%

Construction Management and Site

Inspection

5%

Estimated Soft Costs (total)

35%

11

Table 3.2.2.2 - Design Estimate Considerations for Alternative 2

Length of Repair (ft)

2000

Average waterside slope

2:1

Agricultural Soil Thickness (ft)

0.75

Average Riparian Bench Width(ft)

10

Bedding layer thickness (ft)

1 to 2

Table 3.2.2.3 - Cost Estimate for Alternative 2

Item

No.

Description

Unit

Quantity

Unit Price

Total Cost

1

Mobilization and

Demobilization

Lump

Sum

1

$225,000.00

$225,000.00

2

Clearing and Grubbing

Acre

3.00

$25,000.00

$75,000.00

3

Earthfill

Ton

9,987

$30.00

$299,610.00

4

Agricultural Soil

Ton

3,677

$35.00

$128,695.00

5

Bedding Layer

Ton

1,390

$51.00

$70,890.00

6

Rock Slope Protection

Ton

5,788

$55.00

$318,340.00

7

Launch Rock (Rockfill)

Ton

27,384

$50.00

1,369,200.00

8

Beaver Fence

9

Erosion Control Fabric

LF

3,909

$8.00

Sq

11,584

$9.00

Yd

Subtotal Construction Costs:

$31,272.00

$104,256.00

Environmental Mitigation Costs:

$2,622,263.00

$655,565.00

(25% of Subtotal Construction Cost)

Estimated Soft Costs:

$1,147,017.00

Estimated Total Costs:

$4.195,620.00

Total Estimated Repair Cost Per L.F.: 2,097.81

12

Notes:

1. Includes geotechnical exploration and topographic/bathymetric surveys.

2. Includes land and right-of-way and environmental permitting activities.

3.2.3 Alternative 3 – Setback Levee

Alternative 3 consists of the construction of a setback levee that parallels the

existing levee for approximately 3,000 feet including tie-ins. The levee would be

constructed approximately 25 feet from the landside toe of the existing levee providing

approximately 100 feet of additional erosion protection (See Figure 3.2.3.1 – Alternative

3 Repair Footprint). The setback levee will be constructed with a 3 Horizontal to 1

Vertical (H: V) waterside slope, 20-foot wide crown, and 2H: 1V or 3H: 1V landside

slope which is consistent with USACE’ standard levee prism geometry criteria. The crest

elevation will be designed to match the existing levee crown elevation and will tie-in

upstream and downstream of the erosion site.

This alternative will not directly mitigate on-going erosion and bank migration.

Ultimately, the setback levee could be subject to the same erosional processes if not

provided with some form of protection (i.e. rock slope protection). This alternative

would increase the duration of flood protection but will not provide protection against

erosion. Alternative 3 has a larger construction footprint relative to Alternative 2 but may

result in less environmental impacts by avoiding in-stream construction activities.

Maintenance associated with Alternative 3 is anticipated to be low until the river reaches

the setback levee.

13

Figure 3.2.3.1 - Alternative 3 Repair Footprint

The estimated cost for Alternative 3 is about $7.6 million a total and $2,500.00

per linear foot. The higher cost is attributed mostly to land acquisition, utility and

roadway relocation, and import material costs. Typical cross-section for this alternative

has been presented in Figure 3.2.3.2, and design estimate considerations and cost estimate

have been presented in Table 3.2.3.1 and Table 3.2.3.2 respectively. Soft cost will be

same as it is used for Alternative 2.

14

[Type a quote from the document or the summary of an interesting point. You can

Figure

3.2.3.2

Typical Repair

Section Use the Text Box Tools tab to change

position

the text

box –anywhere

in the document.

the formatting of the pull quote text box.]

Table 3.2.3.1 - Design Estimate Considerations for Alternative 3

Length of Setback Levee (ft)

Approx. Height of Setback Levee (ft)

Approx. Length of Relocated Access Rd (ft)

3000

13

2000

Average Waterside Slope (H:V)

3:1

Average Landside Slope (H:V)

2:1

Crown Width (ft)

16

15

Table 3.2.3.2 - Cost Estimate for Alternative 3

Item

No.

1

2

4

5

6

Description

Mobilization and

Demobilization

Land Acquisition and

Temporary Easement

Clearing and Grubbing

Imported Embankment

Fill and Placement

Seeding and Erosion

Control

Unit

Quantity

Unit Price

Total $

Lump

Sum

1

$225,000.00

$225,000.00

Acre

20.0

$5000.00

$100,000.00

Acre

9.50

$25,000.00

$237,500.00

Ton

108,761

$35.00

$3,806,635.00

Acre

9.50

$18,000.00

$171,000.00

7

Levee Access Road

Sqft

42,000

$2.50

$105,000.00

8

SJC Board of Education

Access Road Relocation

Sqft

59,800

$7.50

$448,500.00

9

Power Line Relocation

LF

3,000

$50.00

$150,000.00

Each

1

$180,000.00

$180,000.00

Each

1

$80,000.00

$80,000.00

LT

3,000

$50.00

$150,000.00

10

11

12

18” Pump Intake

Relocation

Relocation of Gate and

Kiosk at School Entrance

GTE Telecommunication

Line Relocation

Subtotal Construction Costs:

$5,653,635.00

Estimated Soft Costs:

$1,978,772.00

Estimated Total Costs:

$7,632,407.00

Total Estimated Repair Cost Per L.F.: 2,544.00

3.2.4 Alternative 4 – Relief Channel

Alternative 4 consists of constructing a relief channel through the point bar

upstream of the proposed erosion repair site. The proposed design relief channel is

16

approximately 300 feet in width and 2000 feet in length (see Figure 3.2.4.1 – Alternative

4 Repair Footprint).

This alternative may reduce flow in the existing channel during moderate and

high water events. However, erosion is still anticipated during high flow conditions with

an unprotected bank. Additionally, this alternative may require permanent realignment of

the river channel and additional rock slope protection to other areas impacted by the new

channel alignment and hydraulics. Maintenance cost associated with this alternative will

be higher than other two alternatives as this alternative will have two channels to

maintain.

Alternative 4 includes the excavating of about 450,000 cubic yards of

unconsolidated soil with an impacted area of about 16 acres. Disposal will be off-site and

will require additional land acquisition.

17

Figure 3.2.4.1- Alternative 4 Repair Footprint

Alternative 4 will cost about $12 million to implement. Future costs may escalate due to

unknowns associated with future hydraulics and the need for additional rock slope

protection. Typical cross-section of this alternative has been presented in Figure 3.2.4.2,

and design estimate considerations and cost estimate have been presented in Table 3.2.4.1

and 3.2.4.2 respectively. Soft cost will be same as it is used for Alternative 2.

18

[Type a quote from the document or the summary of an interesting point. You can

Figure

3.2.4.2Typical Cross-Section

position

the text

box anywhere

in the document. Use the Text Box Tools tab to change

the formatting of the pull quote text box.]

Table 3.2.4.1 - Design Estimate Considerations for Alternative 4

Approx. Length of Channel (ft)

2000

Approx. Depth of Channel (ft)

24

Channel Bottom width (ft)

200

Channel Side Slope (H:V)

2:1

Approx. Cross-sectional Area (sqft)

6000

Approx. Excavated Material (cy)

450,000

Table 3.2.4.2 - Cost Estimate for Alternative 4

Item

No.

1

2

3

Description

Mobilization and

Demobilization

Vegetation Clearing

Channel Excavation and

Hauled off Excavated

Material

Unit

Quantity

Unit Price

Lump

Sum

1

$225,000.00

$225,000.00

Acre

26.0

$25,000.00

$650,000.00

CY

450,000

$16.00

$7,200,000.00

Subtotal Construction Costs:

Total $

$8,075,000.00

19

Estimated Environmental Mitigation

Cost (10% of Construction Cost):

$807,500.00

Estimated Soft Costs:

$2,826,250.00

Estimated Total Costs:

$11,708,750.00

Total Estimated Repair Cost Per L.F.: $4,037.50

Note: Channel cross-sectional area was assumed to be same as the existing main channel

and depth is also considered to be same as main channel.

3.3 Recommended Alternative

Based on the analysis above, Alternative 2 – Waterside Repair has been selected

for remedy of erosion problem for the following reasons:

Alternative 2 provides direct mitigation to on-going erosion.

This Alternative requires minimal easement and land acquisition.

Implementation of Alternative 2 has minimal conflict with existing

infrastructure.

This has minimum environmental impact and has the ability to mitigate onsite.

This Alternative is the cheapest alternative among three possible alternatives

discussed in this report.

20

Chapter 4

DESIGN PARAMETERS FOR FEASIBLE ALTERNATIVE

4.1 Data Gathering and Processing

Detailed topographic and bathymetric surveys of the erosion site were conducted

by the California Department of Water Resources (DWR) and were used for design

purpose (Figure 4.4.1 to Figure 4.4.5). The survey used the North American Datum

(NAD83) and North American Vertical Datum 88 (NAVD88). The UNET model

developed by USACE was converted to HEC-RAS one dimensional steady state model

by PBS&J, was used as a base model to determine the hydraulic characteristics (i.e.

velocity, stage etc) of the channel.

The UNET is a one-dimensional unsteady open-channel flow model that can simulate

flow in a single reach on complex networks of interconnected channels. The UNET

model for the San Joaquin River Basin was developed by the US Army Corps of

Engineers Sacramento District. Unsteady flow UNET model for San Joaquin River Basin

was obtained and converted to steady-flow HEC-RAS models by PBS&J, a private

consultant for Department of Water Resources to evaluate and analyzed the hydraulic

characteristics of the San Joaquin River System. For this project purpose the steady state

Hydrological Engineering Center- River Analysis System (HEC-RAS) UNET model

converted by PB&J was used as a base model as sufficient geometry data was not

available to create a base model for this project purpose.

21

4.2 Hydraulic Analysis

The HEC-RAS 4.1.0 model developed by USACE will be used for this study. The

HEC-RAS is capable performing one-dimensional water surface profile calculation.

Water surface profiles are computed from one cross section to the next by solving the

energy equation with an iterative procedure called the standard step method. The energy

equation is written as follows:

Z2 + Y2 +

α2 V2

2g

2

= Z1 + Y1 +

α1 V1

2g

2

+ he

Where: Z1, Z2 = elevation of the main channel inverts in ft

Y1, Y2 = depth of water at cross sections in ft

V1, V2 = average velocities (total discharge/ total flow area) in ft/sec

α1, α2 = velocity weighting coefficients

g = gravitational acceleration in ft/sec2

he = energy head loss in ft

22

Following diagram shows the term of Energy Equation:

Figure 4.2.1 – Presentation of Terms in the Energy Equation (Gary W. Brunner, 2010)

The energy head loss (he) between two cross sections is comprised of friction losses and

contraction or expansion losses. The equation for the energy head loss is as follows:

he =LS̅f + C |

α2 V

2

2

2g

α1 V

-

1

2g

2

|

Where: L = discharge weighted reach length

S̅f = representative friction slope between two sections

C = expansion or contraction loss coefficient

The discharge weighted reach length, L, is calculated using the following equation:

L=

Llob ̅̅̅̅̅

Qlob + Lch ̅̅̅̅̅

Qch + Lrob ̅̅̅̅̅

Qrob

̅̅̅̅̅+ ̅̅̅̅̅

̅̅̅̅̅

Q

Q +Q

lob

ch

rob

23

Where Llob, Lch, Lrob = cross section reach lengths specified for flow in the left

overbank, main channel, and right overbank, respectively

̅̅̅̅̅

̅̅̅̅̅= arithmetic average of the flows between sections for the left

Qlob , ̅̅̅̅̅

Qch ,Q

rob

overbank, main channel, and right overbank, respectively

To determine total conveyance and the velocity coefficient for a cross section,

HEC-RAS subdivides the flow area into units for which the velocity is uniformly

distributed. The approach used in HEC-RAS is to subdivide flow in the overbank areas

using the input cross section n-value break points (locations where n-value change) as the

basis for subdivision (See Figure 4.2.2). The total conveyance for the cross section is

obtained by summing the three subdivision conveyances (left, channel, and right). HECRAS uses following equation to determine conveyance for the subdivisions:

Q=KS0.5

f

K=

1.486

2

AR ⁄3

n

Where: K = conveyance for subdivision

n = Manning’s roughness coefficient for subdivision

A = flow area for subdivision

R = hydraulic radius for subdivision (area / wetted perimeter)

24

Figure 4.2.2 – HEC-RAS Conveyance Subdivision Method (Gary W. Brunner, 2010)

HEC-RAS computes velocity coefficient (α) using the following equation:

(At )2 [

α=

K3lob K3ch K3rob

+

+

]

A2lob A2ch A2rob

K3t

Where: At = total flow area of the cross section

Alob, Ach, Arob = flow area of left overbank, main channel and right overbank,

respectively

Kt = total conveyance of the cross section

Klob, Kch, Krob = conveyance of left overbank, main channel and right overbank,

respectively

HEC-RAS compute friction loss using following equation:

Hf = S̅f L

Where, L = discharge weighted reach length

S̅f = representative friction slope for a reach which is calculated by the following

equation:

25

Q1 + Q2 2

S̅f = (

)

K1 + K2

Contraction and expansion losses in HEC-RAS are calculated by the following equation:

hce = C |

α1 V

1

2g

2

-

α2 V

2

2g

2

|

Where, C = the contraction and expansion coefficient

4.2.1 – Calibration of the Model

HEC-RAS model has been used for the hydraulic analysis of the project. HECRAS UNET model was used as a base model to do the analysis. The available San

Joaquin River hydraulic cross sections nearest to the site were selected from the UNET

model and interpolated to represent the extents of the eroded site. These sections were

then updated based on actual survey data. The survey data only covers the right half of

the channel since that is where the repair is needed. So the left half of the channel

sections are stayed unchanged as interpolated. This updated hydraulic model served as

the base model for the project. Figure 4.2.1.1 shows the alignment of the river and crosssection into the model.

United State Geological Survey (USGS) and DWR gauging station, SAN

JOAQUIN RIVER NEAR VERNALIS (VNS) which is located approximately 0.75 mile

upstream of SJR RM 71.5R site has been used to calibrate the model. Figure 4.2.1.2

shows the location of the Gauging station. The station provides both flow and stage data

at every 15 minutes. The model was run with a known flow and calibrated by changing

the n-values until the desired stage was obtained.

26

Project Area

RM 71.5R

Figure 4.2.1.1 – HEC-RAS Channel Alignment

27

Figure 4.2.1.2 – Location of VNS Gauging Station

Manning’s n-values obtained through the calibration process of the model has

been presented in the following table.

Table 4.2.1.1 – Manning’s n-Value

Manning’s n-value

Project Condition

Existing Condition

Left Overbank

Main Channel

Right Overbank

0.095

0.032

0.095

28

4.2.2 Simulation Run

Few simulation runs have been performed using calibrated model to find out the

maximum velocity the channel may experience and also the water surface elevation for

that particular flow. Several simulations have been performed in order to determine the

hydraulic characteristics of the system. Channel maximum velocity is required to

compute rock size to mitigate on-going erosion. For this purpose, the flow for what the

levee has been designed for (design flow) and project 100-year flow and few more

random flows were used for simulation run. The levee in this project has been designed to

convey the design flood of 52,000 cfs along San Joaquin River with a minimum

freeboard of 3.0 feet. The project 100 year peak flow is 79,650 cfs which was obtained

from UNET model. Hydraulic analysis for the existing system has been performed to find

out the maximum velocity. One simulation has been run with project design flow (52,000

cfs), one simulation with 100 year flow (79650 cfs) and six more simulations have been

run for different flow condition (70,000 cfs, 60,000 cfs, 40000 cfs, 30,000 cfs, 20,000 cfs,

and 10,000 cfs) . Simulations with flows lesser than 100 year flow have been run as the

channel may not experience maximum velocity at maximum flow. Maximum velocity

can occur at flow lower than 100 year flow or design flow. However, the simulation

result shows that the channel experience maximum velocity at 100 year flow and for that

flow there is no available freeboard and flow overtop the levee. The result of the

simulation has been presented in table 4.2.2.1.

29

Table 4.2.2.1 – HEC-RAS Output

River Station

Plan

71.73

71.73

71.73

71.73

71.73

71.73

71.73

71.73

100 YR

Design

70000

60000

40000

30000

20000

10000

Flow

Total

(cfs)

Min

Ch El

(ft)

W.S.

Elev

(ft)

Vel

Chnl

(ft/s)

Flow

Area

(sq ft)

Froude

# Chl

79650

52000

70000

60000

40000

30000

20000

10000

1.3

1.3

1.3

1.3

1.3

1.3

1.3

1.3

38.31

32.97

36.78

34.72

30.15

27.53

23.68

18.66

5.04

4.53

4.81

4.66

4.29

4.06

3.61

2.81

33668.1

22655.5

30468.8

26236

16896.6

9598.03

5885.3

3555.59

0.17

0.17

0.16

0.16

0.17

0.17

0.17

0.16

Upstream End of Repair

71.695

71.695

71.695

71.695

71.695

71.695

71.695

71.695

71.66

71.66

71.66

71.66

71.66

71.66

71.66

71.66

100 YR

Design

70000

60000

40000

30000

20000

10000

100 YR

Design

70000

60000

40000

30000

20000

10000

79650

52000

70000

60000

40000

30000

20000

10000

79650

52000

70000

60000

40000

30000

20000

10000

1.05

1.05

1.05

1.05

1.05

1.05

1.05

1.05

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

38.28

32.94

36.75

34.69

30.11

27.49

23.65

18.63

38.29

32.95

36.76

34.7

30.13

27.52

23.68

18.64

5.10

4.58

4.87

4.71

4.34

4.11

3.59

2.75

4.53

3.98

4.3

4.13

3.69

3.41

2.88

2.14

33154

22183.5

29966.5

25751.3

16442.1

9175.56

5863.31

3636.37

33866.1

22952.5

30689.6

26500.8

17242.6

9558.68

6998.49

4670.45

0.17

0.17

0.16

0.17

0.17

0.17

0.17

0.15

0.15

0.14

0.14

0.14

0.14

0.14

0.13

0.12

71.625

71.625

71.625

100 YR

Design

70000

79650

52000

70000

0.56

0.56

0.56

38.24

32.9

36.71

4.85

4.29

4.61

32873.9

22004.7

29713.1

0.16

0.15

0.15

30

Table 4.2.2.1 (Contd.)

Flow

Min

W.S.

Total

Ch El Elev

(cfs)

(ft)

(ft)

60000

0.56

34.65

40000

0.56

30.07

30000

0.56

27.46

20000

0.56

23.63

10000

0.56

18.61

Vel

Chnl

(ft/s)

4.44

4.01

3.69

3.13

2.31

Flow

Froude

Area

# Chl

(sq ft)

25543.3 0.15

15890.2 0.15

9145.93 0.15

6511.7

0.14

4323.92 0.12

River Station

Plan

71.625

71.625

71.625

71.625

71.625

60000

40000

30000

20000

10000

71.59

71.59

71.59

71.59

71.59

71.59

71.59

71.59

100 YR

Design

70000

60000

40000

30000

20000

10000

79650

52000

70000

60000

40000

30000

20000

10000

0.31

0.31

0.31

0.31

0.31

0.31

0.31

0.31

38.19

32.84

36.66

34.6

30.02

27.4

23.57

18.57

5.12

4.59

4.88

4.72

4.3

3.99

3.43

2.55

31933.5

20788.3

28791.5

24634.3

15403.1

8665.65

5965.42

3914.15

0.17

0.17

0.16

0.17

0.17

0.16

0.16

0.14

71.555

71.555

71.555

71.555

71.555

71.555

71.555

71.555

100 YR

Design

70000

60000

40000

30000

20000

10000

79650

52000

70000

60000

40000

30000

20000

10000

0.06

0.06

0.06

0.06

0.06

0.06

0.06

0.06

38.17

32.82

36.64

34.58

29.99

27.38

23.55

18.55

5.11

4.54

4.85

4.69

4.25

3.94

3.38

2.49

31793.8

21059.1

28673.7

24474.7

15598.1

8825.41

6086.69

4012.86

0.17

0.16

0.16

0.16

0.16

0.16

0.15

0.13

71.52

71.52

71.52

71.52

71.52

71.52

71.52

71.52

100 YR

Design

70000

60000

40000

30000

20000

10000

79650

52000

70000

60000

40000

30000

20000

10000

-0.19

-0.19

-0.19

-0.19

-0.19

-0.19

-0.19

-0.19

38.15

32.8

36.62

34.56

29.97

27.35

23.53

18.53

5.06

4.49

4.79

4.63

4.2

3.88

3.32

2.43

31993.2

21361.6

28915.7

24826.9

15815.2

9011.62

6294.88

4118.81

0.16

0.16

0.16

0.16

0.16

0.16

0.15

0.13

31

River Station

Plan

71.486

71.486

71.486

71.486

71.486

71.486

71.486

71.486

100 YR

Design

70000

60000

40000

30000

20000

10000

Table 4.2.2.1 (Contd.)

Flow

Min

W.S.

Total

Ch El Elev

(cfs)

(ft)

(ft)

79650

0.66

38.14

52000

0.66

32.8

70000

0.66

36.61

60000

0.66

34.55

40000

0.66

29.97

30000

0.66

27.35

20000

0.66

23.53

10000

0.66

18.53

71.451

71.451

71.451

71.451

71.451

71.451

71.451

71.451

100 YR

Design

70000

60000

40000

30000

20000

10000

79650

52000

70000

60000

40000

30000

20000

10000

1.51

1.51

1.51

1.51

1.51

1.51

1.51

1.51

38.15

32.8

36.62

34.56

29.98

27.36

23.53

18.53

4.46

3.87

4.22

4.05

3.53

3.17

2.63

1.86

33677.6

22436.4

30493.2

25801.9

17055.3

10420

7642.24

5373.08

0.14

0.13

0.14

0.14

0.13

0.12

0.11

0.09

71.417

71.417

71.417

71.417

71.417

71.417

71.417

71.417

100 YR

Design

70000

60000

40000

30000

20000

10000

79650

52000

70000

60000

40000

30000

20000

10000

2.37

2.37

2.37

2.37

2.37

2.37

2.37

2.37

38.14

32.78

36.6

34.54

29.96

27.34

23.51

18.51

4.45

3.91

4.23

4.04

3.58

3.23

2.71

1.97

33734.9

21962.3

30527.7

26290.5

16653.3

10119.6

7376.6

5088.05

0.14

0.14

0.14

0.14

0.14

0.13

0.12

0.1

71.382

71.382

71.382

71.382

71.382

71.382

100 YR

Design

70000

60000

40000

30000

79650

52000

70000

60000

40000

30000

3.22

3.22

3.22

3.22

3.22

3.22

38.1

32.75

36.57

34.51

29.91

27.29

4.64

4.09

4.42

4.24

3.81

3.47

33560.9

22435.2

30335.3

26047.2

16002.1

9587.1

0.15

0.15

0.15

0.15

0.14

0.14

Vel

Chnl

(ft/s)

4.86

4.25

4.6

4.42

3.93

3.58

3

2.14

Flow

Froude

Area

# Chl

(sq ft)

32509.2 0.16

21729.2 0.15

29364.7 0.15

25143.1 0.15

16269.3 0.15

9560.01 0.14

6804.72 0.13

4666.62 0.11

32

River Station

Plan

71.382

71.382

20000

10000

71.35

100 YR

71.35

Design

71.35

70000

71.35

60000

71.35

40000

71.35

30000

71.35

20000

71.35

10000

Downstream End of Repair

71.313

100 YR

71.313

Design

71.313

70000

71.313

60000

71.313

40000

71.313

30000

71.313

20000

71.313

10000

4.3

Table 4.2.2.1 (Contd.)

Flow

Min

W.S.

Total

Ch El Elev

(cfs)

(ft)

(ft)

20000

3.22

23.47

10000

3.22

18.48

Vel

Flow

Froude

Chnl

Area

# Chl

(ft/s) (sq ft)

2.92 6905.49 0.13

2.14 4678.13 0.11

79650

52000

70000

60000

40000

30000

20000

10000

4.07

4.07

4.07

4.07

4.07

4.07

4.07

4.07

38.07

32.71

36.54

34.47

29.85

27.23

23.41

18.42

4.74

4.28

4.54

4.4

4.1

3.81

3.32

2.6

33165.2

21926.2

29919.1

25579.4

15065.5

8752.43

6119.72

3846.33

0.16

0.16

0.16

0.16

0.16

0.16

0.16

0.15

79650

52000

70000

60000

40000

30000

20000

10000

4.92

4.92

4.92

4.92

4.92

4.92

4.92

4.92

38.06

32.69

36.53

34.46

29.84

27.21

23.38

18.39

4.66

4.2

4.46

4.32

3.98

3.75

3.31

2.64

33664.7

22335.2

30402.4

26025.6

16415.9

9436.76

6278.28

3783.74

0.16

0.16

0.15

0.16

0.16

0.16

0.16

0.15

Riprap Design

The ability of riprap slope protection to resist the erosive forces of channel flow

depends on the interrelation of the following factors: stone shape, size, weight, and

durability; riprap gradation and layer thickness; and channel alignment, cross section,

gradient, and velocity distribution.

33

4.3.1 Stone Shape

Riprap should be blocky in shape rather than elongated. The stone should have

sharp, angular, clean edges as the angular and cubical stone provide more resistant in

movement than rounded stone.

4.3.2 Stone Size and Weight

The ability of riprap revetment to resist erosion is related to the size and weight of

stones. The relation between size and weight of stone is described by the following

equation:

1⁄

3

6W%

D% = (

)

πγs

Where D% = equivalent-volume spherical stone diameter, ft

W% = weight of individual stone having diameter of D%

γs = saturated surface dry specific or unit weight of stone, pcf

4.3.3 Layer Thickness

All stone should be contained within the riprap layer thickness to provide

maximum resistance against erosive forces. Layer thickness should not be less than D100

(spherical diameter of the upper limit W100 stone) or less than 1.5 times of D50 (spherical

diameter of the upper limit W50 stone). When the riprap is placed under water, the

thickness determined by using D100 or D50 should be increased by 50 percent for

uncertainties associated with this type of placement.

34

4.3.4 Side Slope Inclination

Side slope should ordinarily not be steeper than 1V on 1.5H, except in special

cases where it may be economical to use larger hand-placed stone keyed into the bank, to

provide stability of riprap slope protection.

4.3.5 Channel Roughness, Shape, Alignment, and Gradient

As boundary shear forces and velocities depend on channel roughness, shape,

alignment, and invert gradient, these factors must be considered in determining the size

of stone required for riprap revetment. Manning’s n for riprap placed in the dry (section is

dry during placement of riprap) can be calculated using the following form of Strickler’s

equation:

1⁄

6

n = K[D90 (min)]

Where K = 0.034 for velocity and stone size calculation

D90(min) = size of which 90 percent of sample is finer, from minimum or lower

limit curve of gradation specification, ft

4.3.6 Selection of Rock Size

Rock size computation should be conducted for flow condition that produces

maximum velocities at the riprap boundary. The method for determining rock size uses

depth-average local velocity. Local velocity and local flow depth are used in the

procedure to quantify the imposed forces. Riprap size and unit weight quantify the

resisting force of the riprap. The depth average local velocity over the slope, Vss can be

calculated at a point 20 percent of the slope length from the toe of slope. A two

dimensional hydraulic analysis is preferable to determine Vss. However, Vss also can be

35

determined by using the average channel velocity, Vavg using following equation

(USACE, 1990 EM 1110-2-2302):

Vss

Vavg

=1.74-0.52log(R⁄W)

Where Vavg = average channel velocity at the upstream end of bend

R = center-line radius of the bend

W = water surface width

R and W are based on flow in the main channel only and do not include overbank areas.

The basic equation for the representative rock size in straight or curved channels is as

follows:

1⁄

2

γw

D30 =Sf Cs CvCT d [(γ - γ )

s

w

2.5

V

√K1 gd

]

Where; D30 = riprap size of which 30 percent is finer by weight

Sf = safety factor (safety factor used to increase rock sizes to resist hydrodynamic

and a variety of nonhydrodynamic-imposed forces and/or uncontrollable physical

conditions. The minimum value of safety factor is 1.1)

Cs = stability coefficient for incipient failure = D85/D15 = 1.7 to 5.2

= 0.30 for angular rock

= 0.375 for rounded rock

Cv = vertical velocity distribution coefficient

= 0.10 for straight channels, inside of bends

= 1.283 – 0.2lg(R/W), outside of bends (1 for (R/W) > 26)

36

CT = thickness coefficient

d = local depth of flow (same location as V)

γw= unit weight of water

V = local depth average velocity

K1 = side slope correction factor

g = gravitational constant

The relation between D30 and D50 is follows:

1

D85 ⁄3

D50 = D30 ( )

D15

Where; D30 = riprap size of which 30 percent is finer by weight

D50 = riprap size of which 50 percent is finer by weight

D85 = riprap size of which 85 percent is finer by weight

D15 = riprap size of which 15 percent is finer by weight

For this project purpose, CHANLPRO software, developed by USACE was used

to find the required minimum rock size. CHANLPRO provides riprap design guidance

for channels subjected to high velocity forces with low turbulence flows. The program

gives different stable gradation results depending on the depth, water surface width, bend

radius, and local velocity. The CHANLPRO program version 2.0 (USACE, 1998) was

used to select a gradation to adequately protect the site. The program uses the equations

that were presented in section 4.3.6. Selection of Rock Size to find gradation of riprap.

Average channel velocity at upstream end of bend (River Station 71.695) has been used

as an input and the program will calculate the local depth average velocity. From Table

37

4.2.2.1, at River Station 71.695 average channel velocity is 5.10 ft/sec but for design

purpose an average velocity of 5.5 ft/sec has been used. The following parameters were

used as input to the model

Specific weight, pcf = 150

Local flow depth, ft = 32.0

Average channel velocity, ft/sec = 5.5

Channel bank slope, ft/ft = 1.5H:1V

Center-line radius of the bend, R, ft = 250

Water surface width, W, ft = 250

The computer program (CHANLPRO) identified D50 size of minimum 10.5 inches is

required for this project condition. Program input and output is attached in Appendix B.

4.3.7 Gradation of Riprap

The gradation of rock in riprap revetment affects the riprap’s resistant to erosion.

Rock should be reasonably well graded throughout the in-place layer thickness. The rock

shape should be angular with the minimum dimension of the rock not less than one third

of the maximum dimension. Slope protection rock should be clean, free of dirt or mud,

loose concrete or mortar, trash, and organic matter. Table 4.3.7.1 shows the proposed

gradation to be used for this site based on CHANLPRO result:

38

Table 4.3.7.1 – Gradation Table

Size

D100

D90

D50

D30

D15

D5

4.4

Diameter (in)

Max.

18.0

12.0

9.5

3.0

Min.

13.3

12.7

10.5

8.8

7.1

0

Weight (Ib)

Max.

265

78

39

10

Min.

106

94

53

31

17

0

Repair Section Design

According to section 4.3.3, the minimum thickness of riprap for repair section

will be 18 inches as the D50 size of rock is 12 inches. The maximum thickness of repair

section depends on its impact to river hydraulics as this repair encroaches into the

channel available conveyance area and also depends on cost as cost goes up with

thickness increment. Most of the places along the repair length require more than

minimum required thickness of riprap as erosion in some places were more than other

places resulted in irregular channel bank. Various layer thicknesses (atleast 18 inches)

have been provided all along the repair length to provide smooth and regular bank to the

channel and to improve hydraulics of the existing system. The repair section comprises

three major components: 1. Launch rock, 2. Riparian bench, and 3. upper rock slope

protection. Typical cross section of the repair has been presented in Figure 4.4.1. and

repair footprint has been presented in Figure 4.4.2., Figure 4.4.3., Figure 4.4.4., and

Figure 4.4.5.

39

4.4.1 Launch Rock

Toe scour is the most frequent cause of failure for wide variety of protection

technique including rock revetments. Channels with highly erodible bed and banks can

experience significant scour along the toe of the new revetment. This can be prevented by

providing sufficient launch rock. Launch rock is defined as the rock that is placed along

expected erosion areas at an elevation above the zone of attach. As the attack and

resulting erosion occur below the stone, the stone is undermined and rolls/ slides down

the slope, stopping the erosion. Thickness of launch rock should be 1.5 times of thickness

of upper rock slope protection for uncertainties associated with this the placement of rock

under water.

4.4.2 Riparian Bench

Riparian bench is provided at the top of launch rock typically at 2 to 4 feet above of

summer mean water surface elevation. For this project a riparian bench is set at elevation

14.7 ft (summer mean plus 2 ft). See Appendix C for summer mean elevation calculation

form CDEC data. The purpose of providing riparian bench is to create habitat for

restoration of vegetation lost due to bank erosion.

4.4.3 Rock Slope Protection

The upper rock slope protection sits on top of the riparian bench. The height that riprap is

placed up a levee or bank can vary substantially and is site specific. For the project site,

the height has been determined as the height of the existing berm of the levee. The slope

of the riprap should not be steeper than 1.5H: 1V for stability purpose and can be as flat

as 3H: 1V without affecting the existing hydraulics of the system. For this project, a slope

40

of 2H: 1V has been used as 3H:1V slope will encroach too much into channel available

conveyance area and 1.5H:1V slope will be too steep to do regular maintenance. The void

between the rock will be filled with agricultural soil and 9 inches thick layer of

agricultural soil will be placed on top of rock slope to facilitate growth of vegetation.

Figure 4.4.1- Typical Cross-Section

41

Figure 4.4.2 - Repair Footprint - Plan 1 of 3

42

Figure 4.4.3- Repair Footprint - Plan 2 of 3

43

Figure 4.4.4 - Repair Footprint - Plan 3 of 3

44

Figure 4.4.5 - Full Repair Footprint

45

46

Chapter 5

EVALUATION OF REPAIR IMPACT ON EXISTING RIVER HYDRAULICS

5.1 Introduction

The proposed repair will encroach into the available conveyance area. The rock

slope protection and proposed vegetation on the main channel repaired slope may also

increase bank roughness for stream flow computations. A hydraulic impact analysis has

been prepared to analyze the anticipated impacts of the proposed repairs on the San

Joaquin River flow conveyance capacity in the vicinity of the repair.

5.2 Hydraulic Analysis

The purpose of the hydraulic modeling and analysis is to verify the hydraulic

impacts of the proposed projects based on USACE design criteria. UASCE generally

requires that based on existing conditions, the project water surface elevation not increase

more than 0.1 foot and not encroach upon the minimum design freeboard of 3.0 feet. To

analyze the impacts of the proposed repair, the calibrated model which was used for

existing condition has been used as a base model. To simulate the post-project condition,

the sections within the site limits were updated to include the rock slope protection

repairs and the Manning’s roughness values were revised in each section to account for

the rock slope protection and fully developed vegetation. The repair site is within the

main channel and it will be covered with different plants on the lower and upper zones of

the bank in addition to rock slope protection. These roughness changes within the main

channel were considered in the modeling by assuming new Manning’s coefficients for

main channel sections where the roughness changes. As the repair is on main channel,

47

during high flow this section will be covered with water and will provide less effective

resistance. Based on Ven Te Chow (Open-Channel Hydraulics, 1973, Table 5-6), for

irregular and rough section in major stream, the value of n varies from 0.035 to 0.1.

Table 5.2.1 shows the Manning’s n-values that have been used in the model.

Table 5.2.1 – Manning’s n-Value for Post Repair Condition

Project

Condition

Existing

Condition

Post Project

Condition

Left

Overbank

Main

Channel

Repaired

Slope

Right

Overbank

0.095

0.032

--

0.095

0.095

0.032

0.045

0.095

In order to determine the hydraulic impacts of the proposed repair, this project

uses the 100 year peak flow (79,650 cfs) as baseline for the engineering design. The

model also has been run for design flow (52,000 cfs) just to evaluate the impact on the

design condition of the system.

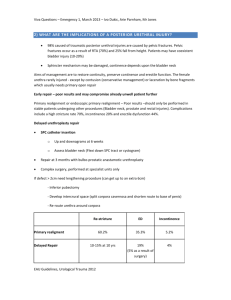

The simulations results show that the repair has very insignificant impact on water

surface elevation which is the main concern of the encroachment into the waterway. For

100 year flood (79,650 cfs), flow overtop the levee for existing condition and with repair

on it with a maximum water surface elevation increment of 0.03 ft which is insignificant

compare to USACE allowable limit. USACE allows a water surface elevation increment

upto 0.1 ft for any encroachment into the waterway for 100 year flow. For design flood

(52,000 cfs), the water surface elevation increment due to encroachment into the river is

also 0.03 ft which is also very insignificant compare to available conveyance area. The

result of the analysis is presented in table and figures.

48

Figure 5.2.1 shows the repair section on existing system with 100-year water

surface elevation from River Station 71.59 to 71.486 (see Appendix D for more. Figure

5.2.2 represents the 100-year and design flow water surface elevation for existing system

and post project condition. The figure depicts that there is very little or no change in

water surface elevation due to repair on the right bank of the river. Figure 5.2.3 shows the

velocity profiles for 100-year and design flow for existing condition and post project

condition on left bank, right bank and main channel. The velocity profiles portray that

there is insignificant impact of repair on velocity of the river system. In all figure

legends, E-100 YR means existing condition with 100-year flow, PR-100 YR means post

project condition with 100-year flow, Design- 52000 means existing condition with

design flow of 52000 cfs and Post-Design means post repair condition with design flow.

49

Figure 5.2.1 – Cross-Section with Repair on Existing System with 100-Year Water

Surface Elevation (From River Station 71.59 to 71.486)

50

Figure 5.2.2 – Water Surface Profile for 100–Year and Design Flow for Existing and Post

Project Condition

51

Project Location

Figure 5.2.3 – Velocity Profile for 100–Year and Design Flow for Existing and Post

Project Condition

52

Table 5.2.2 shows the change in water surface elevation (WSE) and velocity (V) due to

repair in the main channel.

Table 5.2.2 – Comparison of WSE and V for Existing Condition and Post Repair

Condition.

River

Station

Plan

Q Total

Min

Ch El

W.S.

Elev

Change

in WSE

Vel

Chnl

Change

in Vel

(ft)

39.23

39.24

33.83

33.86

(ft/s)

6.06

6.06

5.01

5.00

(ft/s)

E - 100 YR

PR - 100 YR

E - Design

PR - Design

(ft)

-1.02

-1.02

-1.02

-1.02

(ft)

72.567

72.567

72.567

72.567

(cfs)

79650

79650

52000

52000

72.55

72.55

72.55

72.55

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

-0.02

-0.02

-0.02

-0.02

39.03

39.05

33.73

33.75

0.02

72.4

72.4

72.4

72.4

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

-5.64

-5.64

-5.64

-5.64

38.4

38.42

33.28

33.3

0.02

72.06

72.06

72.06

72.06

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

10.81

10.81

10.81

10.81

38.53

38.55

33.24

33.27

0.02

71.8

71.8

71.8

71.8

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

1.8

1.8

1.8

1.8

38.38

38.39

33.04

33.07

0.01

71.765

71.765

E - 100 YR

PR - 100 YR

79650

79650

1.55

1.55

38.35

38.37

0.02

0.01

0.03

0.02

0.02

0.03

0.03

7.11

7.11

5.64

5.63

0.00

-0.01

0.00

-0.01

8.88

8.87

7.03

7.02

-0.01

5.07

5.06

4.36

4.35

-0.01

4.97

4.97

4.44

4.43

0.00

5.00

5.00

-0.01

-0.01

-0.01

0.00

53

Contd Table 5.2.2

River

Station

Plan

Q Total

Min

Ch El

W.S.

Elev

Change

in WSE

Vel

Chnl

Change

in Vel

(cfs)

(ft)

(ft)

(ft)

(ft/s)

(ft/s)

71.765

71.765

E - Design

PR - Design

52000

52000

1.55

1.55

33.01

33.03

0.02

4.50

4.49

-0.01

71.73

71.73

71.73

71.73

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

1.3

1.3

1.3

1.3

38.31

38.33

32.97

33

0.02

5.04

5.03

4.53

4.52

-0.01

5.10

5.09

4.58

4.58

-0.01

4.53

4.58

3.98

4.03

0.05

4.85

4.88

4.29

4.35

0.03

5.12

5.22

4.59

4.69

0.10

5.11

0.01

0.03

-0.01

Upstream End of Repair

71.695

71.695

71.695

71.695

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

1.05

1.05

1.05

1.05

38.28

38.3

32.94

32.96

0.02

71.66

71.66

71.66

71.66

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

0.8

0.8

0.8

0.8

38.29

38.31

32.95

32.98

0.02

71.625

71.625

71.625

71.625

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

0.56

0.56

0.56

0.56

38.24

38.26

32.9

32.92

0.02

71.59

71.59

71.59

71.59

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

0.31

0.31

0.31

0.31

38.19

38.2

32.84

32.84

0.01

71.555

E - 100 YR

79650

0.06

38.17

0.01

71.555

PR - 100 YR

79650

0.06

38.18

0.02

0.03

0.02

0.00

5.12

0.00

0.05

0.06

0.10

54

Contd Table 5.2.2

River

Station

Plan

Q Total

Min

Ch El

W.S.

Elev

Change

in WSE

Vel

Chnl

Change

in Vel

(cfs)

(ft)

(ft)

(ft)

(ft/s)

(ft/s)

71.555

71.555

E - Design

PR - Design

52000

52000

0.06

0.06

32.82

32.83

0.01

4.54

4.58

0.04

71.52

71.52

71.52

71.52

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

-0.19

-0.19

-0.19

-0.19

38.15

38.16

32.8

32.81

0.01

5.06

5.06

4.49

4.52

0.00

71.486

71.486

71.486

71.486

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

0.66

0.66

0.66

0.66

38.14

38.15

32.8

32.79

0.01

4.86

4.94

4.25

4.35

0.08

71.451

71.451

71.451

71.451

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

1.51

1.51

1.51

1.51

38.15

38.15

32.8

32.8

0.00

4.46

4.54

3.87

3.97

0.08

71.417

71.417

71.417

71.417

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

2.37

2.37

2.37

2.37

38.14

38.14

32.78

32.78

0.00

4.45

4.46

3.91

3.93

0.01

71.382

71.382

71.382

71.382

E - 100 YR

PR - 100 YR

E - Design

PR - Design

79650

79650

52000

52000

3.22

3.22

3.22

3.22

38.1

38.1

32.75

32.74

0.00

4.64

4.66

4.09

4.13

0.02