Bozlar_et_al_SupplMater_20120810

advertisement

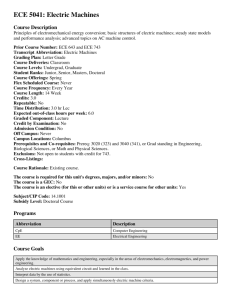

SUPPLEMENTAL MATERIAL Dielectric Elastomer Actuators with Elastomeric Electrodes Michael Bozlar,1,a) Christian Punckt,1,2,a) Sibel Korkut,1,2 Jian Zhu,3 Choon Chiang Foo,3,4 Zhigang Suo,3 and Ilhan A. Aksay1,b) 1 Department of Chemical and Biological Engineering, Princeton University, Princeton, NJ 08544, USA 2 Vorbeck Princeton Research Center, Vorbeck Materials Corp., 11 Deerpark Drive, Monmouth Junction, NJ 08852, USA 3 School of Engineering and Applied Sciences, Harvard University, Cambridge, MA 02138, USA 4 Institute of High Performance Computing, 1 Fusionopolis Way, #16-16 Connexis, Singapore 138632, Singapore Processing of CE electrodes 120 mg of CB particles (Ketjenblack EC-600JD, AkzoNobel, Chicago, IL) were suspended in 40 mL of tetrahydrofuran (99.9 %, inhibitor-free, Sigma-Aldrich, St. Louis, MO) by tip sonication (Vibra Cell, Sonics & Materials Inc., Newtown, CT) at 10 % power in an ice-bath for 1 h. Subsequently, the suspension was mixed with 3.8 g of vinyl terminated PDMS oil (Gelest, Inc., Morrisville, PA), which had been preheated to 70 °C. While keeping it at 70 °C, this mixture was continuously stirred for about 4 h to allow for solvent evaporation. Then, 22 mg of the catalyst (Platinum-cyclovinylmethylsiloxane, Gelest) and 99 mg of the crosslinker (Tetrakis-(dimethylsiloxy)silane, Gelest) were added. After mixing with a spatula for 10 min, the slurry was cast directly onto both sides of the prestrained DE using a 50 µm thick polyester film with a 13.5 mm circular hole to define the electrode shape and thickness. CB/PDMS slurry excess was removed with a squeegee. Finally, the samples a) These authors contributed equally to this work. b) Author to whom correspondence should be addressed. Electronic mail: iaksay@princeton.edu 1 were left for curing at room temperature for at least 3 days prior to testing. This technique yields electrode thickness variations in the range of 5 to 10 %. Microscopy The thickness of the prestrained DE was measured using optical microscopy (Zeiss Axioplan 2, Carl Zeiss MicroImaging, Inc., Thornwood, NY) and was in good agreement (less than 10 % difference) with the thickness estimated based on the prestrain level assuming constant volume. Electrode thicknesses were measured after electromechanical testing of the actuators. To this end, the electrodes were carefully peeled off from the acrylic films, and their cross sections were analyzed with a scanning electron microscope (SEM) (Tescan Vega1, Cranberry Township, PA), as displayed in Figure 2(c). Electromechanical tests For the electromechanical testing of the actuators, electrical connections between the electrodes and the voltage source were made with flexible carbon adhesive tape (SPI Supplies, West Chester, PA). To ensure good electrical contact between the electrodes and the carbon tape, a small amount of electrically conductive carbon grease (Nye Lubricants, Inc., Fairhaven, MA) was used. A computer-controlled potentiostat (PAR VersaSTAT 3 potentiostat, Oak Ridge, TN) with downstream voltage amplification (TREK Model 20/20C amplifier, TREK Inc., Medina, NY) was used to apply triangular voltage ramps to the actuator devices. In contrast to using voltage pulses, this way viscoelastic effects are minimized, and the performance of the actuators near equilibrium can be studied. During electromechanical tests, images of the actuator were simultaneously recorded, with a CCD camera (PixeLINK, Ottawa, ON) at a rate of about 0.35 Hz and stored on the computer. 2